Patents

Literature

40results about "Marine product drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

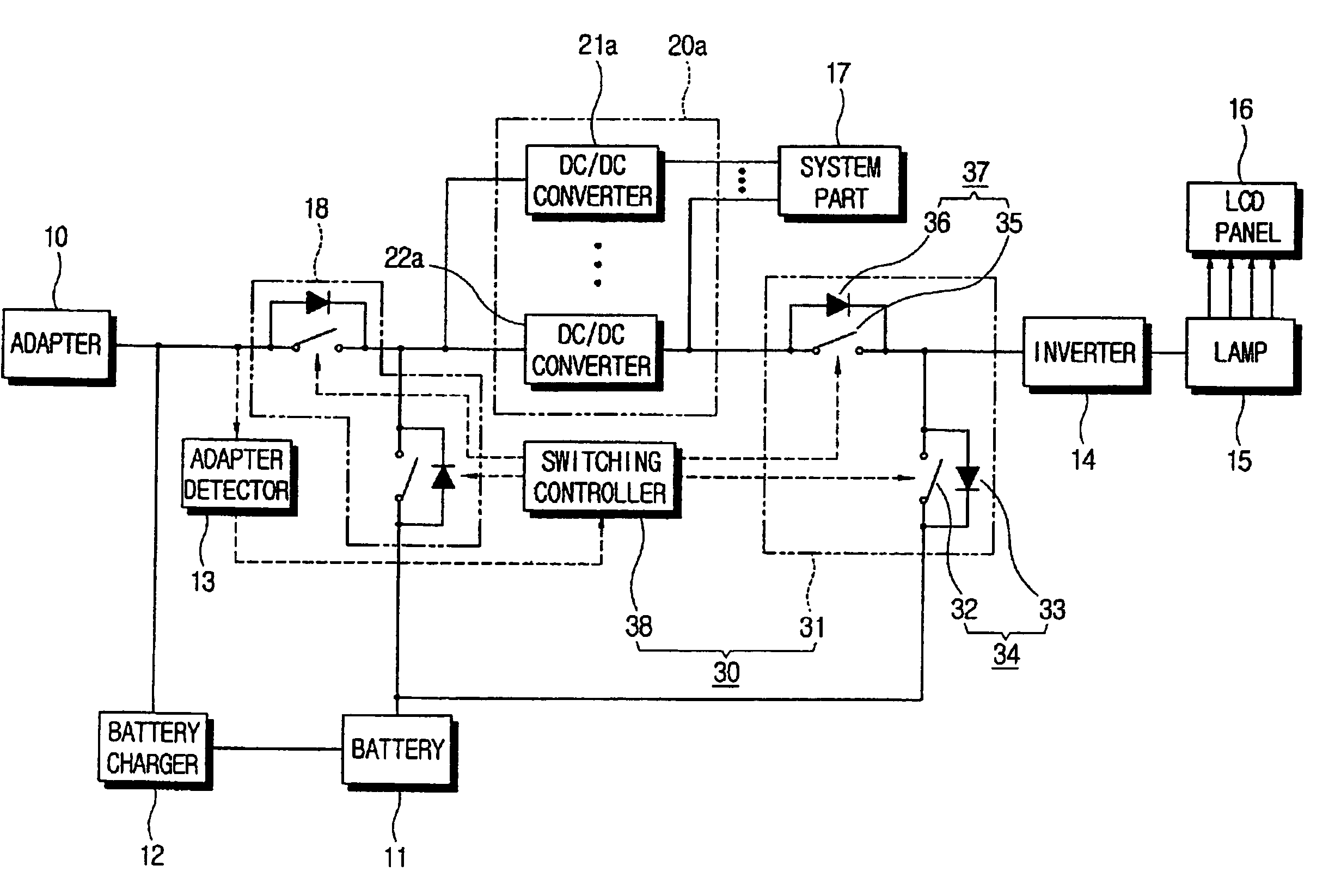

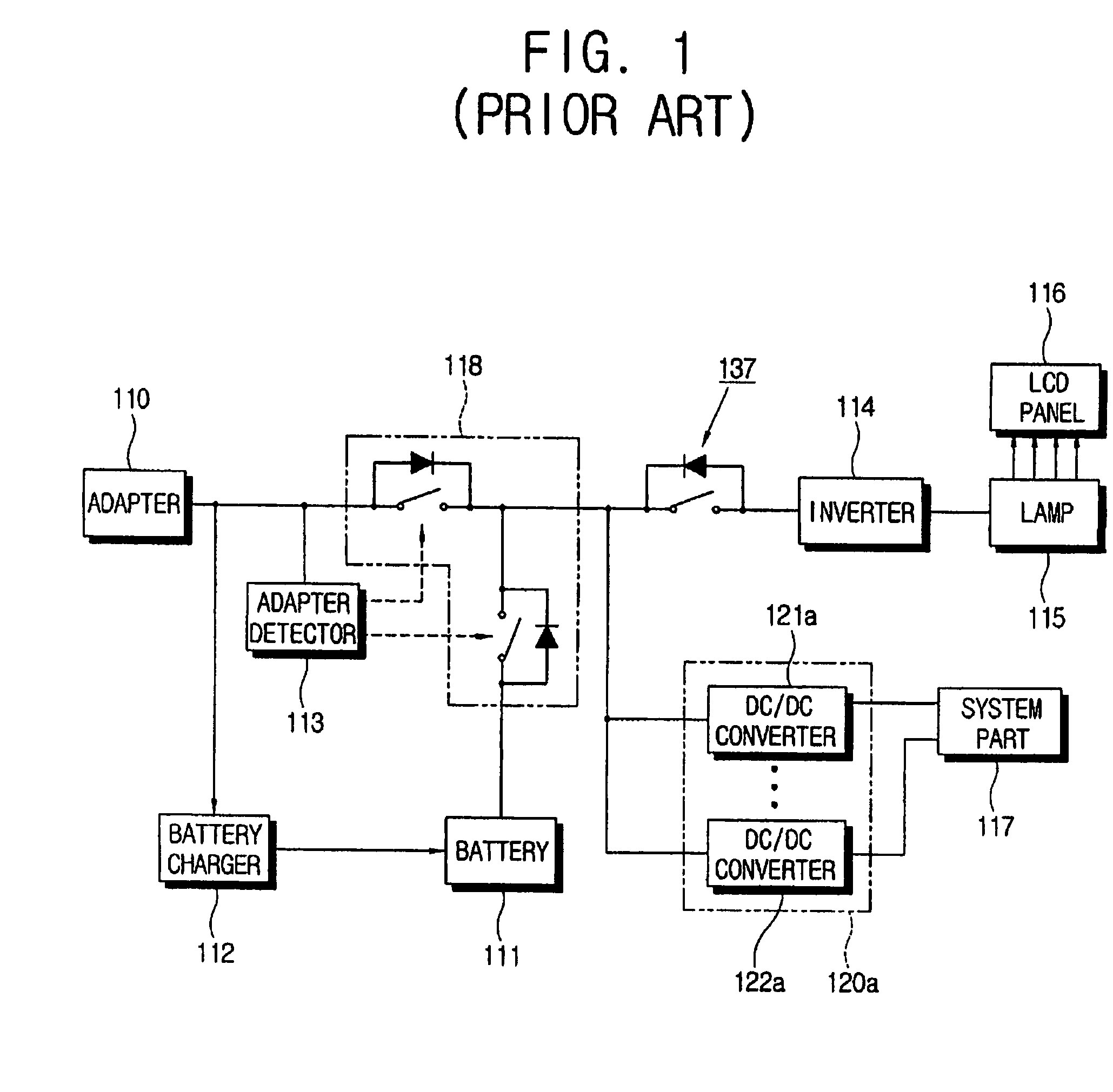

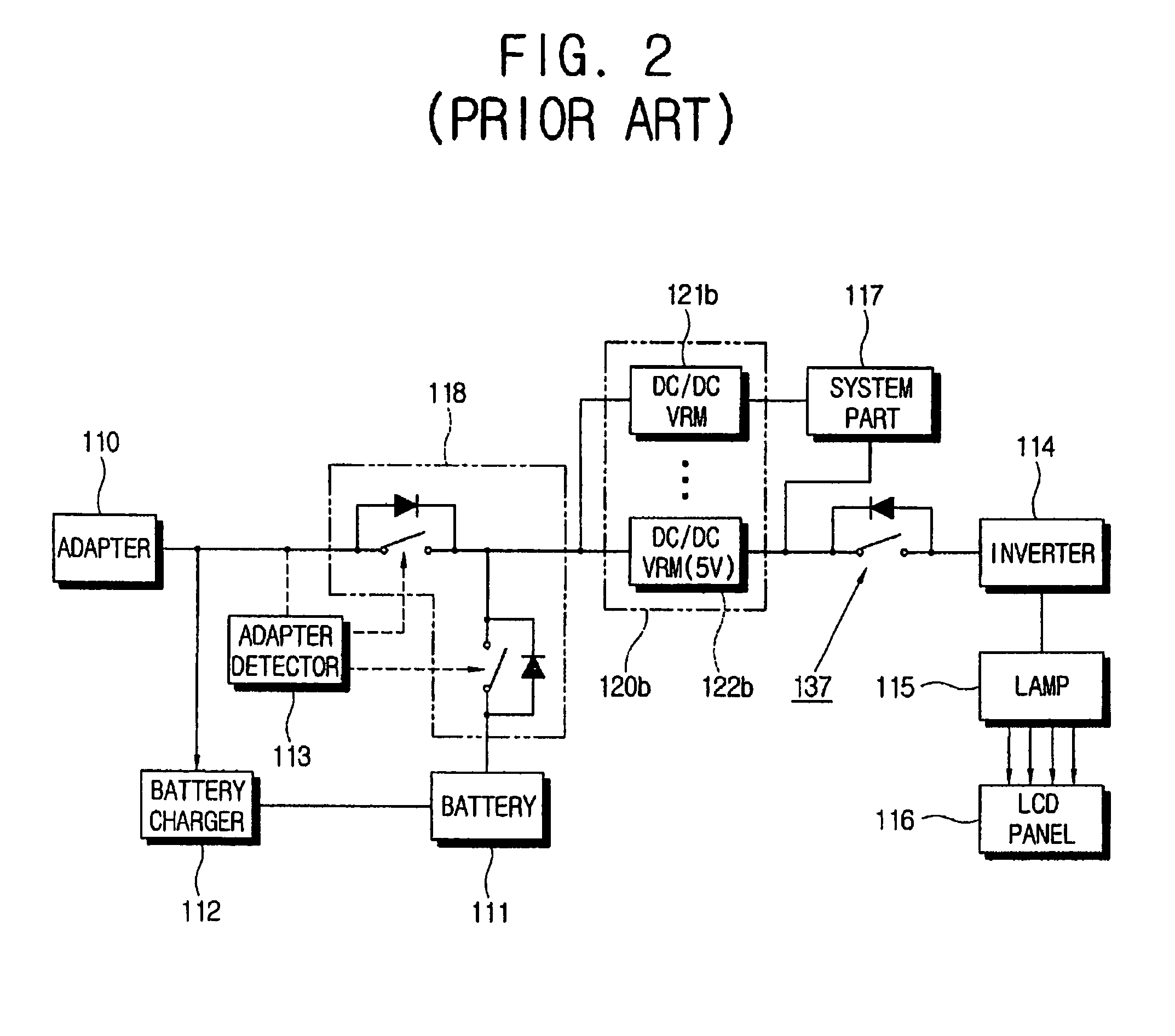

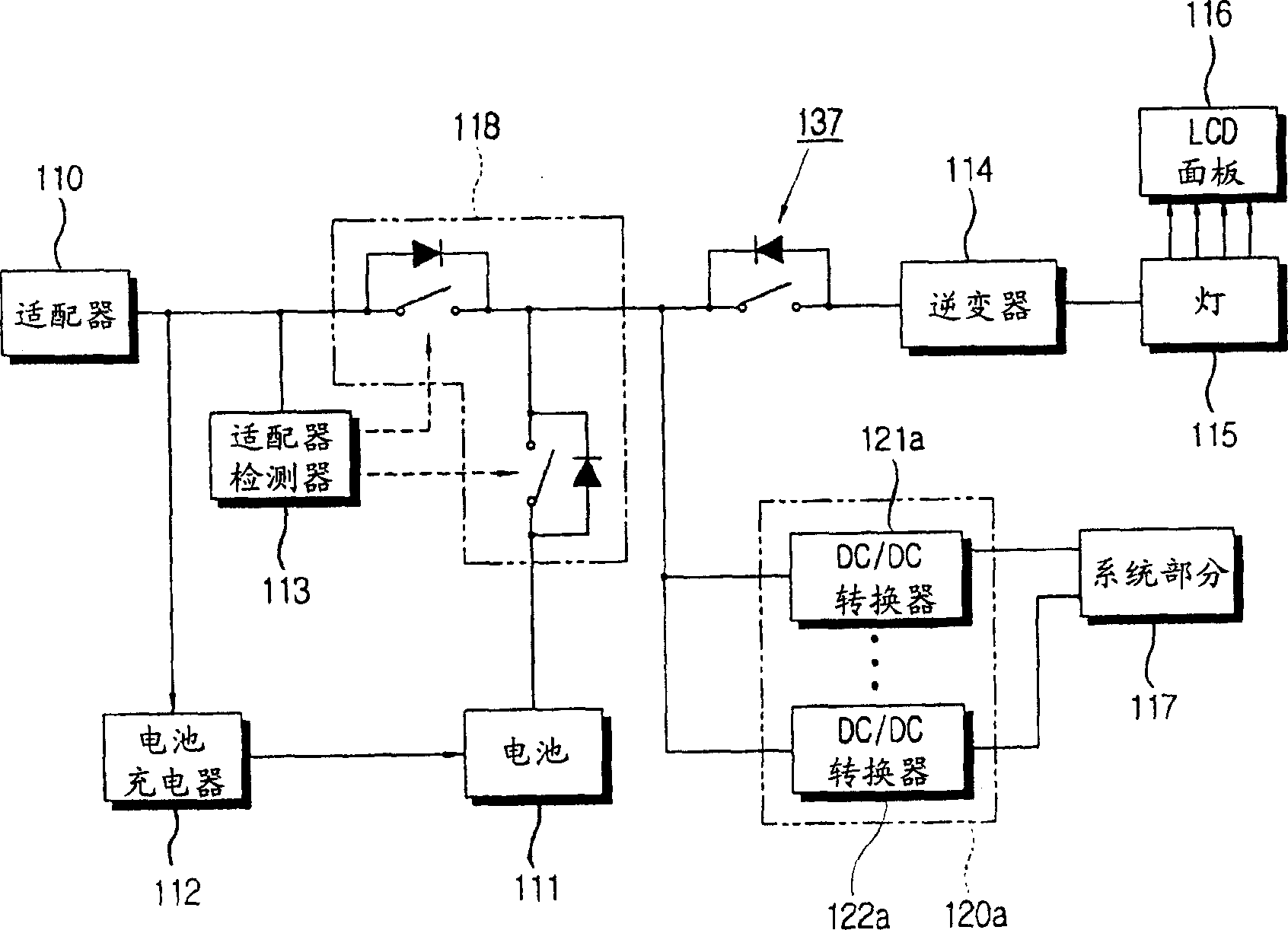

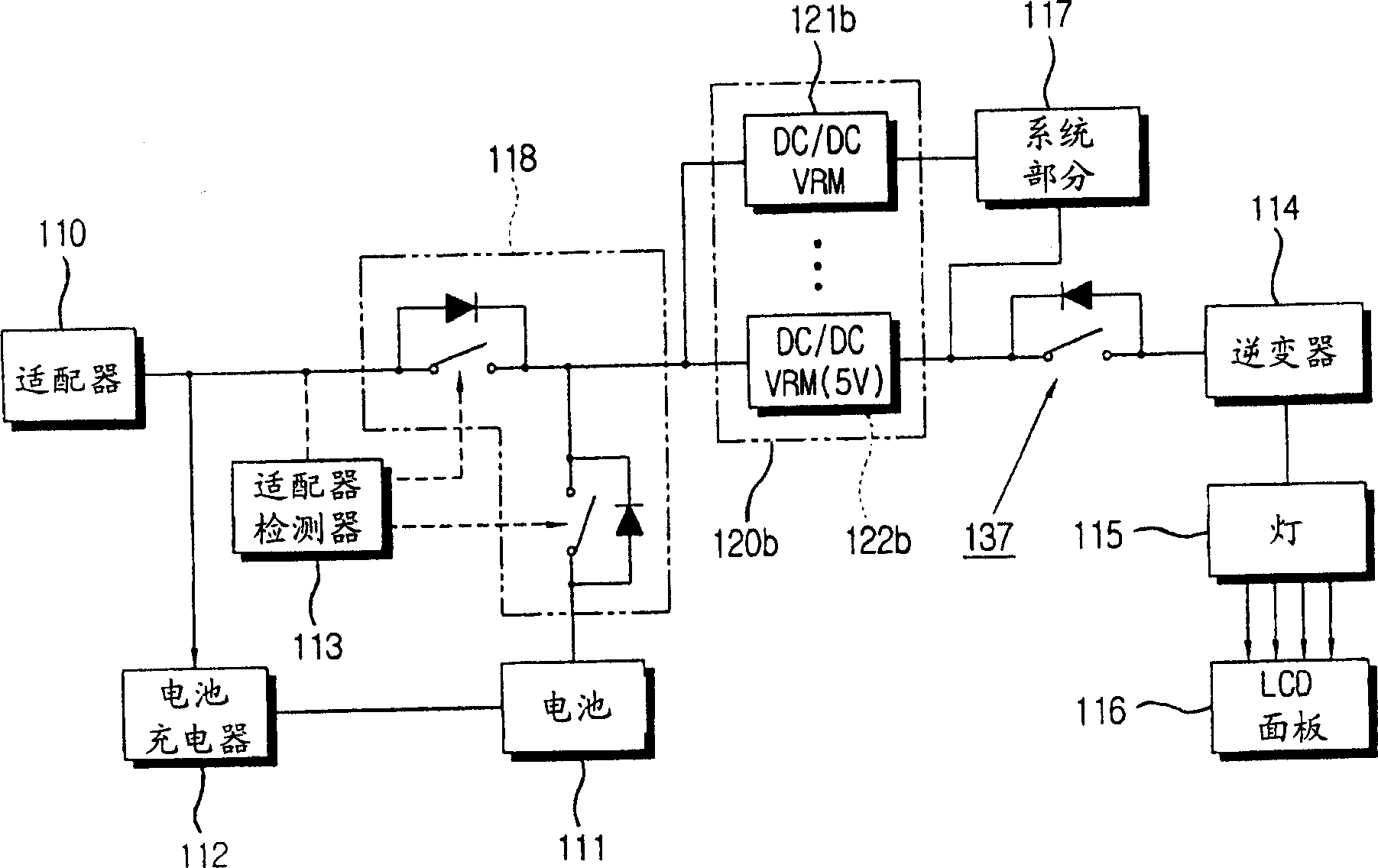

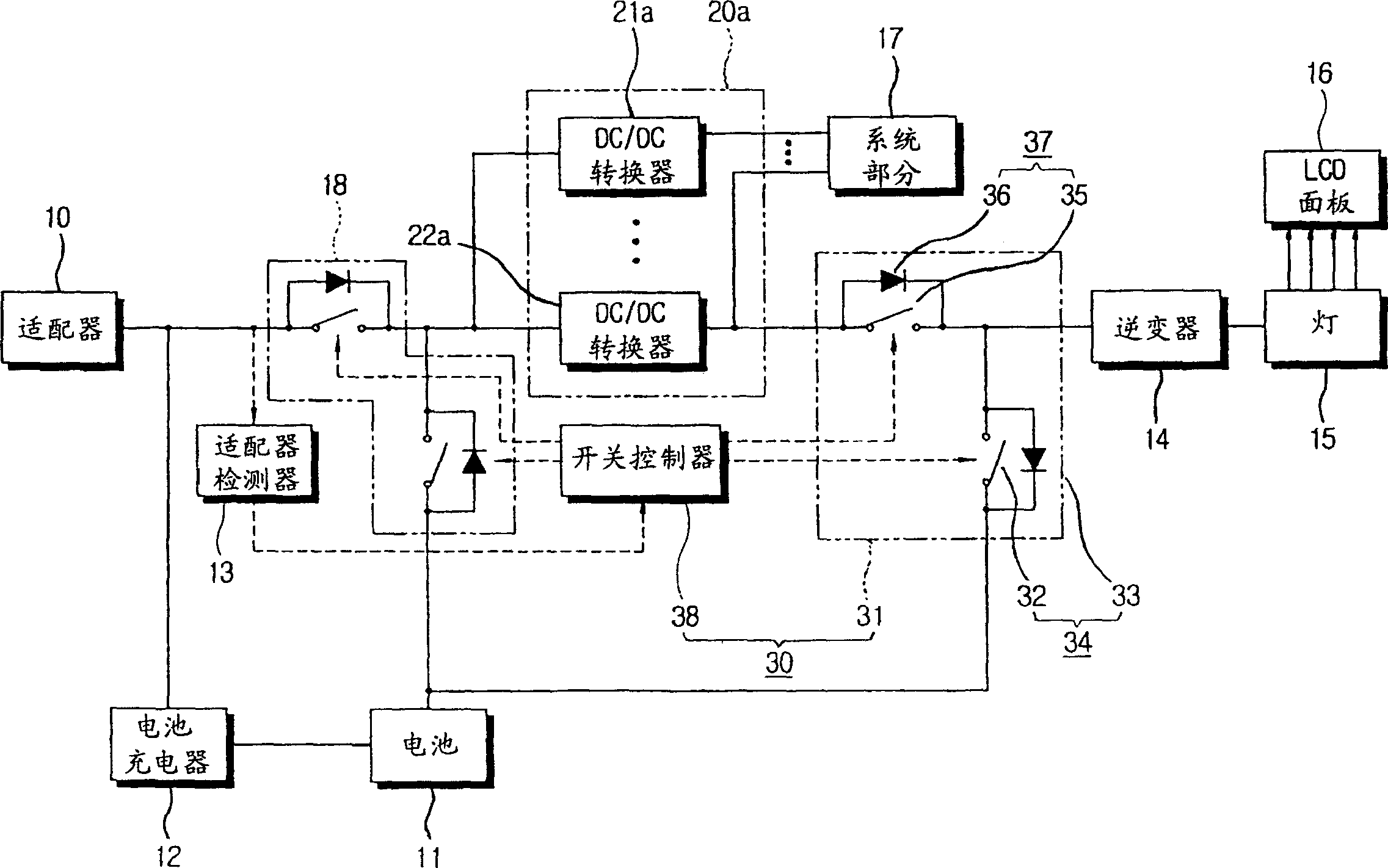

Electronic device having path of power supplied to display part switched according to whether external power is supplied

InactiveUS7446432B2Narrow rangeExtend battery lifeBatteries circuit arrangementsDrying solid materials with heatDisplay devicePower detector

An electronic device operable from one of an external power supply and a battery. The electronic device includes a display part, a power converter, an inverter generating an operating voltage for the display part, a system part generating information to be displayed on the display part and operable from an output of the power converter, a battery, an input power detector, and a switching controller. The switching controller controls power to the inverter so that where the input power detector detects availability of an external power, the switching controller supplies the external power to the power converter and the power converter supplies power to the inverter to generate the operating voltage for the display part; and where the input power detector detects the external power is not available, the switching system supplies battery power to the power converter and the inverter independently.

