Hanging type up-flow kelp drying equipment

A drying equipment and hanging technology, which is applied in the field of hanging upflow kelp drying equipment, can solve problems such as waste of energy consumption, uneven heating, accelerated drying, etc., and achieve the effect of reducing energy consumption and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

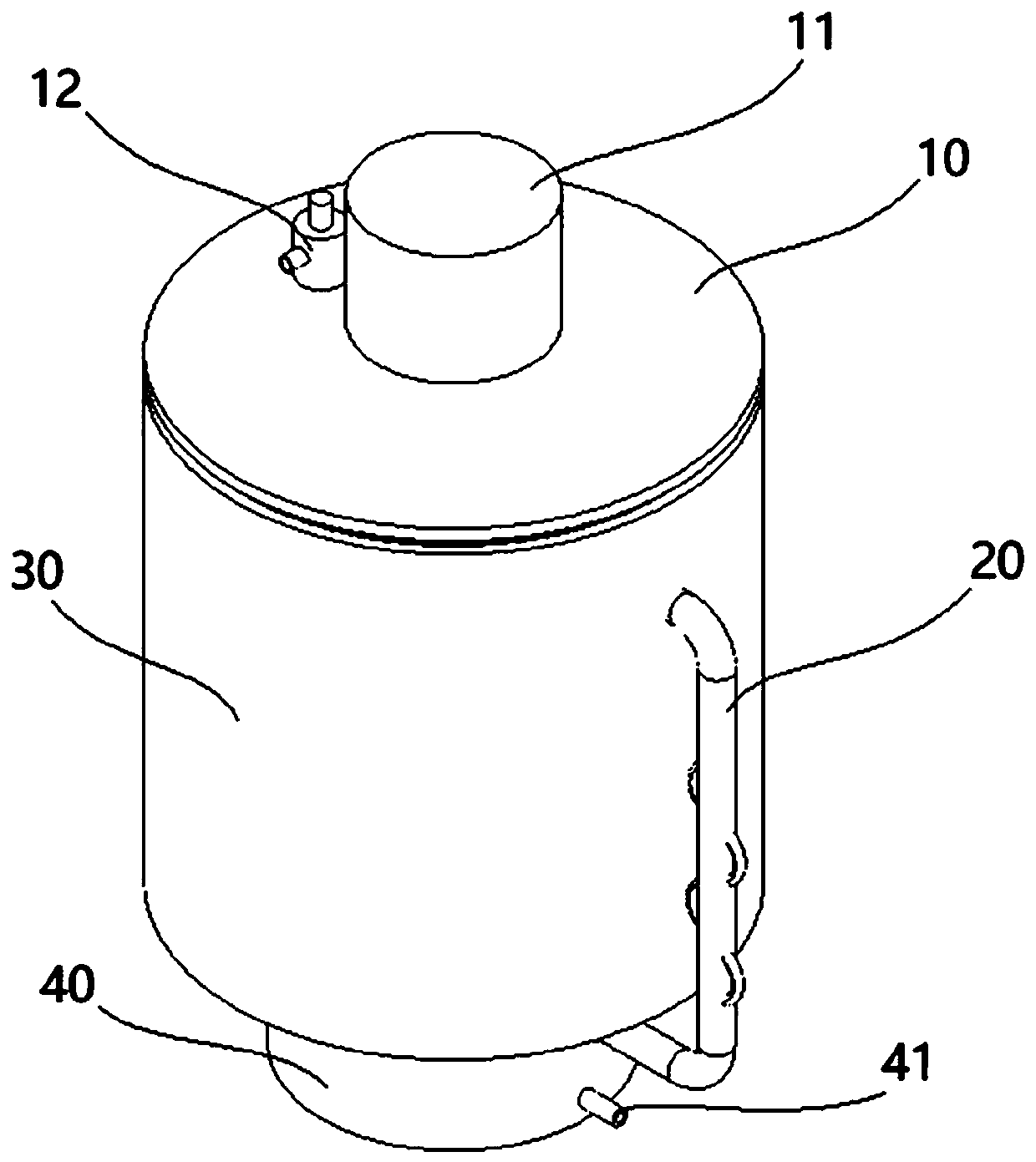

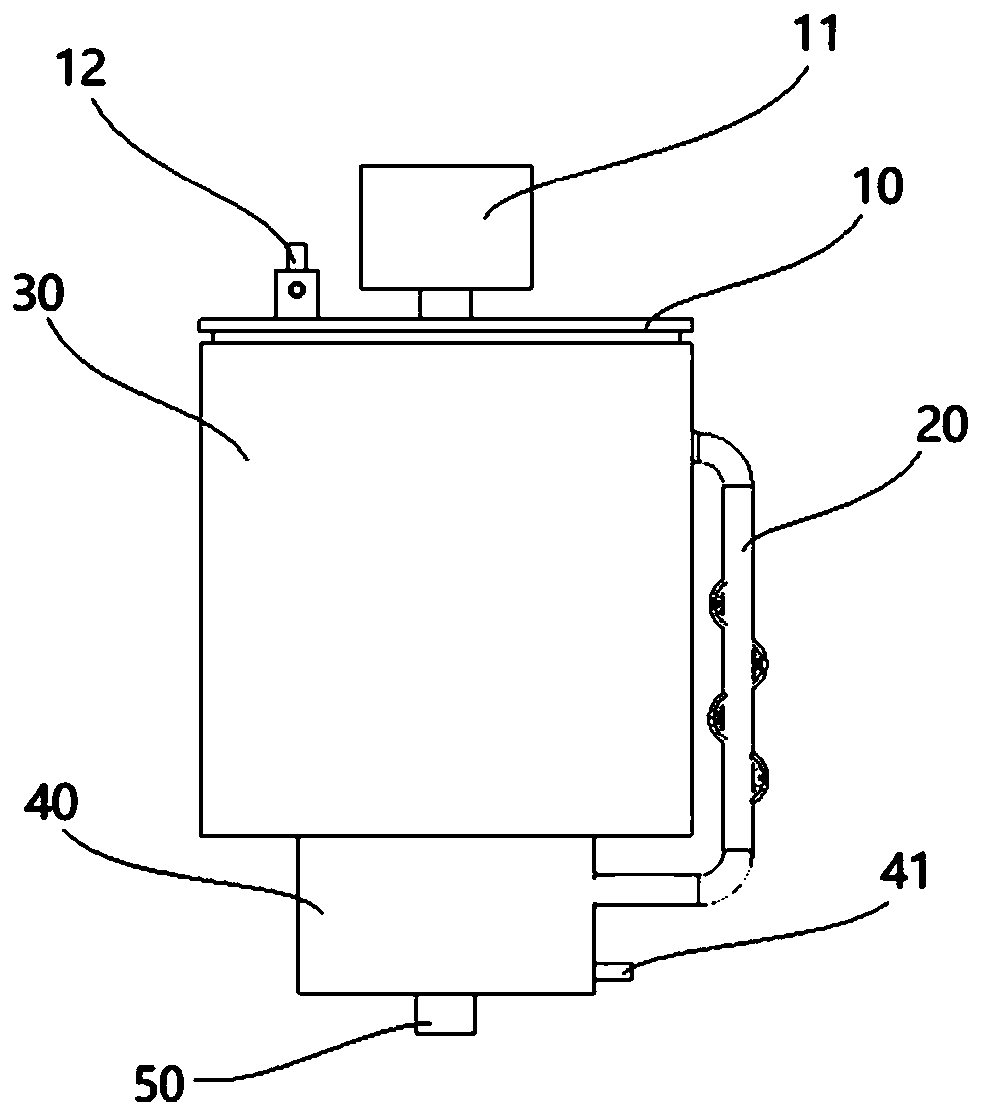

[0037] see Figure 1-15 Shown, a kind of hanging type upwelling kelp drying equipment comprises:

