Patents

Literature

72results about How to "Loss will not cause" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

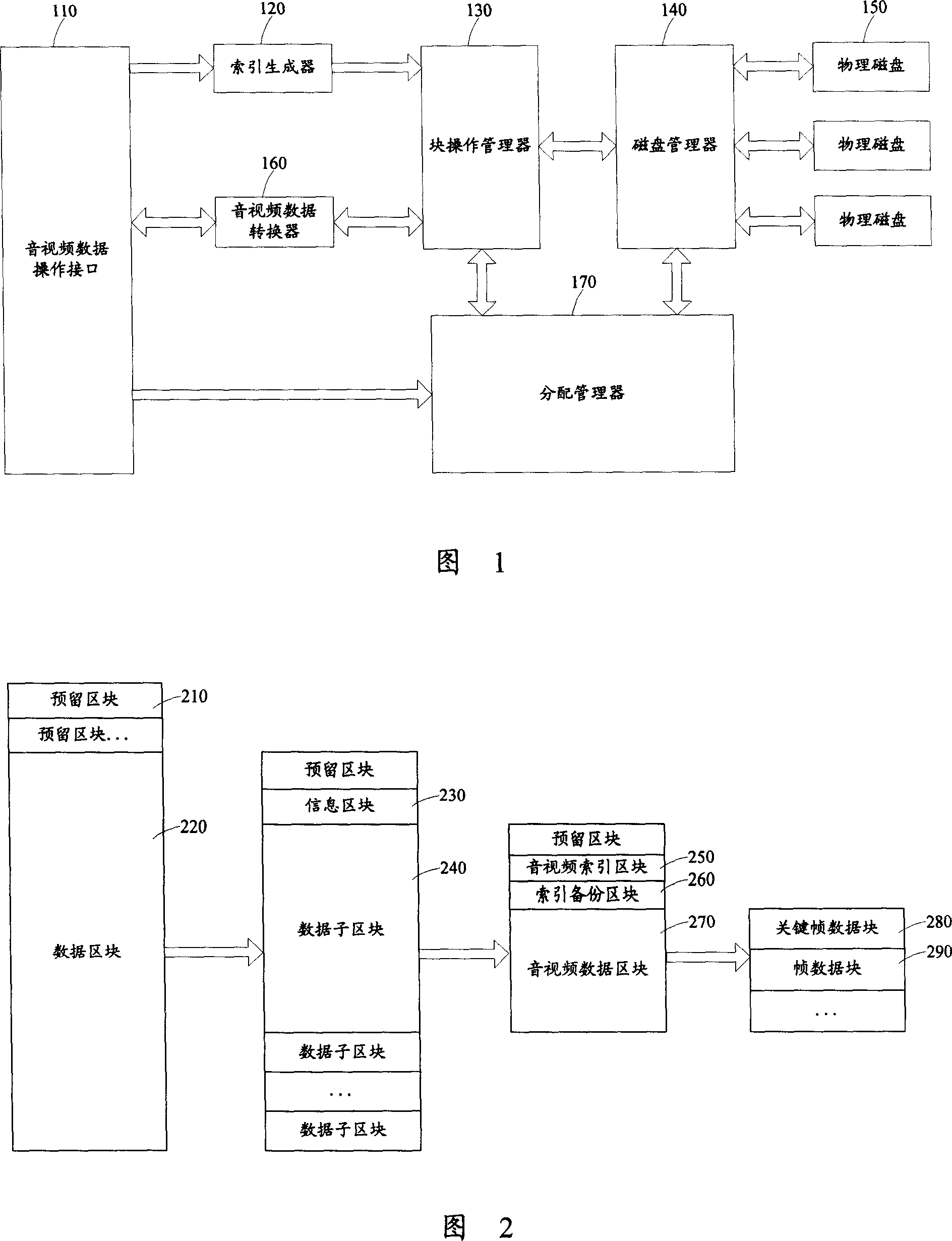

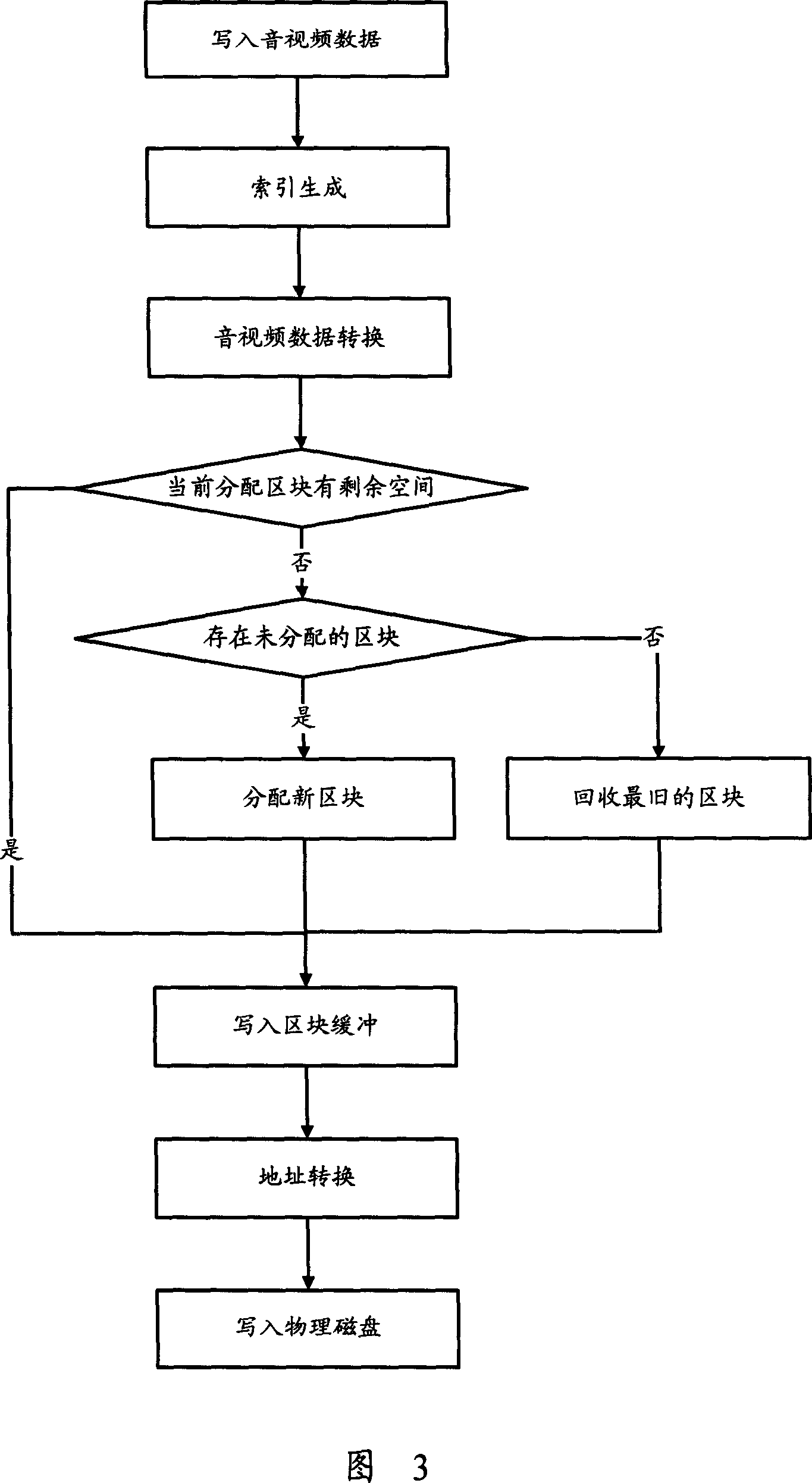

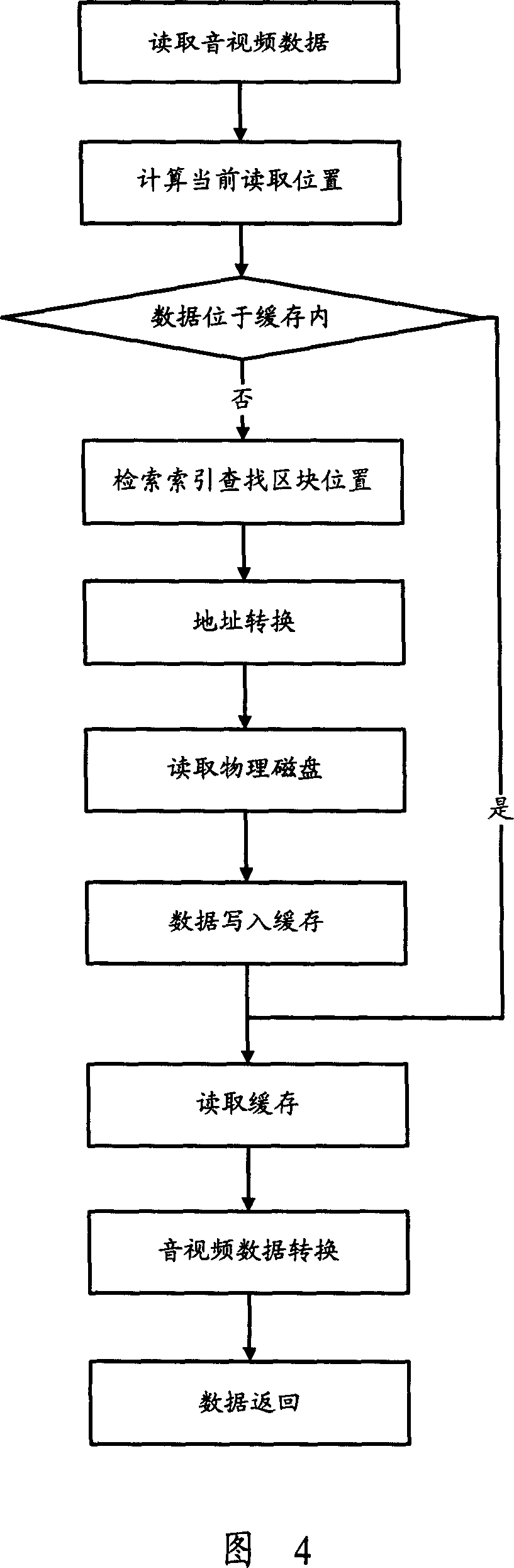

Audio/video data access method and device based on raw device

InactiveCN101008919AWill not cause lossExtended service lifeRecording carrier detailsMemory adressing/allocation/relocationElectricityFile system

This invention discloses one audio frequency data memory method based on bare device, which comprises the following steps: aligning magnetic disc space into several blocks and designing each with certain number and storing the blocks into each disc space block for operations in writing or reading data. This invention has property for lossless data to keep data in electricity break.

Owner:ZHEJIANG UNIV

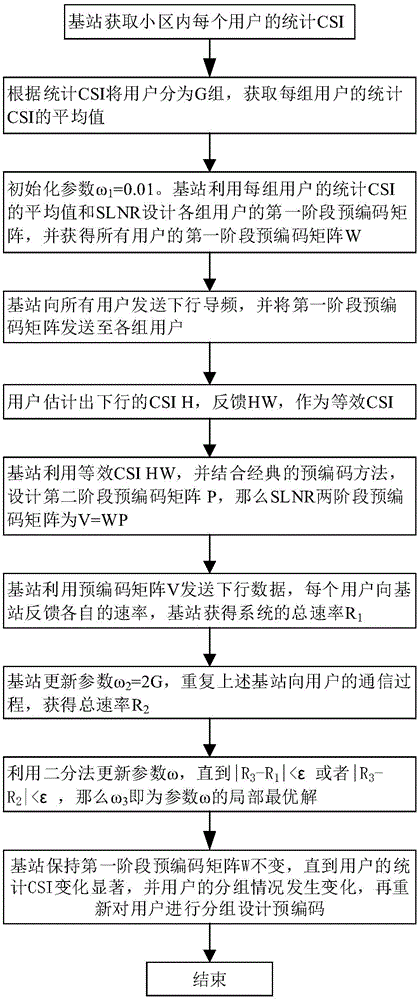

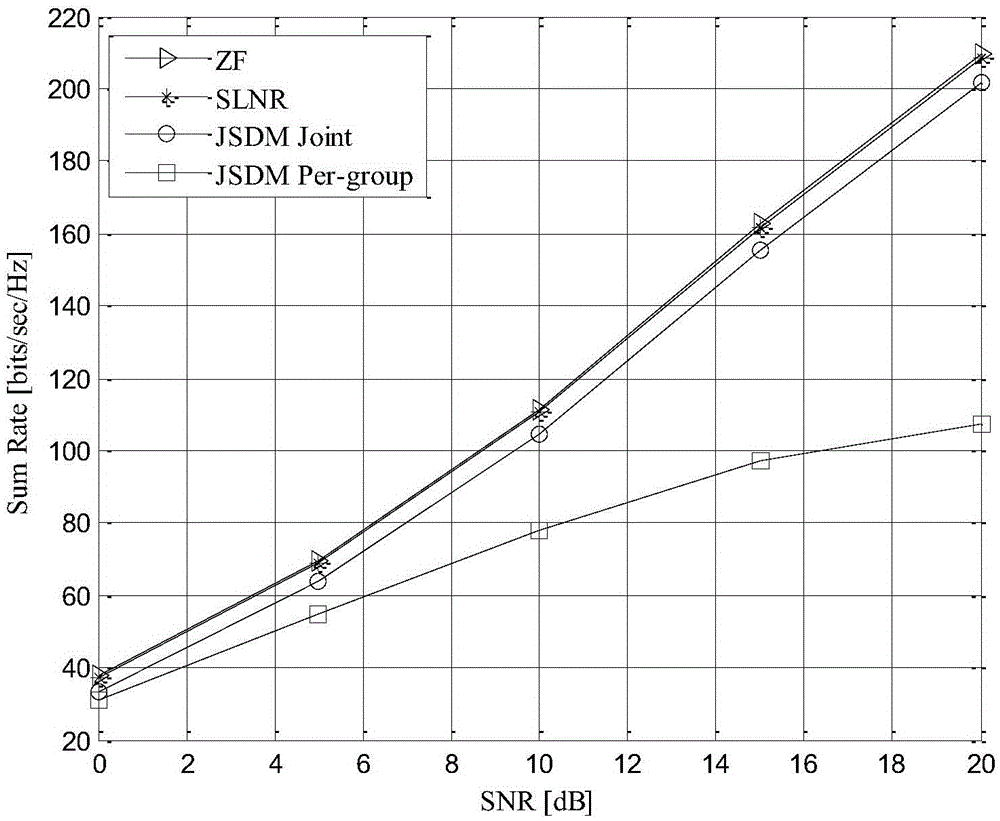

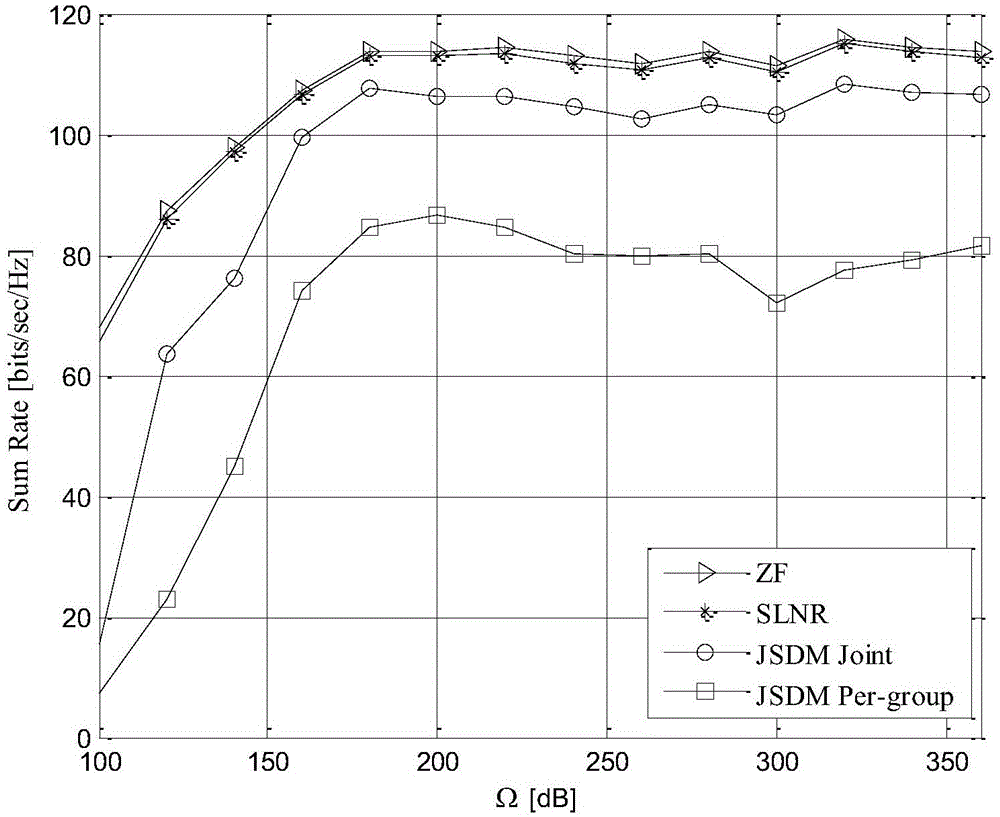

Signal to leakage noise ratio (SLNR)-based two-stage precoding method in large-sale MIMO FDD system

ActiveCN105162507AExcellent overall rate performanceHigh computational complexitySpatial transmit diversityRound complexityPrecoding

The invention discloses a signal to leakage noise ratio (SLNR)-based two-stage precoding method in a large-scale MIMO FDD system. The operation complexity of precoding design of a first stage of each group of users is low, and the overall rate performance of the SLNR two-stage precoding method provided by the invention is superior to a JSDM precoding method proposed by Junyoung Nam et al. In addition, the method provided by the invention performs precoding design based on the SLNR of each group of users, does not cause channel state information loss, and does not influence performance of SLNR two-stage precoding even if angles of arrival of sending signals of two adjacent groups of users and a base station overlap.