Owner:SAMSUNG ELECTRONICS CO LTD

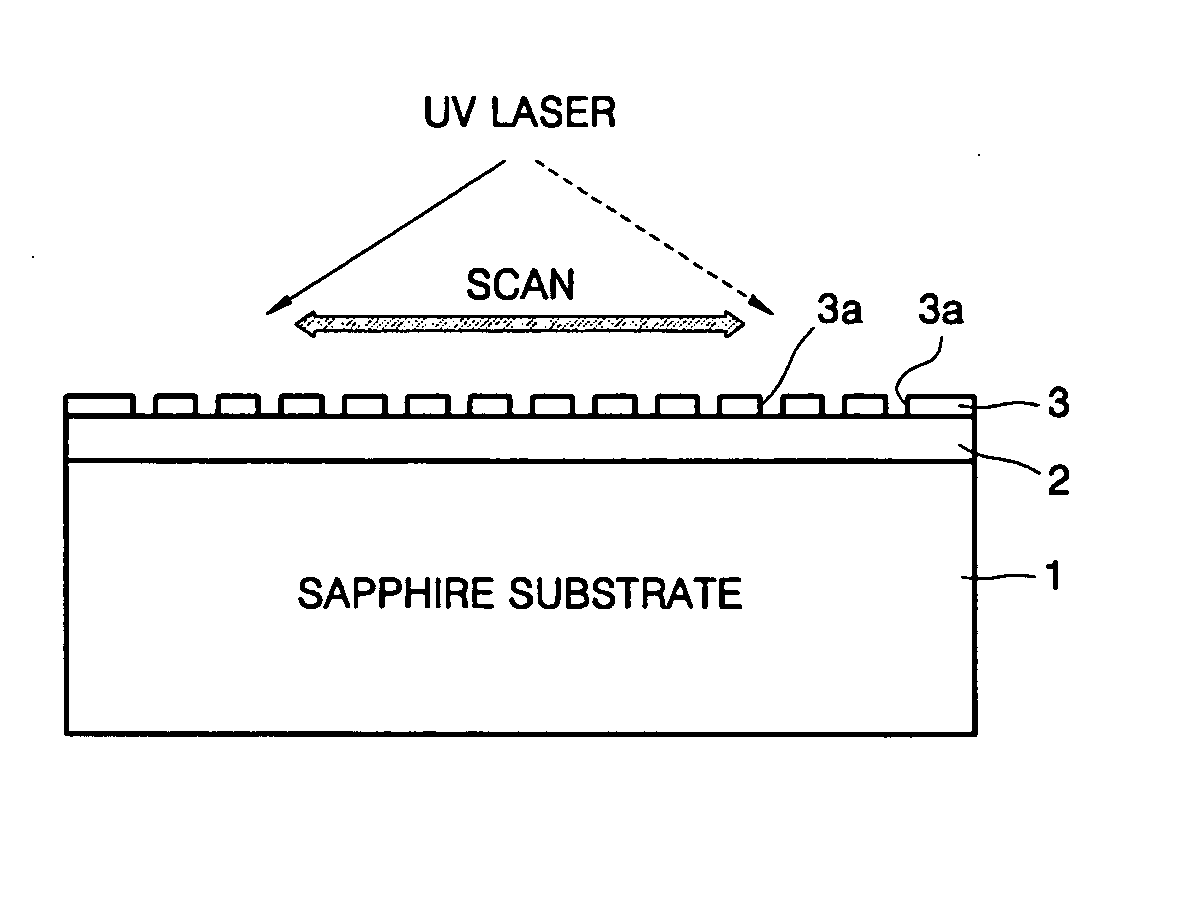

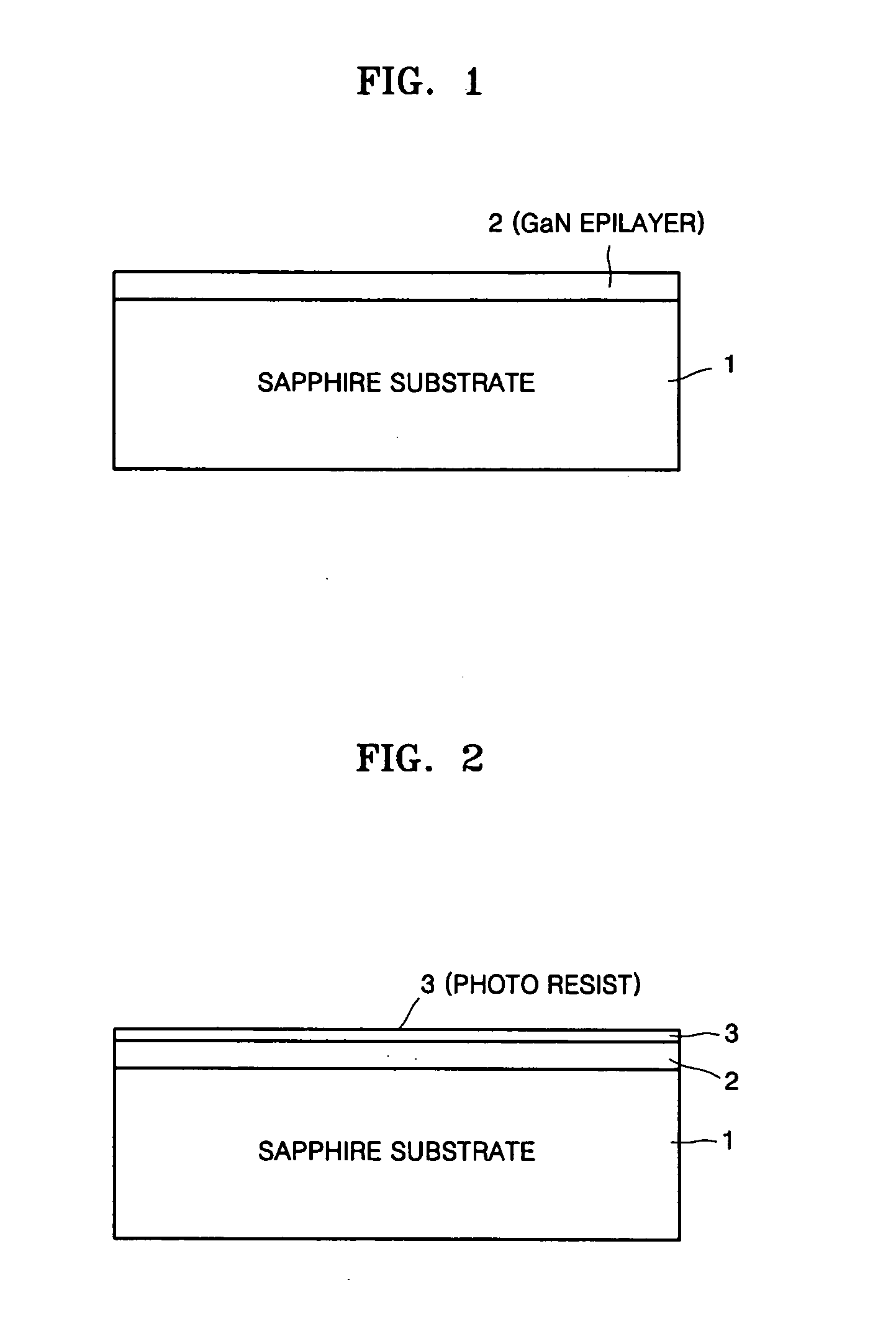

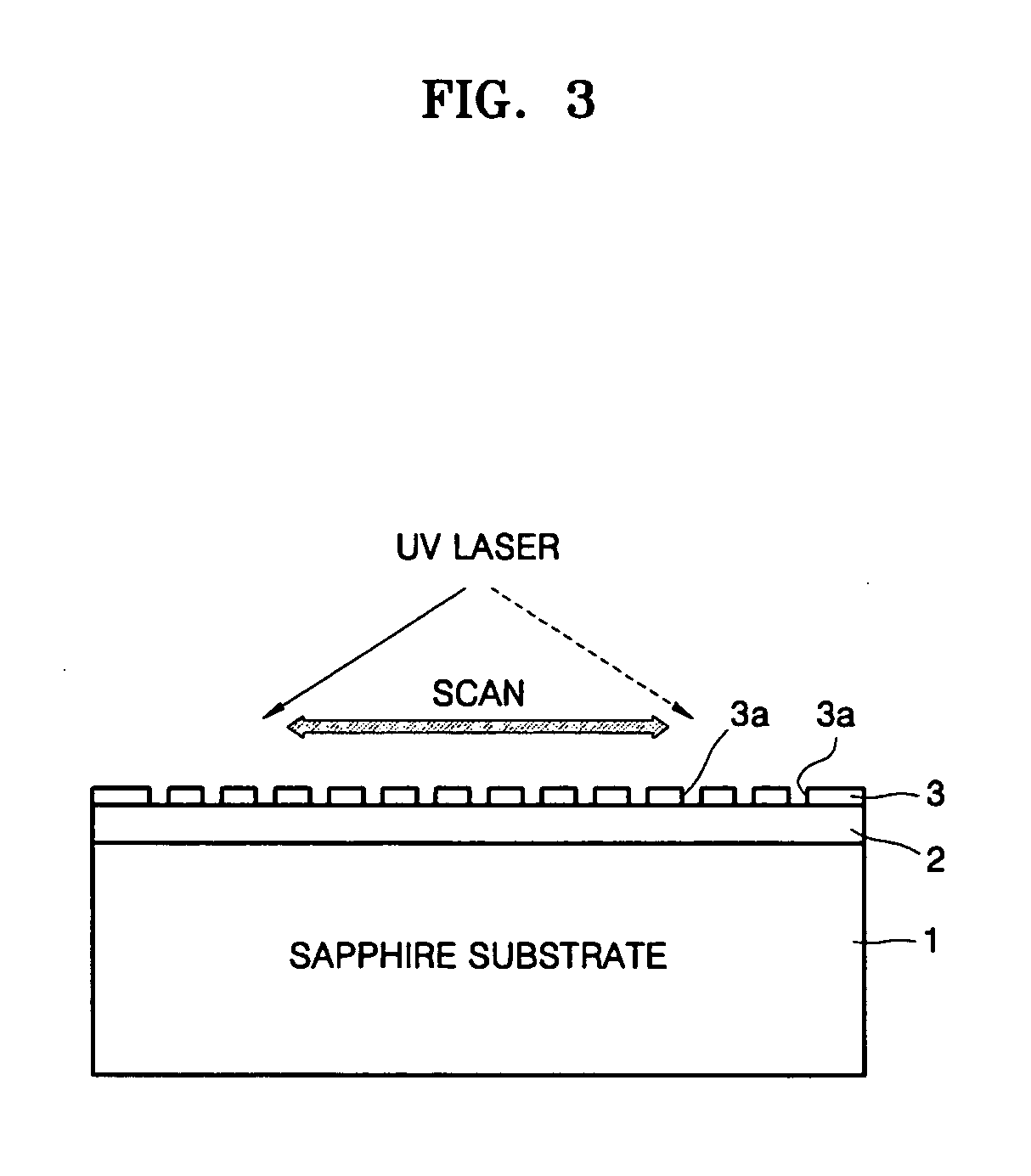

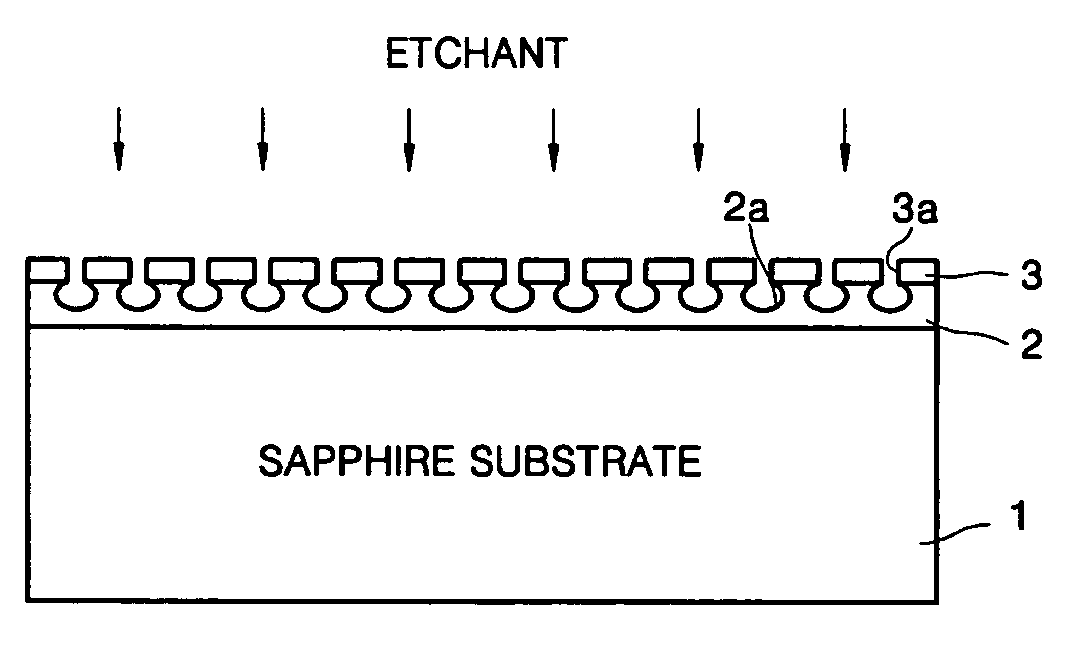

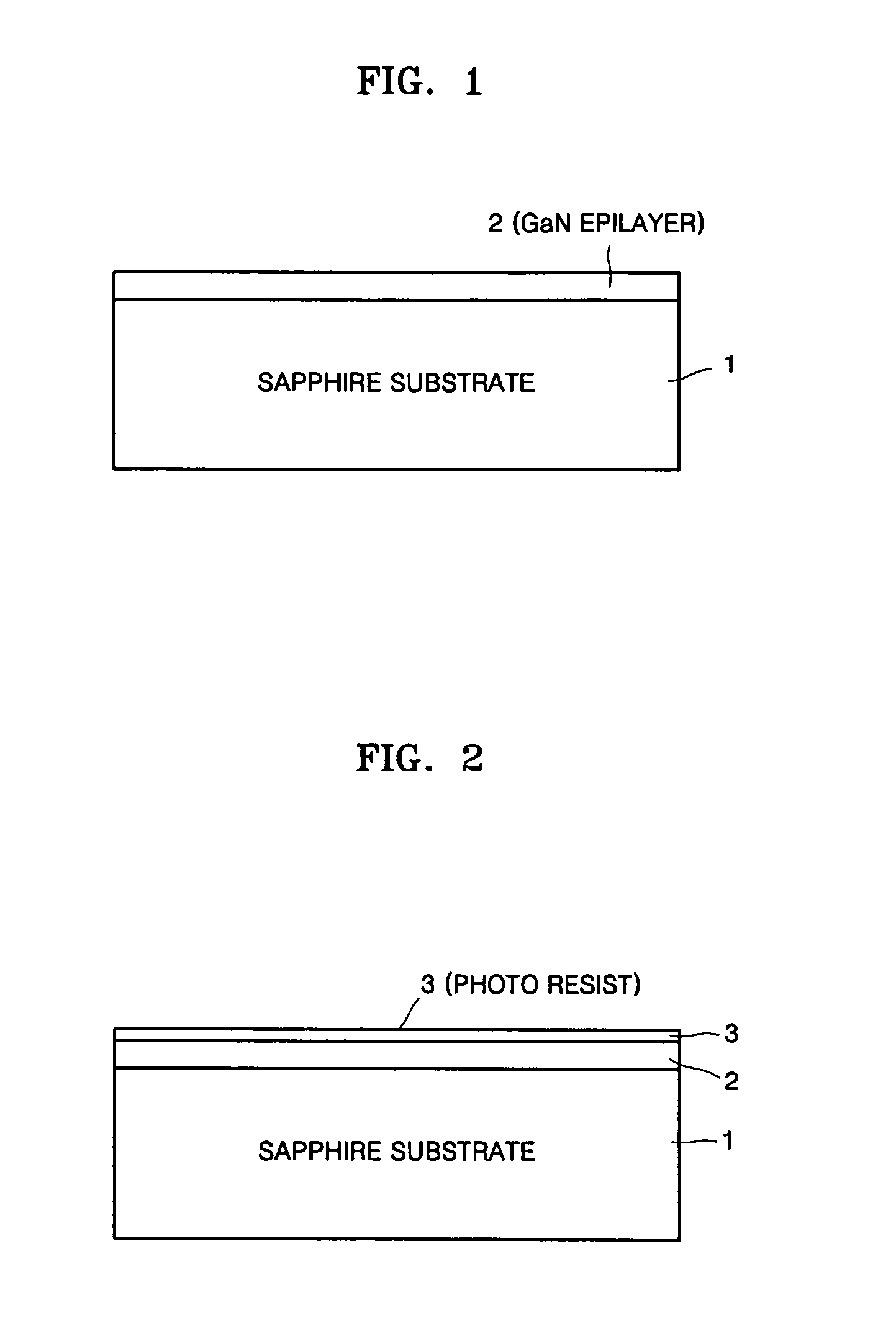

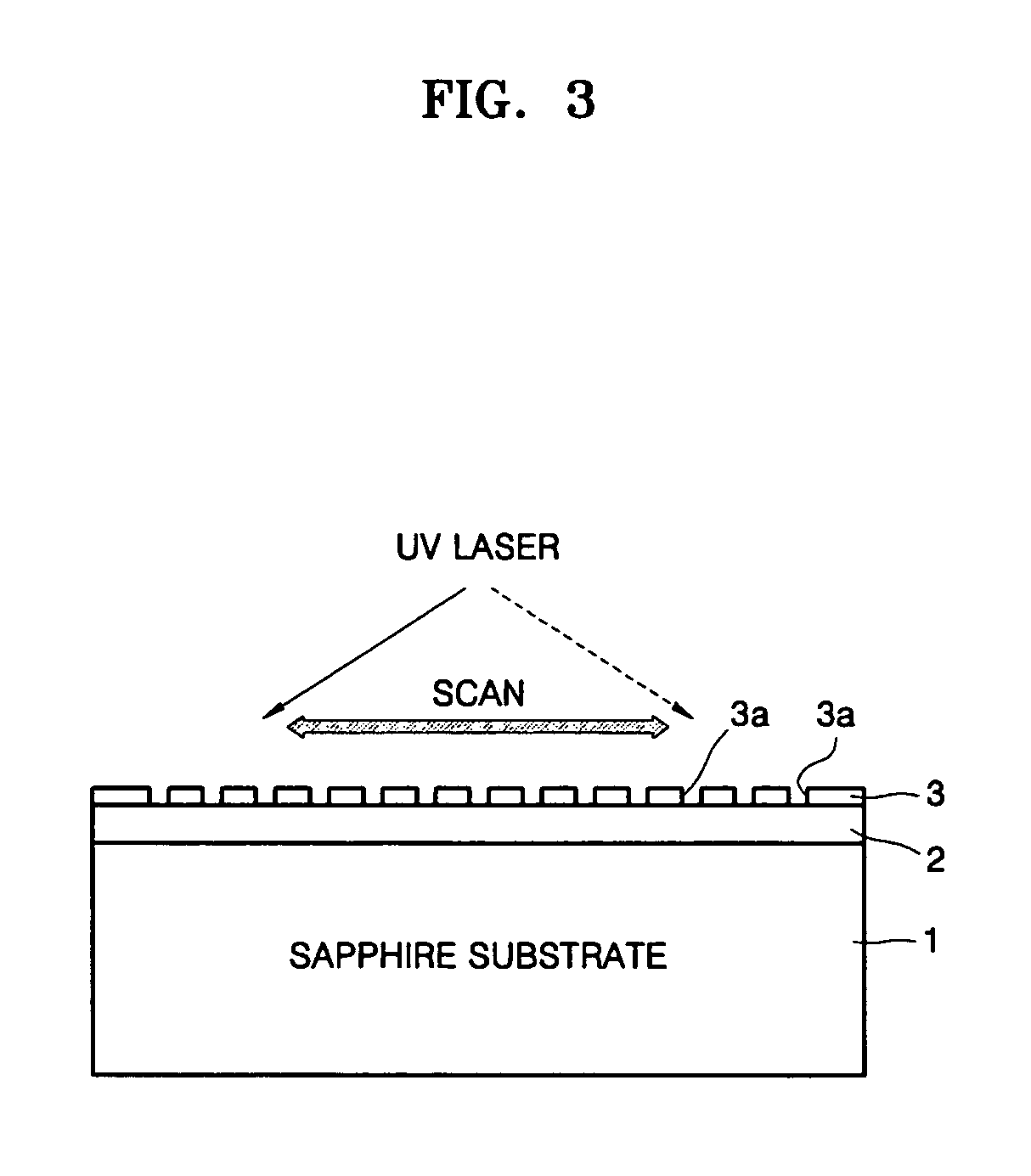

Epitaxial growth method

InactiveUS20060160334A1Low costWell formedDrying solid materials with heatDrying gas arrangementsCrystalline materialsSingle crystal

Provided is an epitaxial growth method for forming a high-quality crystalline growth semiconductor wafer. The method includes forming a buffer layer on a single crystalline wafer using a single crystalline material; forming a mask layer on the buffer layer; forming a plurality of holes in the mask layer using a laser to expose portions of the buffer layer; forming wells having a predetermined depth in the exposed portions of the buffer layer by injecting an etchant into the holes; removing the mask layer and annealing the buffer layer to form a porous buffer layer having cavities obtained by the wells; and forming a crystalline material layer on the porous buffer layer using an epitaxial growth process.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

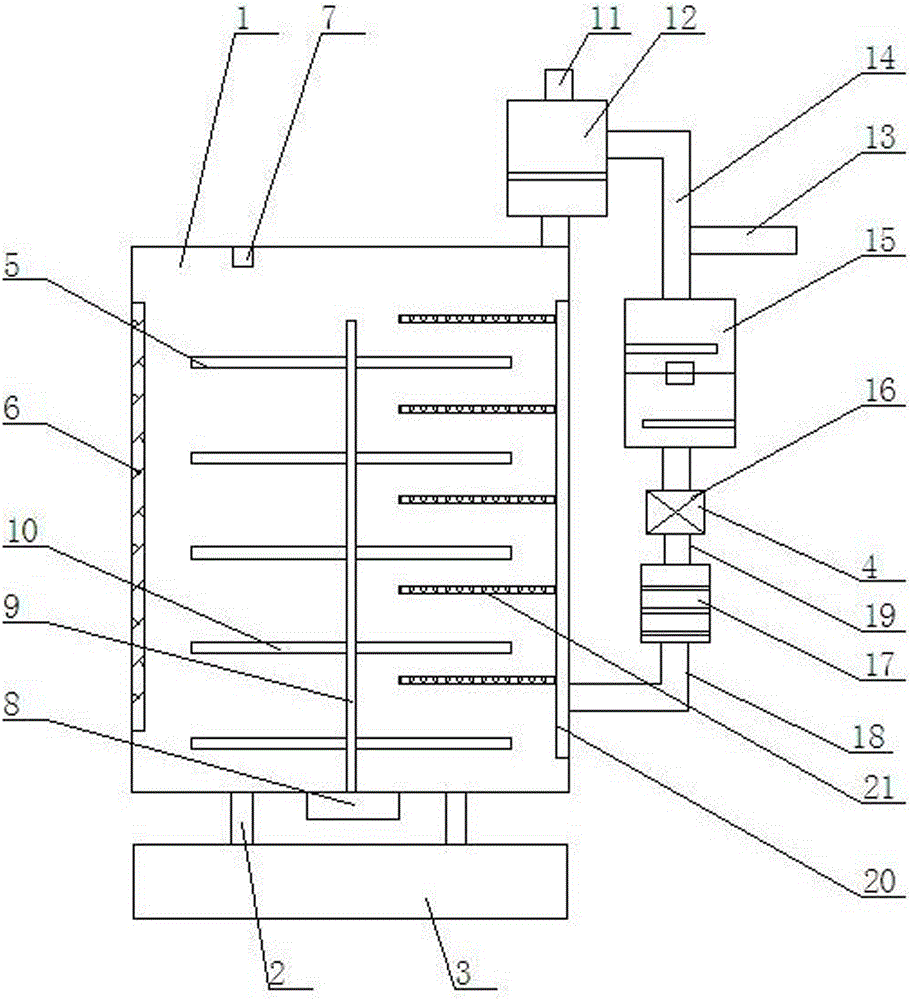

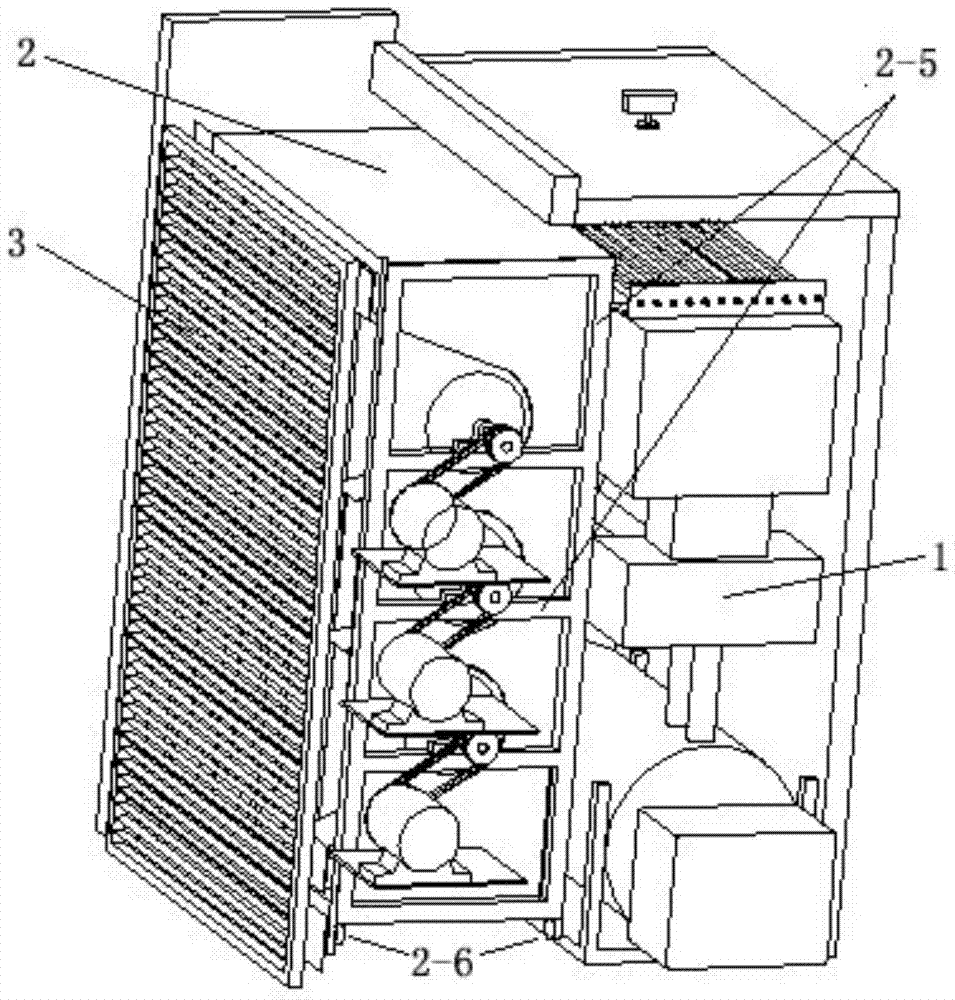

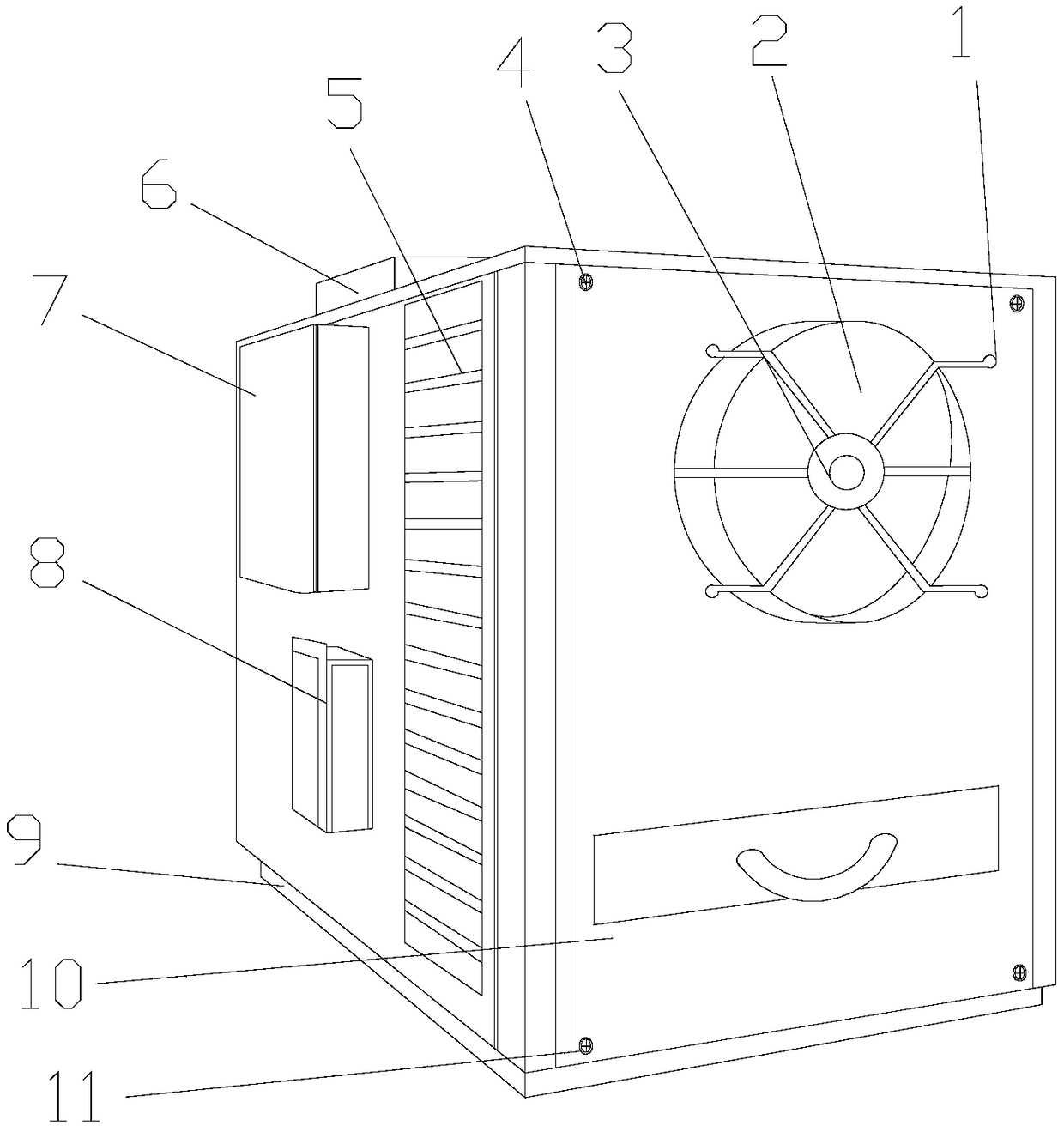

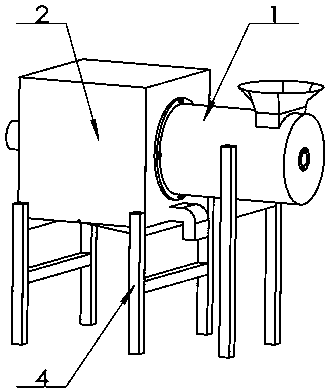

Spirulina drying device

InactiveCN105995676AQuality improvementFood preservationDrying gas arrangementsAnimal scienceMedicine

The invention relates to a spirulina drying device. The spirulina drying device comprises a drying box, a supporting frame, a rack and a circulating hot air device, wherein the drying box is arranged on the rack by virtue of the supporting frame at the lower end; the circulating hot air device is arranged at the right end of the drying box; a rotary spirulina placing frame is arranged at the middle part inside the drying box; an ultraviolet irradiation sterilization tube is arranged on the left side wall of the interior of the drying box, and a temperature detector is arranged at the top of the interior of the drying box; the rotary spirulina placing frame is composed of a rotary motor, a rotating shaft and multiple reticular spirulina trays, the rotary motor is arranged at the middle part of the bottom end of the drying box and connected with a rotating cylinder inside the drying box, and multiple reticular spirulina trays are arranged at the left end and right end of the rotating shaft; an exhaust pipe is arranged at the right side of the top end of the drying box, and one filtration drum provided with a built-in cellucotton filter screen is arranged on the exhaust pipe. The spirulina drying device adopts the circulating hot air device for drying and the ultraviolet irradiation sterilization tube for sterilization and can further kill residual bacteria in the spirulina after drying in a fully drying process.

