Laver drying equipment

A technology of drying equipment and seaweed, which is applied in drying, drying machines, lighting and heating equipment, etc., and can solve the problems of external crispness and internal moisture, great influence of humidity, heat loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

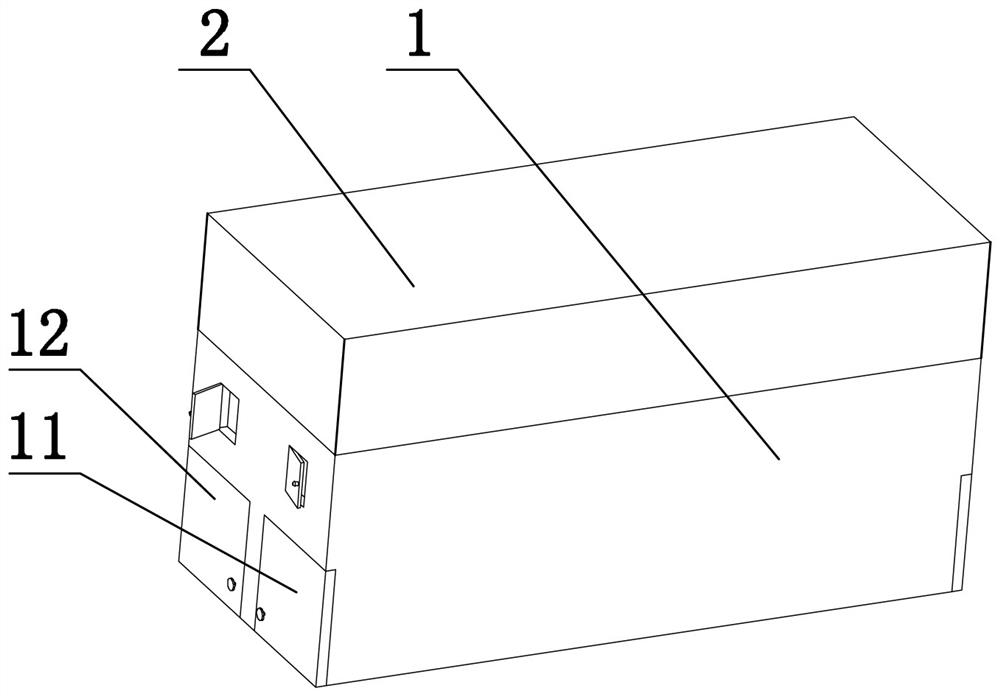

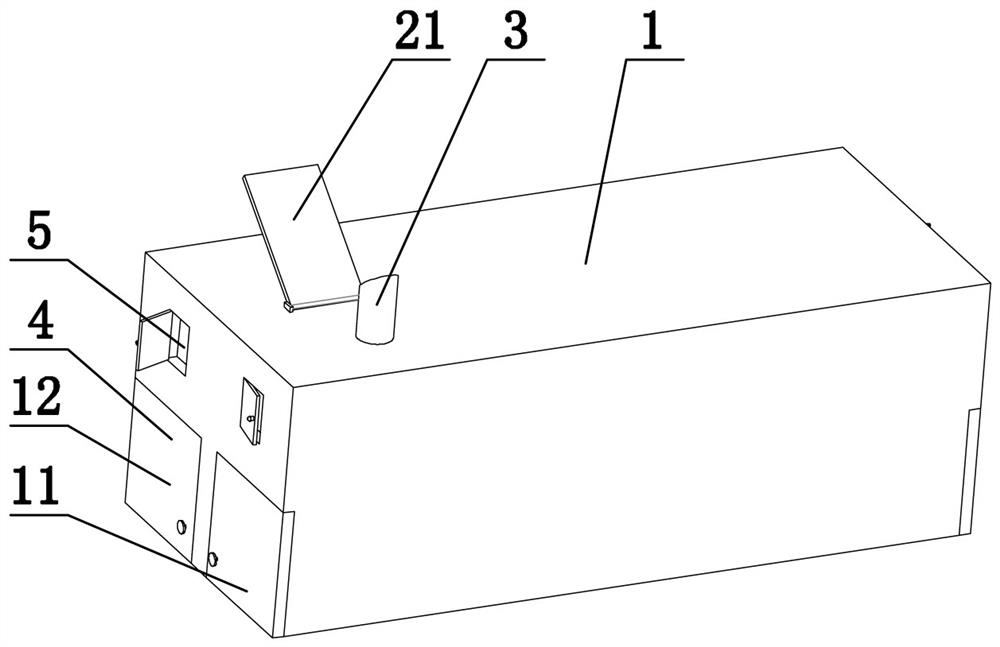

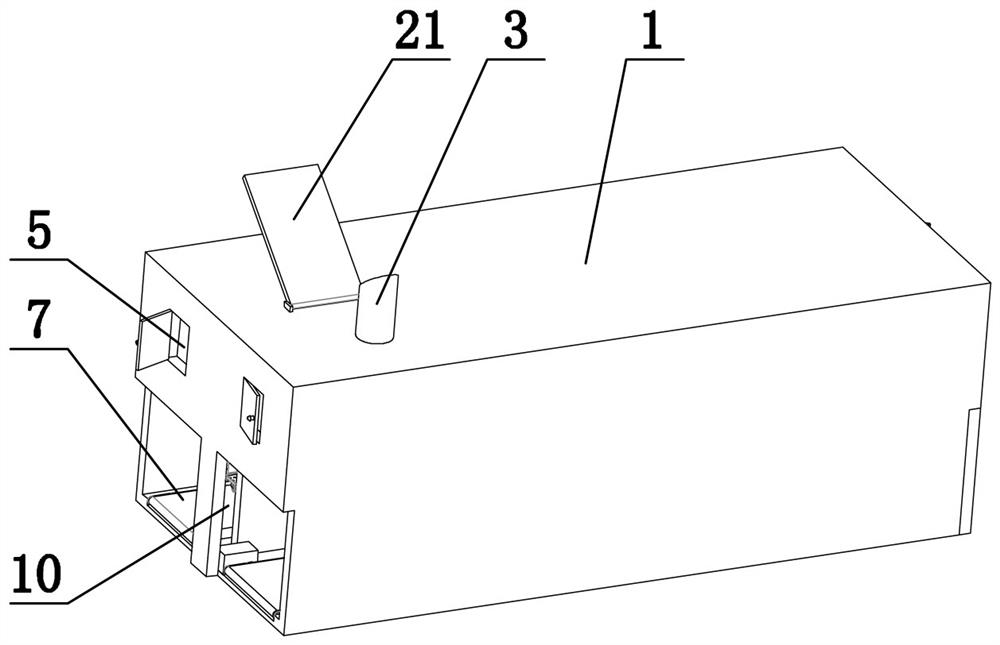

[0020] Such as Figure 1-5 As shown, the laver drying equipment provided by the present invention includes heating equipment, a heating pipeline and a drying room 1. The heat generated by the heating equipment is transmitted to the drying room 1 through the heating pipeline. It is characterized in that: the drying room 1 is equipped with a high temperature Room 2, the drying room 1 includes a first drying room 11 and a second drying room 12, the first drying room 11 and the second drying room 12 are equipped with an air inlet pipe 3, a front door 4, an air intake window 5, an exhaust Window 6, conveyer belt 7, circulation fan 8 and several storage racks 9, also be provided with ventilation door 10 between the first drying room 3 and the second drying room 4, described air inlet duct 3 is communicated with high temperature chamber 2, the first A baffle plate 21 is also provided between the air inlet pipe 3 of the drying room 11 and the air inlet pipe 3 of the second drying room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com