Owner:HUAZHONG UNIV OF SCI & TECH

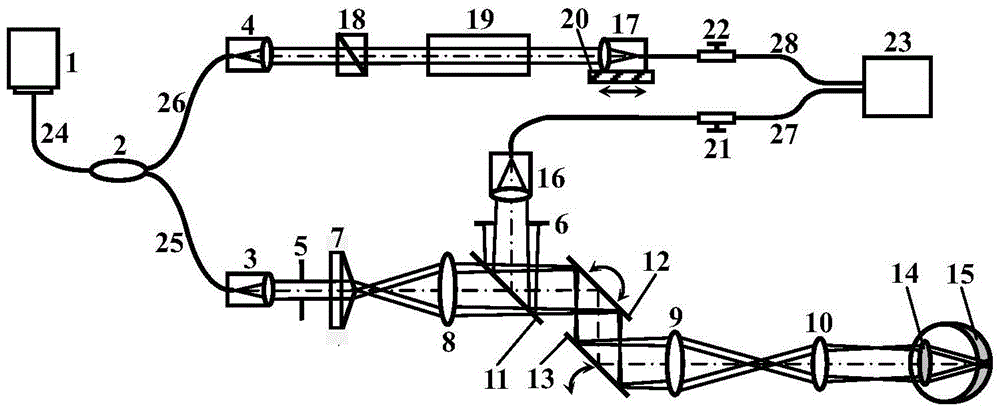

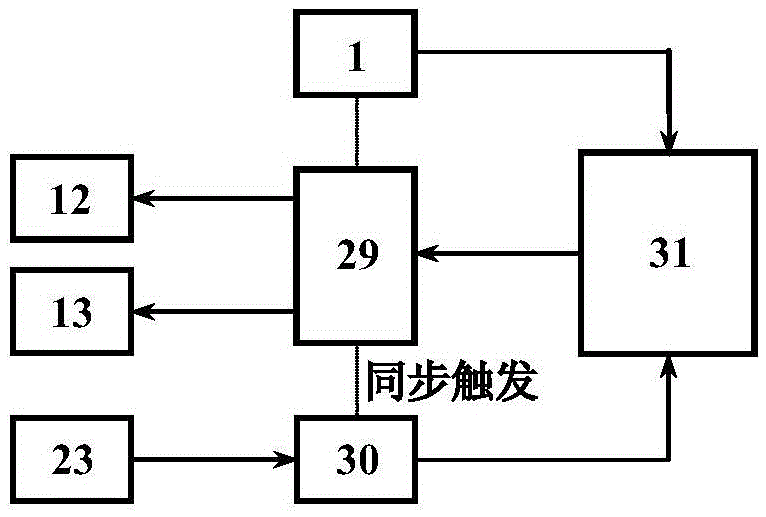

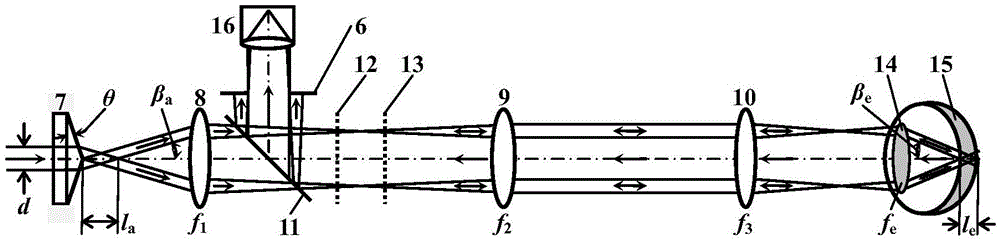

Long-focus deep-dark-field retina OCT system adopting Bessel band lighting mode

InactiveCN105615824ASmall core diameterAvoid Horizontal ResolutionEye diagnosticsRefractive errorNormal retina

The invention discloses a long-focus deep-dark-field retina OCT system adopting a Bessel band lighting mode. The long-focus deep-dark-field retina OCT system comprises a light source, an optical fiber coupler, an iris diaphragm, an axicon, a spectroscope, a horizontal and vertical scanner, a detection end, a data acquisition card, a computer and the like. According to the system, the axicon is adopted to from Bessel band dark field lighting; lateral resolution about 37% higher than that of a normal retina OCT system without the cost of a retina AO-OCT system and the like, and the long-focus deep-dark-field retina OCT system is a simple system for filling up gaps between the normal retina OCT system and the retina AO-OCT system; the focal depth range is remarkably expanded, and the lateral resolution maintains unchanged in the long focal depth range, so that high lateral resolution observation can be conducted on all tissues in the depth range of the retina, and the long focal depth is further beneficial to imaging of ametropic eyes; retina images with a high signal to noise ratio, a high contrast ratio and high three-dimensional feeling can be obtained.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

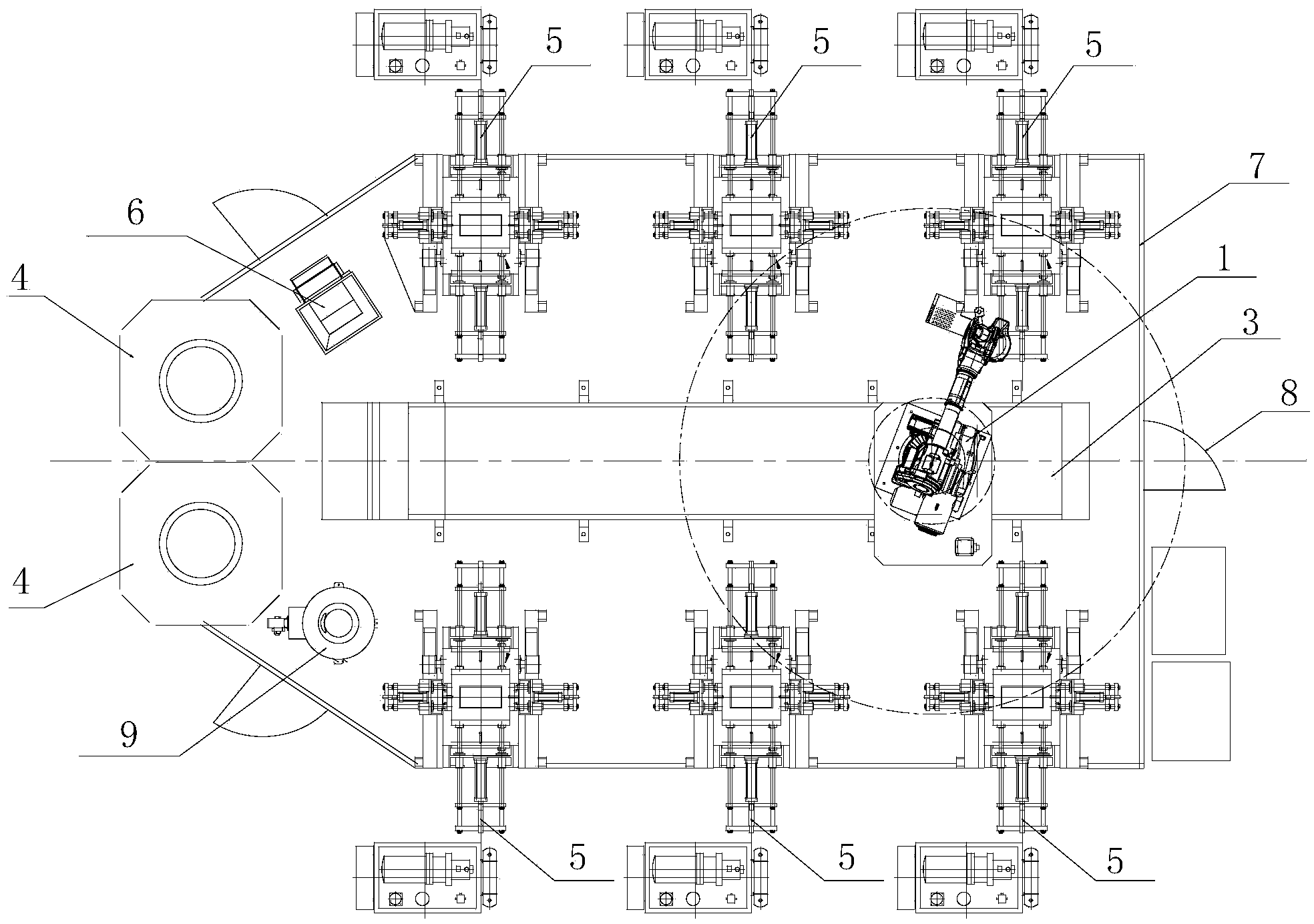

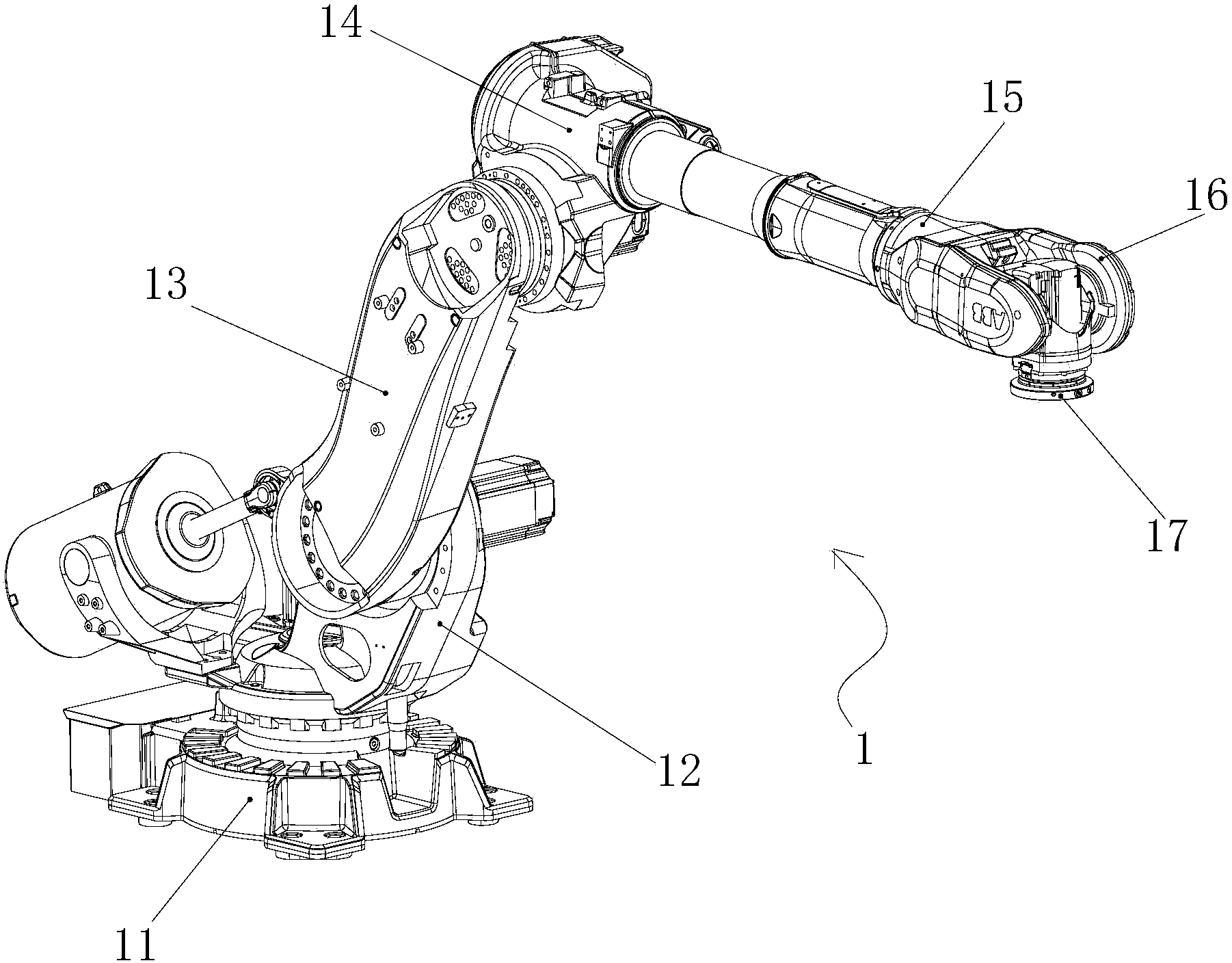

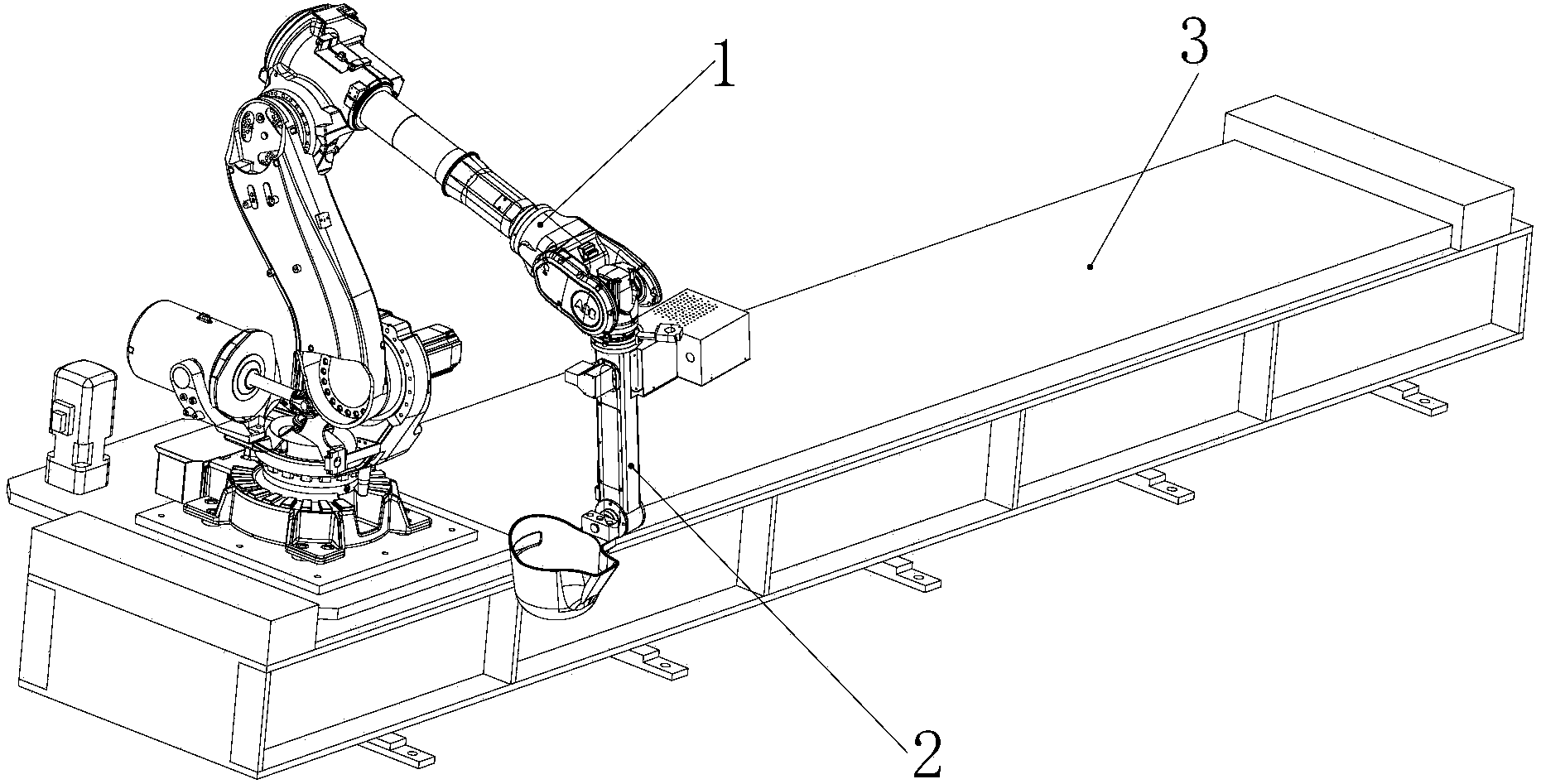

Automatic production system for metal gravity casting

ActiveCN103722163AImprove pass rateReduce the chance of injuryCasting plantsMolten metal supplying equipmentsControl systemMaterials science

The invention discloses an automatic production system for metal gravity casting. The system comprises a heat-preserving furnace, a sliding table, a plurality of gravity casting machines, a robot, a liquid taking arm and a control system, wherein the heat-preserving furnace is used for containing molten metal and keeping the temperature of the molten metal within a certain range; the sliding table is arranged beside the heat-preserving furnace and used for bearing the robot; the gravity casting machines are arranged on the two sides of the sliding table; the robot is arranged on the sliding table and can make reciprocating movement on the sliding table; the liquid taking arm is connected with the robot and provided with a liquid taking spoon and a servo driving system for driving the liquid taking spoon to rotate; the control system is used for controlling the liquid taking arm to take liquid from the heat-preserving furnace when the robot slides to the heat-preserving furnace and controlling the robot to move to the position beside the pre-determined gravity casting machine after the liquid is taken, then, the liquid taking arm is controlled to pour the molten metal to the pre-determined gravity casting machine, and next, the robot is controlled to slide to the initial position after the molten metal is poured by the liquid taking arm. According to the production system, the production efficiency, the safety and the percent of pass of products can be improved.