Owner:HARBIN HUAZAO BIOTECH DEV

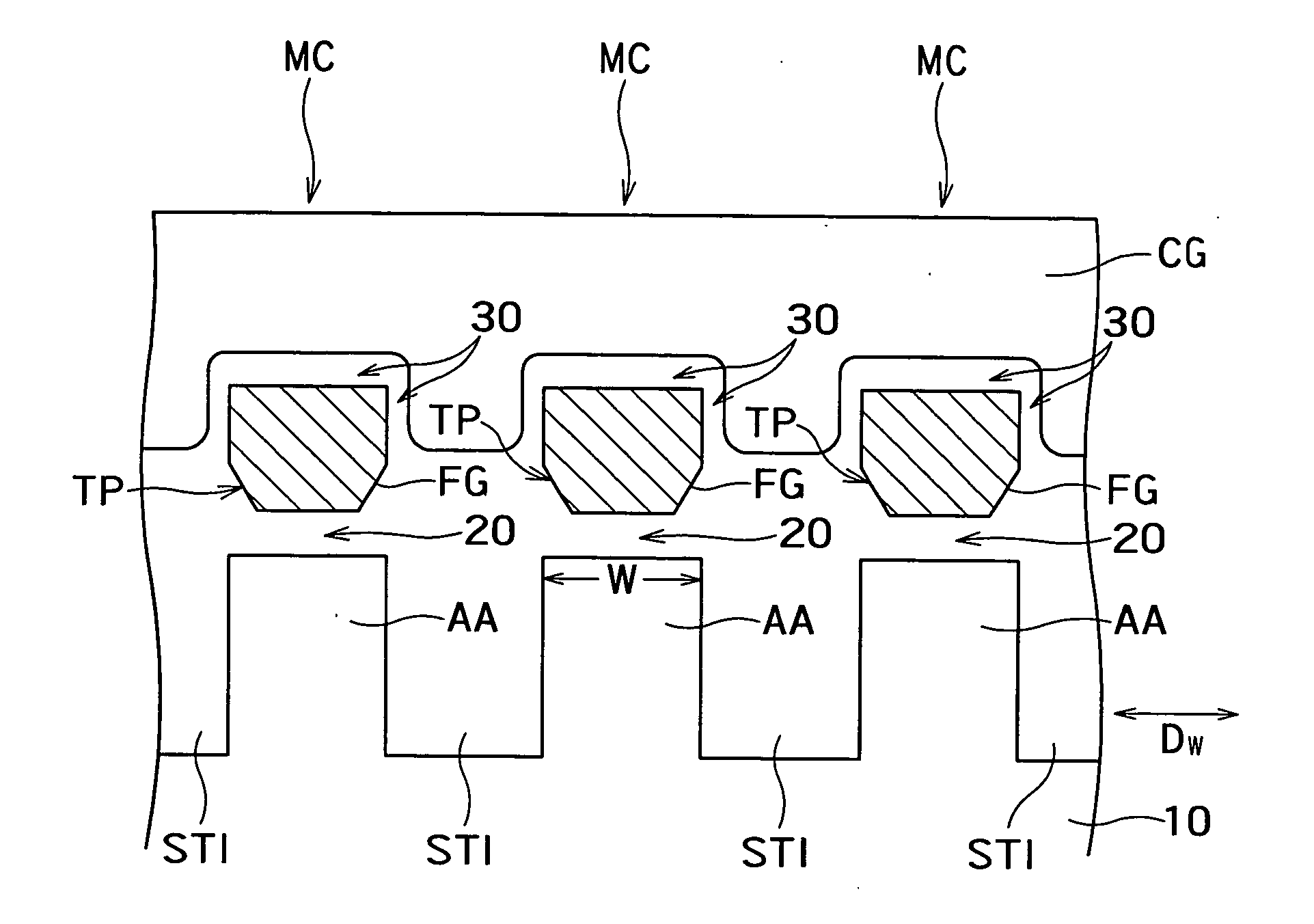

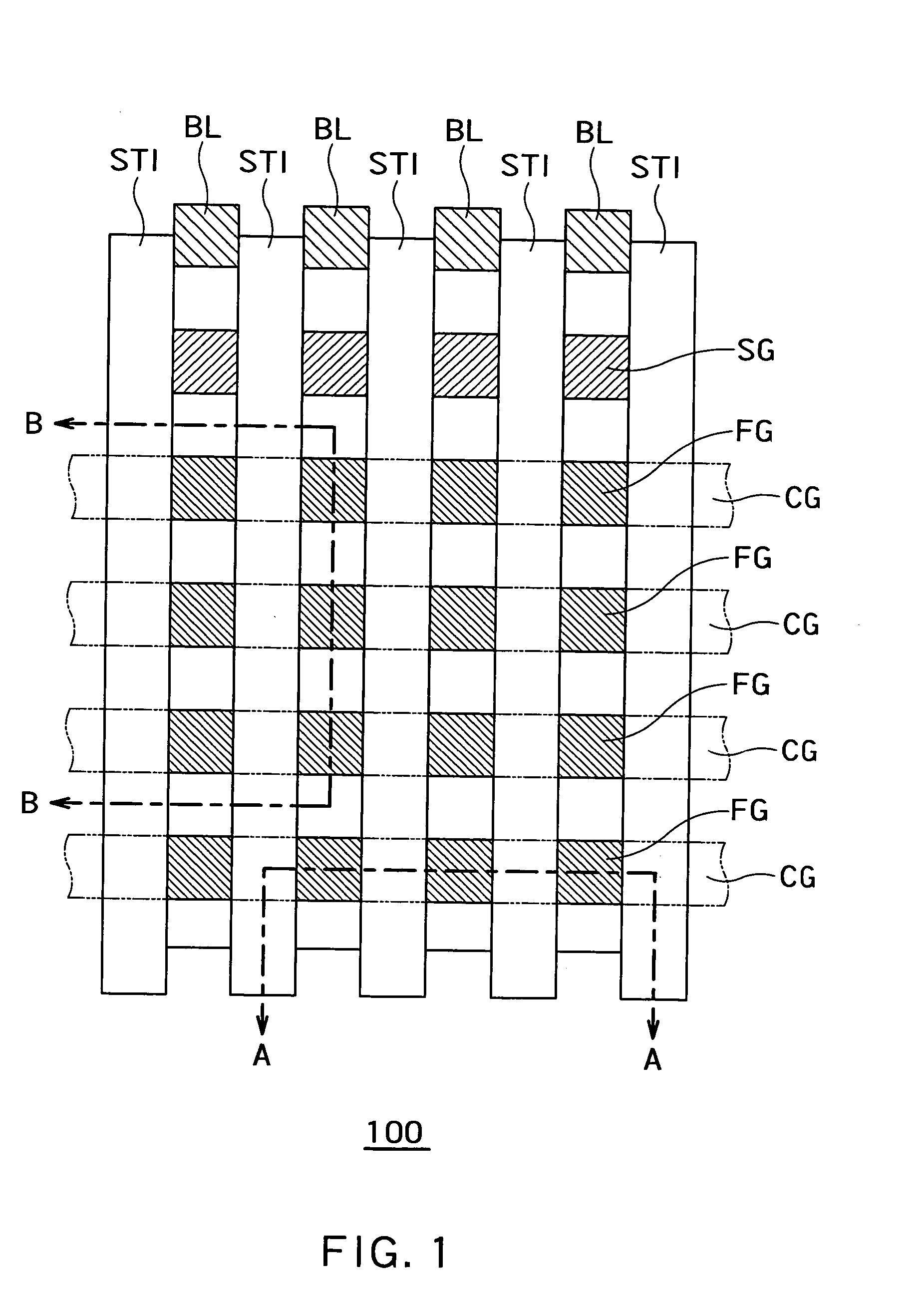

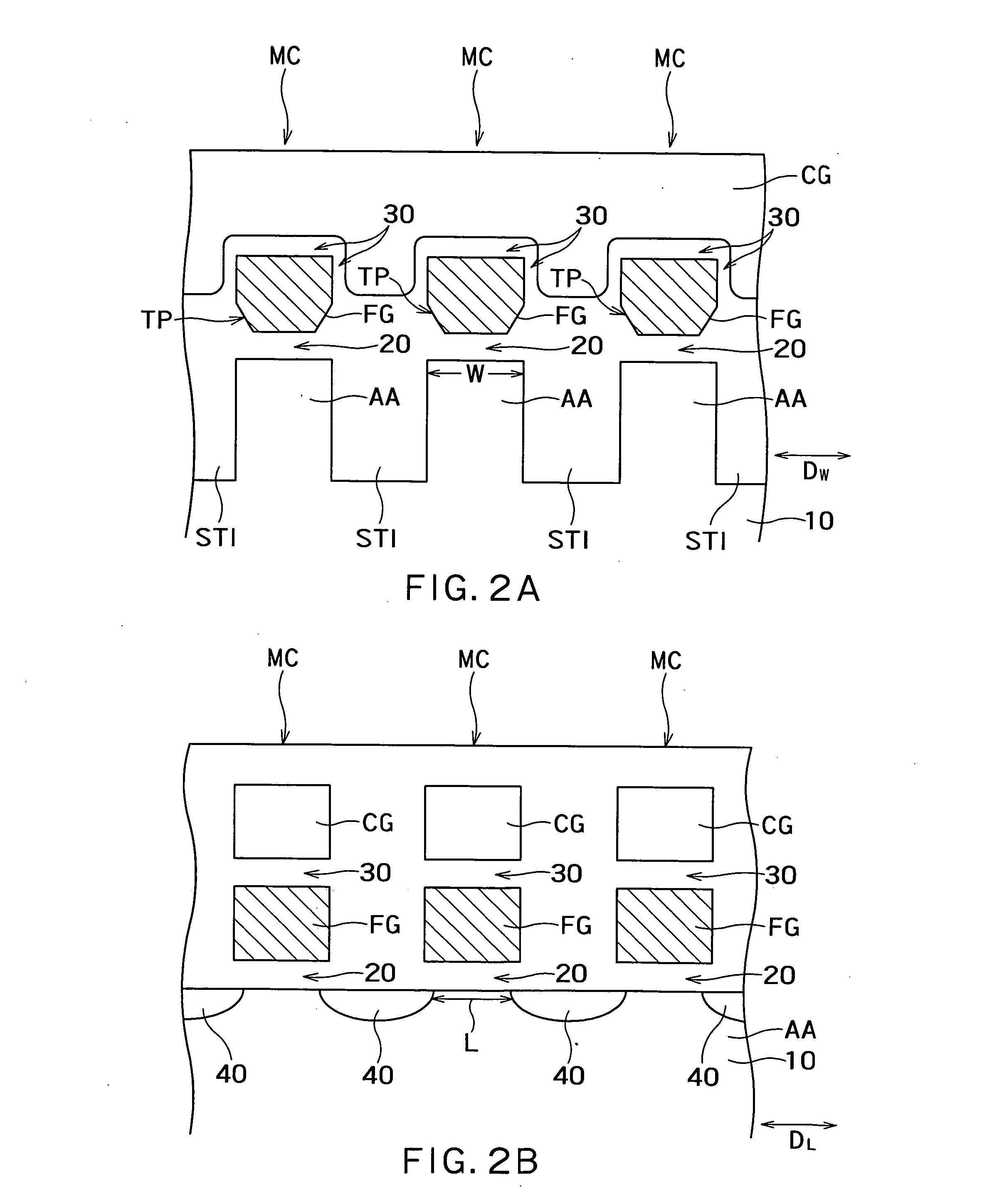

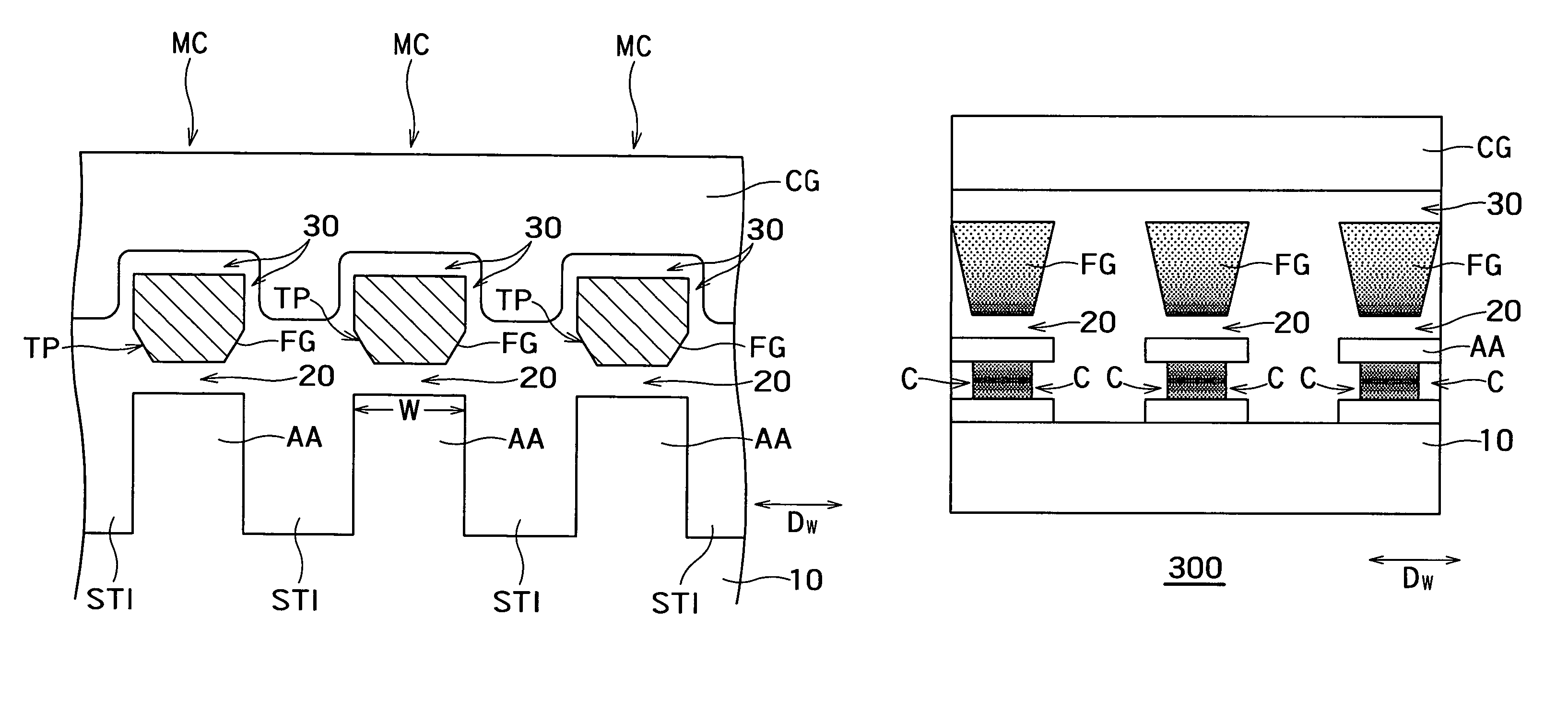

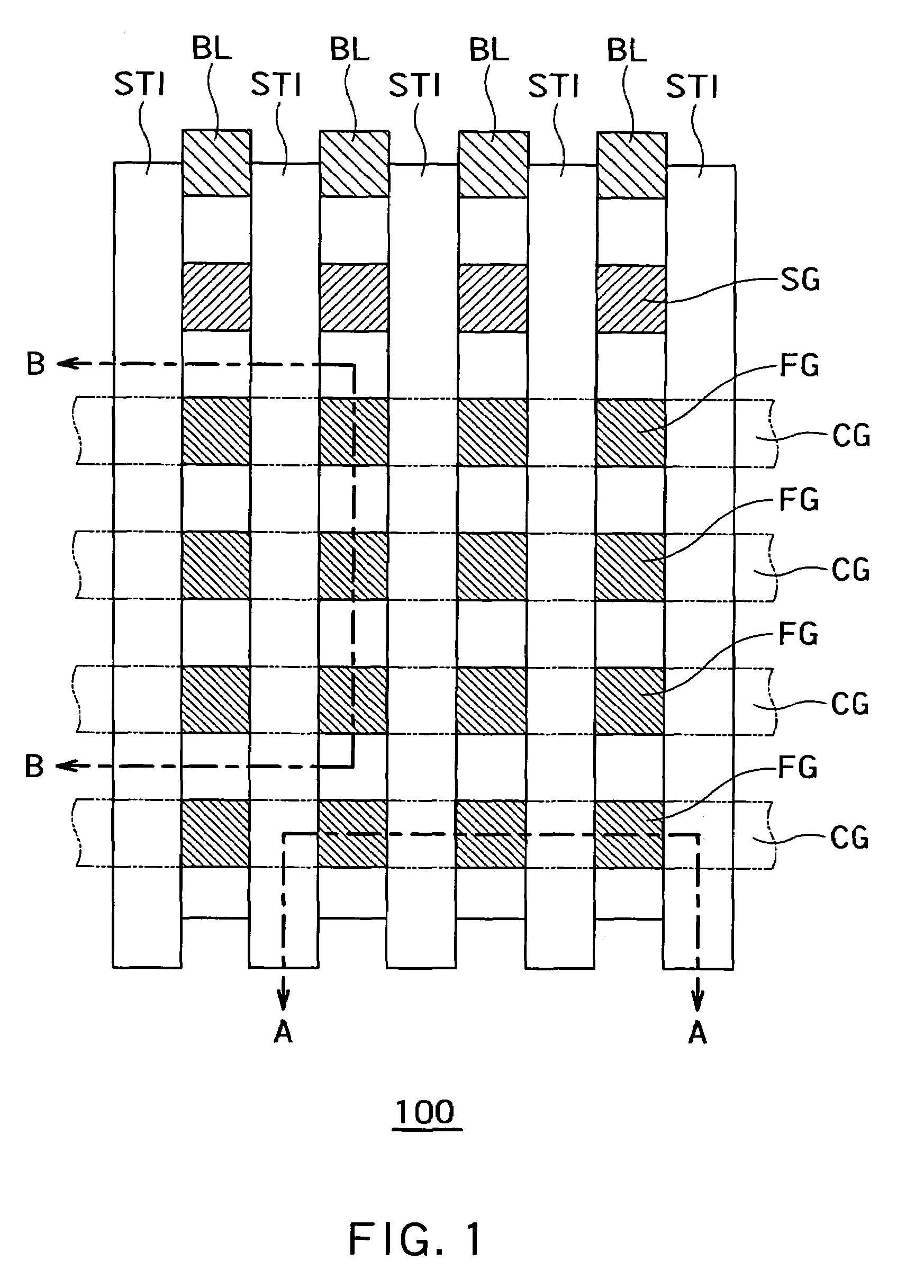

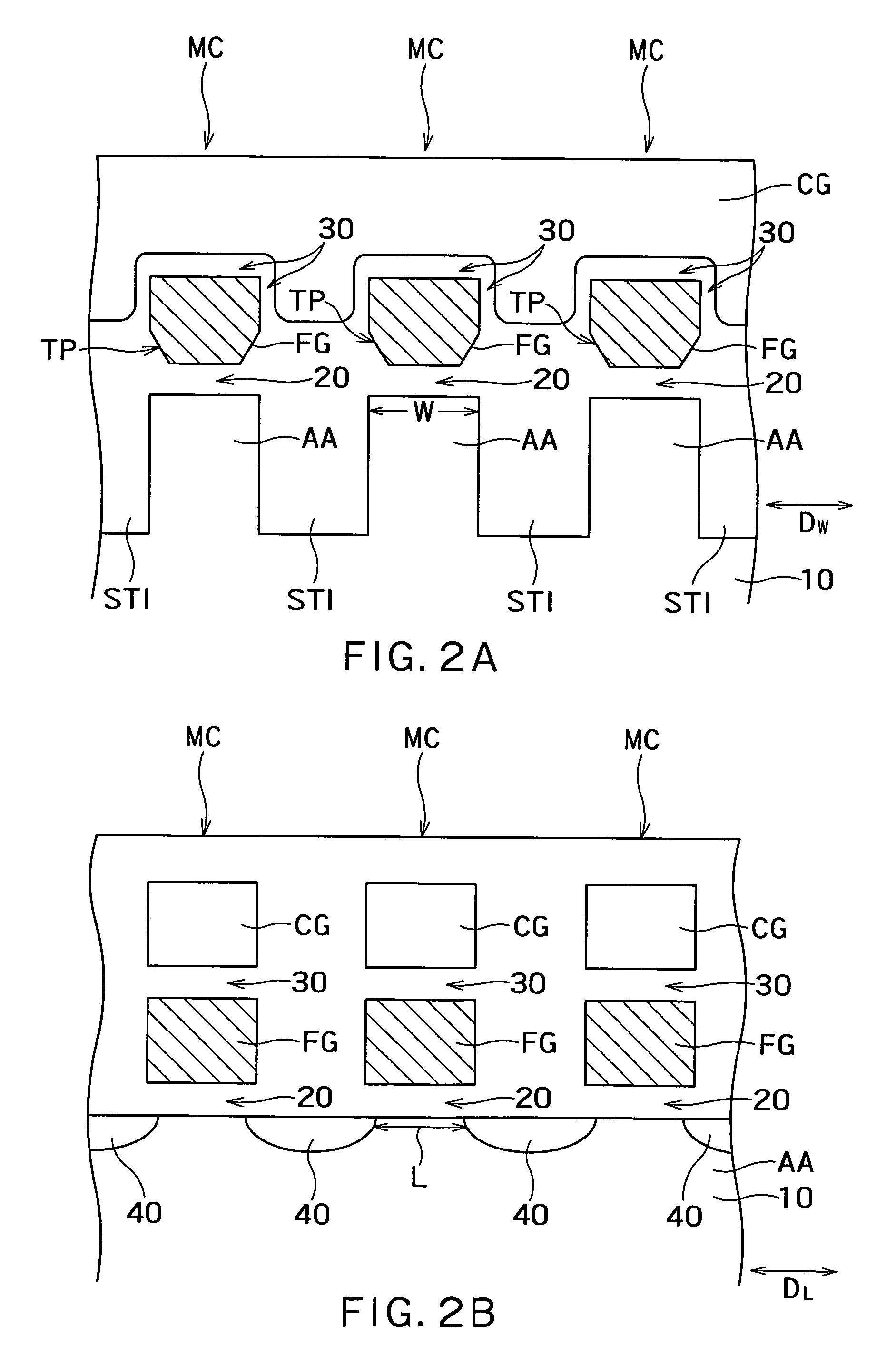

Nonvolatile semiconductor storage device and manufacturing method therefor

InactiveUS20060214217A1Reduce distractionsEasy to controlTransistorDrying solid materials with heatSemiconductor storage devicesSemiconductor

A nonvolatile semiconductor storage device includes a semiconductor substrate; a plurality of isolation regions formed in the semiconductor substrate; an element-forming region formed between adjacent isolation regions; a first gate insulating film provided on the element-forming region; a floating gate electrode which is provided on the first gate insulating film and in which a width of a lower hem facing the element-forming region is narrower than a width of the element-forming region in a section taken in a direction perpendicular to a direction in which the isolation regions extend; a second gate insulating film provided on the floating gate electrode; and a control gate electrode provided on the second gate insulating film.

Owner:KK TOSHIBA

Epitaxial growth method

InactiveUS7435666B2Well formedLow costDrying solid materials with heatDrying gas arrangementsCrystalline materialsSingle crystal

Provided is an epitaxial growth method for forming a high-quality crystalline growth semiconductor wafer. The method includes forming a buffer layer on a single crystalline wafer using a single crystalline material; forming a mask layer on the buffer layer; forming a plurality of holes in the mask layer using a laser to expose portions of the buffer layer; forming wells having a predetermined depth in the exposed portions of the buffer layer by injecting an etchant into the holes; removing the mask layer and annealing the buffer layer to form a porous buffer layer having cavities obtained by the wells; and forming a crystalline material layer on the porous buffer layer using an epitaxial growth process.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

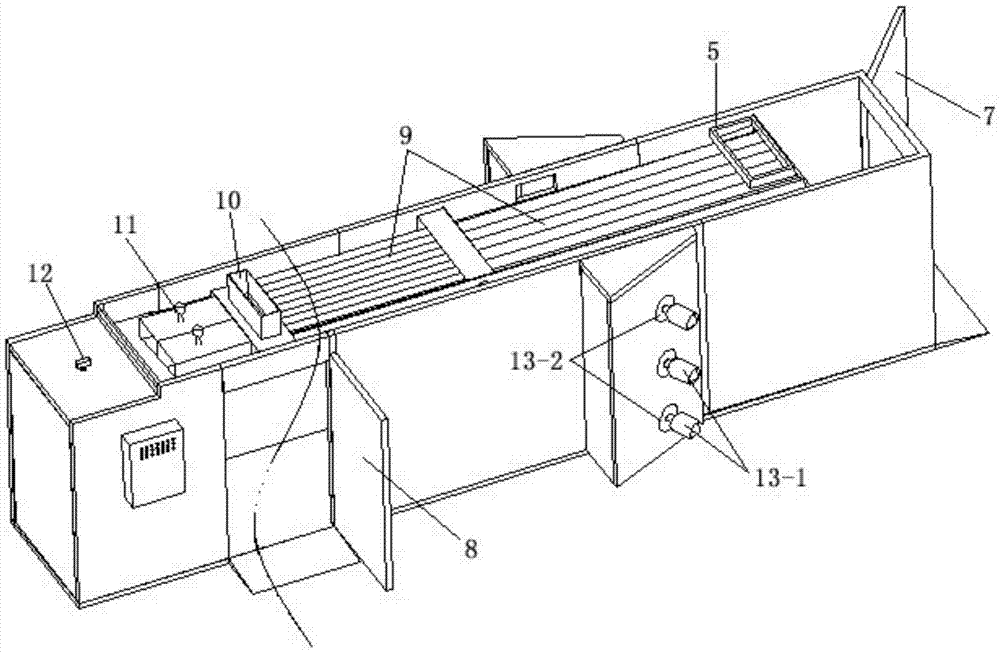

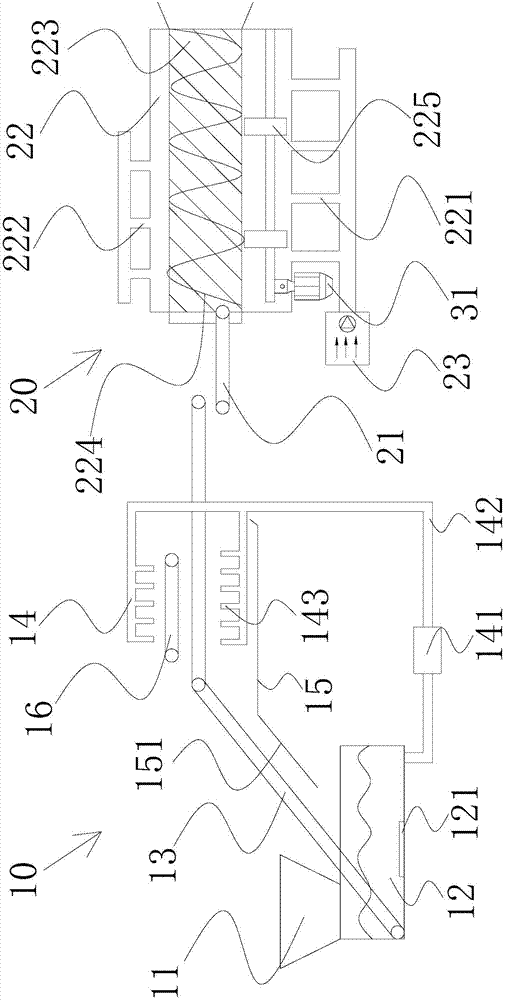

Dryer

ActiveCN105444555AImprove drying efficiencyEasy to disassemble and repairFood processingDrying gas arrangementsDrying timeAir heating

The invention relates to a dryer, which comprises a dryer housing, an air heating room, an air supply room, a drying channel, an air inlet which is communicated with the air heating room, an air outlet which is communicated with the front end of the drying channel, a material inlet which is formed in the front end of the drying channel, and a material outlet which is formed in the rear end of the drying channel, wherein a heat source heat exchanger is arranged in the air heating room; and a direct-blowing type air supply device is arranged in the air supply room. The dryer also comprises an air regulation guide plate, an exhaust waste heat recycling device, an intelligent fresh air humidity regulation device and a hot air compensation device. The dryer has the beneficial effects that the dryer can be used for drying laver and other products; constant-temperature and stable air supply can be realized; the air supply device is convenient to dismount, maintain and clean; the exhaust waste heat recycling function and partial exhaust recycling function are realized; thermal discharge is reduced and a product is energy-saving so that the production cost is reduced; and the hot air compensation device is capable of improving the drying efficiency of the dryer and shortening the drying time.

Owner:WENZHOU XINGBEI MACHINERY TECH CO LTD

Electronic device having path of power supplied to display part switched according to whether external power is supplied

InactiveCN1848593ABatteries circuit arrangementsDrying solid materials with heatControl powerPower detector

Owner:SAMSUNG ELECTRONICS CO LTD

Nonvolatile semiconductor storage device and manufacturing method therefor

InactiveUS7489006B2Reduce distractionsEasy to controlTransistorDrying solid materials with heatSemiconductor storage devicesEngineering

A nonvolatile semiconductor storage device includes a semiconductor substrate; a plurality of isolation regions formed in the semiconductor substrate; an element-forming region formed between adjacent isolation regions; a first gate insulating film provided on the element-forming region; a floating gate electrode which is provided on the first gate insulating film and in which a width of a lower hem facing the element-forming region is narrower than a width of the element-forming region in a section taken in a direction perpendicular to a direction in which the isolation regions extend; a second gate insulating film provided on the floating gate electrode; and a control gate electrode provided on the second gate insulating film.

