Device for spirally squeezing and dehydrating enteromorpha

A technology of screw pressing and pressing dehydration, which is applied in the direction of drying solid materials, marine product drying, and drying solid materials without heating, which can solve the problems of unable to dehydrate Enteromorpha and achieve the effect of high-efficiency dehydration treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

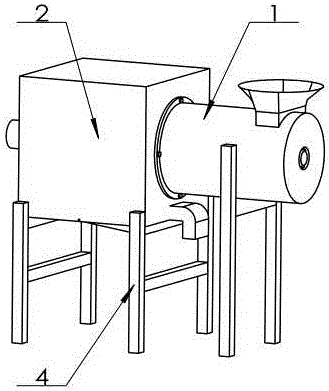

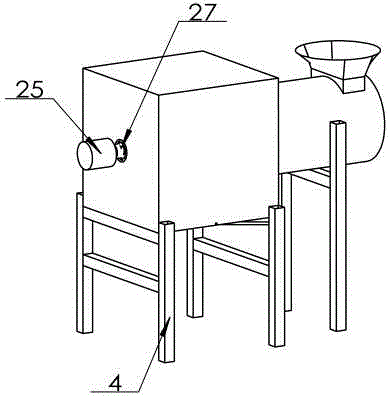

[0017] like Figure 1 to Figure 6 As shown, the present invention mainly includes a general term for screw dehydration 1, a press dehydration assembly 2, an overrunning clutch 3 and a fixed frame 4, and the present invention will be described in detail below in conjunction with the accompanying drawings.

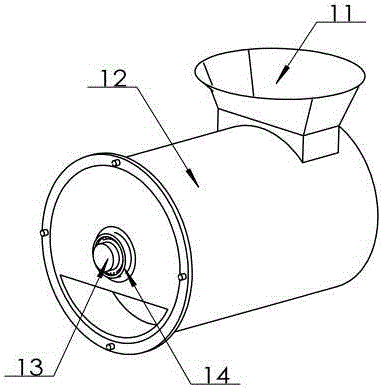

[0018] like Figure 1 to Figure 2 As shown, the spiral guard 12 is provided with a feed inlet 11, as Figure 3 to Figure 4 As shown, a helical blade shaft 13 is arranged inside the helical shield 12. The function of the helical blade shaft is to squeeze and dehydrate Enteromorpha by rotation and transport Enteromorpha to the press dehydration assembly 2. The two parts of the helical blade shaft 13 The ends are mounted on the spiral guard 12 through bearings 14.

[0019] like Figure 1 to Figure 2 As shown, the fixed frame 4 is installed at the lower end of the screw dehydration assembly 1 and the press dehydration assembly 2 .

[0020] like Figure 5 As shown, the spira...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com