Owner:广东意戈力智能装备有限公司

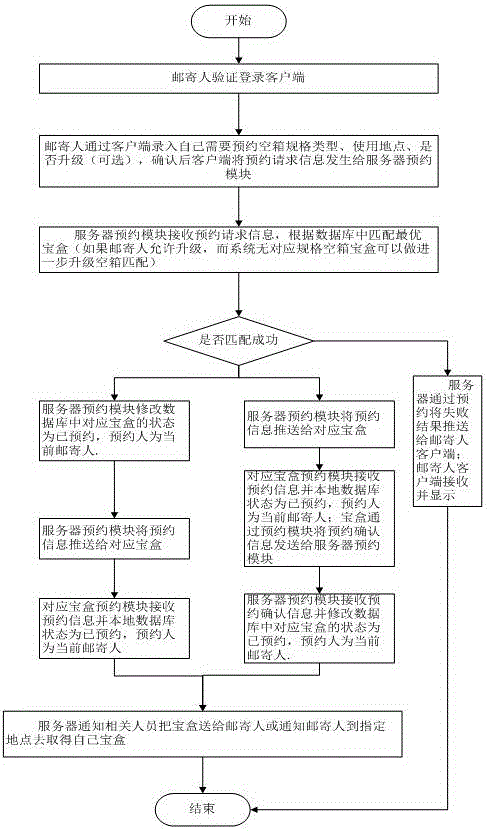

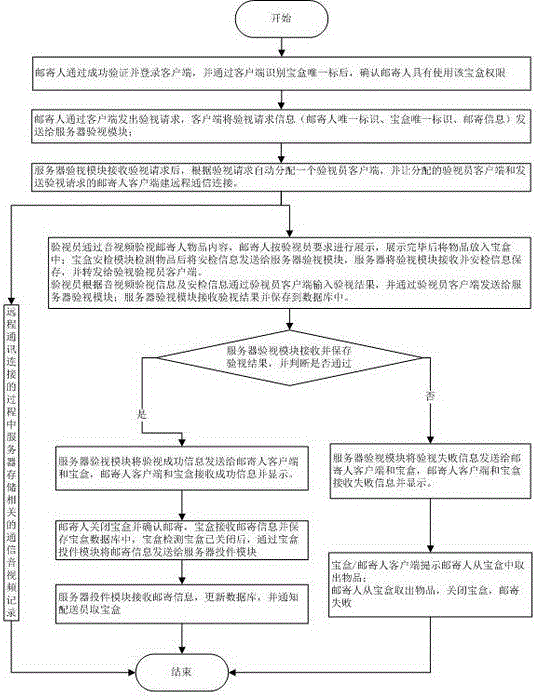

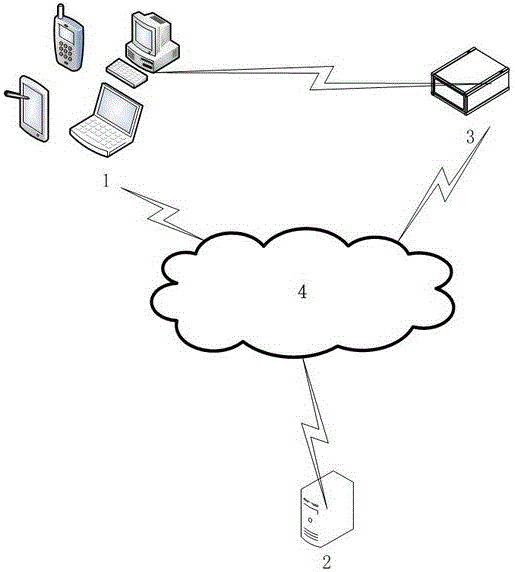

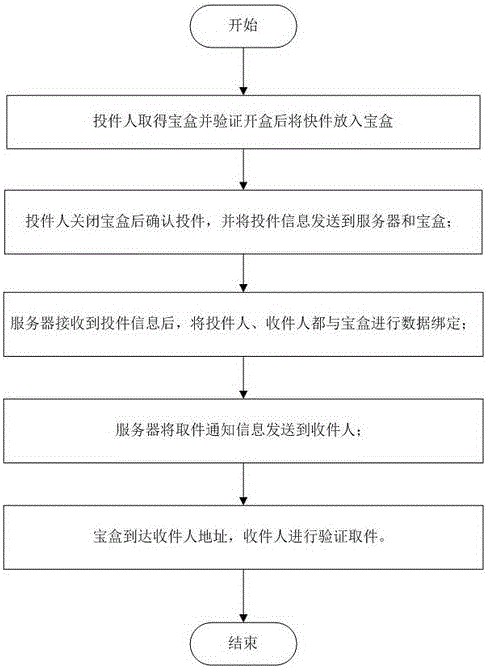

Treasure box mailing system and method

InactiveCN106203899AImprove securityCommunication is convenient and simpleApparatus for meter-controlled dispensingIndividual entry/exit registersWorkloadData library

The invention discloses a treasure box mailing system and method. The mailing system comprises a client, a treasure box and a server, the client and the treasure box communicate with the server via the network, the server comprises a user module, a mail inspection module, a mail sending module, a mail taking module and a database, and the treasure box comprises a safety check module, an audio and video module and a treasure box database. The mailing method comprises a treasure box booking step, a mail sending step and a mail taking step, and remote inspection is needed when a mail is sent. According to the invention, onsite inspection is not needed when the fast mail is sent, convenience is provided for senders, and the workload of delivery staff is reduced at the same time.

Owner:CHENGDU WOLAILA GRID INFORMATION TECH

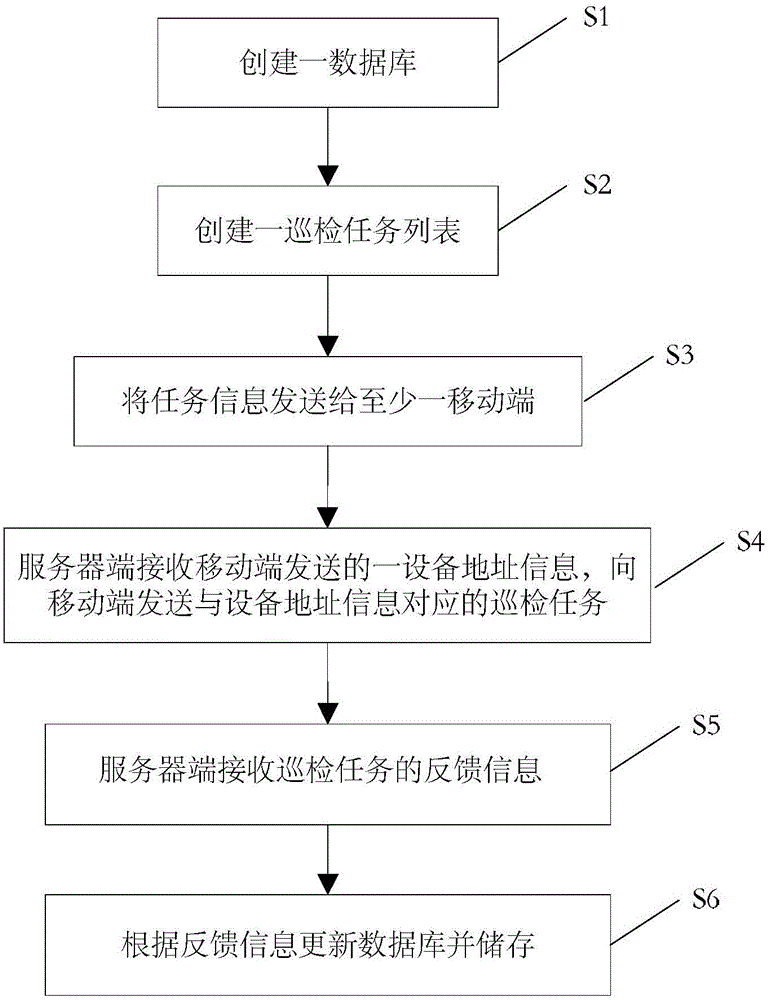

Intelligent fire inspection method

InactiveCN106649506AAccurate and targetedAccurate efficiencyDatabase updatingResourcesComputer scienceEffective management

The invention provides an intelligent fire inspection method. The method comprises the steps that a database is created at a server; an inspection task list is created according to location information and personnel information, wherein the inspection task list comprises at least one inspection task; task information of the inspection task list is sent to at least one mobile terminal corresponding to the inspection task list; the server receives a piece of equipment address information of the mobile terminal and sends the inspection task corresponding to the equipment address information to the mobile terminal; the server receives feedback information of the inspection task; the database is updated according to the feedback information, and the feedback information is stored. Through the intelligent fire inspection method, fire information can be managed in a unified mode, real-time updating of data is realized, and inspection personnel can be dynamically and effectively managed and supervised; the method has the advantages that information management is convenient, updating speed is high, accuracy is high, and resources are saved.

Owner:SHANGHAI FIRE RES INST OF THE MIN OF PUBLIC SECURITY +1

Preparation method of instant selenium-enriched corn flour

InactiveCN103876021ALoss will not causeDelicate tasteFood dryingFood ingredient functionsGranularityCorn flour

The invention discloses a method for preparing additive-free instant selenium-enriched corn flour by a spray-drying process. The method is characterized by comprising the following steps: with selenium-enriched corns subjected to selenium biological nutrient enrichment as a raw material, performing processes of cleaning, peeling, degerming, powder coarsening, curing, powder thinning, slurry settling, spray drying, and quantitative subpackaging to prepare the additive-free instant selenium-enriched corn flour with the water content of less than 7wt%, the granularity of 100-120 meshes, the instant time of shorter than 30 seconds and the selenium content of 10-250 micrograms / 10 grams. The method disclosed by the invention realizes preparation of the instant corn flour under an additive-free condition; the instant corn flour is fine and smooth in taste, has the fragrance of puffed corn flour, realizes selenium quantification, and provides a proper and scientific choice for different people with the need of selenium supplement.

Owner:安徽硒谷生物科技有限公司

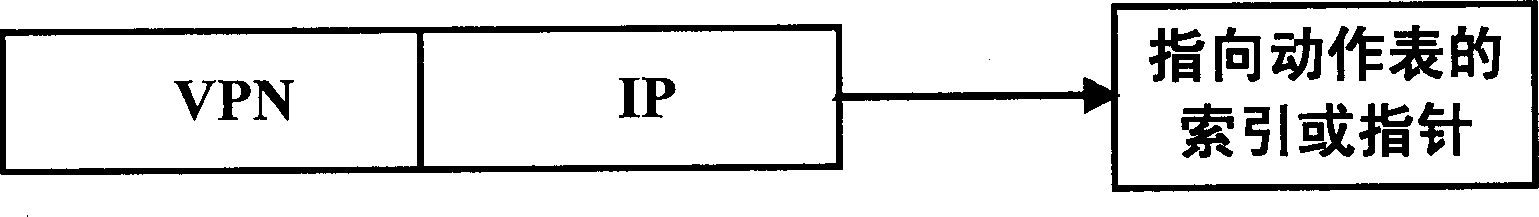

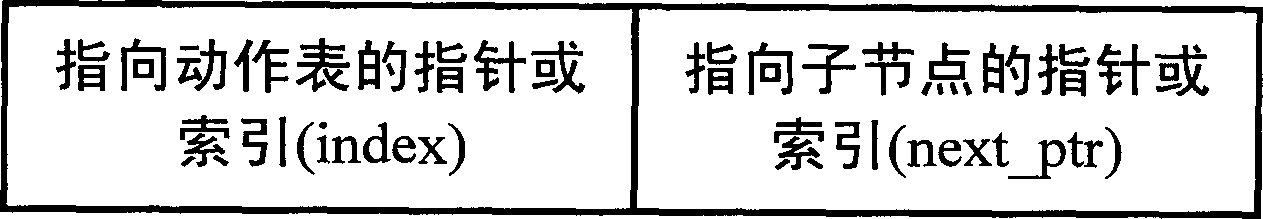

Route managing system and method

InactiveCN1859297ANot easy to cause lossLoss will not causeNetworks interconnectionSpecial data processing applicationsManagement systemSoftware

The present invention relates to route information management system and method. Said system includes software list tree unit, tree table searching unit, TCAM list unit and TCAM table searching unit; wherein tree table searching unit reviewing software tree and feeding back the reviewed result to TCAM table searching unit, TCAM table searching unit reviewing TCAM list, comparing with table searching result of tree table searching unit, and determining route action message. The present invention also provides route information management method. Said invention provides an effective route solution scheme, only using less TCAM resource, to make software tree construction supporting VPN service and no route lose.

Owner:HUAWEI TECH CO LTD

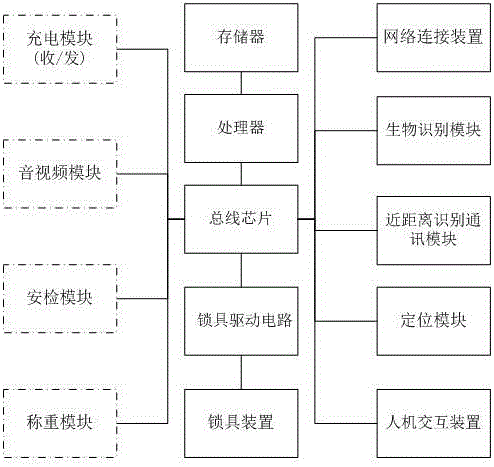

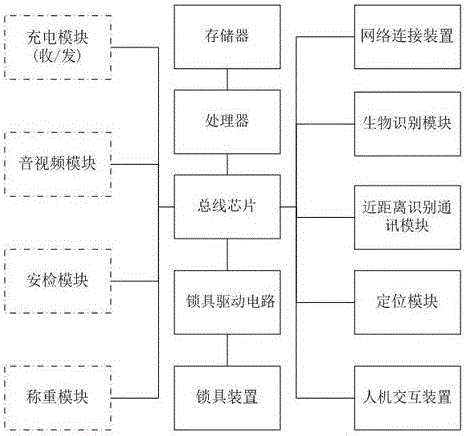

Treasure box, drop and pick up system and method thereof, and query and positioning method of the treasure box

InactiveCN106097467AVarious ways to openImprove securityFranking apparatusIndividual entry/exit registersPasswordComputer science

The invention discloses a treasure box, a drop and pick up system and a method thereof, and a query and positioning method of the treasure box. The treasure box is provided with a biological identification module, a close-range module and a positioning module. Through the biological identification module and the close-range module, identification verification modes of the treasure box are increased and are not limited in password identification. The box can be opened conveniently. Simultaneously, state information of the treasure box can be known at any time and can be traced.