Owner:KK TOSHIBA

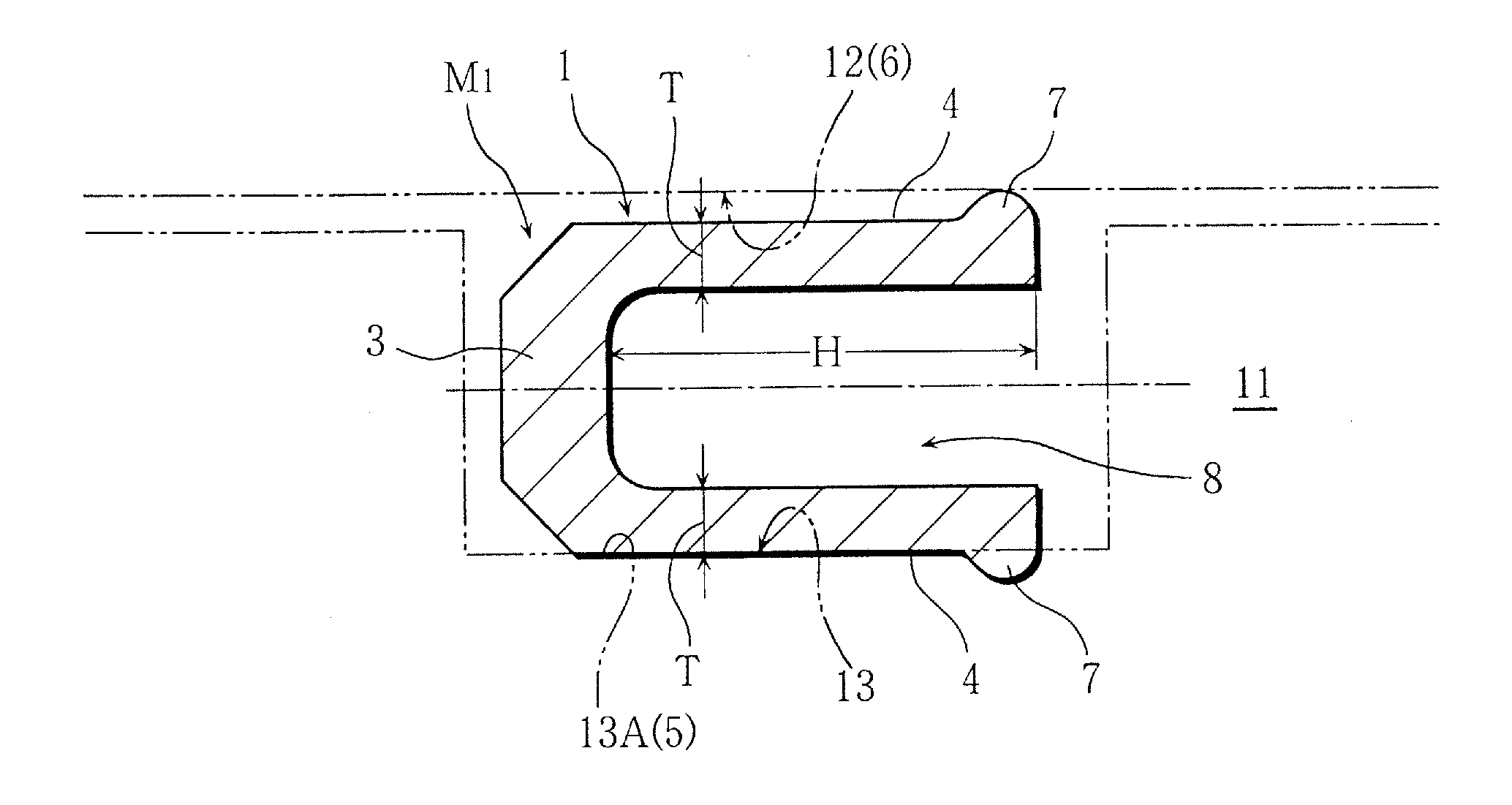

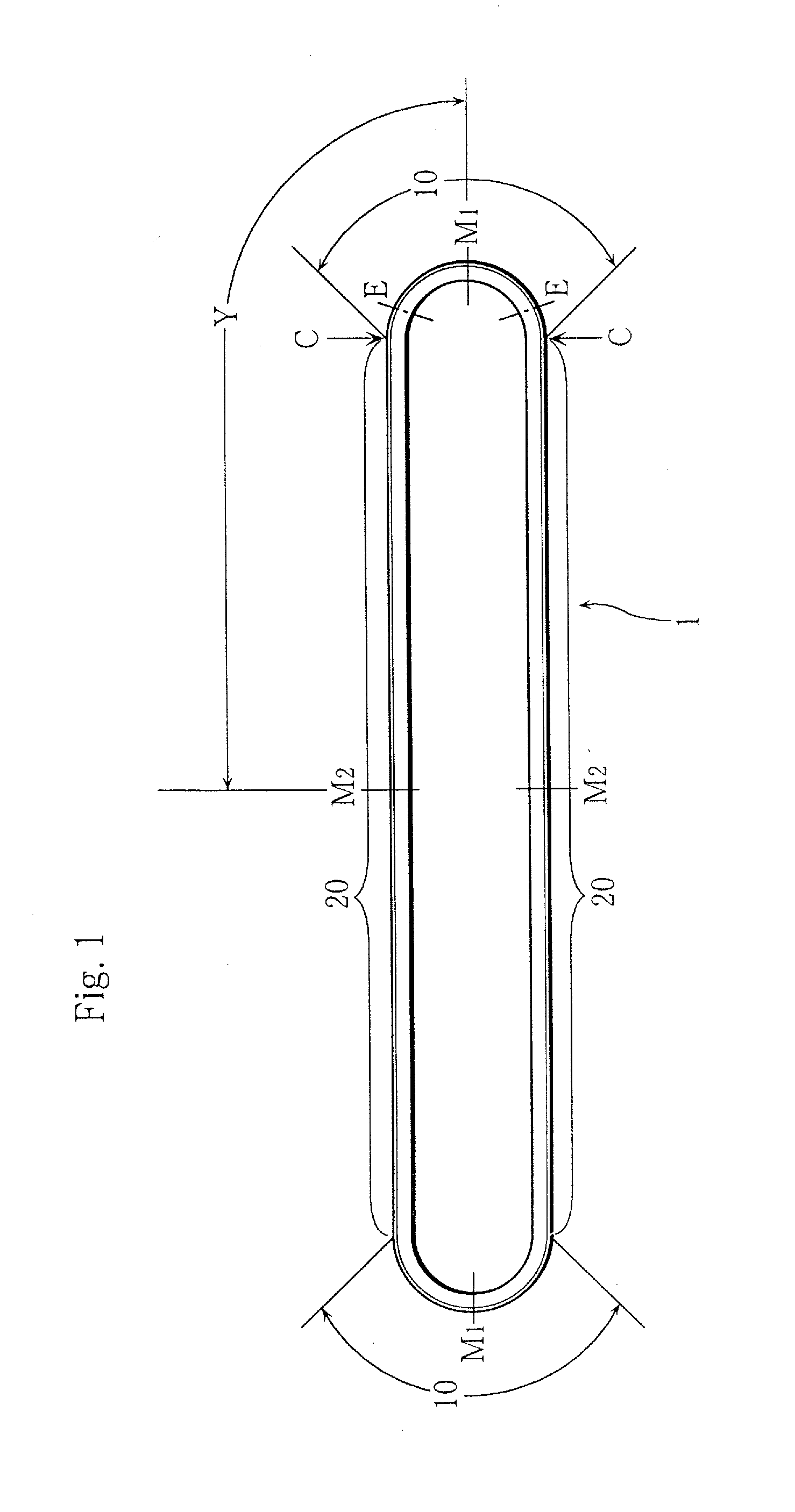

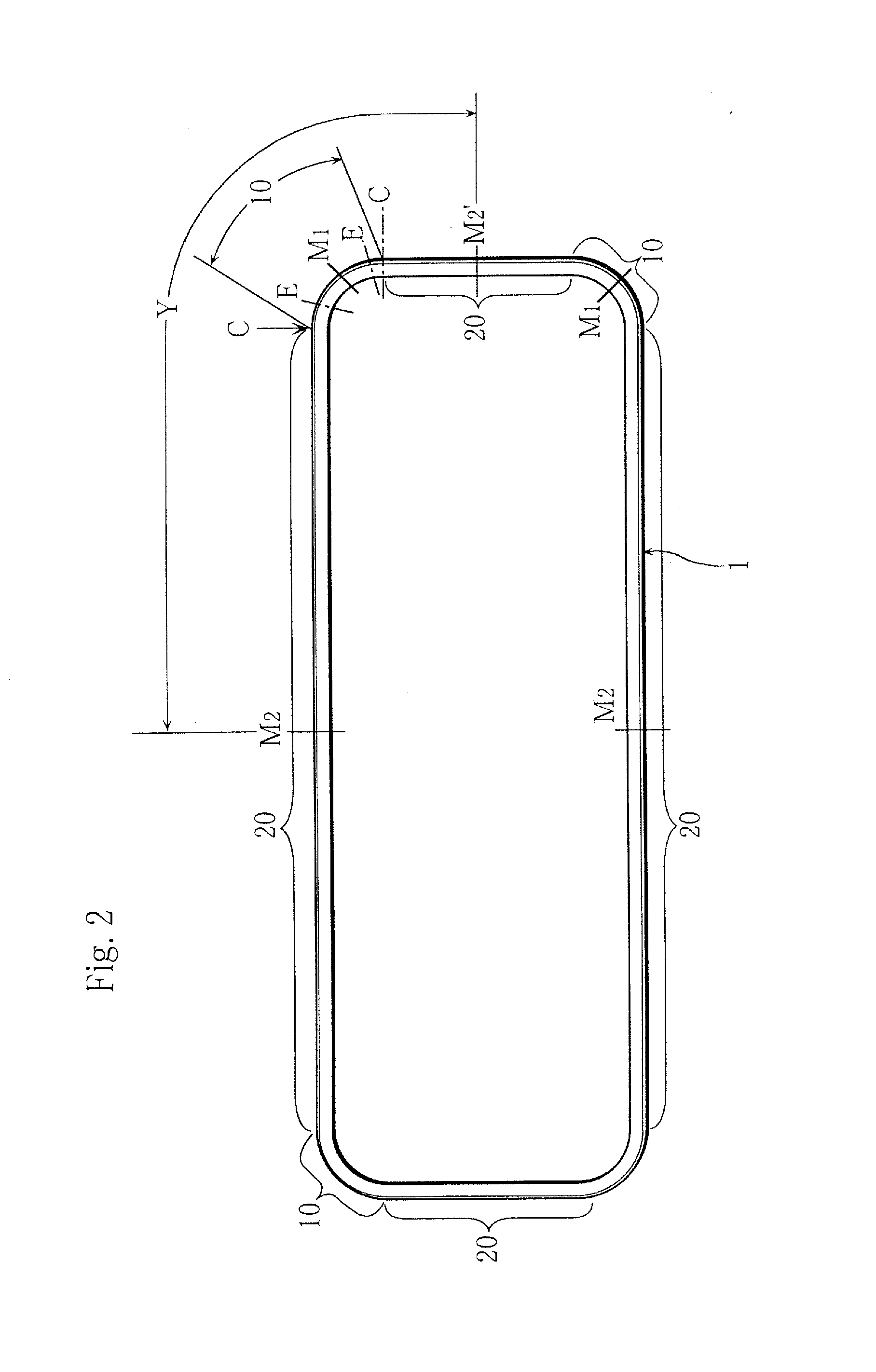

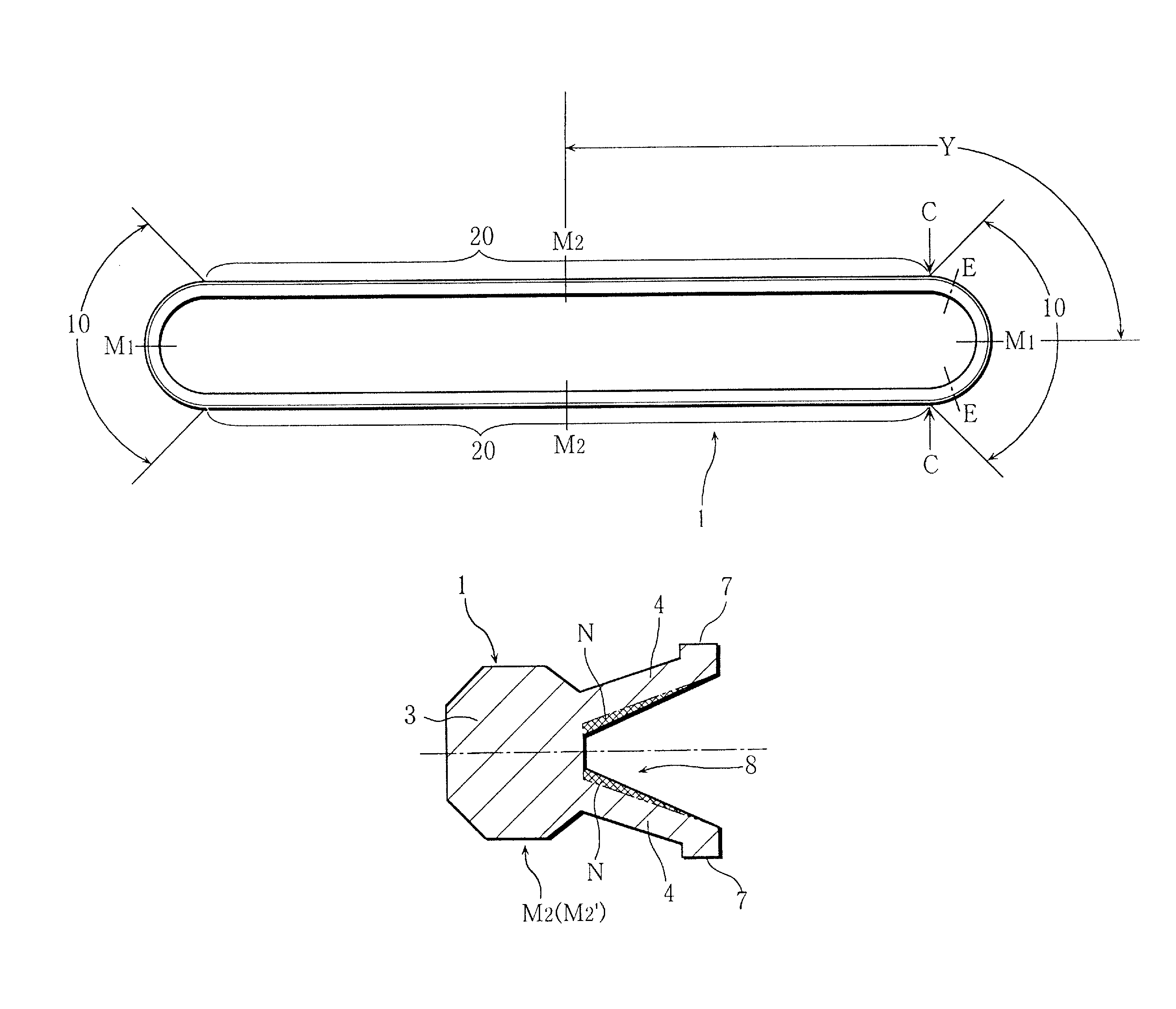

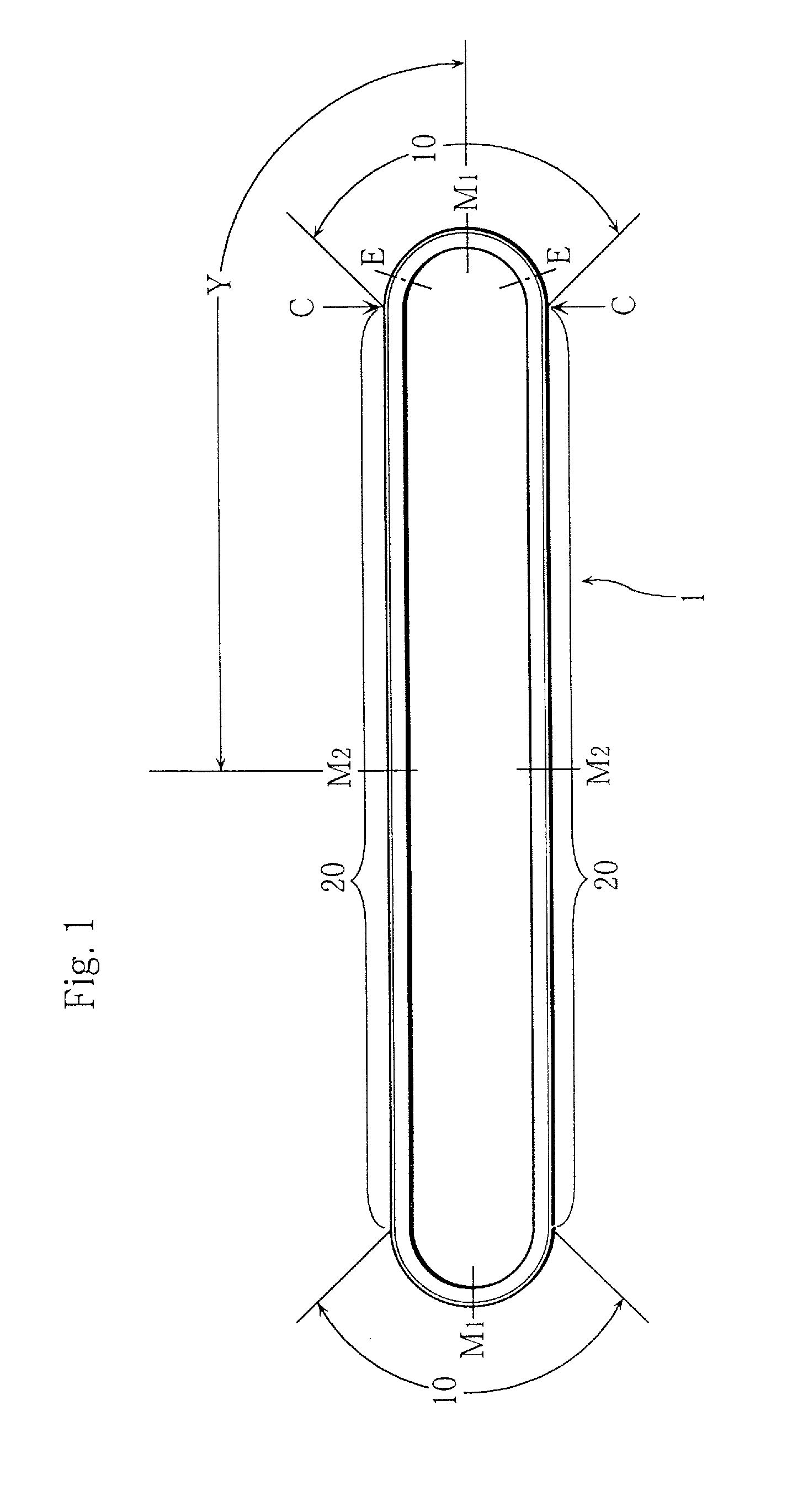

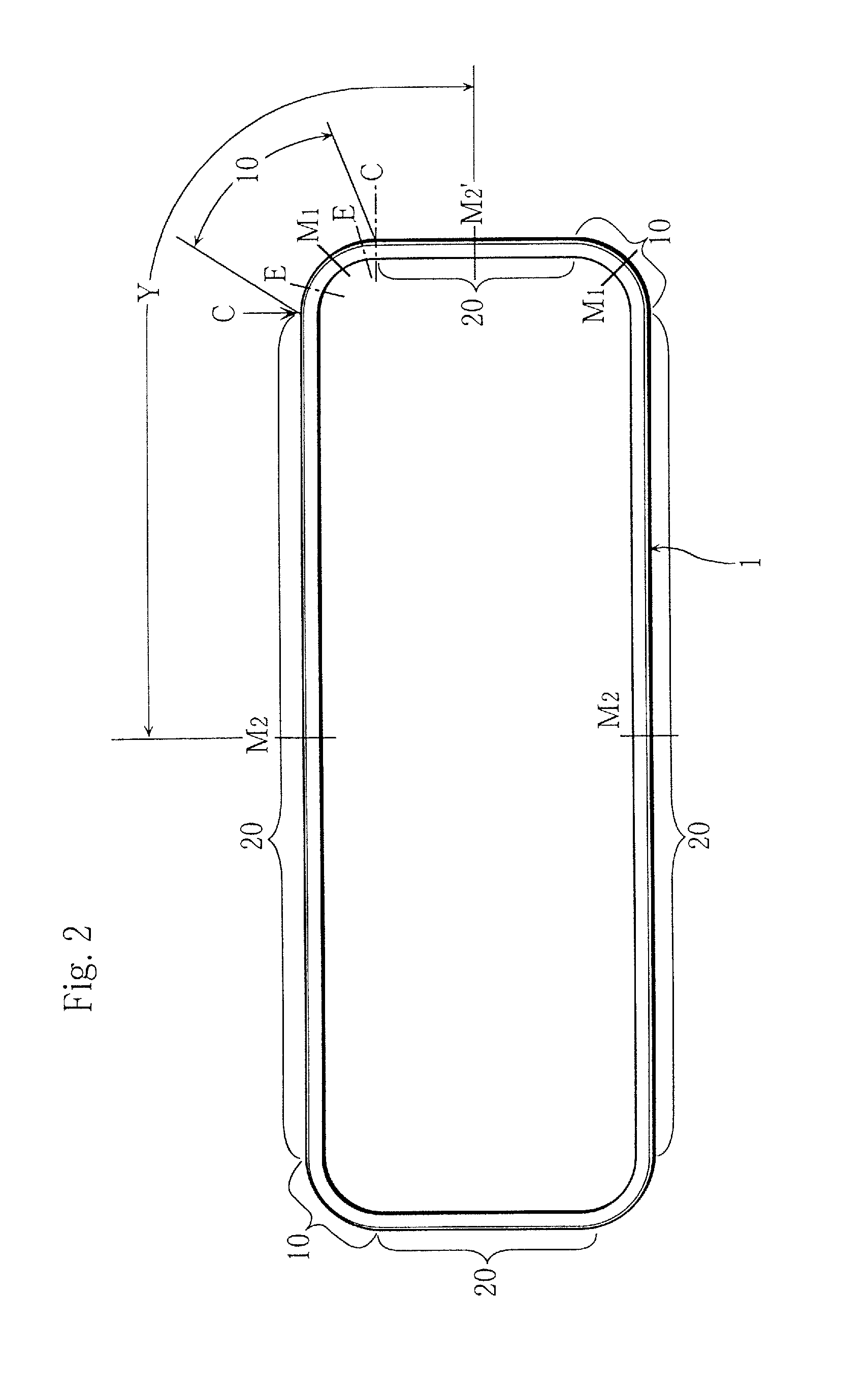

Metal seal

A metal seal of a non-circular ring which shows uniform sealing ability on whole periphery. The whole configuration of the metal seal is a non-circular ring having an R-shaped curved portion and a straight portion, and a cross-sectional configuration of the metal seal is changed as to make cantilever flexural rigidity larger on the straight portion than on the R-shaped curved portion.

Owner:MITSUBISHI CABLE IND LTD

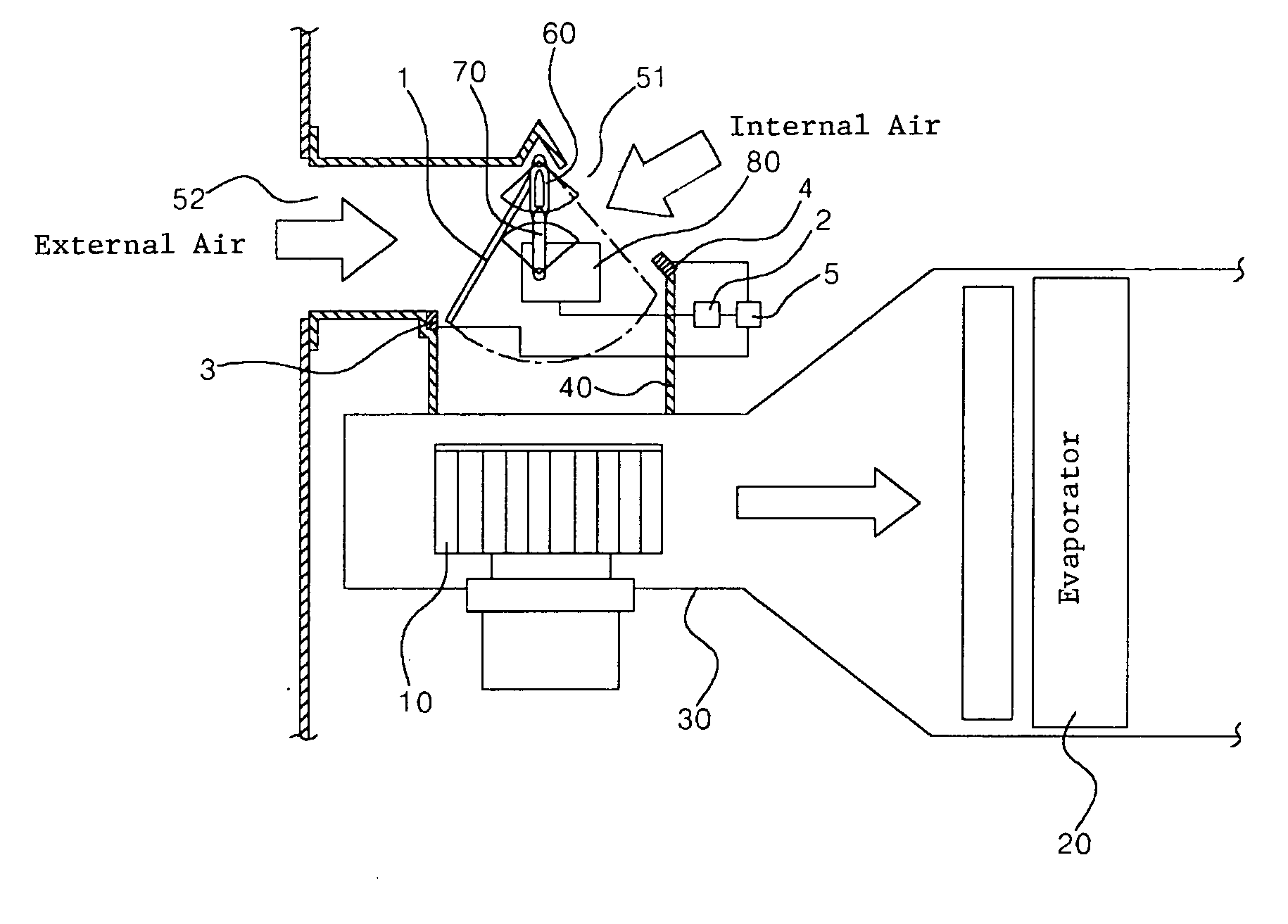

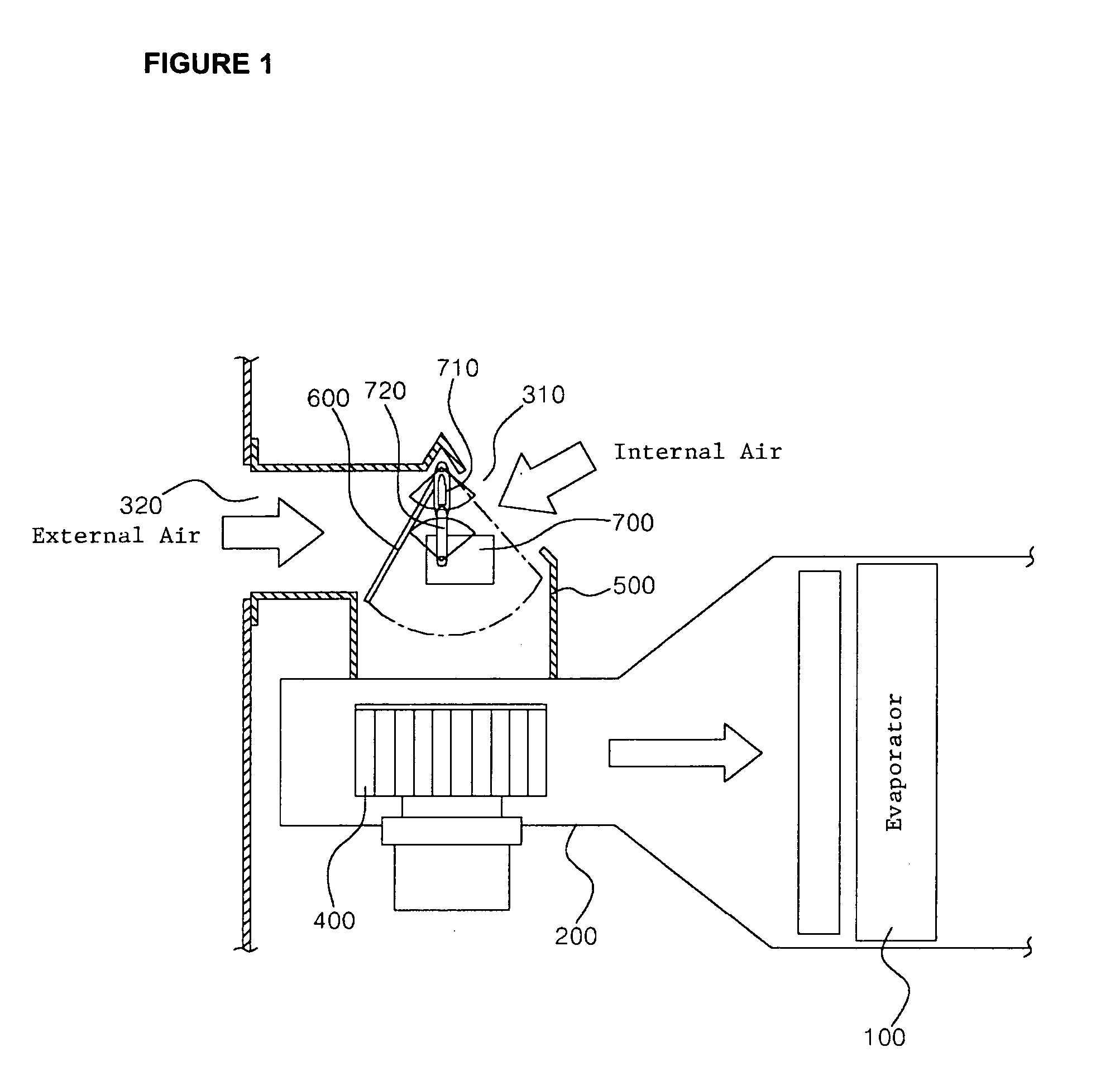

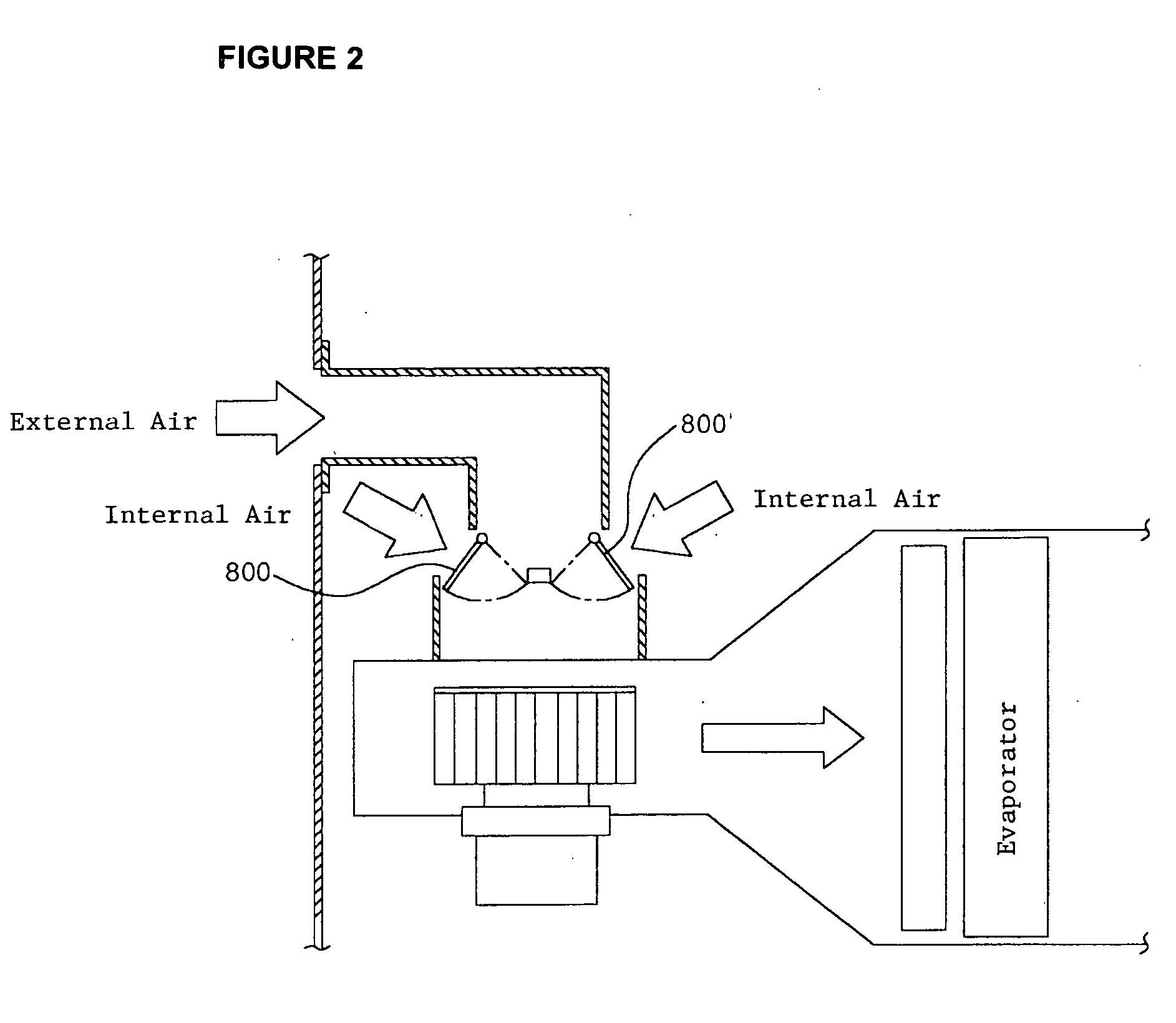

Device for fixation of door on HVAC for automobile

InactiveUS20050250434A1Problem still existAvoid partialAir-treating devicesDrying solid materials without heatElectromagnetElectrical and Electronics engineering

The present invention relates to a door fixation apparatus for a vehicle air conditioner that is capable of preventing various doors or dampers that are installed in an air conditioner from partially opening due to wind pressure when a vehicle is operating or an air conditioner is operated in a state that the doors or dampers are closed. The door fixation apparatus includes a magnetic body that forms at least part of a ventilation opening and closing of the door of the vehicle air conditioner; an electromagnet that is installed adjacent a ventilation opening so that at least part of the magnetic body of the door is magnetically adhered to the electromagnet in a blocking position of the ventilation opening; a power source that supplies the current for magnetizing the electromagnet; and a controller to judge the opening and closing state of the ventilation opening and control a current supply of the power source.