[0038] The body 30 has an accommodation space,

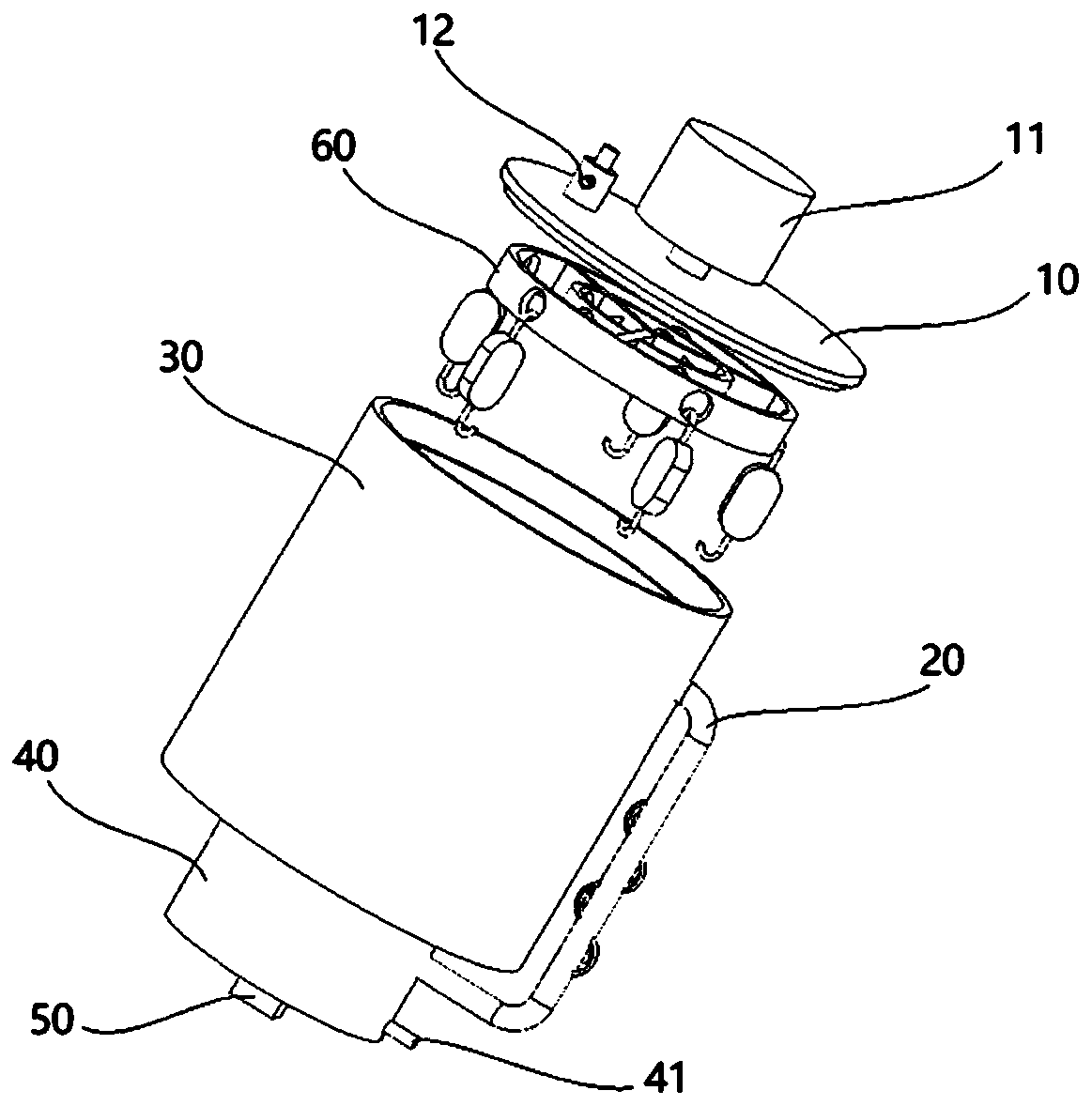

[0039] The cover body 10 is arranged above the body 30, the cover body 10 is connected with a hanging component 60 for hanging the object to be dried, and the hanging component 60 is placed in the accommodation space;

[0040] The air circulation box 40 is located at the bottom of the body 30, the air outlet of the air circulation box 40 is connected with the accommodation space in the body 30, and the bottom of the air circulation box 40 is provided with a heating box 50 for heating the gas.

[0041] Wherein, the air circulation box 40 has at least two air guides 44 surrounding the flowing air, and there are gaps between the air guides 44 and the upper and lower inner walls of the air circulation box 40 .

[0042] The present invention hangs the dried objects on the hanging assembly 60 to carry out hanging drying, which solves t...

Embodiment 2

[0053] The main body 30 of the present invention is cylindrical, with an opening on the top, an accommodating cavity inside, and an air flow hole at the bottom. When the lid is closed, a seal is formed in the body 30 . In order to further increase the sealing effect, a sealing ring can be provided on the contact surface between the lid body 10 and the body 30 .

[0054] Hanger 61 is annular, and its annular diameter is greater than the radius of body 30 cylinder inner diameters, and is less than the diameter of body 30 cylinder inner diameters, and this setting is used to guarantee that hanger 60 hangs two in kelp in this 30, improves Sea-tangle drying capacity, for further increasing sea-tangle drying capacity, can be provided with two ring-shaped hanging racks 61, connected by reinforcing plate, improve the hanging capacity of sea-tangle. Hanging hook 64 is hung on the hanger 61, and this hook 64 is an electronic hook, and the hook is produced by Yongkang Longbei Industry an...

Embodiment 3

[0058] When the suspended upflow kelp drying equipment of the present invention is working: the main body 30 is fixed on the base, and the base is used to maintain the stability of the vertical state of the main body 30. The specific base can be set with a steel frame, or it can be A spacer is selected to pad the bottom of the body 30, and the setting of the base should be understood by those skilled in the art, and will not be described in detail here.

[0059]After fixing the body 30, hang the kelp on the hook 64. The hook 64 of this embodiment is a weighing hook for displaying and recording the initial net weight of the kelp. After the kelp is dried, record the dried weight of the kelp. Calculate the amount of moisture increase to control the water content in the kelp and improve the taste of the kelp. After hanging the kelp, connect the hanging assembly 60 to the output shaft of the motor 11, close the cover 10, and set the motor speed It is 20-30r / min, and the present emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com