Owner:CHENGDU WOLAILA GRID INFORMATION TECH

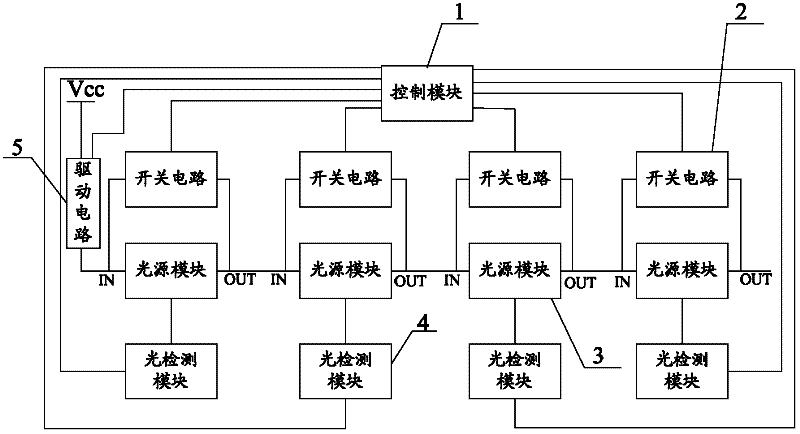

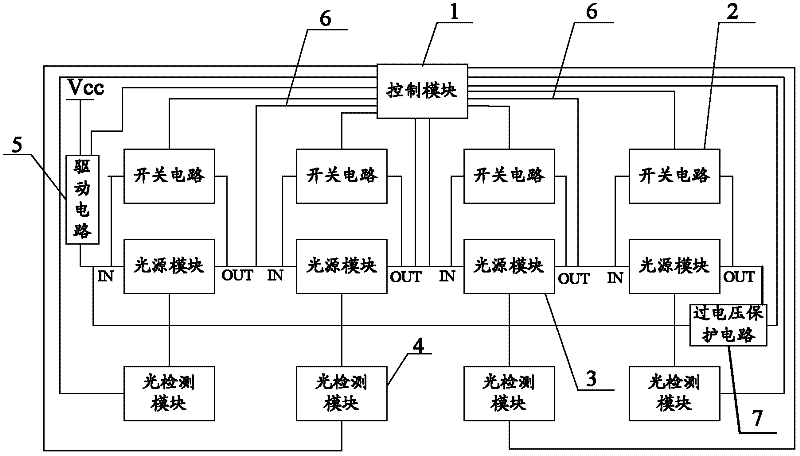

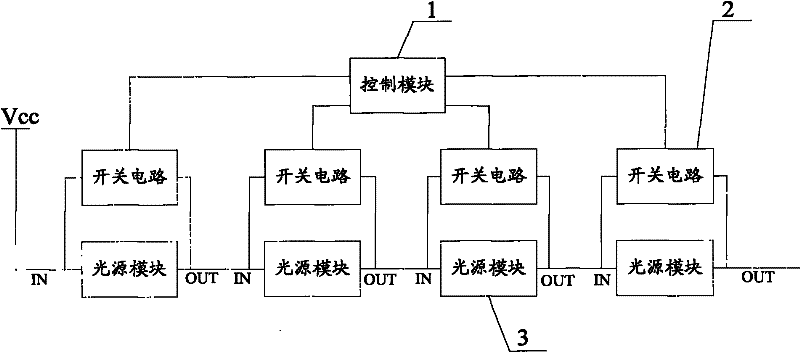

Circuit and method for ensuring normal operation of light source modules

InactiveCN102695317AWork lessSolve technical problems with a relatively narrow scope of applicationElectric light circuit arrangementEnergy saving control techniquesElectricityElectronics

The present invention provides a circuit and a method for ensuring normal operation of light source modules, relating to the technical field of electronics and solving a technical problem of narrow application scope in the prior art. The circuit for ensuring the normal operation of the light source modules comprises a control module and switching circuits. The switching circuits are connected between an electricity input end and an electricity output end of one light source module of at least two light source modules which are in series with each other. When the switching circuits are off, the light source modules operate normally; when the switching circuits are on, the light source modules are shorted out by the switching circuits. The control module, when a fault of one of the light source modules occurs, is used to control the switching circuit that is connected between the electricity input end and the electricity output end of the light source module having a fault, and to switch the switching circuit from off to on status. The circuit and the method are applied to the ensuring of the normal operation of light source modules which are formed by a plurality of modules mutually connected in series.

Owner:HISENSE VISUAL TECH CO LTD

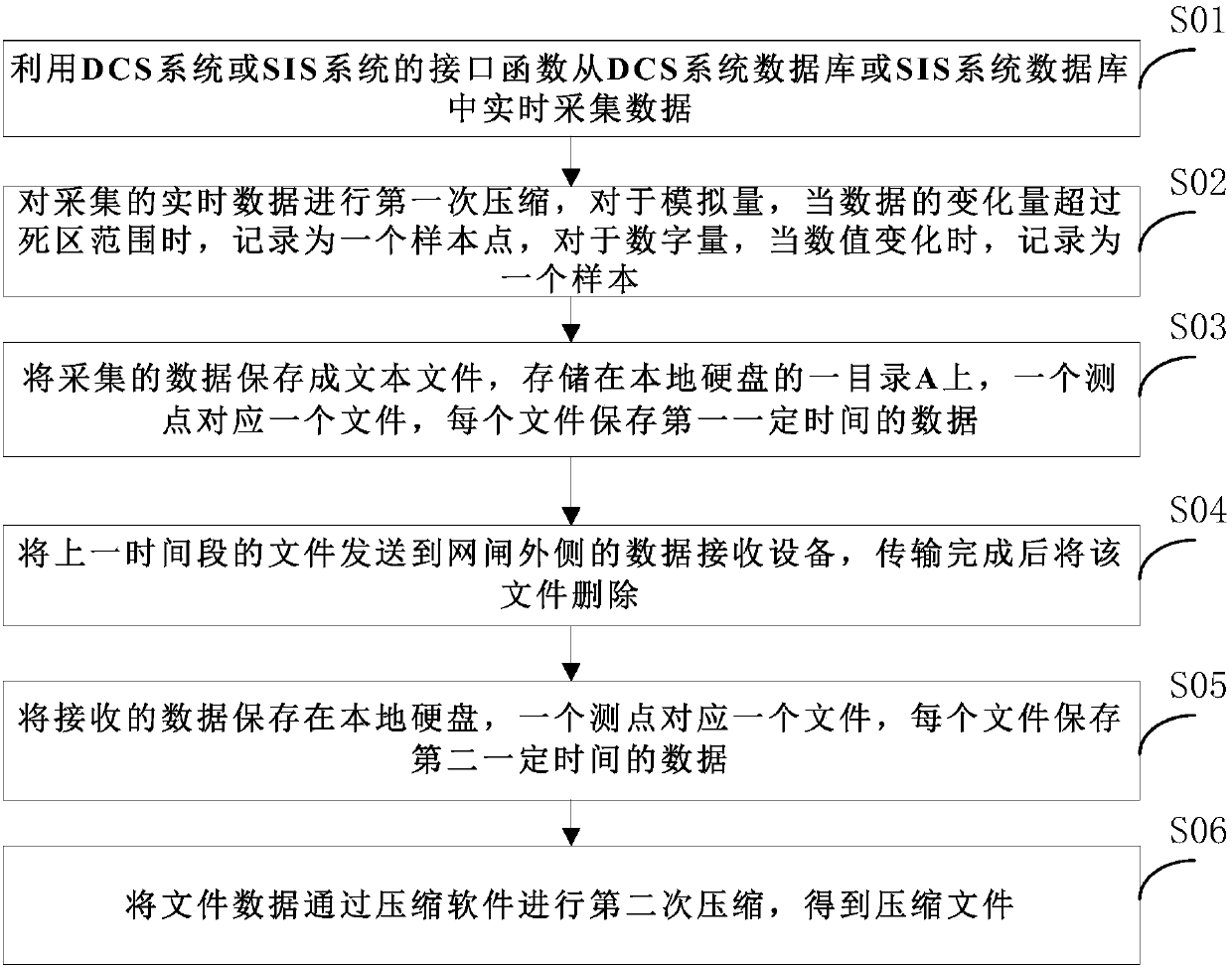

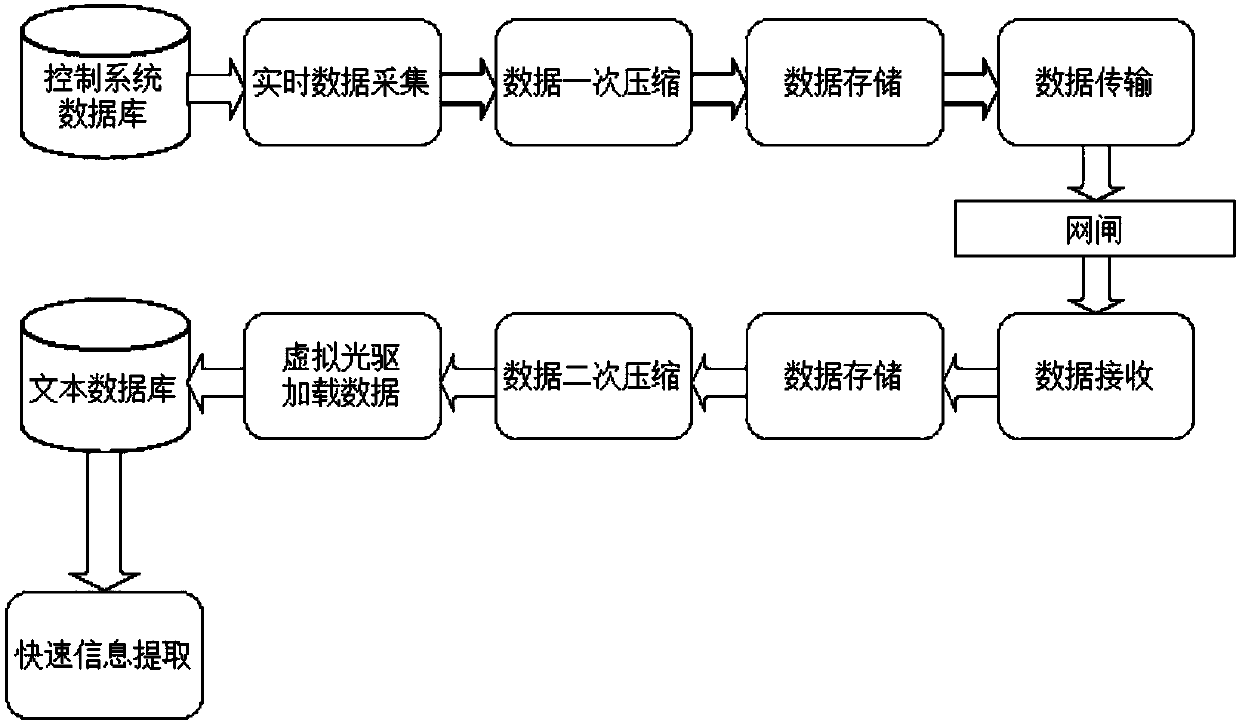

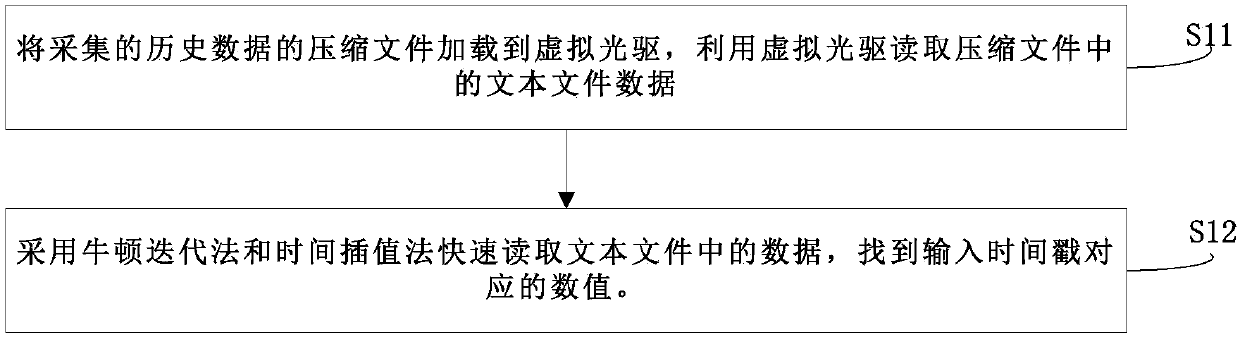

New time sequence data storage method applied to power plant

InactiveCN107807969AEasy to collectHigh Acquisition AccuracyInput/output to record carriersFile access structuresReal-time dataData integrity

The invention discloses a new time sequence data storage method applied to a power plant. The method comprises the steps that an interface function of a DCS (distribution control system) or an SIS (supervisor information system) is utilized to collect real-time data from a DCS database or an SIS database; first compression is performed on the collected real-time data; the collected data is saved in the form of text files, the text files are stored on a directory A of a local hard disk, one measurement point corresponds to one file, and each file saves the data at a first certain time; the filein the last time period is sent to data receiving equipment outside a gateway, and the file is deleted after transmission is completed; received data is saved in the local hard disk, one measurementpoint corresponds to one file, and each file saves the data at a second certain time; and second compression is performed on the file data through compression software, and a compressed file is obtained. Through the method, historical data can be collected quickly and efficiently, the collected data has high integrity, the compression rate is high, and data reading speed is high.

Owner:SHANGHAI HUADIAN ELECTRIC POWER DEV CO LTD

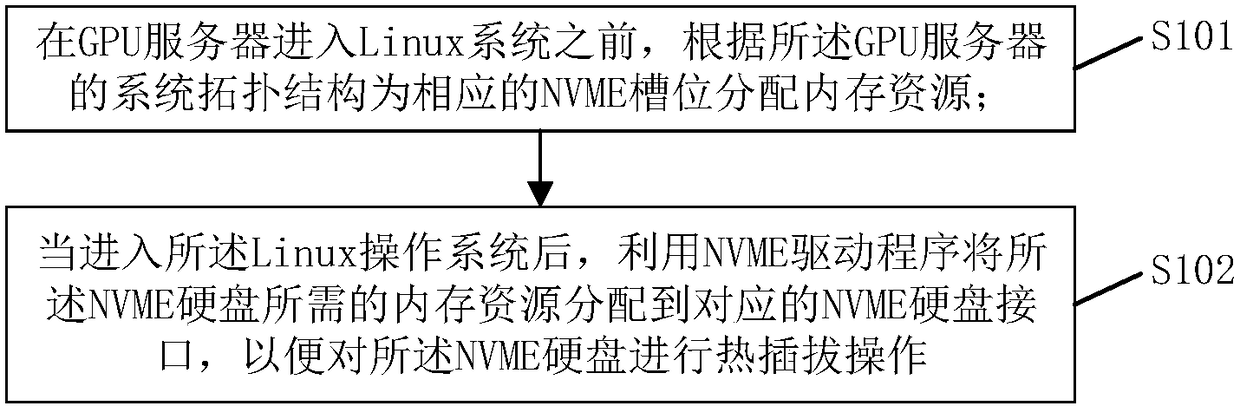

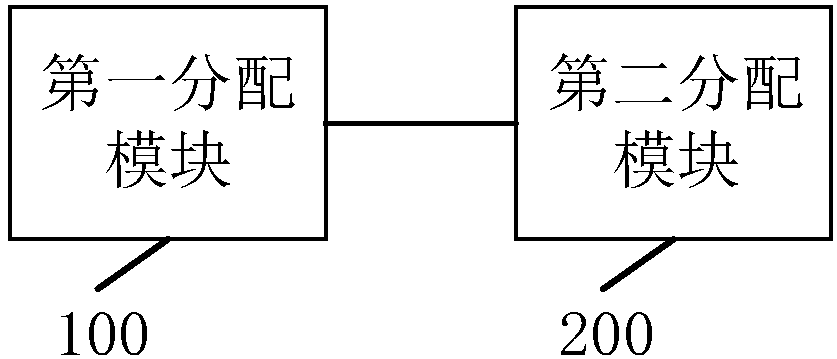

NVME hard disk hot plug setting method and system

InactiveCN108304044ALoss will not causeNormal operation is not lostDetecting faulty computer hardwareDigital processing power distributionOperational systemGNU/Linux

The invention discloses an NVME hard disk hot plug setting method. The setting method comprises the steps that before a GPU server enters a Linux system, memory resources are allocated to corresponding NVME slots according to a system topology structure of the GPU server; after the GPU server enters the Linux operating system, the memory resources required by an NVME hard disk are allocated to corresponding NVME hard disk interfaces by using an NVME driving program, so that the NVME hard disk is subjected to hot-plug operation. The invention further discloses an NVME hard disk hot plug settingsystem, a computer readable storage medium and the GPU server. The NVME hard disk hot plug setting system, the computer readable storage medium and the GPU server have the above advantages.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

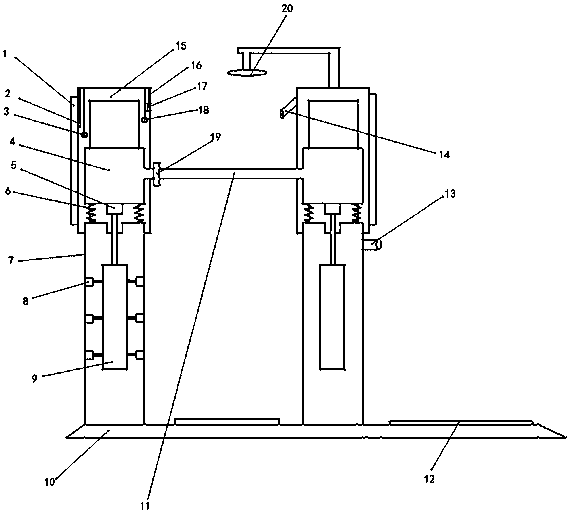

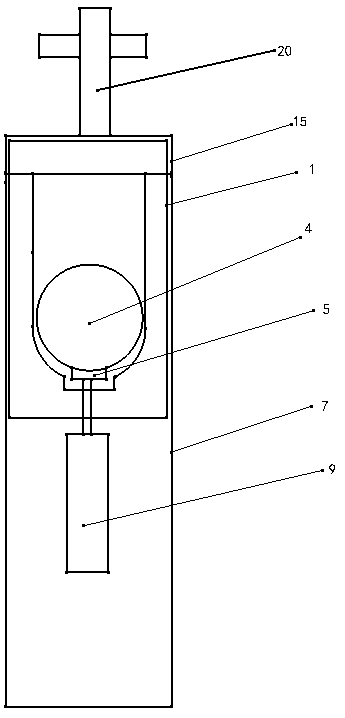

High-interestingness weightlifting equipment

The invention discloses high-interestingness weightlifting equipment, which comprises a base, supporting piles, barbells and limiting shells. An electronic balance is arranged on the base; balance weights and weight sets are arranged in the supporting piles which are provided with cameras; the barbells including a left barbell and a right barbell are connected with each other through a bearing rodwith sponge; convex blocks are arranged below the barbells, the barbells are vertically provided with convex strips, the convex strips and grooves in the limiting shells are in mortise-tenon connection, and compression springs are arranged below the barbells. By improvement of traditional weightlifting equipment, weightlifting becomes meaningful and participatory, everyone is encouraged to participate in exercising through encouraging, and the high-interestingness weightlifting equipment has advantages of high safety in use, less proneness to damages and loss, high applicability and practicality, great utilization effects and the like.