Owner:MODINE KOREA

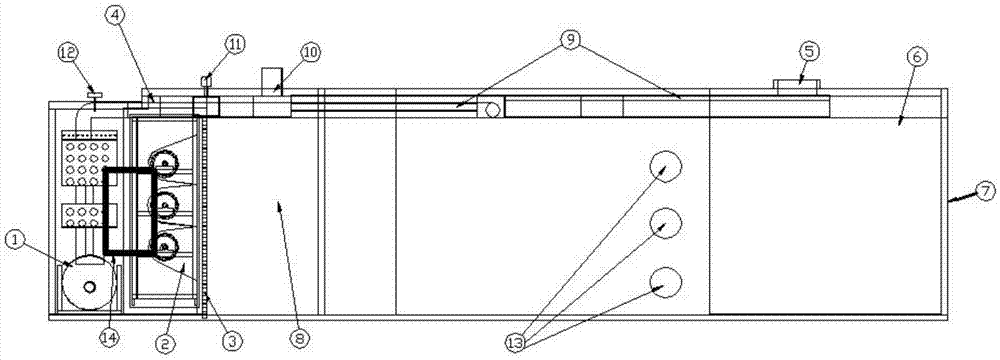

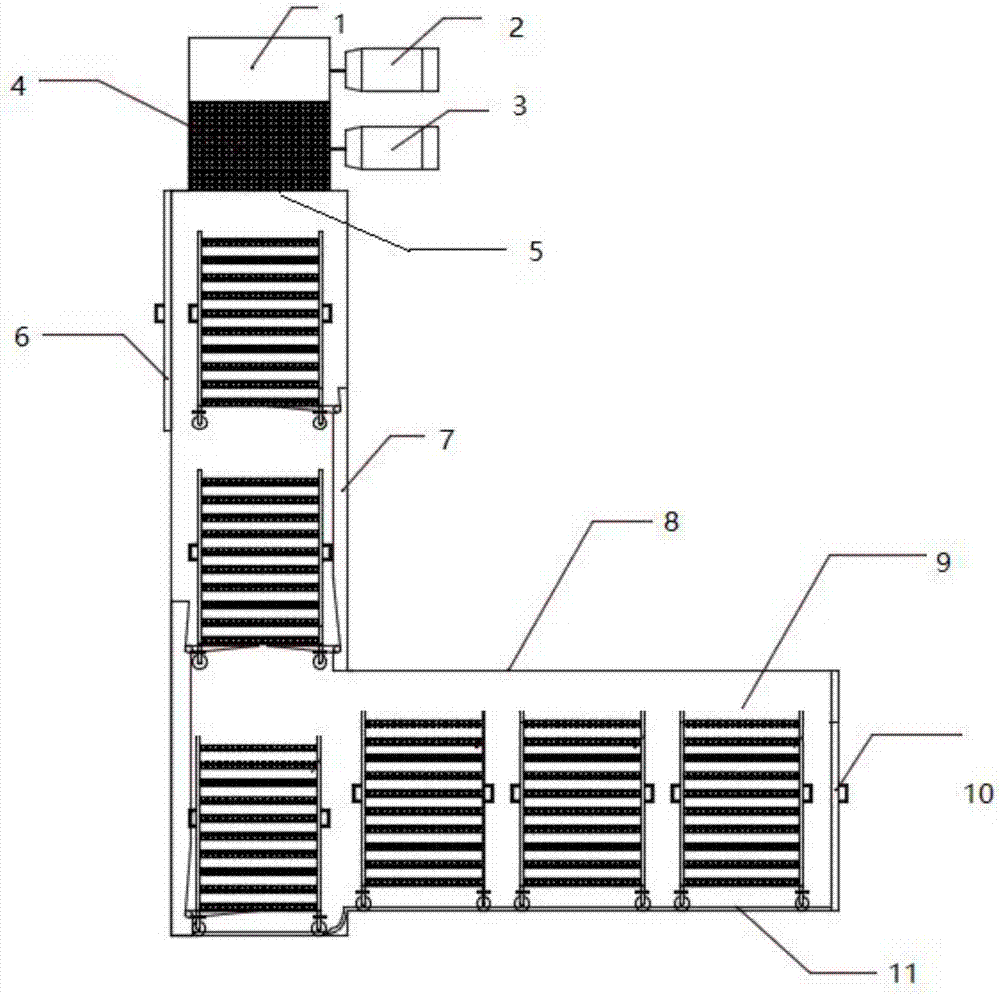

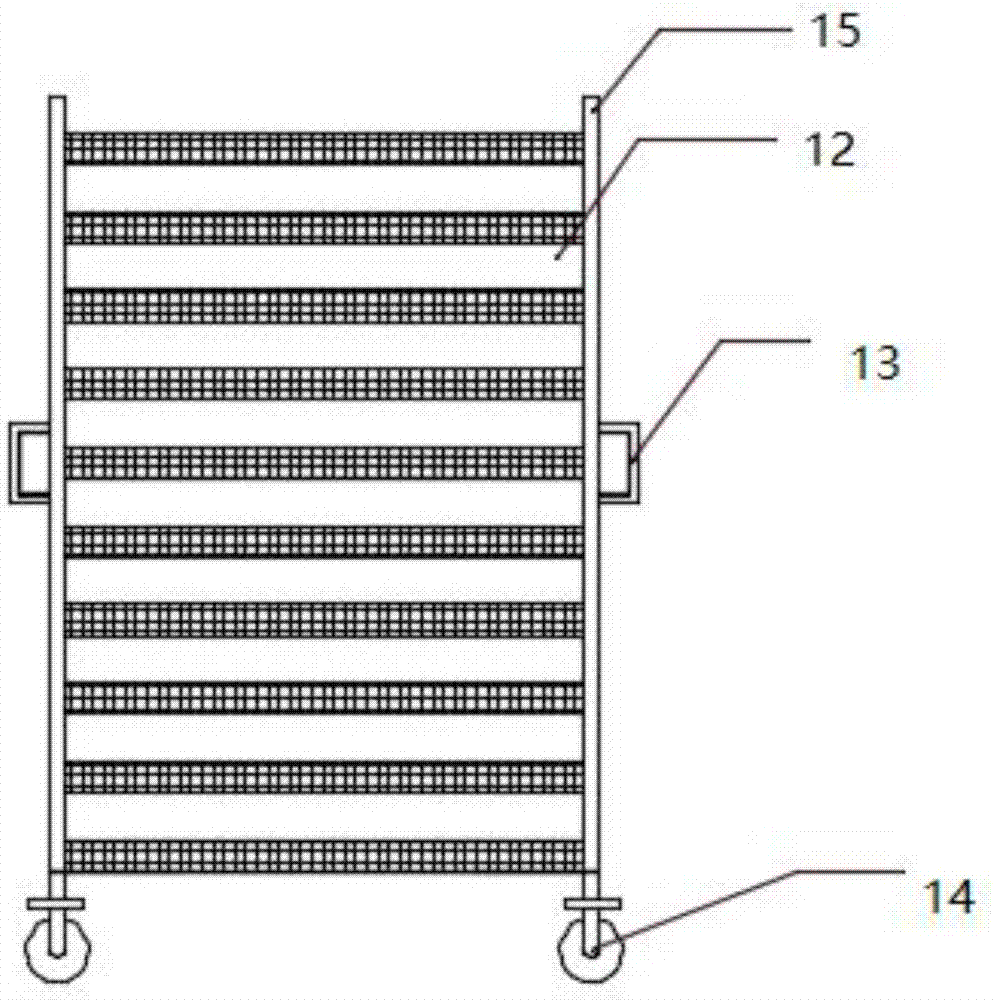

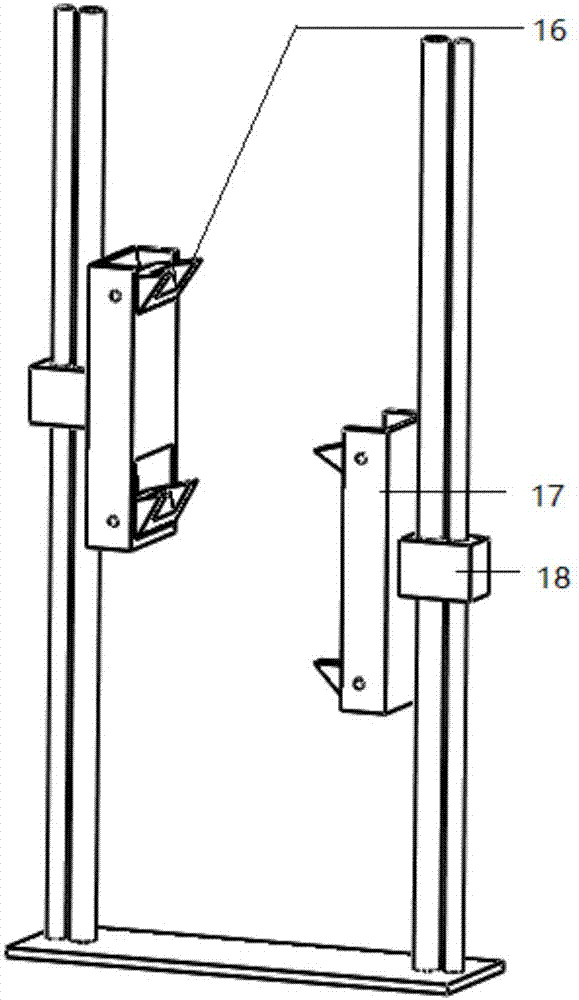

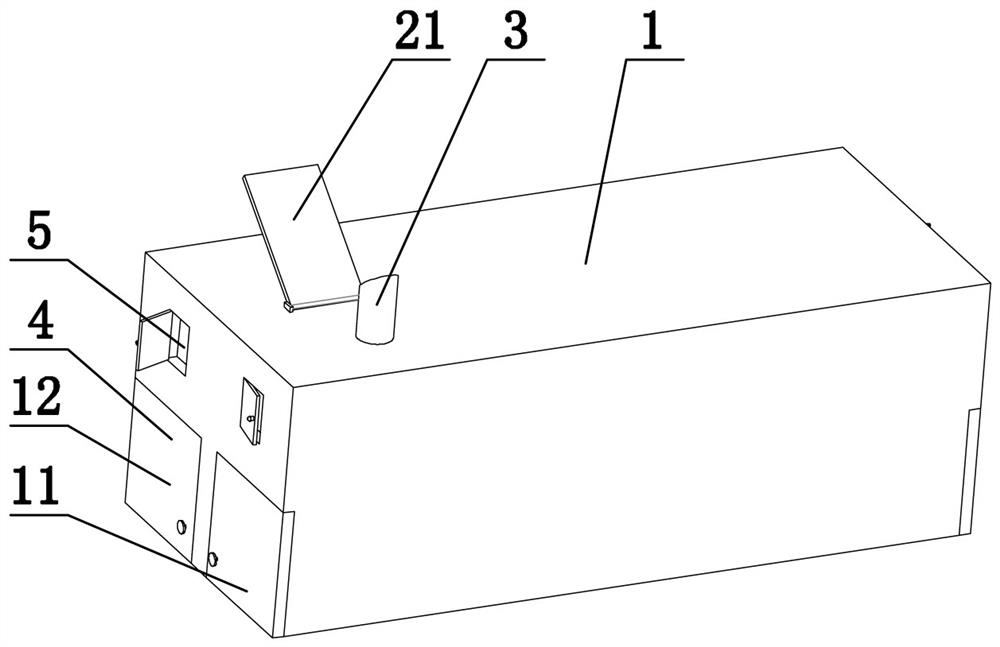

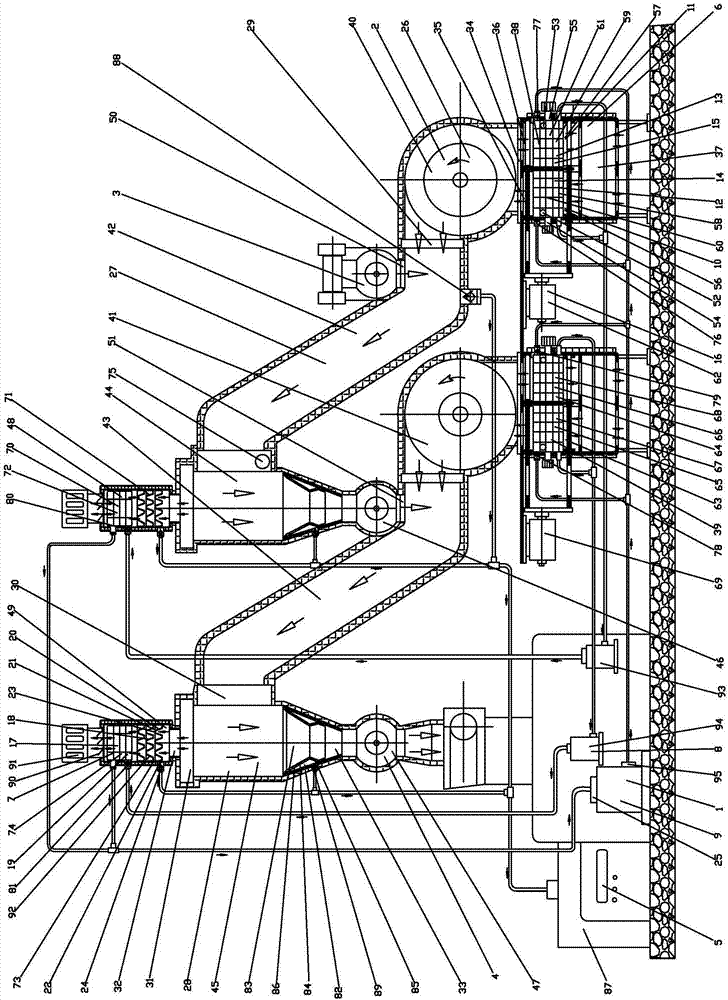

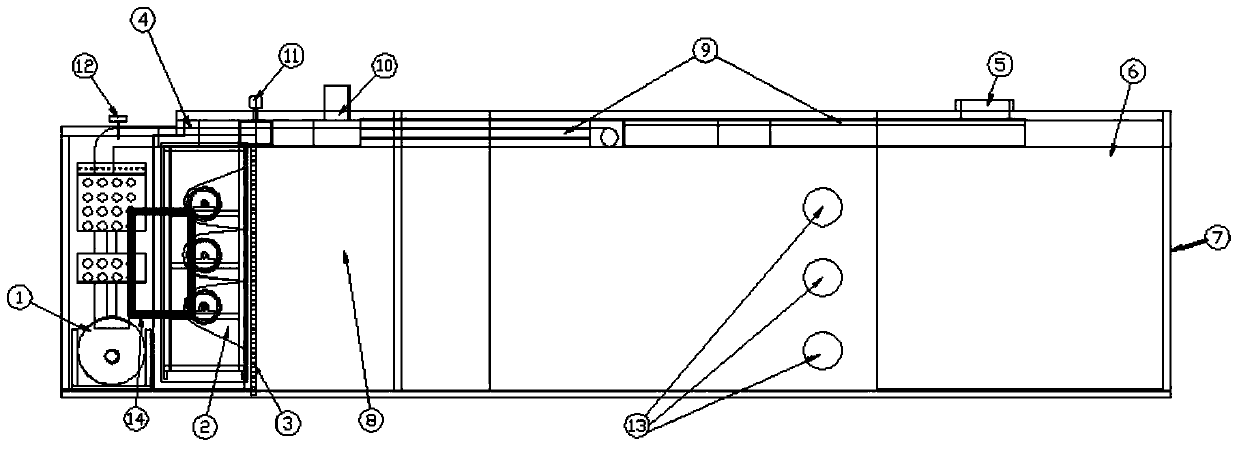

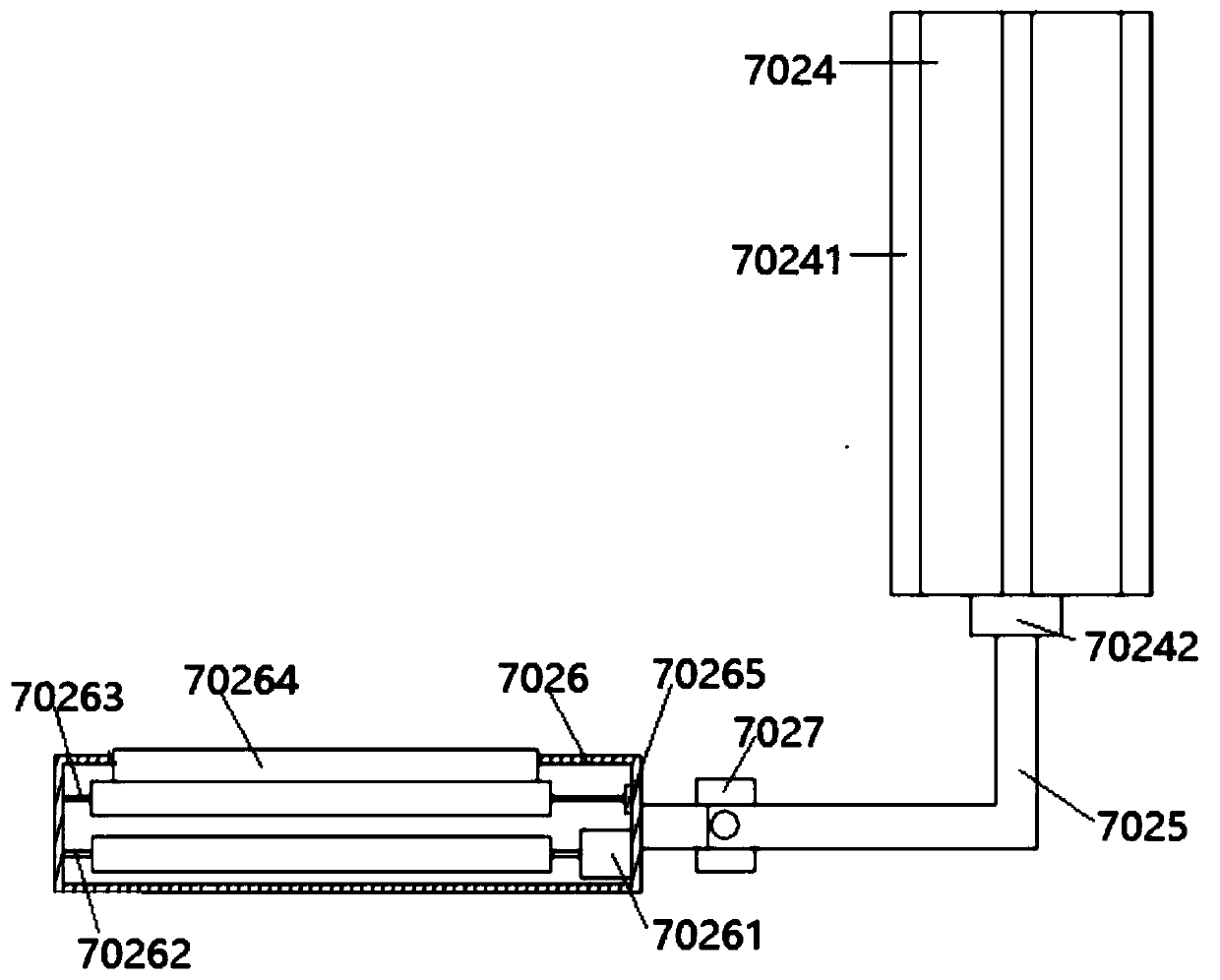

Porphyra drying device

ActiveCN107024103AImprove efficiencyIncrease profitDrying gas arrangementsMarine product dryingContact timePorphyra

The invention discloses a porphyra drying device comprising a heat source device, an air blowing device and a drying pipeline; the heat source device is provided with an air inlet end and an air outlet end; the air blowing device is connected to the air inlet end of the heat source device; the drying pipeline is connected to the air outlet end of the heat source device and is composed of a feeding hole, a discharging hole and a charging trolley located in the pipeline; the drying pipeline is L-shaped and comprises a vertical pipeline and a horizontal pipeline in which an orbit is arranged; and longitudinal lead screw sliding tables are mounted at different heights at two sides inside the vertical pipeline. By utilizing the characteristic of large charging amount of a multilayer meshy storage rack of the charging trolley, the porphyra drying device disclosed by the invention has the effects of increasing the discharging volume within unit time and the efficiency of a dryer; and the L-shaped pipeline structure is beneficial for the dryer to sufficiently utilize hot air and is capable of prolonging the contact time with the hot air and increasing the production efficiency. Compared with a pure horizontal straight-pipeline dryer, the porphyra drying device has the advantages that the horizontal length of a space occupied by a machine is greatly reduced, and the utilization ratio of a space in a height direction is increased.

Owner:SOUTHEAST UNIV

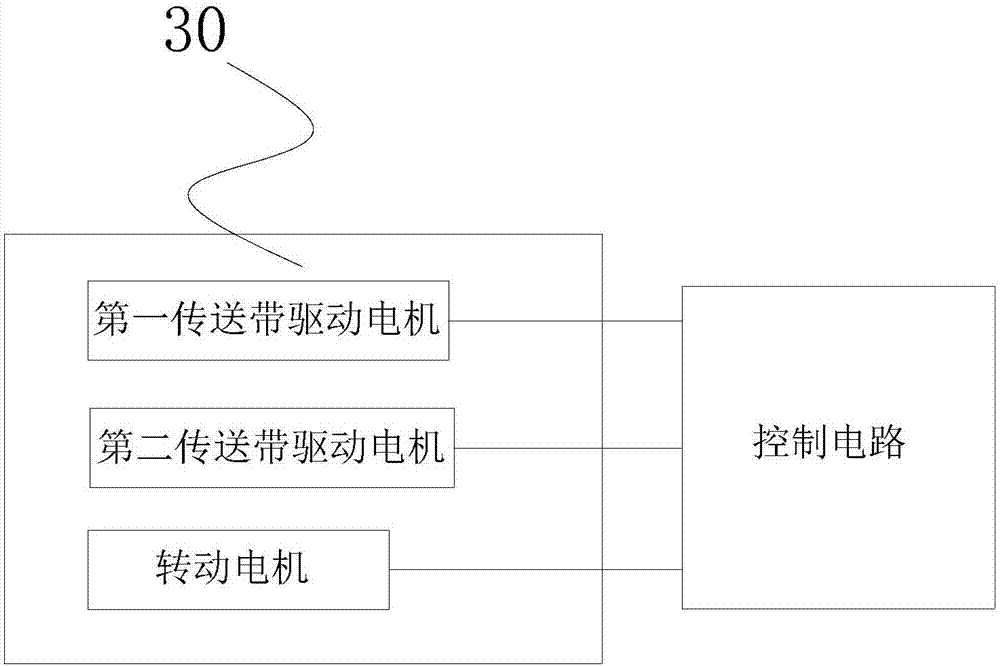

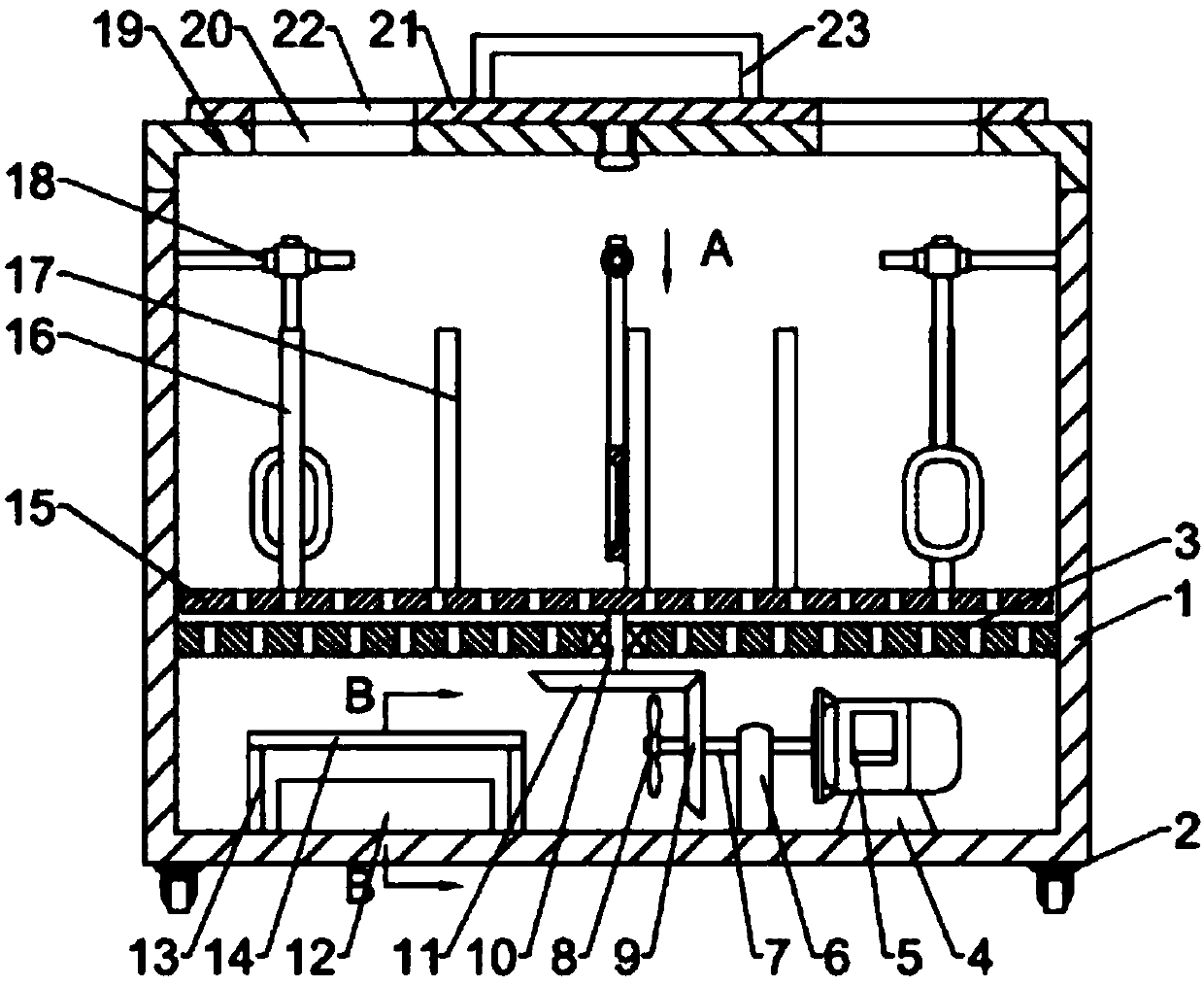

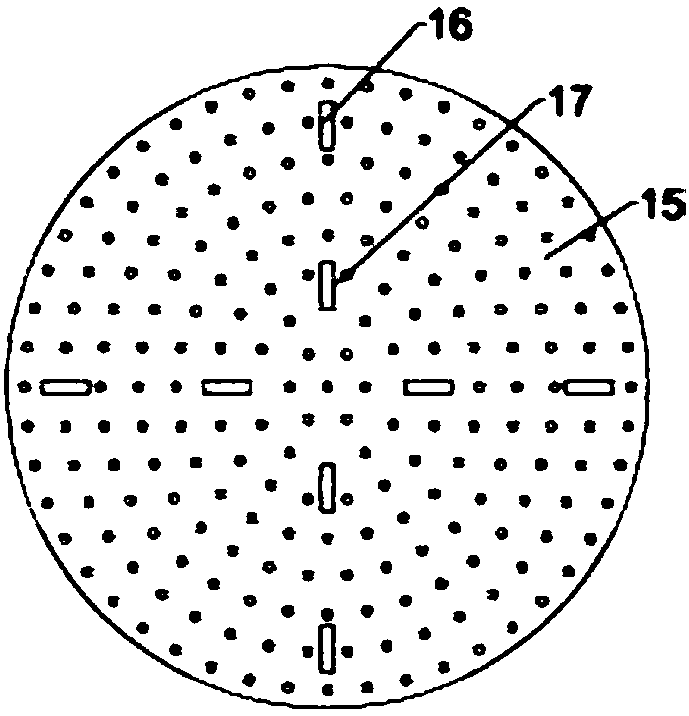

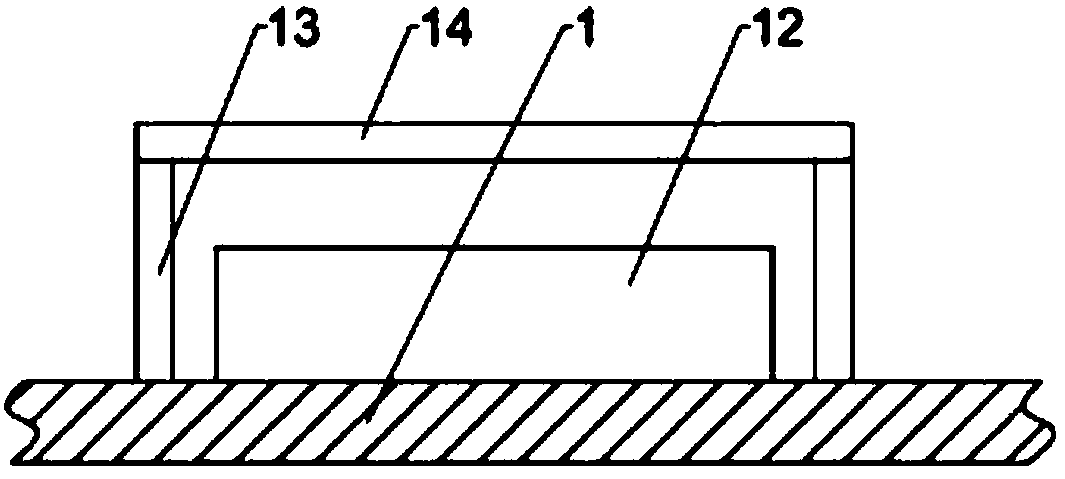

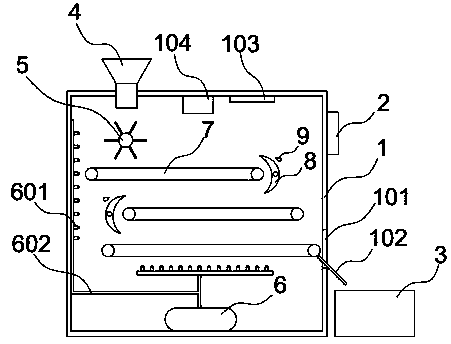

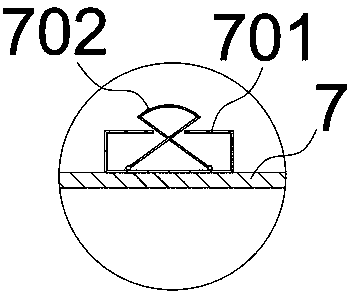

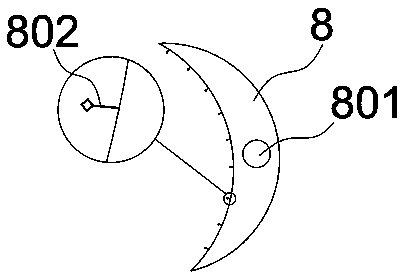

Drying and washing device for seafood

InactiveCN107980884AAll aspects of dryingEfficient dryingFish washing/descalingMarine product dryingAutomatic transmissionEngineering

The invention relates to a drying and washing device for seafood. The drying and washing device comprises a washing mechanism and an oven-drying mechanism, wherein the washing mechanism comprises a feeding hopper, an ultrasonic tank, a first conveying belt and a spray device; the feeding hopper is arranged at the upper part of the ultrasonic tank; the ultrasonic tank comprises a tank body and is connected with an ultrasonic generator; the spray device faces the first conveying belt; the oven-drying mechanism comprises a second conveying belt, an oven-drying chamber and a heat source device; the second conveying belt is arranged below the conveying tail end of the first conveying belt; the top of the oven-drying chamber is provided with multiple hot air exhaust ports; the bottom of the oven-drying chamber is provided with multiple hot air inlets; the multiple hot air inlets are connected to the heat source device. Distinguished from the prior art, according to the technical scheme, thedrying and washing device is used for realizing the automatic transmission in a cleaning process through the first conveying belt; thus, labor cost is reduced, and the seafood completed in washing iseffectively oven-dried and freshness is guaranteed.