Owner:SUZHOU XINYAO HEALTH TECH CO LTD

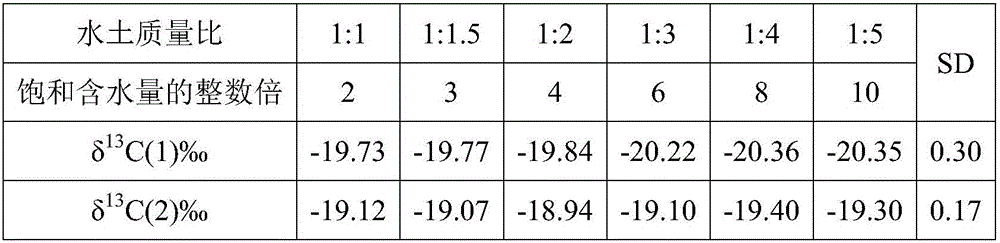

Method for measuring soil soluble organic carbon isotope

InactiveCN106770606AGuaranteed measurementAchieve homogenizationMaterial analysis by electric/magnetic meansSoil massFreeze-drying

The invention discloses a method for measuring a soil soluble organic carbon isotope. In the method, an EA-IRMS method is adopted. The method comprises the following steps: firstly, extracting soil water-soluble organic carbon through a multi-water to soil mass ratio method to obtain a solution containing the soil water-soluble organic carbon; then, concentrating the obtained solution through freeze drying; adding purified water into concentrated substances for re-dissolving, drying and measuring delta<13>C through EA-IRMS. The novel method for measuring the soil soluble organic carbon isotope provided by the invention is rapid and efficient, is easy and convenient to operate, and has high measuring accuracy.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

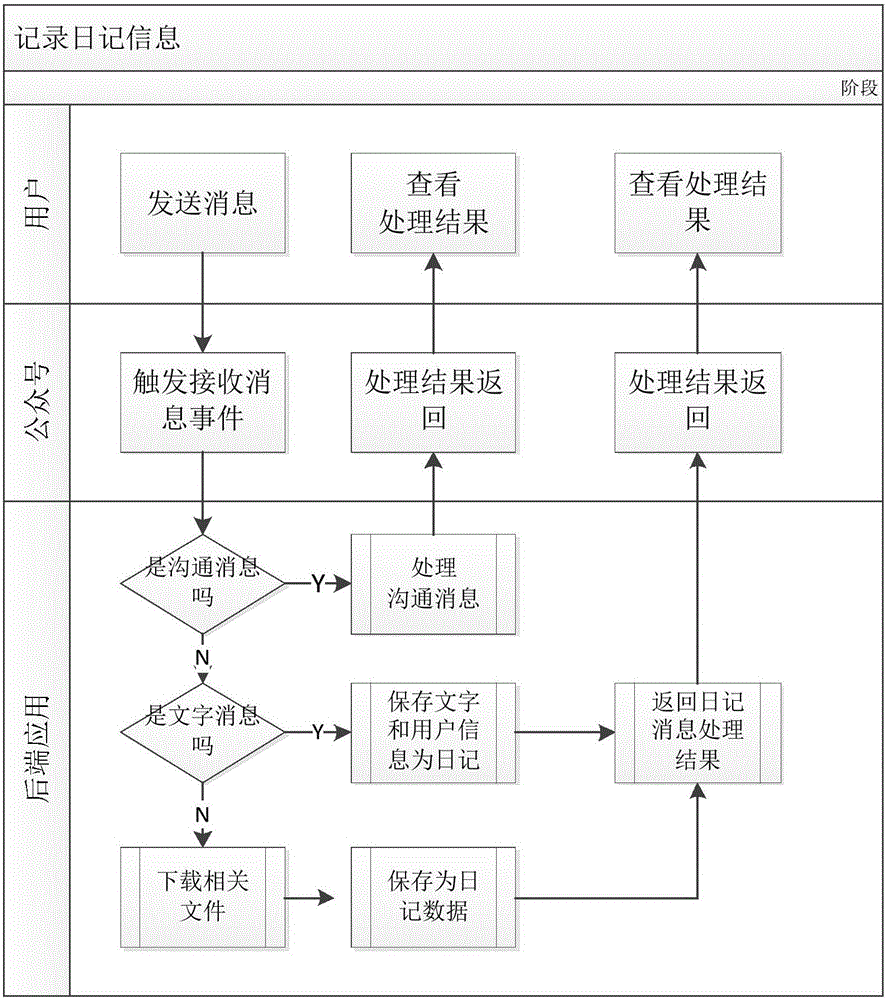

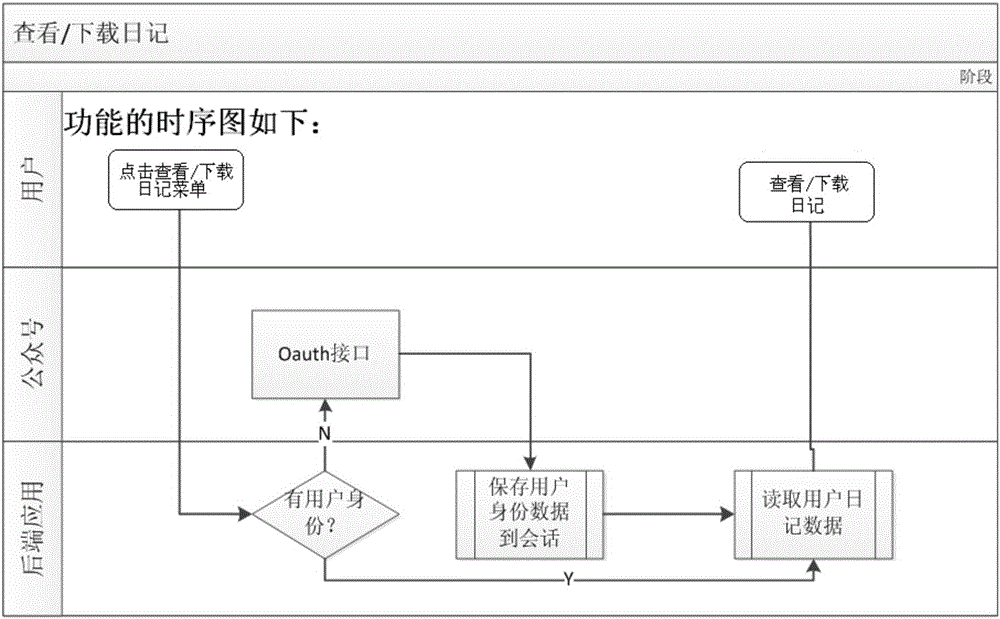

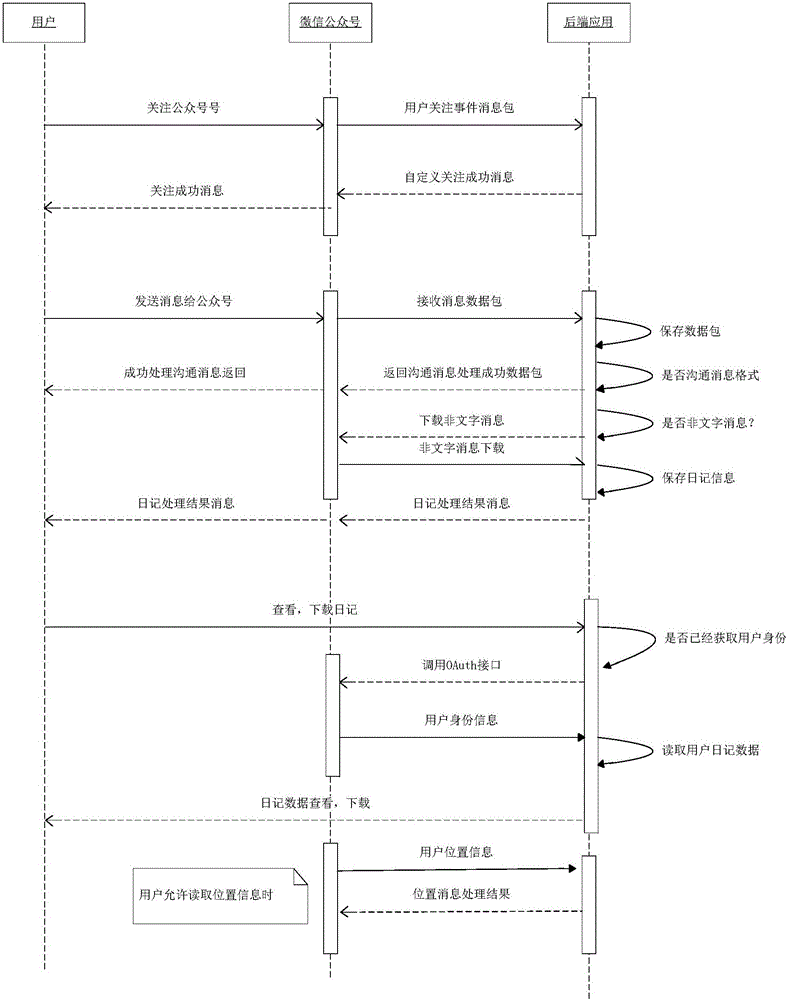

Method for establishing and managing electronic diary by using WeChat platform

InactiveCN105893580AReduce trafficLoss will not causeData switching networksSpecial data processing applicationsTraffic capacityPublic account

The invention discloses a method for establishing and managing an electronic diary by using a WeChat platform. The method comprises the following steps of paying attention to a public account having an electronic diary function by utilizing WeChat; sending diary information to the public account; saving the diary information to a cloud storage server and enabling the diary information to be associated with the identification of a user; storing the diary information as a diary of the user; obtaining position data of the user through an API (Application Program Interface) at the same time if the public account is authorized to read position information by the user, and storing the position data together with the diary information; enabling the user to check / download the diary at any time through a menu of the public account, and also enabling the diary to be directly published through a public account operator. The method for establishing and managing the electronic diary by using the WeChat platform, disclosed by the invention, is based on the WeChat platform, installation of software is not needed, the flow is saved, the use is easy, the privacy safety is ensured, the data are safer as cloud storage is adopted, and the user experience is good; in addition, the method is also applicable to QQ and other social platforms having public accounts and APIs, and the method comprises the steps of paying attention to QQ having an electronic diary function or the public accounts of other social software and then carrying out the same operation.

Owner:北京汇康益生科技有限公司 +1

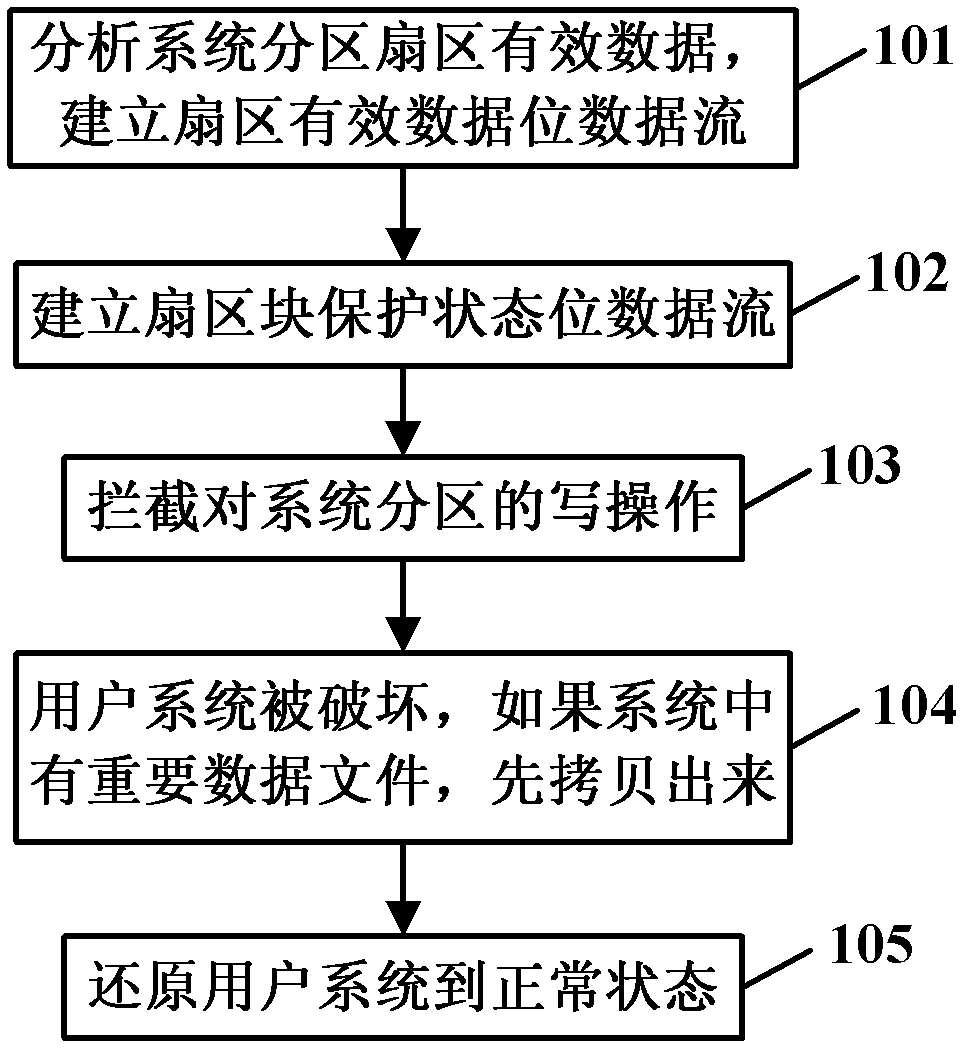

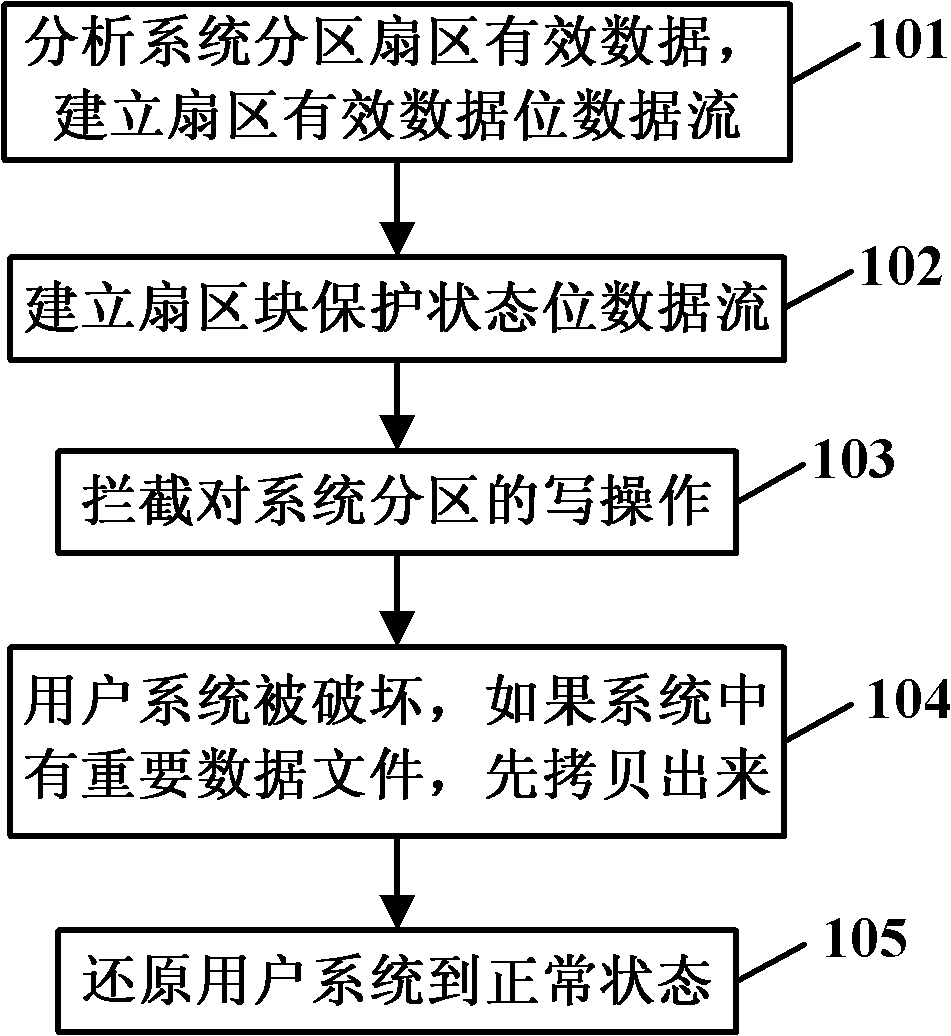

System protecting method based on data security

ActiveCN102609371AEnsure safetyLoss will not causeMemory loss protectionRedundant operation error correctionData streamOriginal data

The invention discloses a system protecting method based on data security, which relates to the field of program control of computers. The system protecting method includes steps: analyzing effective data of a partition of a system, building a data flow of effective data bits of a sector, dividing the sector in the partition of the hard disk system into a plurality of sector blocks, and building a sector block protecting state data flow according to the data flow of the effective data bits of the sector; intersecting write operation of the partition of the system, inquiring the sector block protecting state data flow, copying original data into a free block if the current sector block to be written is a protected block, recording copying information, marking the free block as a buffering block, marking the sector block to be written as a copied block and then completing write operation; and finding back a file before the system is restored when the system is severely damaged and cannot be guided and the partition of the system has important data files, and directly restoring the system if the system is not severely damaged and the partition of the system does not have the important data files. By the aid of the system protecting method, security of data of users can be guaranteed, loss of the data of the users can be avoided, restoring speed is fast, and influence on writing and reading of a hard disk is low.

Owner:WUHAN OPENKER COMPUTING

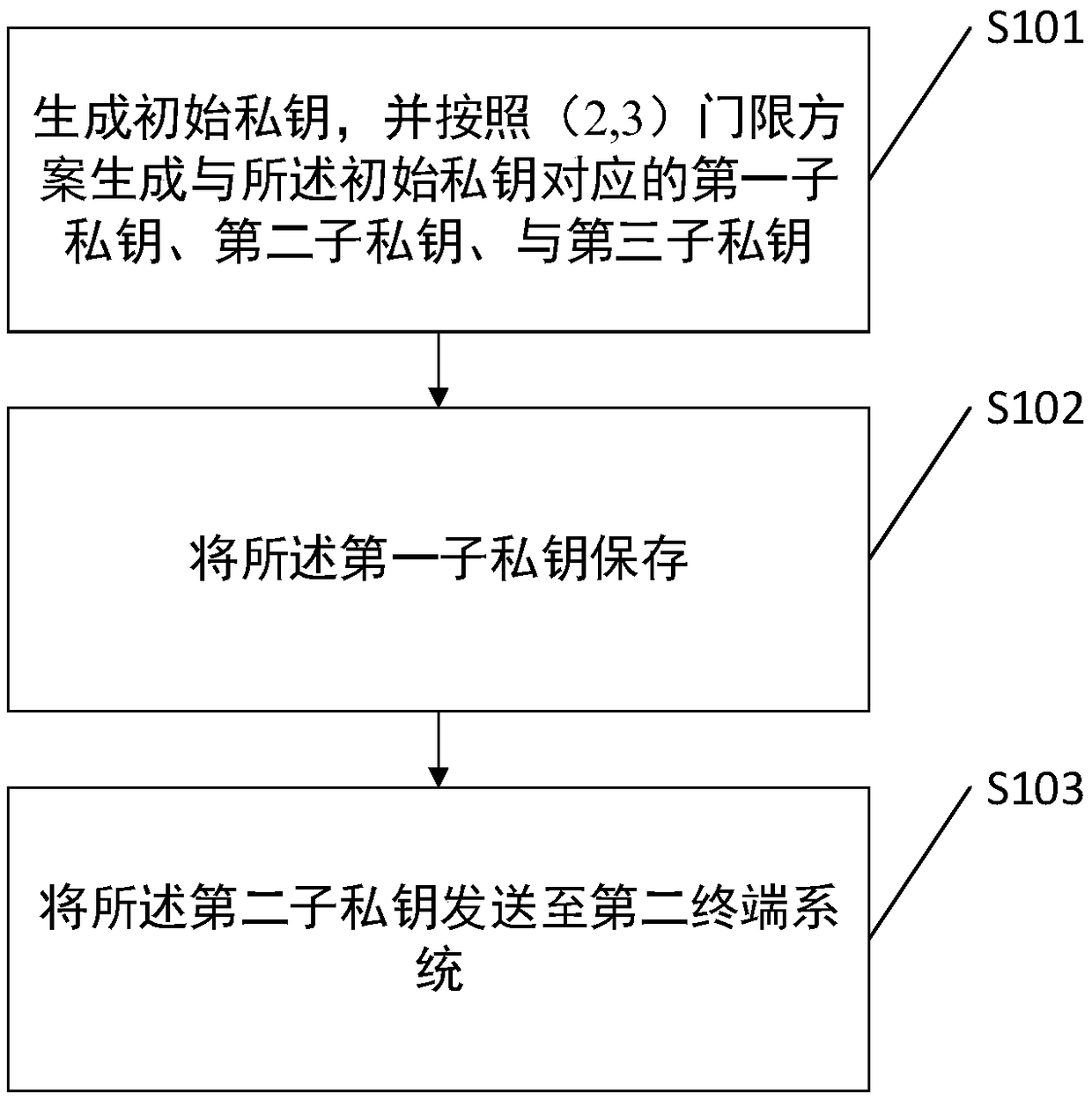

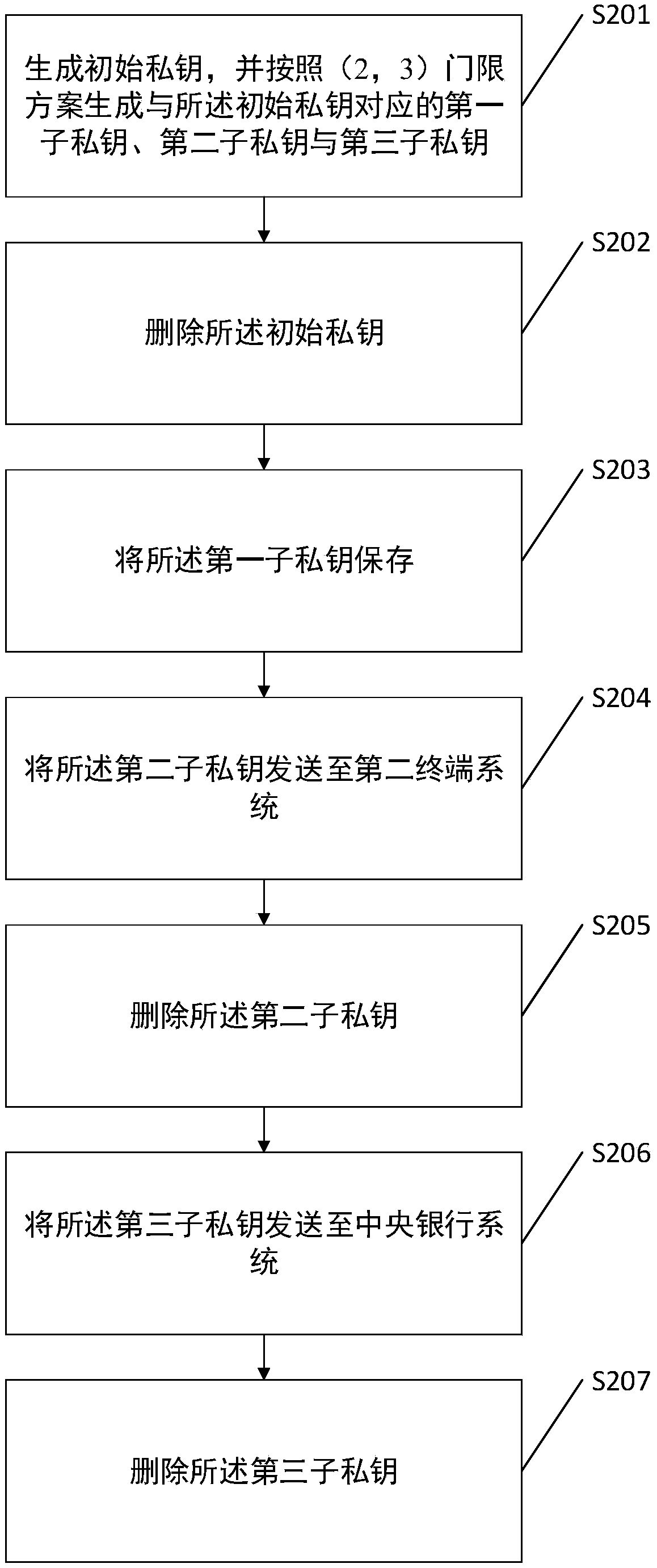

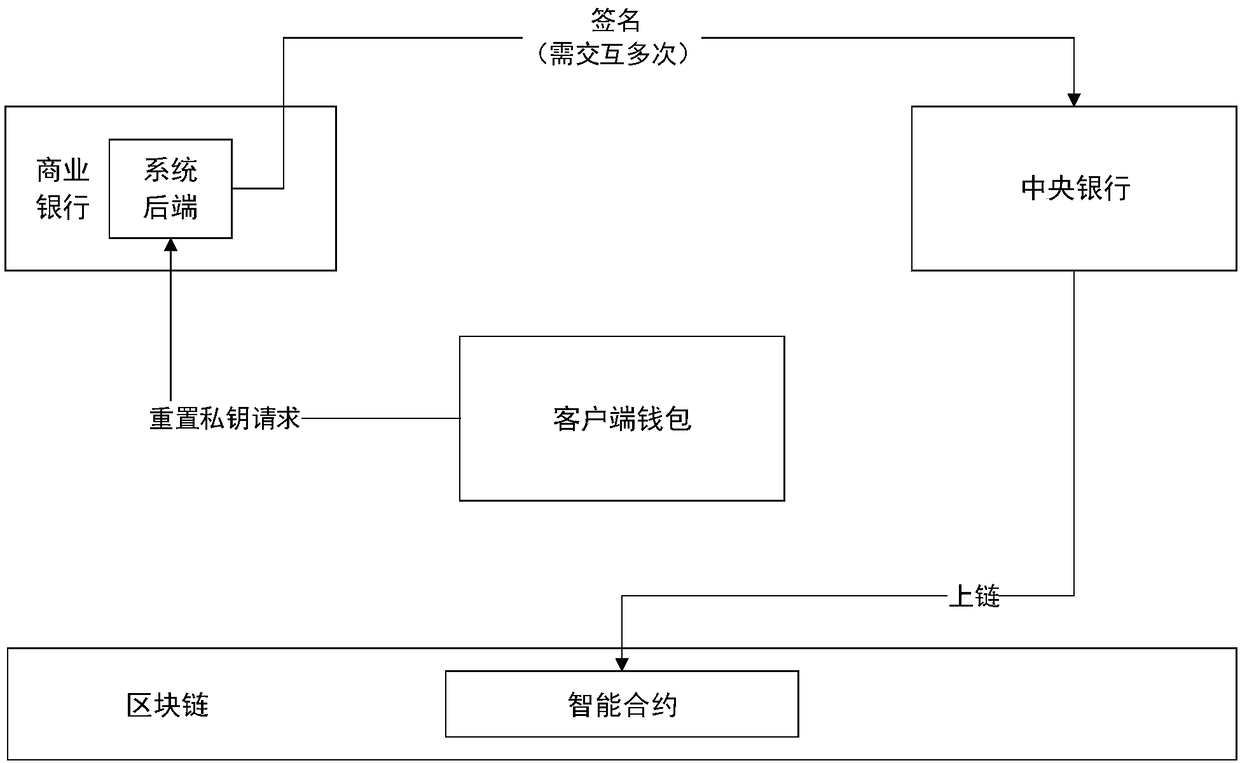

Threshold private key generation method, transaction method and relevant device

InactiveCN108921553AEnsure safetyLoss will not causeKey distribution for secure communicationMultiple keys/algorithms usageKey generationComputer security

The invention discloses a threshold private key generation method, a transaction method based on a threshold signature and a relevant device. According to the threshold private key generation method,a first terminal system generates an initial private key and generates three corresponding sub-private keys according to a (2,3) threshold scheme, wherein the first terminal system and a second terminal system can arbitrarily save one sub-private key and can send another sub-private key to a central bank system. Since all the sub-private keys are generated according to the threshold scheme, signing cannot be completed unless a joint signature of two sub-private keys is available, and danger cannot be caused event if one sub-private key is lost. Similarly, since the three sub-private keys are generated, signing can be completed event if one sub-private key is lost. Therefore, grasp of the private key by a private key legal owner is realized, and transaction security is guaranteed. Besides,since all the three sub-private keys correspond to one initial private key, only one time of signature checking is required. Meanwhile, since one sub-private key is saved in the central bank system, it can be guaranteed that the central bank participates in supervision.