Owner:莆田市秀屿区睿思海洋渔业有限公司

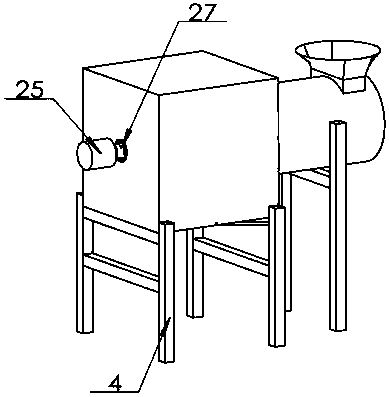

Air-drying equipment used for dried peeled shrimp preparation

InactiveCN107843083ADry evenlyPrevent spoilageDrying gas arrangementsMarine product dryingPunchingShrimp

The invention discloses air-drying equipment used for dried peeled shrimp preparation. The air-drying equipment comprises an air-drying box, wherein a fixed punching plate is fixedly connected below the inner part of the air-drying box; the right side of the lower portion of the fixed punching plate is fixedly connected with a motor mounting frame; a motor is fixedly connected above the motor mounting frame; the output end of the motor is fixedly connected with a horizontal rotary shaft; the left end of the horizontal rotary shaft is fixedly connected with a spiral fan blade; the middle part of the horizontal rotary shaft is fixedly connected with a drive bevel gear; the middle part of the fixed punching plate is rotatably connected with a transmission rotary shaft through a bearing; the lower end of the transmission rotary shaft is fixedly connected with a driven bevel gear; and the driven bevel gear is engaged with the drive bevel gear. Compared with the prior art, the air-drying equipment has the beneficial effects that: the air-drying equipment is simple in structure, is convenient to use, can perform air-drying on dried peeled shrimps, can quickly realize uniform air-drying onthe dried peeled shrimps, avoids a condition that bagged dried peeled shrimps are prevented from being rotten and deteriorated as part of the dried peeled shrimps are air-dried and part of the driedpeeled shrimps are still in a humid state if the dried peeled shrimps are stirred unevenly, and is worthy of being popularized.

Owner:宁波华又网络科技有限公司

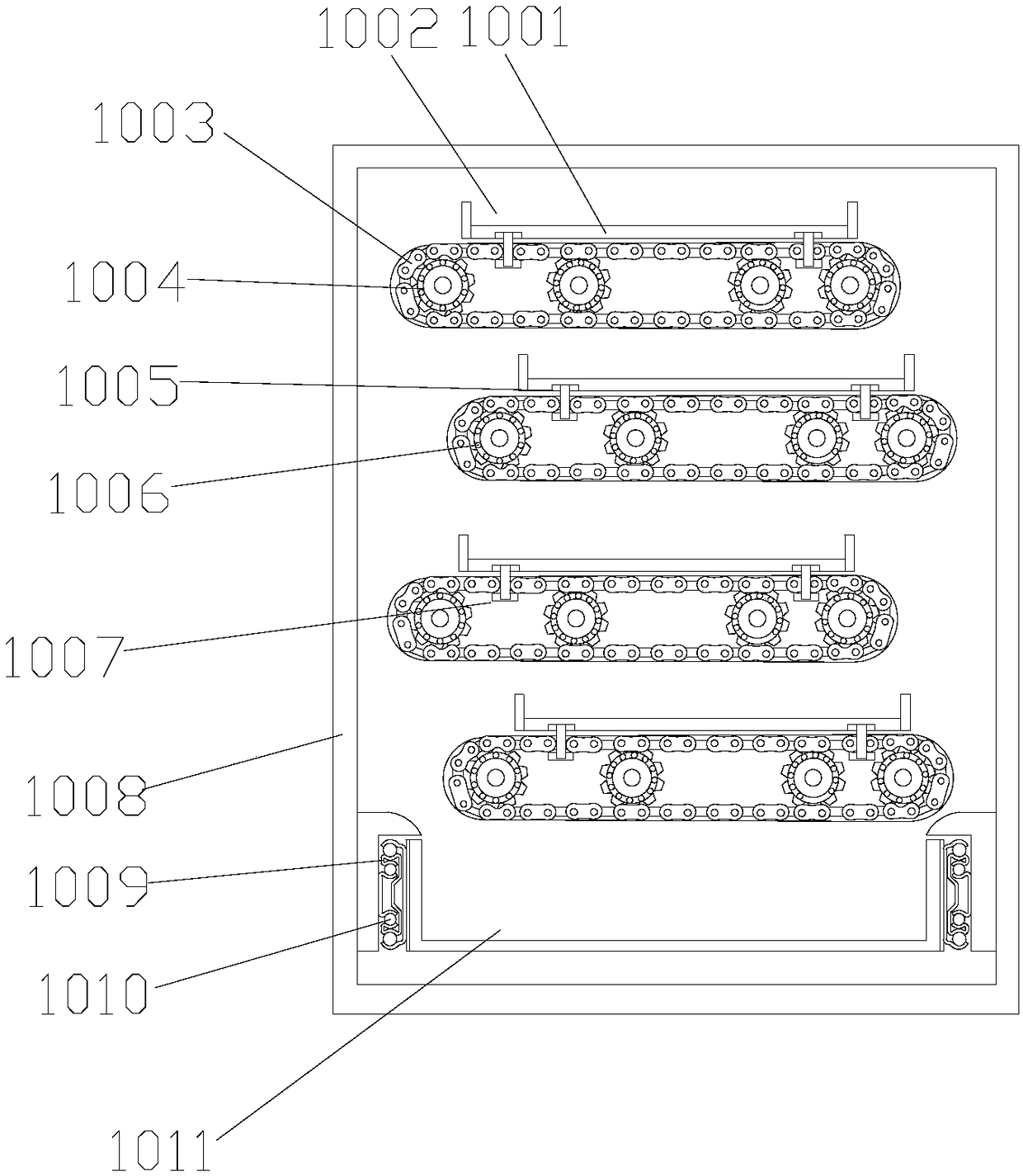

Quick sleeve-fish drying equipment

InactiveCN108302924AExtended stayImprove drying effectDrying solid materials without heatFood preservationMechanical engineeringEngineering

The invention provides quick sleeve-fish drying equipment which comprises a shell. A feeding hopper is connected to the top of the shell, a plurality of conveying belts used for conveying materials are arranged at the positions, below the feeding hipper, inside the shell, a hot gas pump used for supplying hot gas is arranged at the bottom of the shell, a discharging opening is formed in the side face of the bottom of the shell, a rotatable dividing barrel is arranged between the feeding hopper and the conveying belt on the uppermost part, and dividing plates used for dividing the materials areevenly arranged on the periphery of a rotating shaft of the dividing barrel. The equipment has the sterilization function, sleeve-fish drying and heating are even, the drying efficiency is high, andthe sleeve-fish drying quality is improved.

Owner:舟山市普陀区昌津水产有限公司

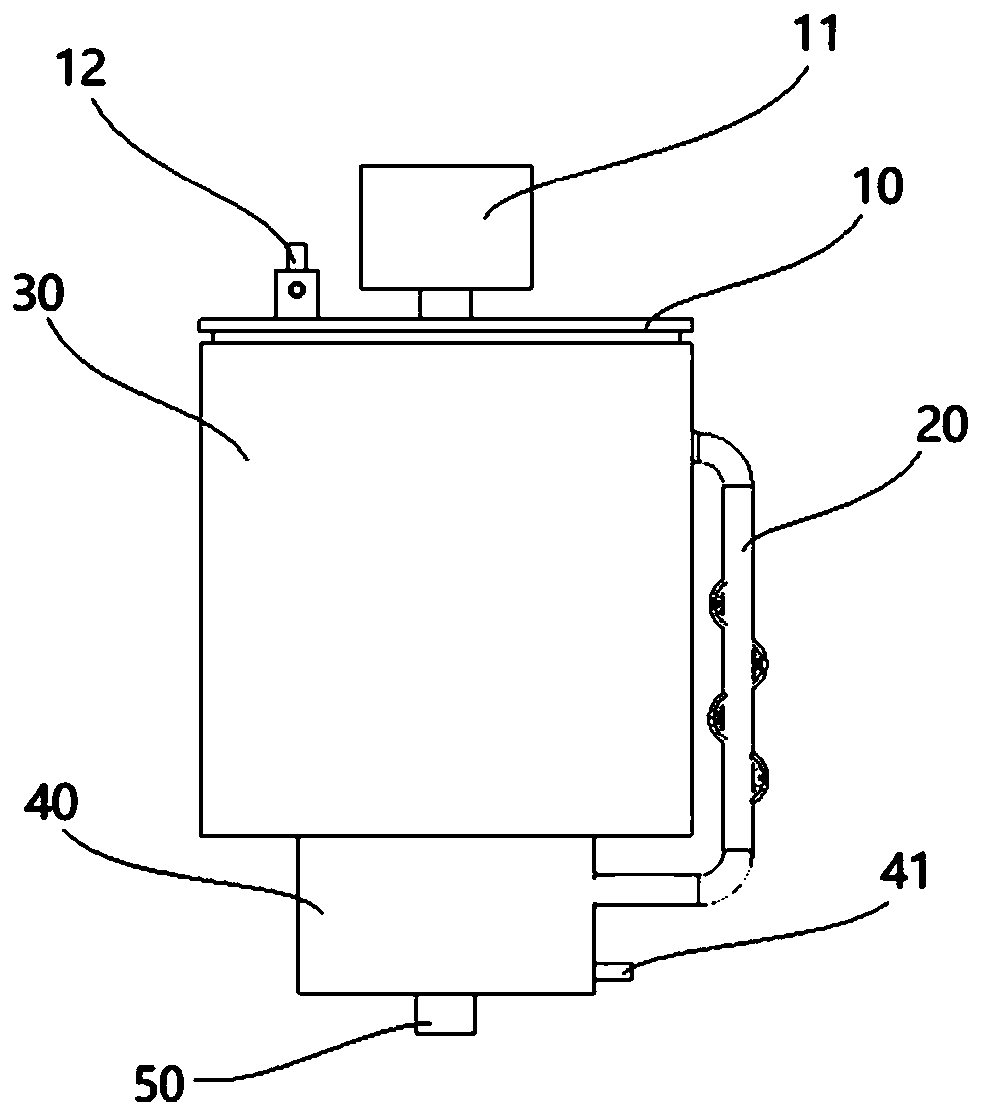

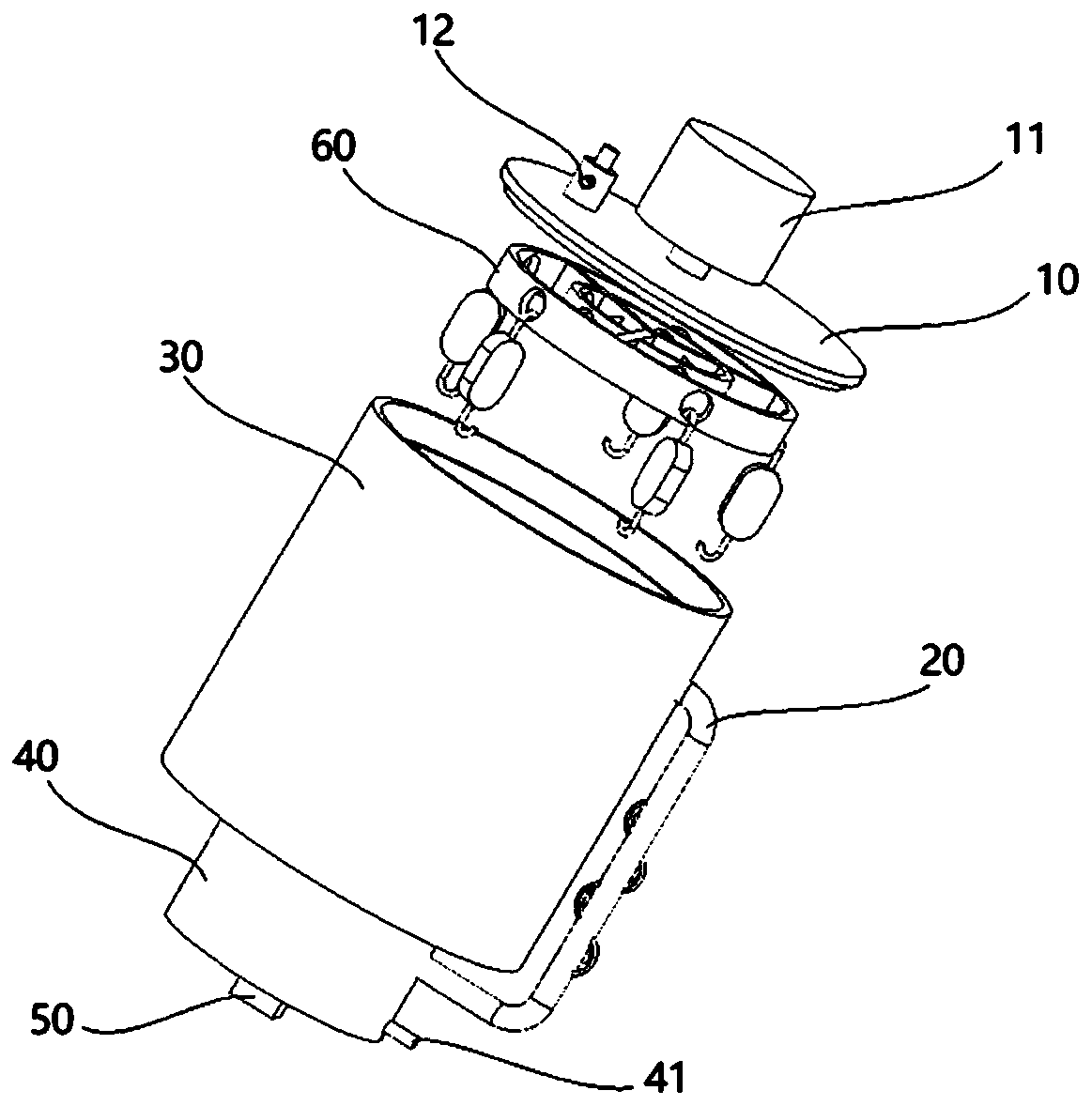

Hanging type up-flow kelp drying equipment

InactiveCN110296592ASolve the problem that it is easy to stick to the equipment and difficult to cleanEvenly heatedDrying gas arrangementsMarine product dryingProcess engineeringProduct gas

The invention discloses hanging type up-flow kelp drying equipment and belongs to the technical field of alga treatment. The drying equipment comprises a main body, a cover body and a gas flow circulating box, wherein the main body is provided with an accommodating space; the cover body is arranged above the main body; the cover body is connected with a hanging assembly for hanging to-be-dried objects; the hanging assembly is placed in the accommodating space; the gas flow circulating box is arranged at the bottom of the main body; the gas outlet of the gas flow circulating box communicates with the accommodating space in the main body; a heating box for heating gas is arranged at the bottom of the gas flow circulating box; the gas flow circulating box is provided with at least two flow guide pieces, and flowing gas flow surrounds the periphery of each two flow guide piece; and gaps are formed between the flow guide pieces and the upper and lower inner wall surfaces of the gas flow circulating box. A hanging type kelp drying process is adopted, the kelp is heated uniformly during heating, the heating energy can be recycled, the drying energy consumption is effectively reduced and the temperature of the whole kelp drying process is controllable.

Owner:ZHEJIANG OCEAN UNIV

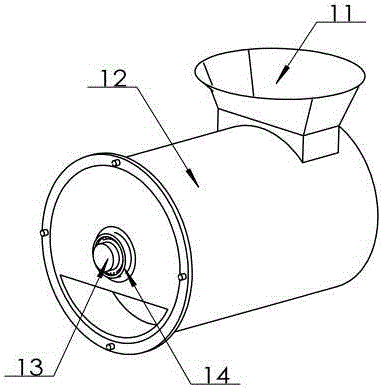

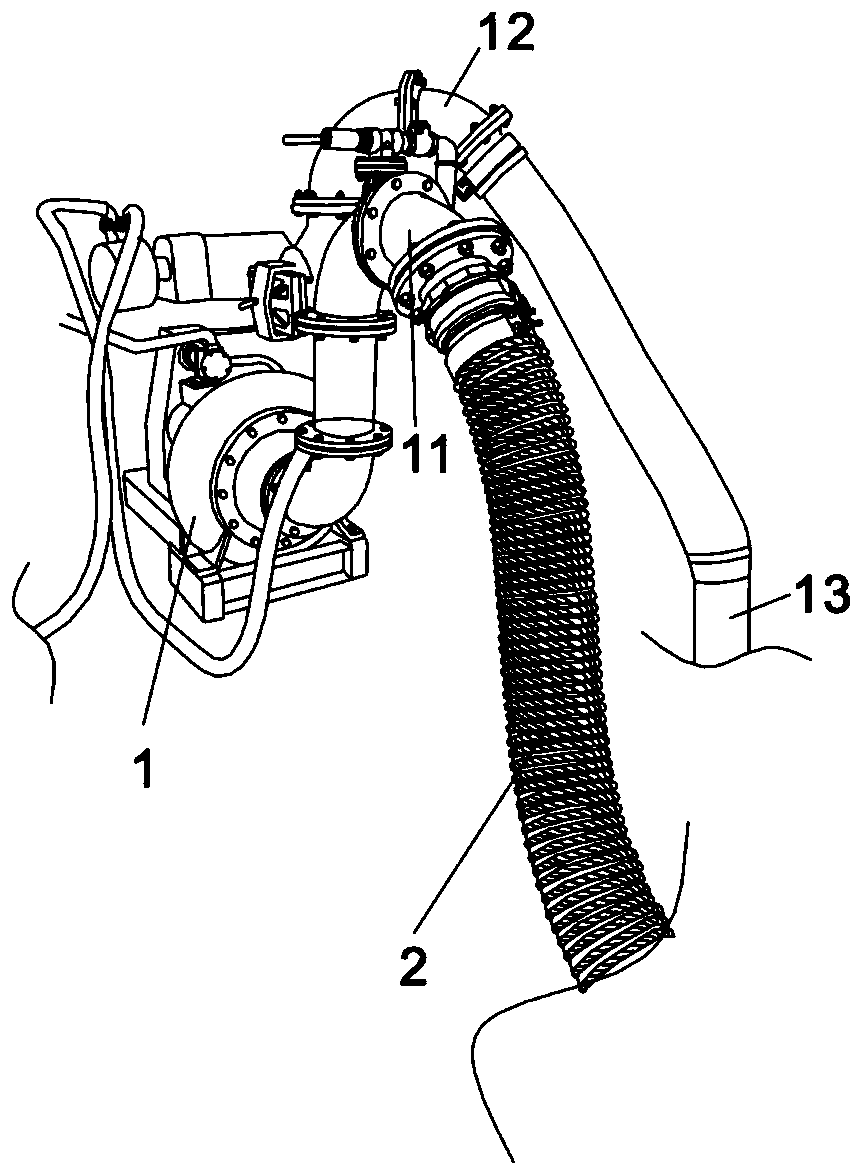

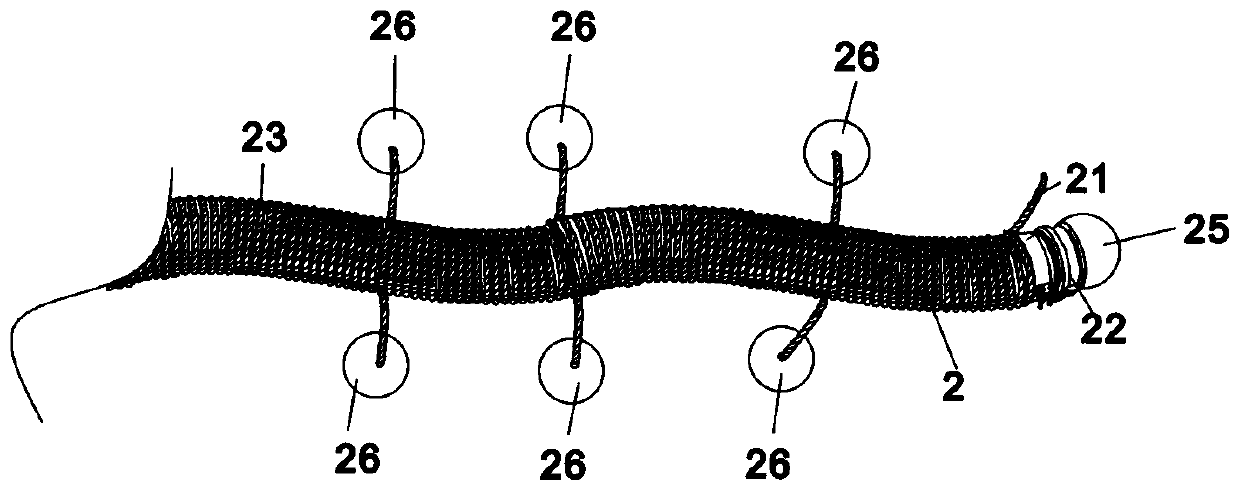

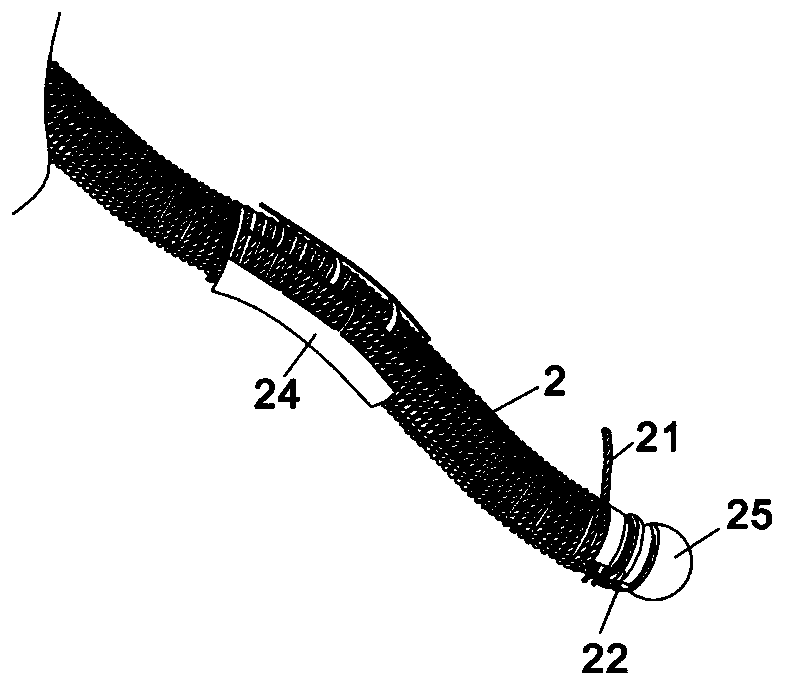

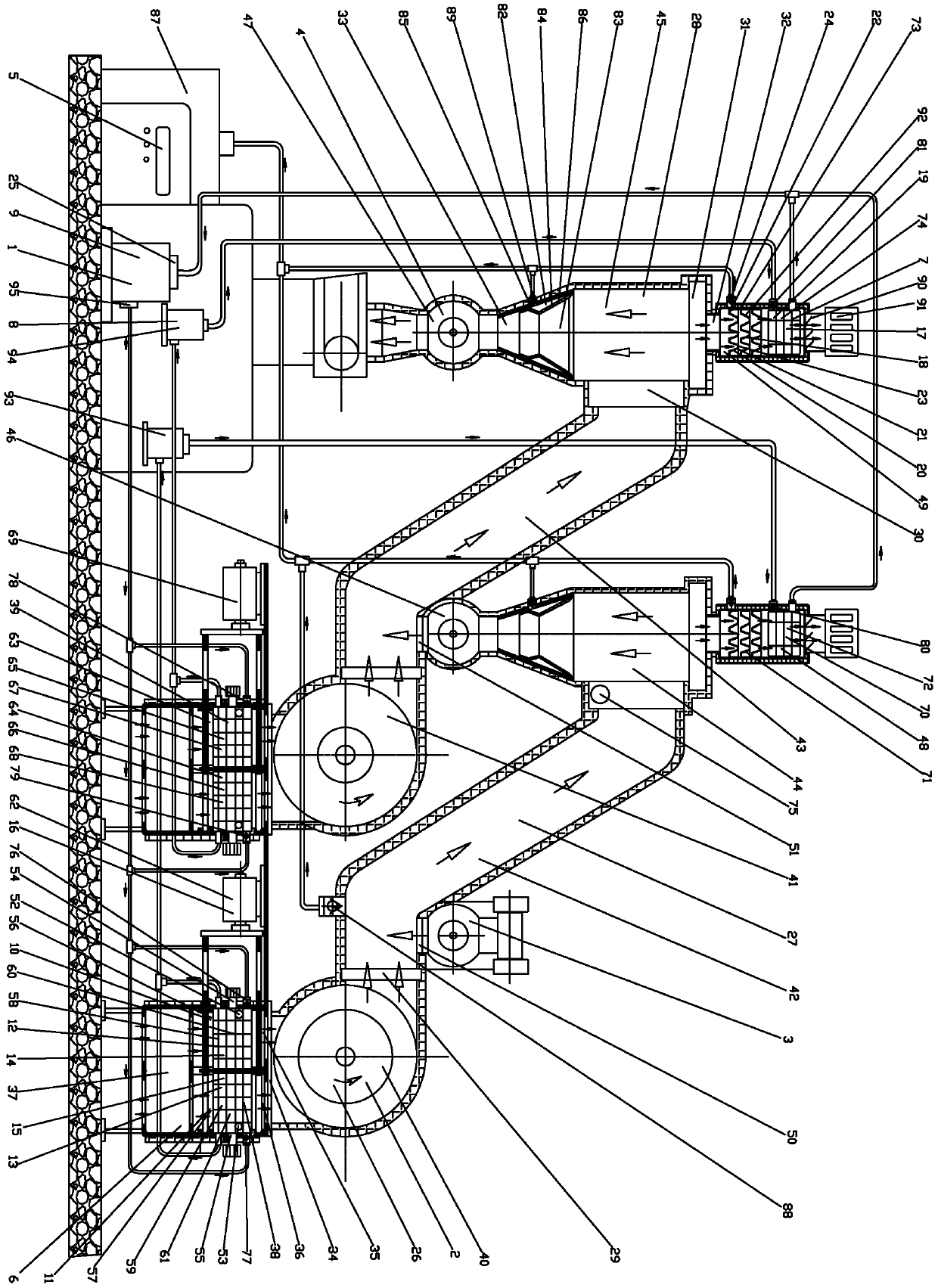

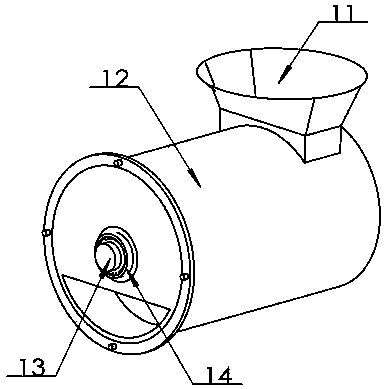

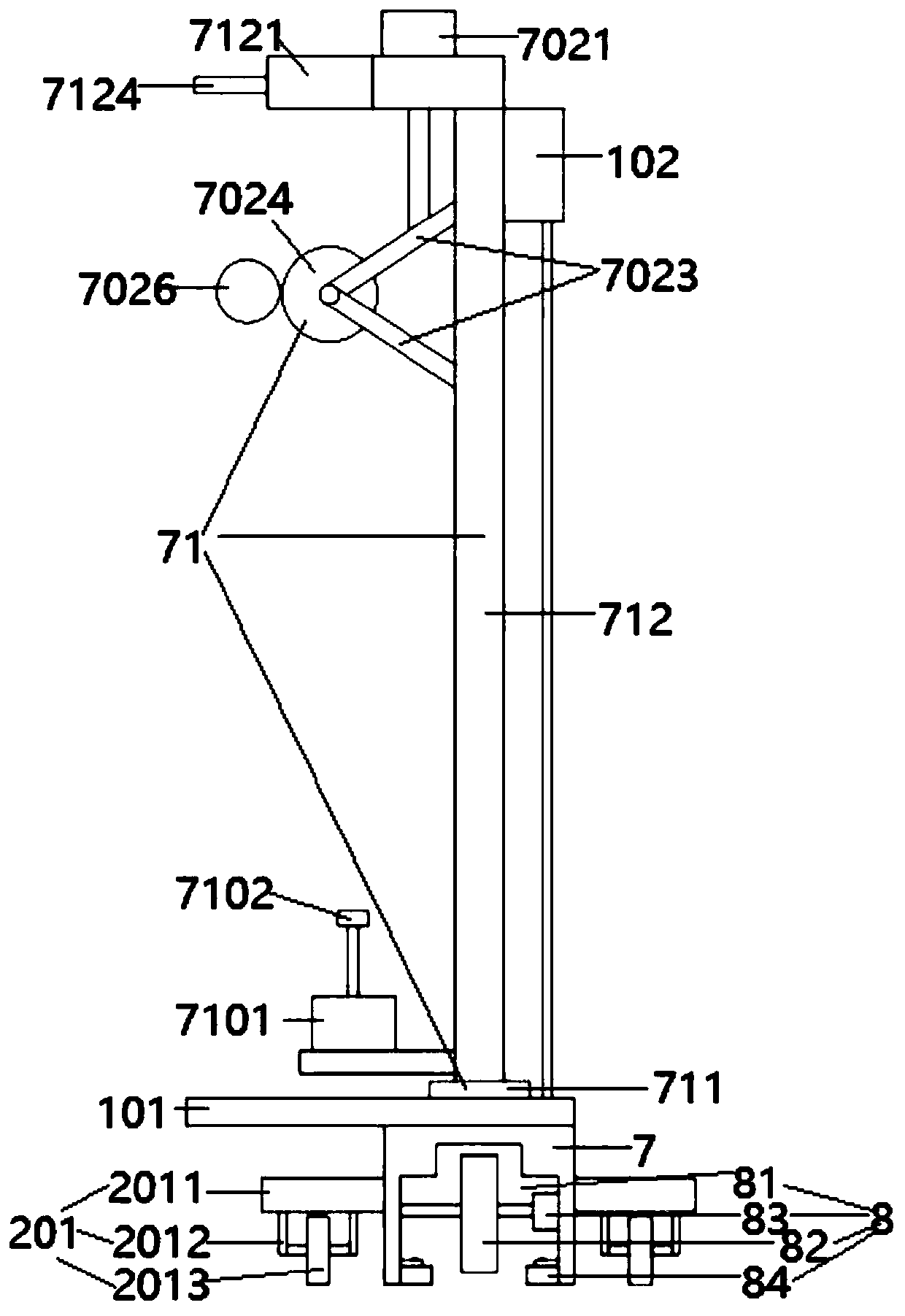

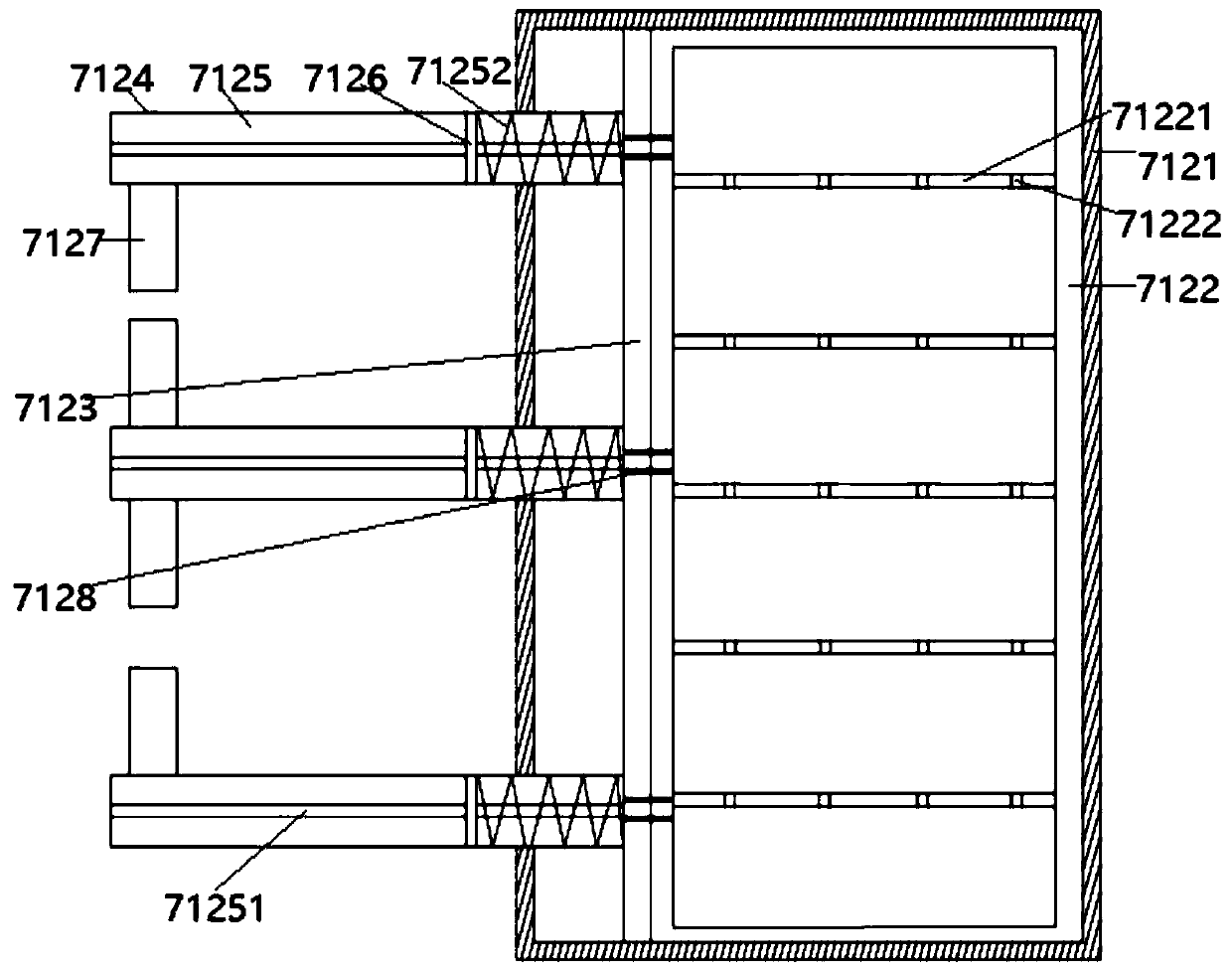

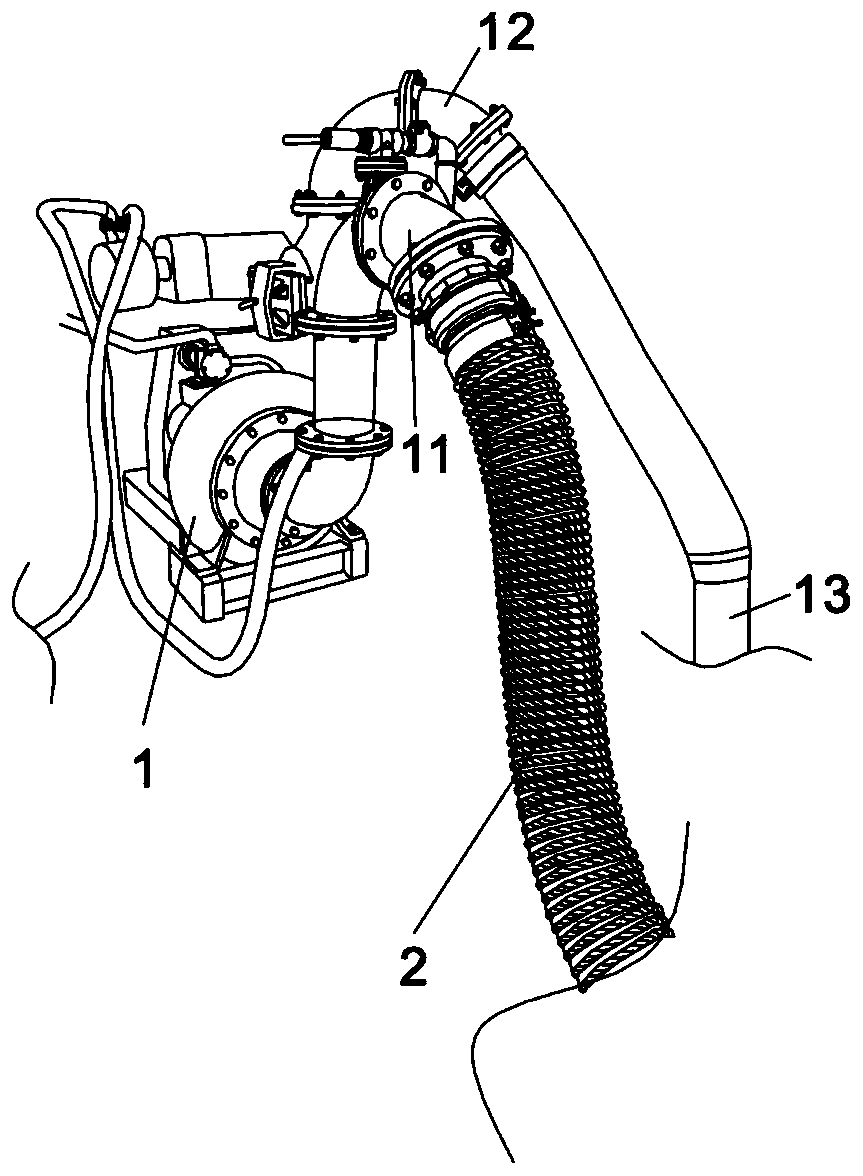

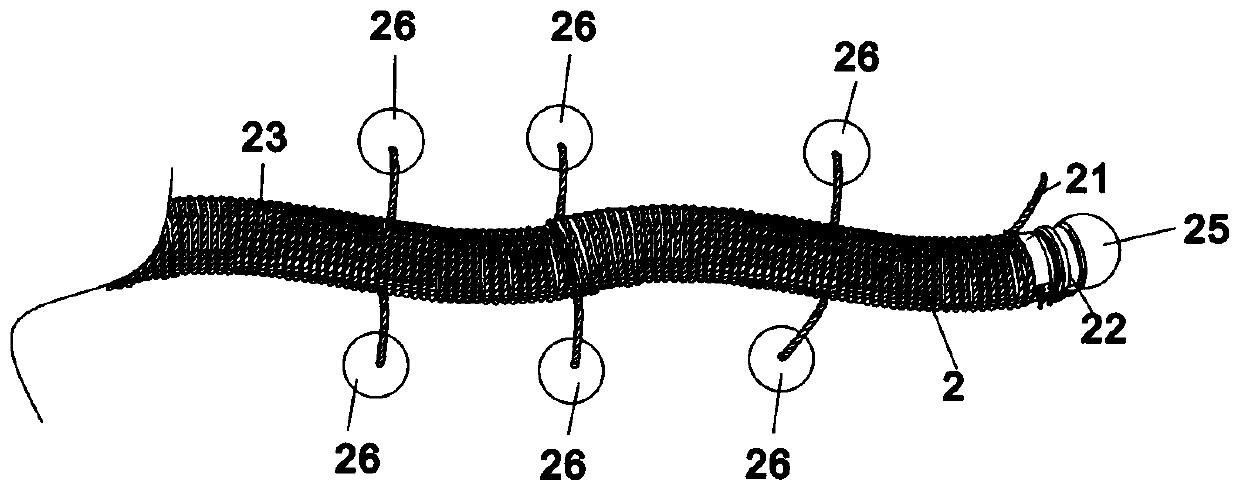

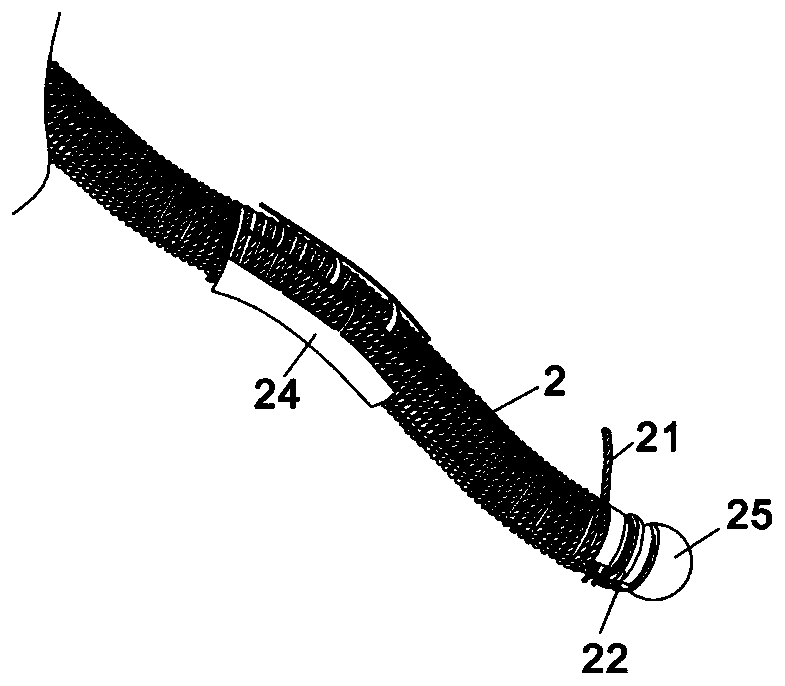

Using method of air-energy wind power dryer

InactiveCN107062867AReduce pollutionImplement energy-saving dryingDrying gas arrangementsMarine product dryingAtmospheric airEvaporation

The invention relates to a using method of an air-energy wind power dryer. The air-energy wind power dryer comprises a heat pump device, a wind conveyer, a rotating feed valve, a rotating discharge valve and a controller; when the air-energy wind power dryer is in use, the rotating feed valve is utilized to feed shrimp shells into the conveying pipeline of the wind conveyer, and a hot air drying device is utilized to feed hot air into the conveying pipeline, so that hot air is utilized to heat and dry shrimp shells; a dewing tank and an evaporator of a deodorization device of the heat pump device are utilized, peculiar smell steam generated by evaporation drying of shrimp shells condensates into water drops to be discharged, the peculiar smell steam generated by shrimp shell evaporation is prevented from being discharged into the atmosphere, and the pollution caused by the peculiar smell steam to the air is reduced; the evaporator of the heat pump device is utilized to constantly absorb heat of the steam generated by heating evaporation of shrimp shells in the conveying pipeline, heat is then conveyed to a condenser after passing through a compressor and an expansion valve, the condenser is utilized to release heat to heat air, and therefore energy-saving drying of the shrimp shells is realized through constant circulation.

Owner:浙江创迪科技有限公司

Laver drying equipment

PendingCN112524906AEfficient use ofReduce lossesFood processingDrying gas arrangementsThermodynamicsProcess engineering

Laver drying equipment comprises heating equipment, heating pipelines and drying rooms, wherein heat generated by the heating equipment is transmitted into the drying rooms through the heating pipelines, a high-temperature room is arranged outside each drying room, the drying rooms comprise a first drying room and a second drying room, each of the first drying room and the second drying room is provided with an air inlet pipe, a front door, an air inlet window, an exhaust window, a conveying belt, a circulating fan and a plurality of storage racks, a ventilation door is further arranged between the first drying room and the second drying room, each air inlet pipe communicates with the corresponding high-temperature room, a baffle plate is further arranged between the air inlet pipe of thefirst drying room and the air inlet pipe of the second drying room, and the baffle plate controls the communication between the air inlet pipes and the high-temperature rooms. The laver drying equipment has the advantages of saving energy, saving processing time and being good in finished product processing effect.

Owner:陈进车

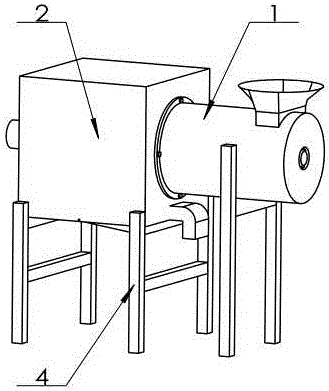

Device for spirally squeezing and dehydrating enteromorpha

InactiveCN105928328AEfficient dehydration treatmentDrying solid materials without heatMarine product dryingFixed frameSpiral blade

The invention discloses a device for spirally squeezing and dehydrating enteromorpha. The device comprises a spiral dehydrating assembly, a squeezing and dehydrating assembly, an overrunning clutch and a fixed frame, and is characterized in that the spiral dehydrating assembly includes a feed port, a spiral protective cover, a spiral blade shaft and bearings; the feed port is formed in the upper end of the spiral protective cover; the two ends of the spiral blade shaft are fixed on the spiral protective cover through the bearings; the squeezing and dehydrating assembly includes a squeezing protective cover, a squeezing plate, a squeezing shaft, a discharge port, a motor, a drain pipe and a bearing; the motor is arranged at the back end of the squeezing protective cover; the discharge port and the drain pipe are arranged at the lower end of the squeezing protective cover; a squeezing structure consisting of the squeezing shaft and the squeezing plate is arranged in the squeezing protective cover; the overrunning clutch is arranged between the spiral dehydrating assembly and the squeezing and dehydrating assembly; and fixed frames are arranged at the lower ends of the spiral dehydrating assembly and the squeezing and dehydrating assembly. The device can effectively realize dehydration of enteromorpha, and is excellent in dehydrating effect and high in working efficiency.

Owner:UNIV OF JINAN

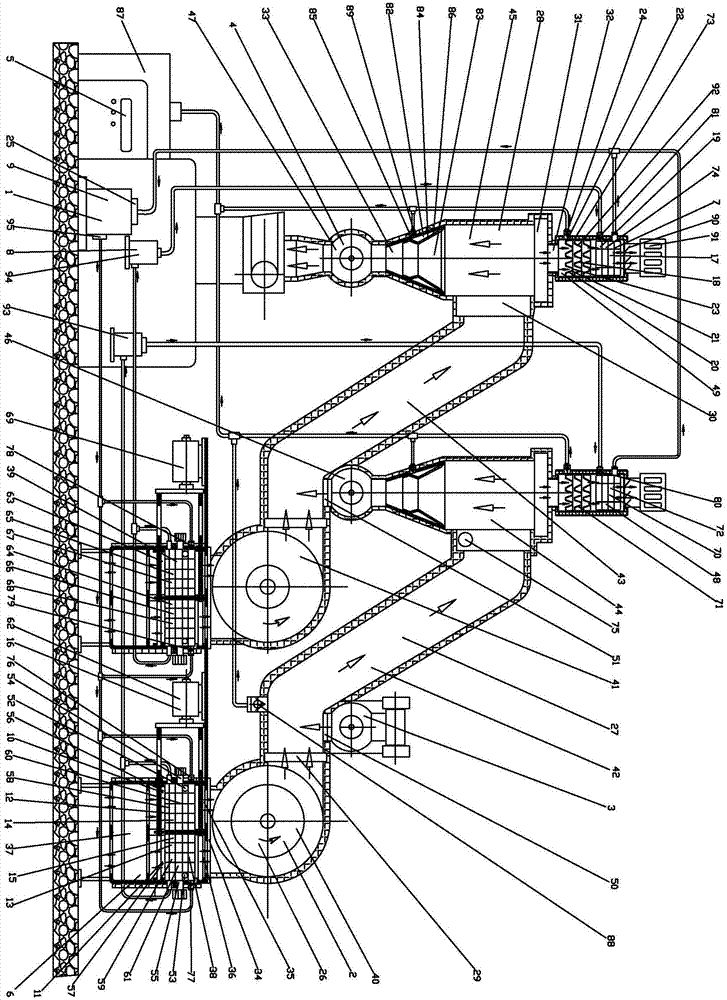

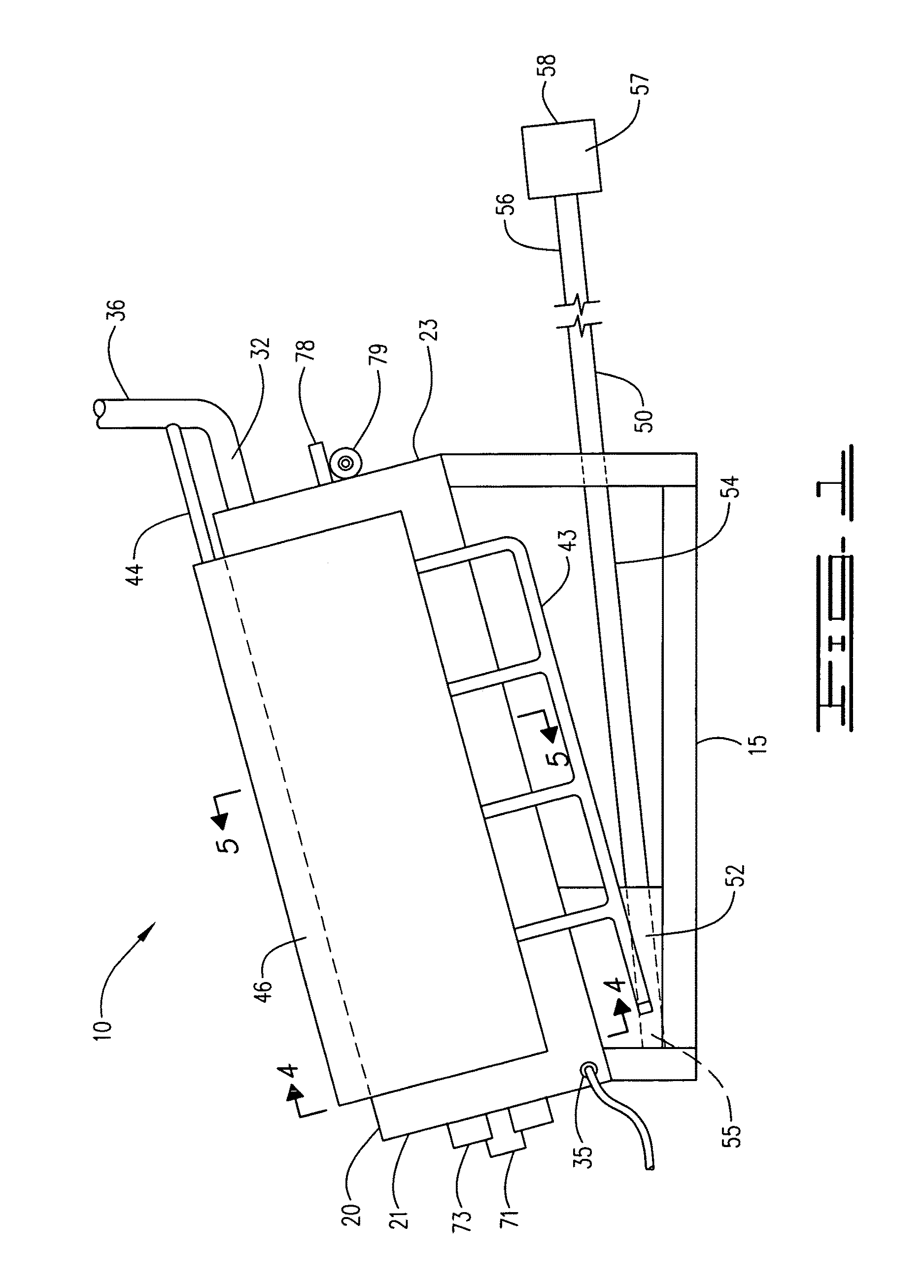

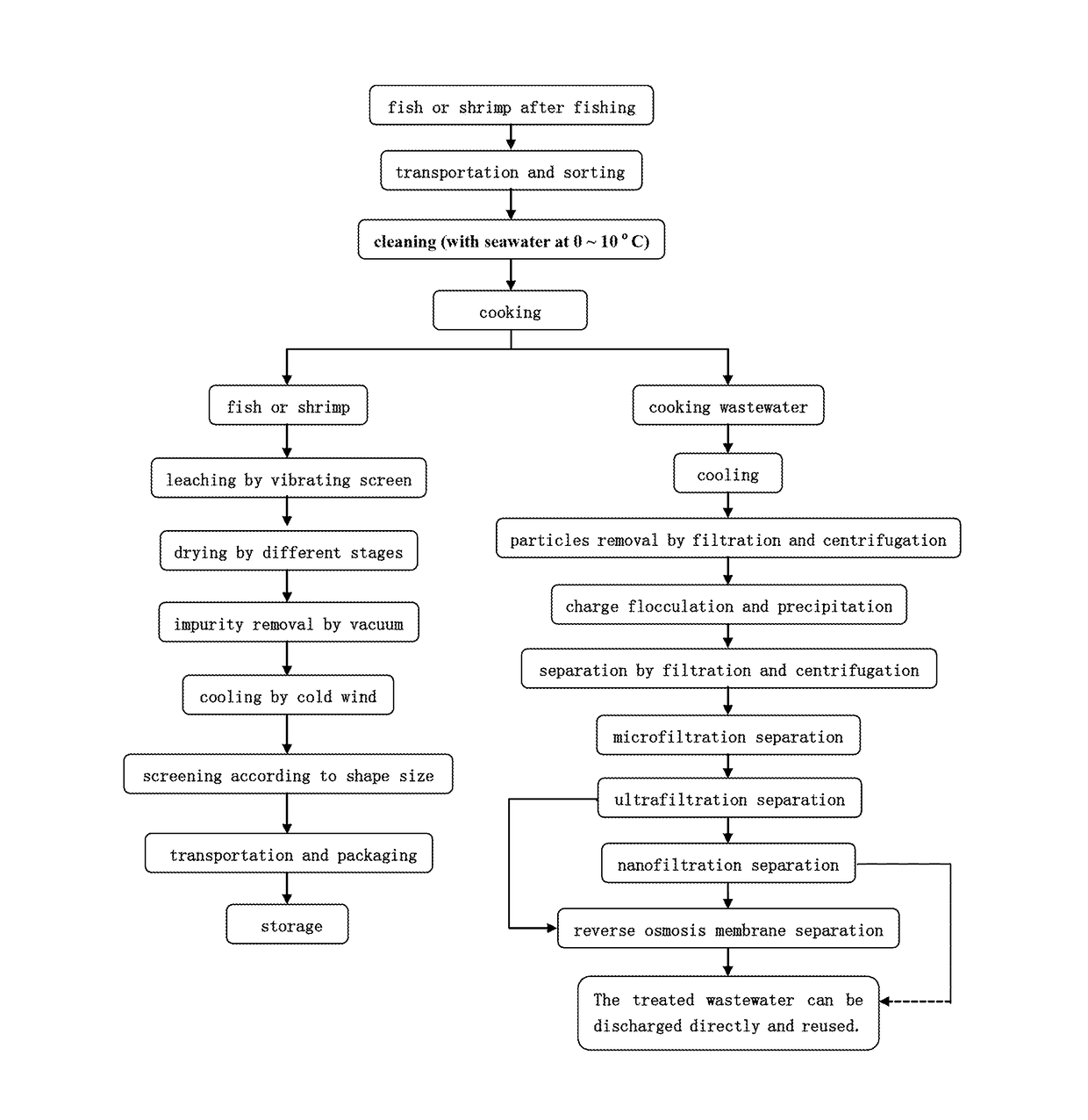

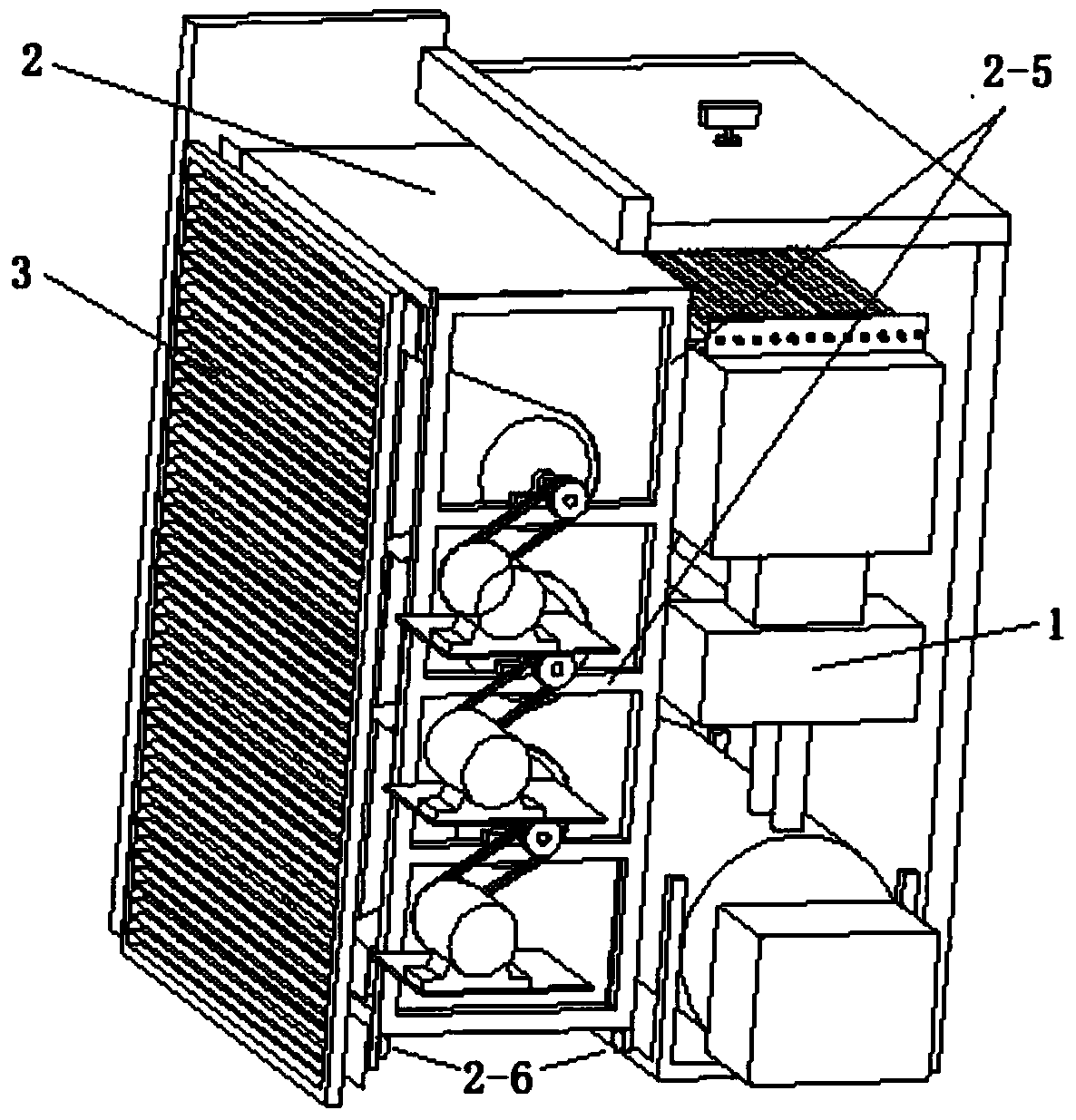

Offshore machining center

PendingCN111480813AGuaranteed freshnessEnsure safetyFish sortingFish washing/descalingAquatic productStern

The invention discloses an offshore processing center, which takes a ship as a carrier and is characterized in that a negative pressure pump is arranged at the stern, a material suction pipe is arranged at the inlet of the negative pressure pump, and the material suction pipe is used as a channel for inputting aquatic products or marine products on a transport ship into the offshore processing center; a cleaning device, a cooking device and a drying device are arranged in the cabin or the ship building; the cleaning device comprises an upper lifting cleaning unit and a horizontally-arranged flushing pot. The upper lifting cleaning unit comprises an upper lifting conveying belt arranged in a slope mode and a spraying device arranged on the upper lifting conveying belt. The upper lifting cleaning unit is located on the lower layer of the flushing pot, the cooking device and the flushing pot are located on the same layer, and the drying device is located below the cooking device. The whole assembly line has the functions of automatic material sucking and feeding, automatic cleaning, automatic cooking, automatic drying and sorting, automatic feeding and shelling, and automatic drying.Because the steps needing manual intervention in the whole processing process are few, the manpower is saved, the processing speed is increased, and the processing amount of 5000 kg of aquatic productraw materials per hour can be basically achieved; the processing speed is high, and the freshness quality of the dried marine products is kept.