Owner:中钞信用卡产业发展有限公司杭州区块链技术研究院

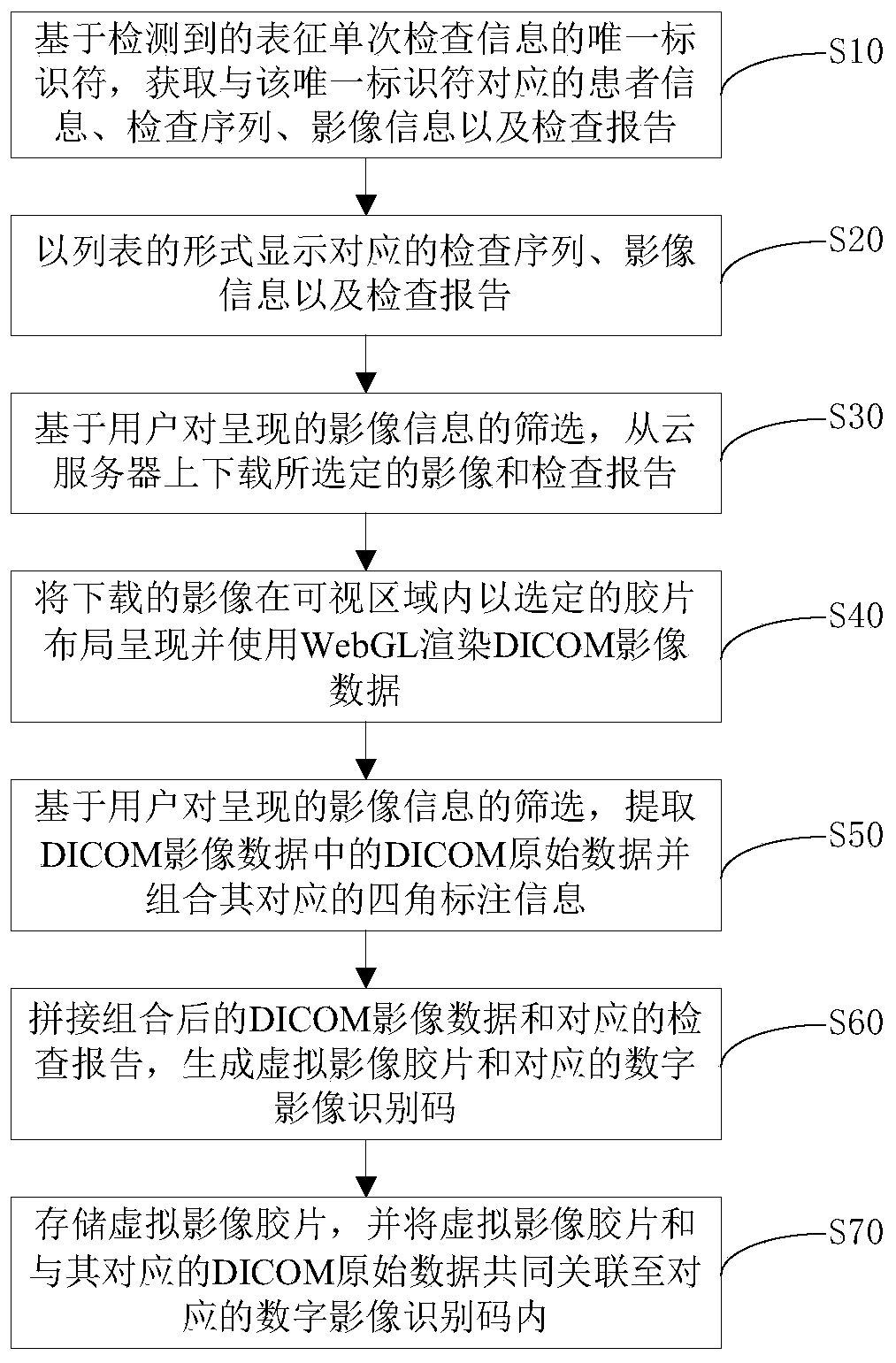

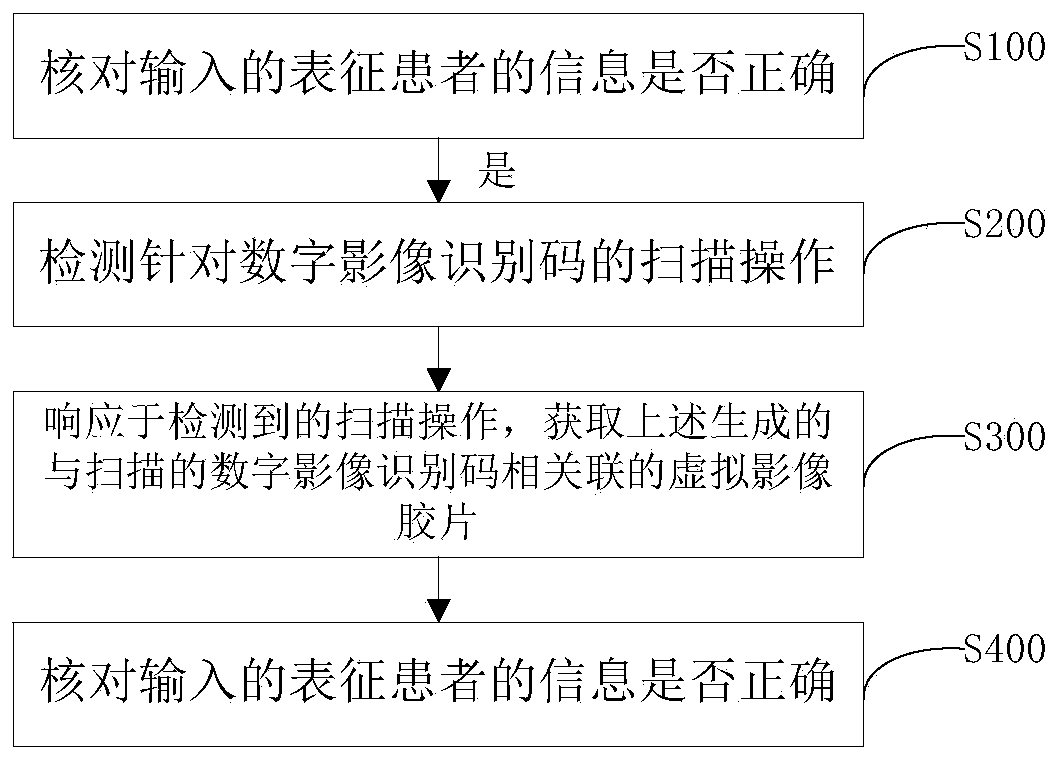

Web-based DICOM digital image and film printing method and system

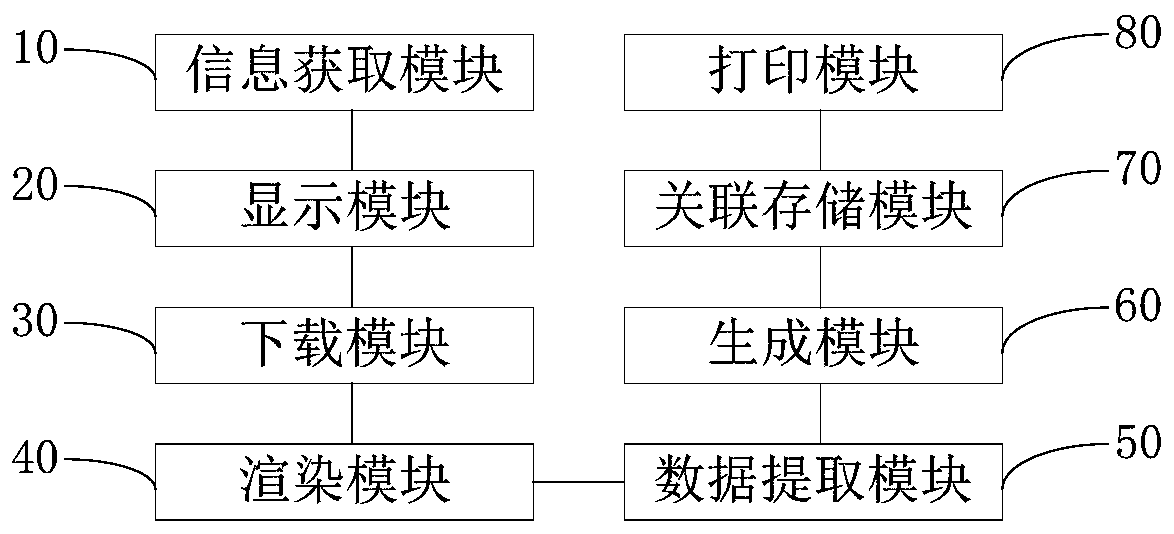

ActiveCN109859814AImprove the efficiency of medical treatmentRealize multiple printingMedical imagesInstrumentsDICOMOriginal data

The invention provides a web-based DICOM digital image and film printing method and system. The web-based DICOM digital image and film printing method includes the steps: based on a detected unique identifier representing single-check information, acquiring patient information, a check sequence, image information, and an inspection report corresponding to the unique identifier; displaying the corresponding check sequence, image information and inspection report in a list form; based on the user's screening of the presented image information, extracting the DICOM original data in the DICOM image data and combining the corresponding four-corner annotation information; splicing the combined DICOM image data and the corresponding inspection report to generate a virtual image film and a corresponding digital image identification code; detecting a scanning operation for the digital image identification code; and acquiring and printing the virtual image film associated with the scanned digital image identification code in response to the detected scanning operation.

Owner:浙江飞图影像科技有限公司

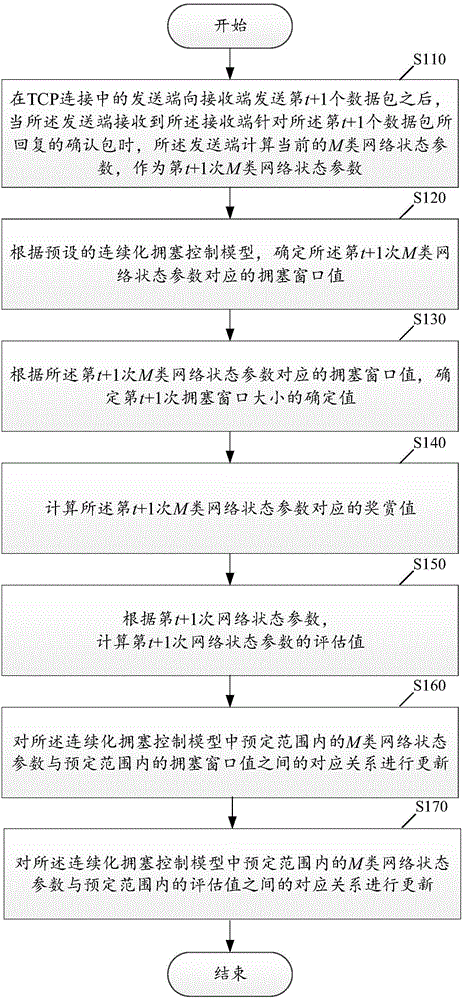

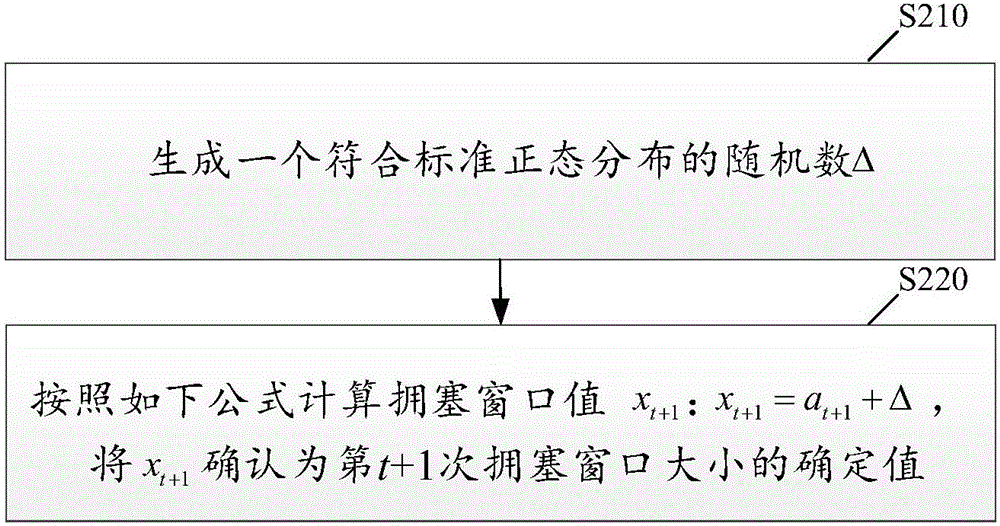

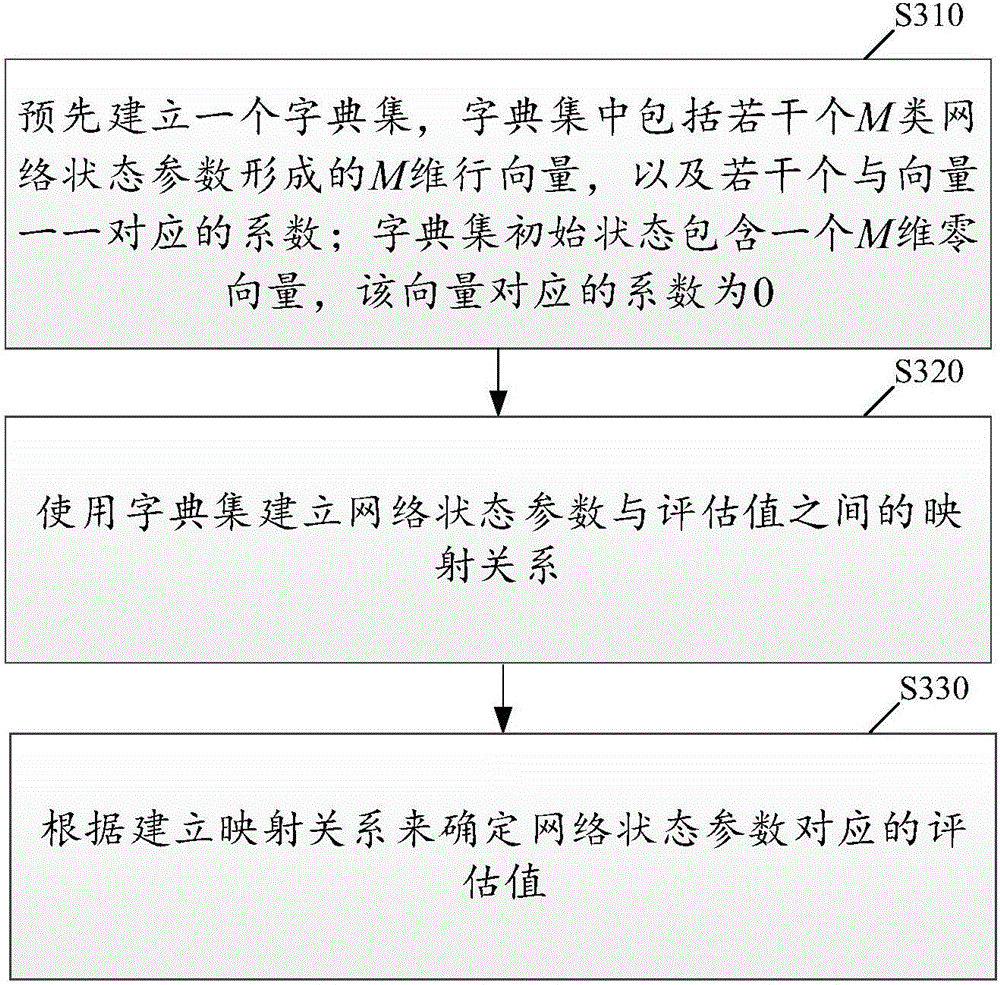

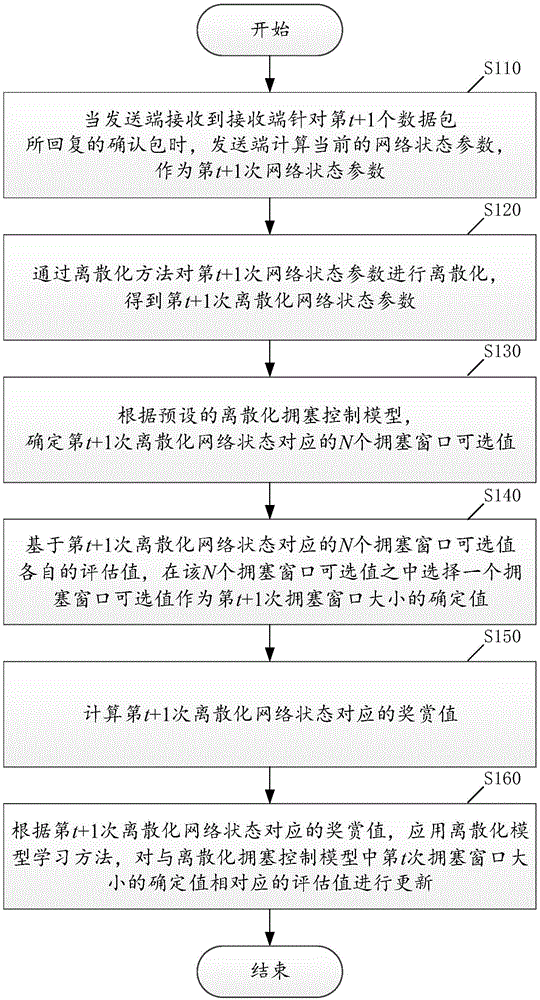

Network congestion control method based on serialization model

ActiveCN106385376AThe calculation result is accurateControl congestionData switching networksCongestion windowState parameter

The present invention provides a network congestion control method based on a serialization model. The method comprises: building a serialization congestion control model in advance, after sending (t+1)th data packet to a receiving terminal by a sending terminal in the TCP connection, when receiving the confirmation packet answered by the receiving terminal aiming at the (t+1)th data packet through the sending terminal, calculating the current network state parameters through the sending terminal, and taking the network state parameters as the (t+1)th M type network state parameters; according to the preset serialization congestion control model, determining the congestion window value corresponding to the (t+1)th M type network state parameters; according to the congestion window value corresponding to the (t+1)th M type network state parameters, determining the determination value of the size of the (t+1)th congestion window; and calculating the award value corresponding to the (t+1)th M type network state parameters, and determining the assessment value corresponding to the (t+1)th M type network state parameters to update the model. The network congestion control method based on the serialization model can effectively control the network congestion problem from the sending terminal.