Owner:玉环市东海鱼仓现代渔业有限公司

Drying equipment capable of improving drying quality

InactiveCN108151451AQuality improvementPrevent moistureDrying solid materials without heatDrying gas arrangementsAutomatic controlPulp and paper industry

The invention discloses drying equipment capable of improving drying quality. The drying equipment structurally comprises a connecting rod, a fan groove, a dustproof cover, fixing screws, heat dissipation holes, an upper sealing cover, an automatic control box, an electric box, a supporting base, a drying device and fixed-mounting holes. The connecting rod and the dustproof cover are welded, and the heat dissipation holes and the drying device are of an integrated structure. According to the drying equipment capable of improving drying quality, the drying device is structurally arranged, marine products are put into the drying device through drying grooves in the drying device, and drying agents in the drying grooves are used for preventing the marine products from being moist; during heating, gear balls, chains and gears are connected together, a motor rotates to drive each chain wound on the corresponding gears to rotate, so that the drying grooves can rotate, and the marine productscan be uniformly dried; and when the marine products fall into a containing groove, the marine products can be quickly pulled out through retainers and slide rail balls in the containing groove, so that the marine products are evenly dried when dried, and the quality of the marine products is improved.

Owner:徐美琴

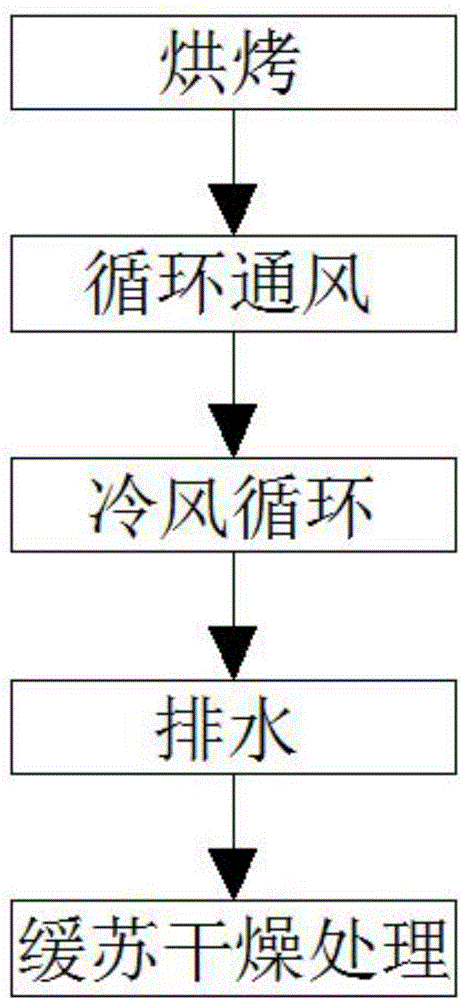

Aquatic product cold air drying method

InactiveCN106766729AShort processing timeReduce processing efficiencyDrying gas arrangementsMarine product dryingCooking & bakingQuality control system

The invention discloses an aquatic product cold air drying method in the technical field of aquatic product processing. The aquatic product cold air drying method is characterized by comprising the steps of: (S1) baking; (S2) circular ventilation; (S3) cold wind circulation: cold wind is fed in a baking room by an imported wind cooler; and under a continuous effect of the imported wind cooler and a high-quality control system, the cold and hot wind speeds in the baking room are alternated until the water content of an aquatic product is 30-40%; (S4) drainage; and (S5) tempering and drying. In the insulation closed baking room, the efficient fan is used for forced circular ventilation to form convection negative pressure; under the continuous effect of the imported wind cooler and the high-quality control system, the cold and hot wind speeds in the baking room are alternated; when the cold wind performs circular convection, the surface temperature of the aquatic product rises; and compared with a traditional method, the aquatic product cold air drying method has the advantages of short machining time, low machining efficiency, increment of the average dryness, saving of the energy consumption, simple operation and low cost.

Owner:湖北允泰坊食品有限公司

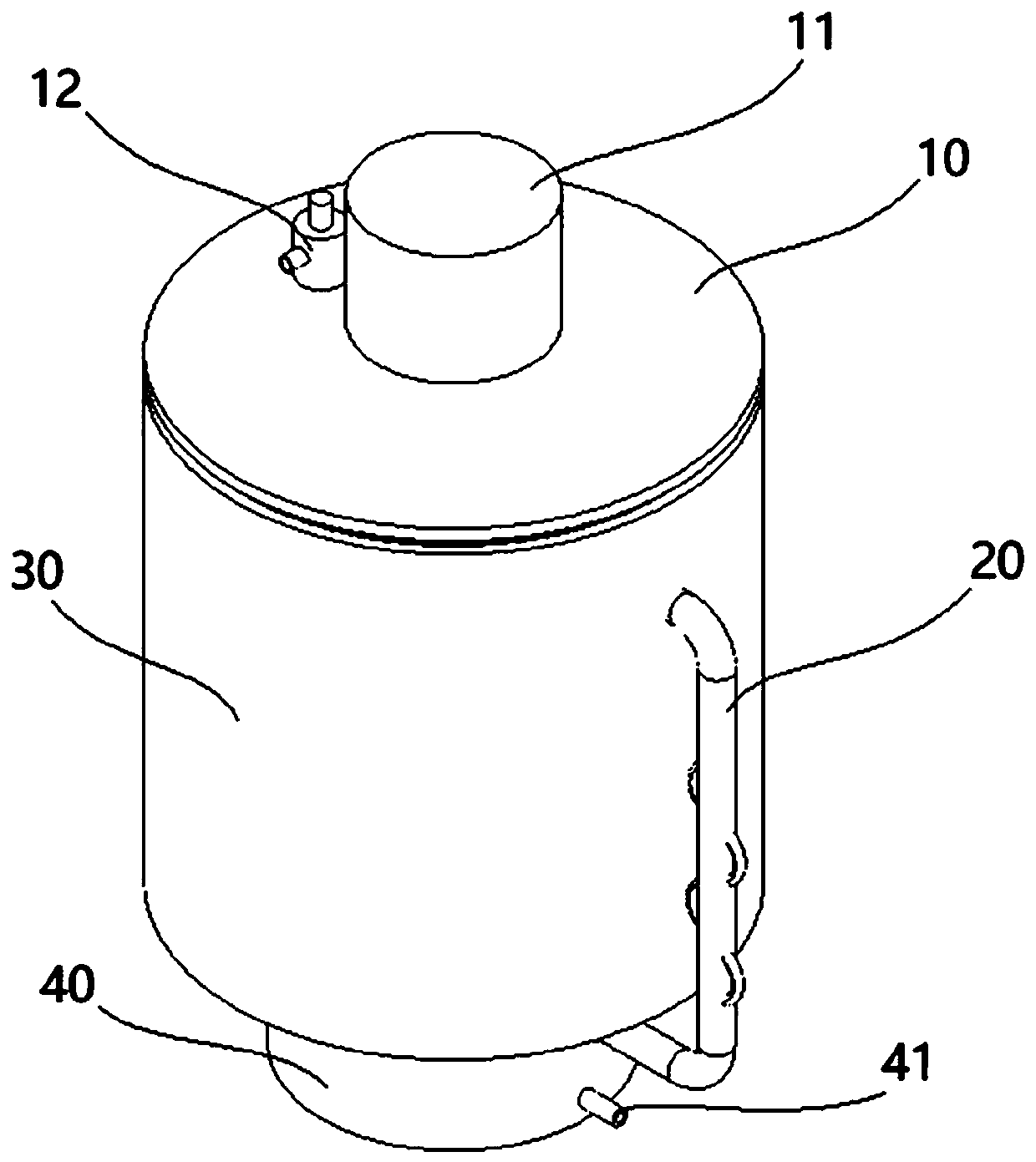

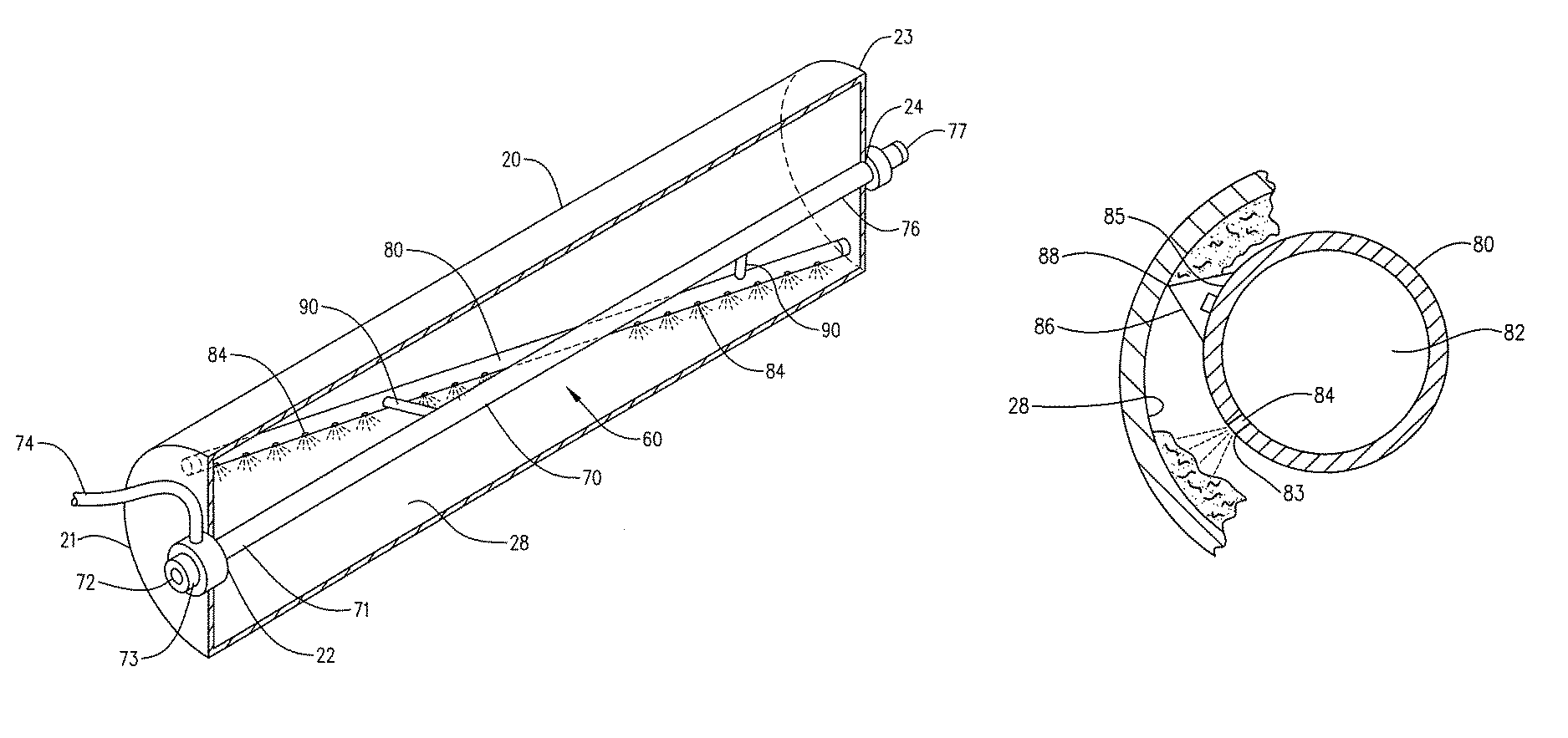

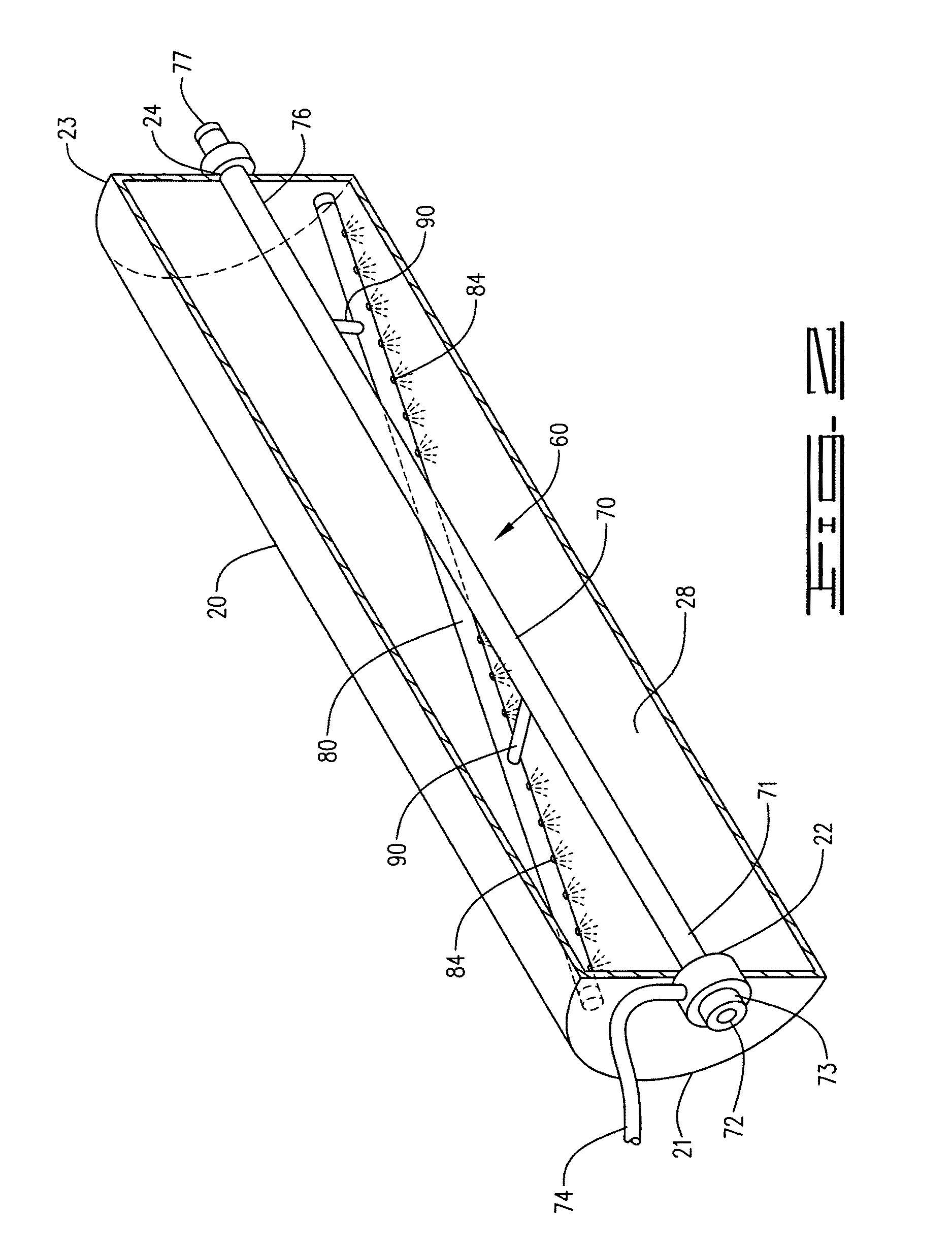

Algae dryer and harvesting apparatus

InactiveUS9567562B1Process environmental protectionDrying solid materials with heatUnicellular algaeAlgaeMechanical engineering

An algae dryer defines an insulated and heated stationary drum within which is positioned a rotating arm extending an axial sprayer to spray a coat of algae on the inside of the drum with a second integrated opposing arm axially extending an offset scraper which engages the inner perimeter of the drum surface and removes the algae from the interior of the drum, depositing the dry algae scrapings into the bottom of the drum through a slot, further directing the harvested algae through an auger to a packaging or processing location.

Owner:STROIAZZO MOUGIN ALIX

Metal seal

Owner:MITSUBISHI CABLE IND LTD

How to use the air energy wind dryer

InactiveCN107062867BReduce pollutionImplement energy-saving dryingDrying gas arrangementsMarine product dryingAtmospheric airEvaporation

The invention relates to a using method of an air-energy wind power dryer. The air-energy wind power dryer comprises a heat pump device, a wind conveyer, a rotating feed valve, a rotating discharge valve and a controller; when the air-energy wind power dryer is in use, the rotating feed valve is utilized to feed shrimp shells into the conveying pipeline of the wind conveyer, and a hot air drying device is utilized to feed hot air into the conveying pipeline, so that hot air is utilized to heat and dry shrimp shells; a dewing tank and an evaporator of a deodorization device of the heat pump device are utilized, peculiar smell steam generated by evaporation drying of shrimp shells condensates into water drops to be discharged, the peculiar smell steam generated by shrimp shell evaporation is prevented from being discharged into the atmosphere, and the pollution caused by the peculiar smell steam to the air is reduced; the evaporator of the heat pump device is utilized to constantly absorb heat of the steam generated by heating evaporation of shrimp shells in the conveying pipeline, heat is then conveyed to a condenser after passing through a compressor and an expansion valve, the condenser is utilized to release heat to heat air, and therefore energy-saving drying of the shrimp shells is realized through constant circulation.

Owner:浙江创迪科技有限公司

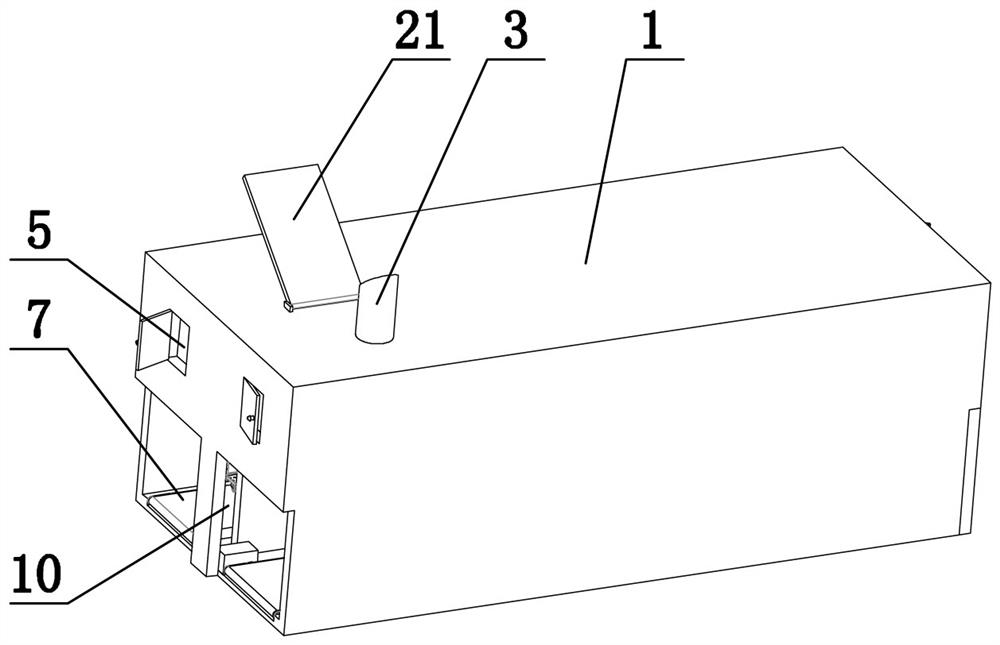

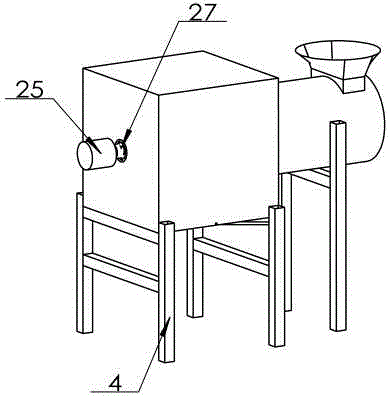

Air energy wind power drying machine

ActiveCN106871621AReduce pollutionImplement energy-saving dryingFood processingDrying gas arrangementsAtmospheric airMoisture condensation

The invention discloses an air energy wind power drying machine. The air energy wind power drying machine comprises a heat pump device, a wind power conveyer, a rotating feed valve, a rotating discharge valve and a controller. When the air energy wind power drying machine is utilized, shrimp shells are fed into a conveying pipeline of the wind power conveyer through the rotating feed valve, hot air is fed into the conveying pipeline through a hot air drying device, and the shrimp shells are heated and dried through hot air; evaporated odor moisture of the dried shrimp shells condenses into water drops through a moisture condensation tank and an evaporator of a deodorization device of the heat pump device, the water drops are discharged, evaporated odor moisture of the shrimp shells is prevented from being discharged into the atmosphere, and pollution of odor moisture to air is reduced; and heat of evaporated moisture of the heated shrimp shells in the conveying pipeline is continuously absorbed through the evaporator of the heat pump device, heat is conveyed to a condenser through a compressor and an expansion valve, heat is released through the condenser to heat air, the operation is continuously cycled, and energy-saving drying of the shrimp shells is achieved.

Owner:河北福悦新能源科技有限公司

A device for screw pressing and dehydrating Enteromorpha

InactiveCN105928328BEfficient dehydration treatmentDrying solid materials without heatMarine product dryingSpiral bladeAgricultural engineering

Owner:UNIV OF JINAN

Continuous on-board processing of seafood after fishing on the sea

ActiveUS10231465B2Low freshness processingQuality improvementSugar food ingredientsDrying solid materials with heatEngineeringFishing

The present invention relates to a continuous on-board drying method for Antarctic krill and a continuous on-board processing method of shelled Antarctic krill. The drying method includes the following steps: 1) subjecting fishing materials to cleaning, sorting, and dewatering with a vibrating screen; 2) rapidly heating the krill to the temperature of up to 70° C. using infra-red rays; 3) hot-air drying; 4) impurity removal by vacuum; 5) cooling to obtain dried krill. The processing method includes the following steps: a) subjecting fishing materials to cleaning, sorting, and dewatering with a vibrating screen; b) rapidly heating the krill to the temperature of up to 70° C. using infra-red rays; c) hot-air drying; d) subjecting the dried krill to shelling treatment to separate shell from meat, to obtain shelled krill; e) impurity removal by vacuum to obtain shelled krill product. The methods in the present invention are highly efficient, energy saving, green and environmental protection, and the krill products have high quality and safety.

Owner:ZHEJIANG UNIV OF TECH

a dryer

ActiveCN105444555BImprove drying efficiencyEasy to disassemble and repairFood processingDrying gas arrangementsFresh airDrying time

The invention relates to a dryer, which comprises a dryer housing, an air heating room, an air supply room, a drying channel, an air inlet which is communicated with the air heating room, an air outlet which is communicated with the front end of the drying channel, a material inlet which is formed in the front end of the drying channel, and a material outlet which is formed in the rear end of the drying channel, wherein a heat source heat exchanger is arranged in the air heating room; and a direct-blowing type air supply device is arranged in the air supply room. The dryer also comprises an air regulation guide plate, an exhaust waste heat recycling device, an intelligent fresh air humidity regulation device and a hot air compensation device. The dryer has the beneficial effects that the dryer can be used for drying laver and other products; constant-temperature and stable air supply can be realized; the air supply device is convenient to dismount, maintain and clean; the exhaust waste heat recycling function and partial exhaust recycling function are realized; thermal discharge is reduced and a product is energy-saving so that the production cost is reduced; and the hot air compensation device is capable of improving the drying efficiency of the dryer and shortening the drying time.

Owner:WENZHOU XINGBEI MACHINERY TECH CO LTD

Kelp airing system

InactiveCN111288761AExtended separation timeNot easy to stickServomotorsMarine product dryingStructural engineeringMechanical engineering

The invention discloses a kelp airing system. The system involves a platform, a first annular airing rope arranged on the platform, a second annular airing rope located on the outer side of the firstannular airing rope, an annular rail located between the first annular airing rope and the second annular airing rope, a first supporting column set and a second supporting column set; and the first airing rope and the second airing rope are connected with the upper ends of the first supporting column set and the upper ends of the second supporting column set respectively, a base is arranged on the annular rail, a travelling mechanism used for driving the base to move along the annular guide rail is arranged on the base, and a kelp separating mechanism is arranged on the base. The kelp airingsystem has the advantages that adjacent kelp is effectively prevented from being bonded, the airing efficiency is improved, and the airing quality is guaranteed.

Owner:杭州林迪德瑞科技有限公司

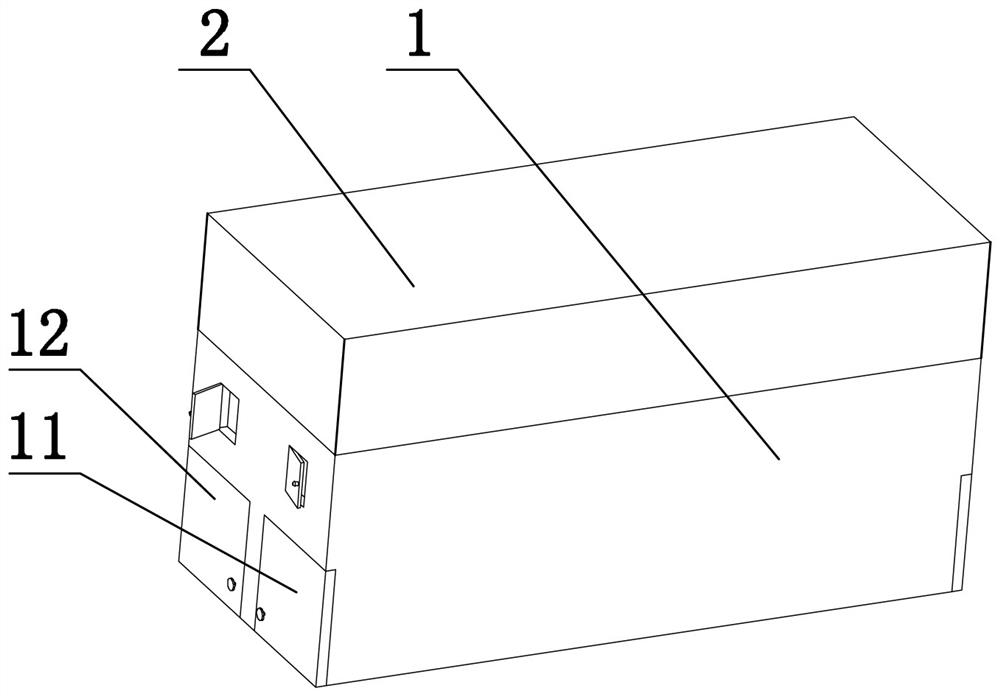

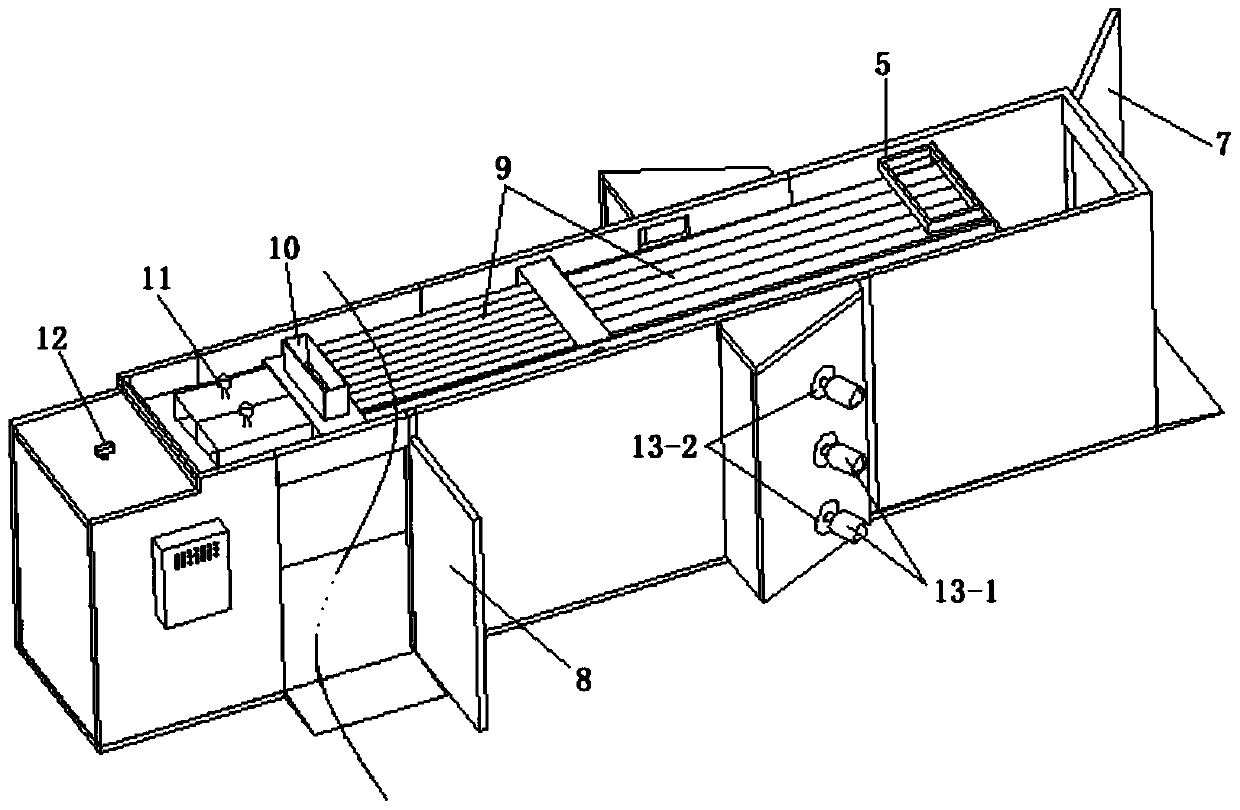

Multi-section tandem type drying device

PendingCN111480683ADoes not affect operationExtended drying timeFeed water supplyDrying gas arrangementsAquatic productProcess engineering

The invention discloses a multi-section tandem type drying device. The device comprises multiple stages of ovens connected in series, the former stage of oven and the later stage of oven are connectedthrough a conveying belt; the ovens are divided into at least two groups, wherein each oven group is provided with at least one stage of oven; the feeding-discharging directions of all the ovens arethe same, wherein an inlet of the first stage of oven serves as an inlet of the current oven group, and an outlet of the last stage of oven serves as an outlet; a transfer conveying belt is arranged between every two adjacent drying oven sets and conveys materials discharged from one drying oven set to the other drying oven set for feeding. The drying device woks in a multi-stage sectional type drying mode, wherein the multi-stage drying ovens are flexibly selected; since the drying and sorting operations are integrated, a drying strategy is reasonably selected for aquatic products of different specifications according to the dryness, wherein the drying time of the large products is long, and the drying time of the small products is short; and the drying strategies of the aquatic productsof different specifications are freely selected, meanwhile, the operation of the whole drying process is not influenced, and the drying time of large-batch products cannot be prolonged due to the drying requirements of individual specifications.

Owner:玉环市东海鱼仓现代渔业有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com