Owner:孙广路

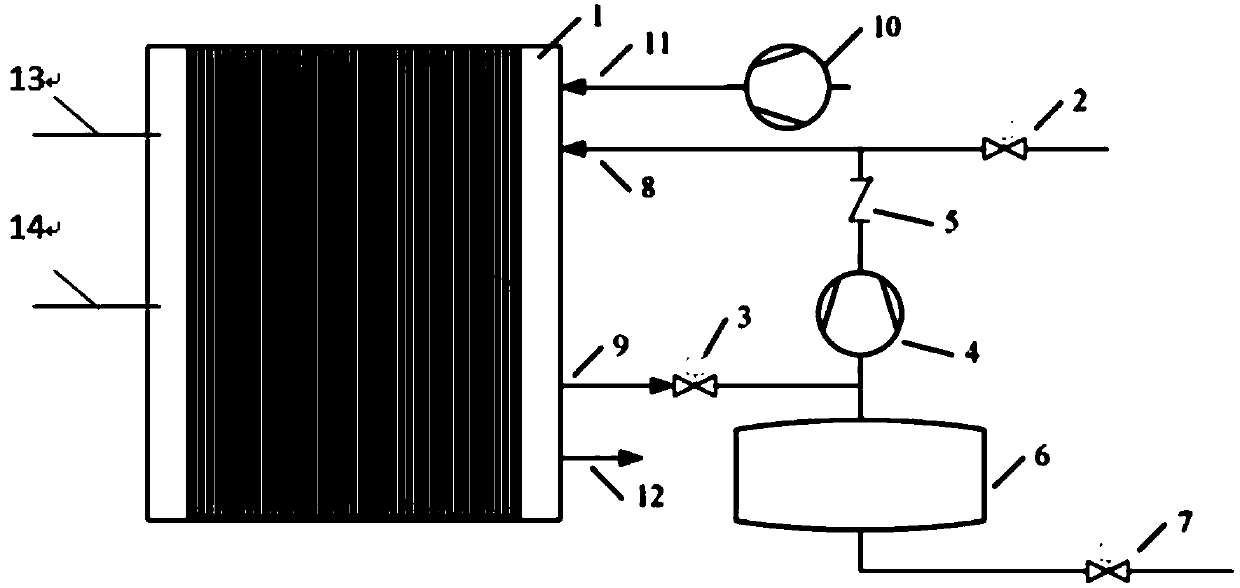

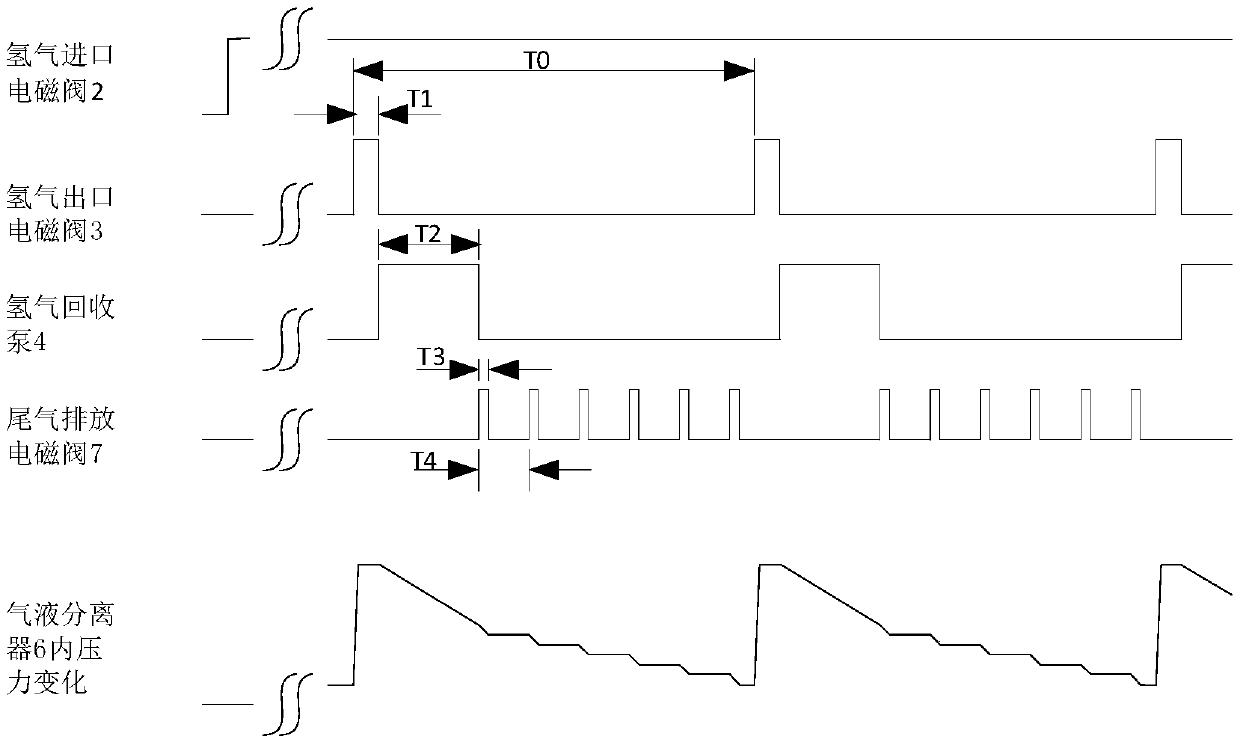

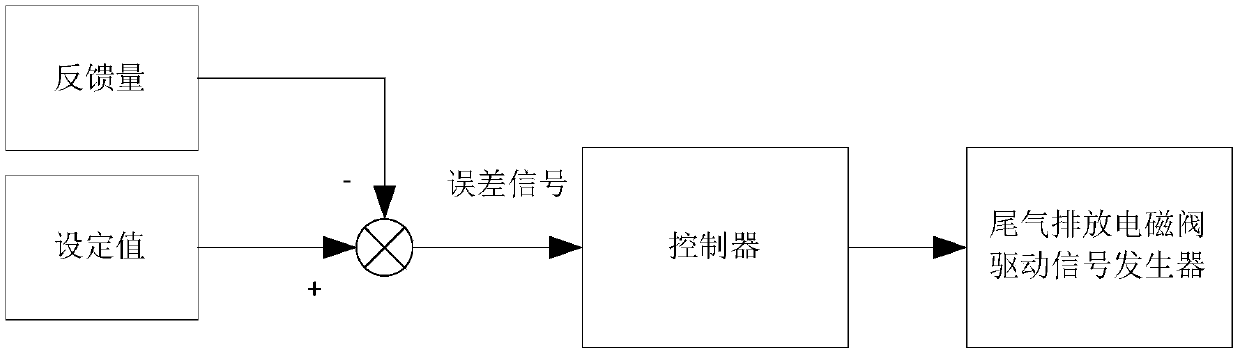

Tail gas emission control method for fuel cell hydrogen recovery system

ActiveCN110635153AMaintain stack performanceReduce hydrogen lossFuel cellsExhaust gasProcess engineering

Owner:上海氢尚新能源科技有限公司

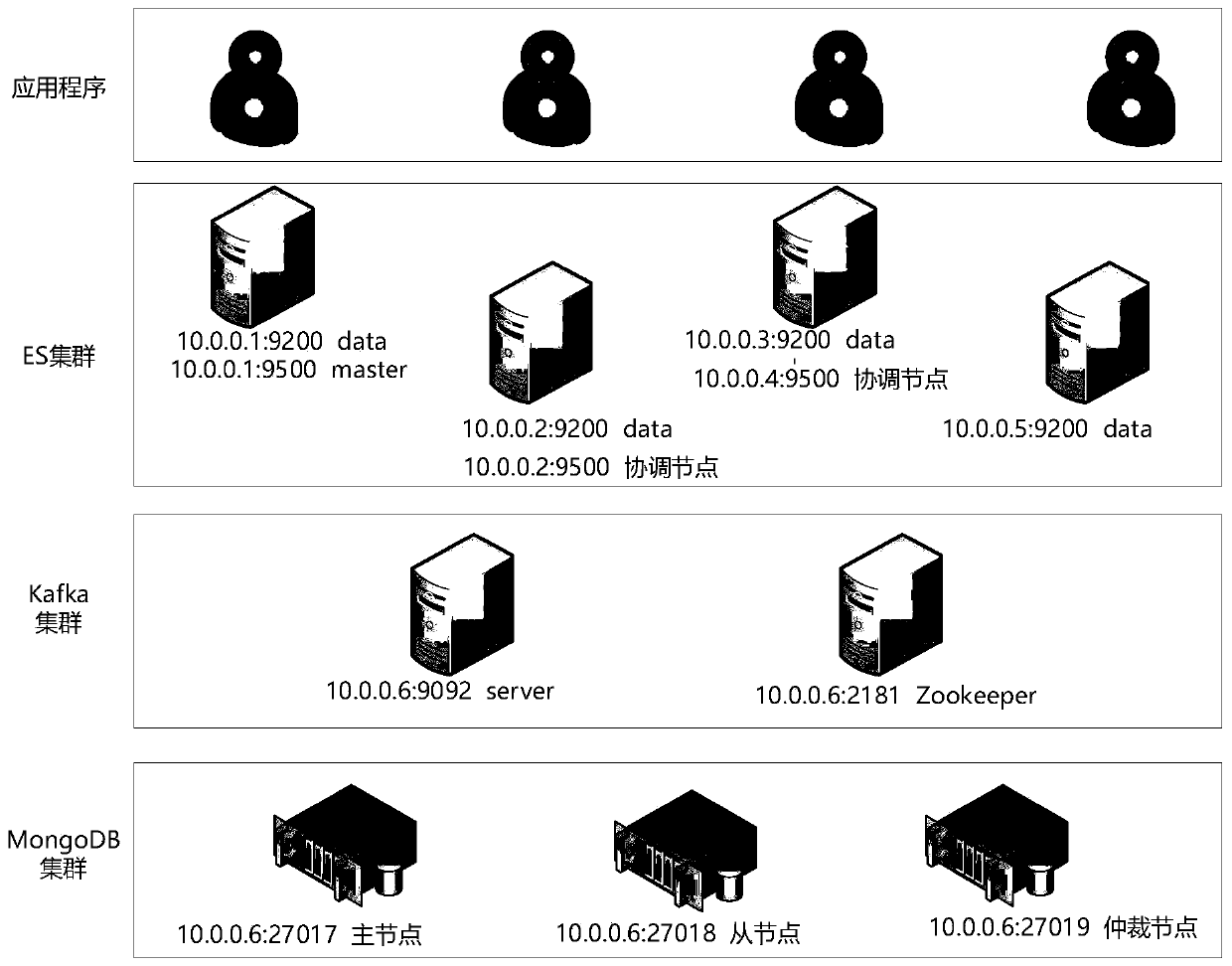

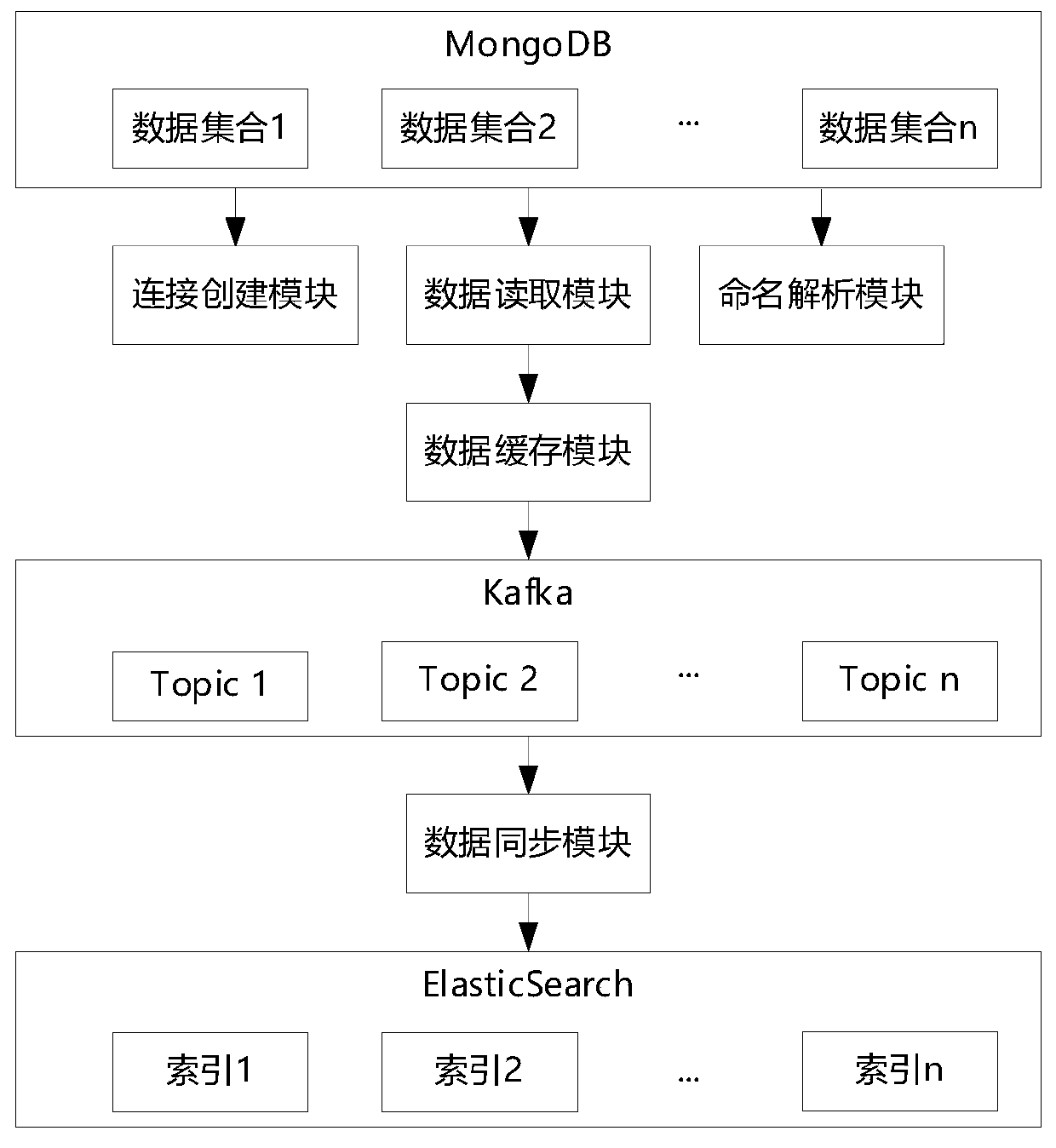

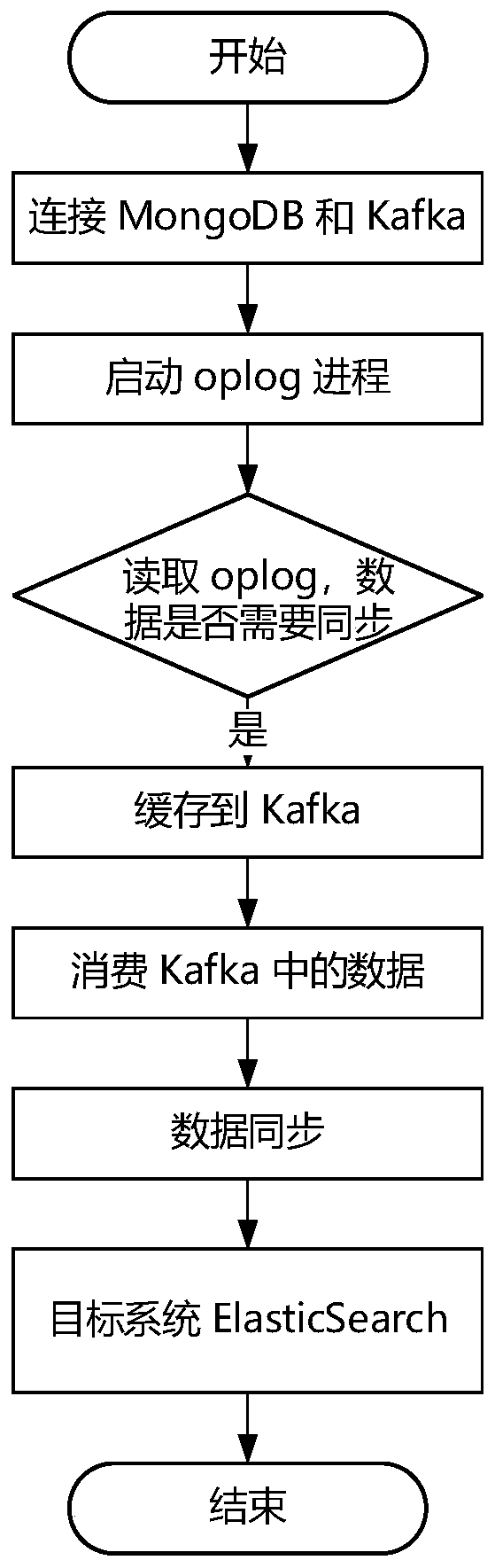

MongoDB data real-time synchronization method and system based on message queue

PendingCN111367991ASolve the lossLoss will not causeDatabase management systemsDatabase distribution/replicationMessage queueData synchronization

The invention provides a MongoDB data real-time synchronization method and system based on a message queue. The objective of the invention is to realize real-time data synchronization from MongoDB toElasticSearch of a target system. The problems that an original synchronization tool is low in synchronization rate in the data synchronization process and synchronization data is lost due to the rapid writing condition of MongoDB are solved, and rapid, accurate and reliable data synchronization from MongoDB to ElasticSearch is guaranteed.

Owner:INST OF INFORMATION ENG CHINESE ACAD OF SCI

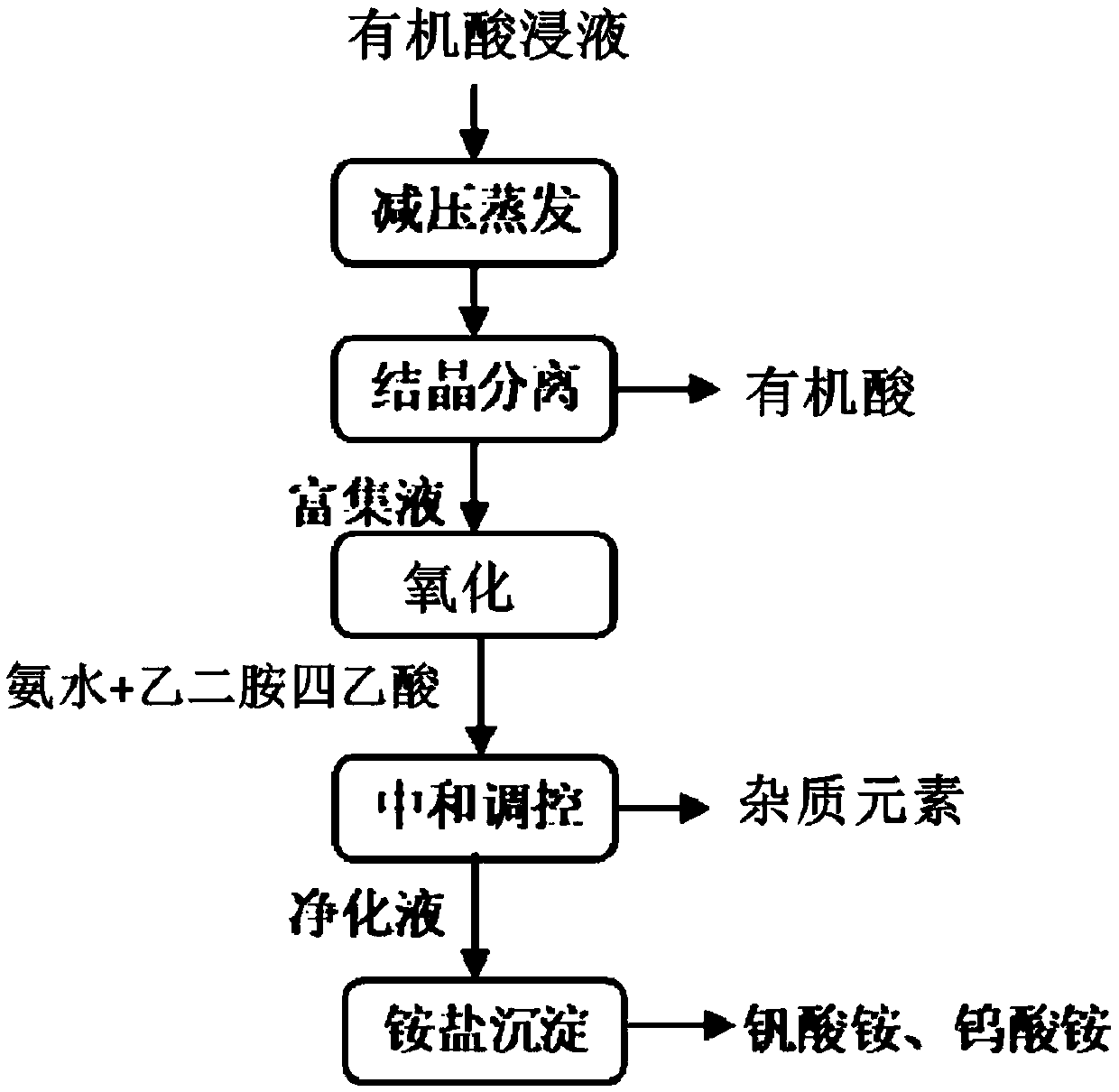

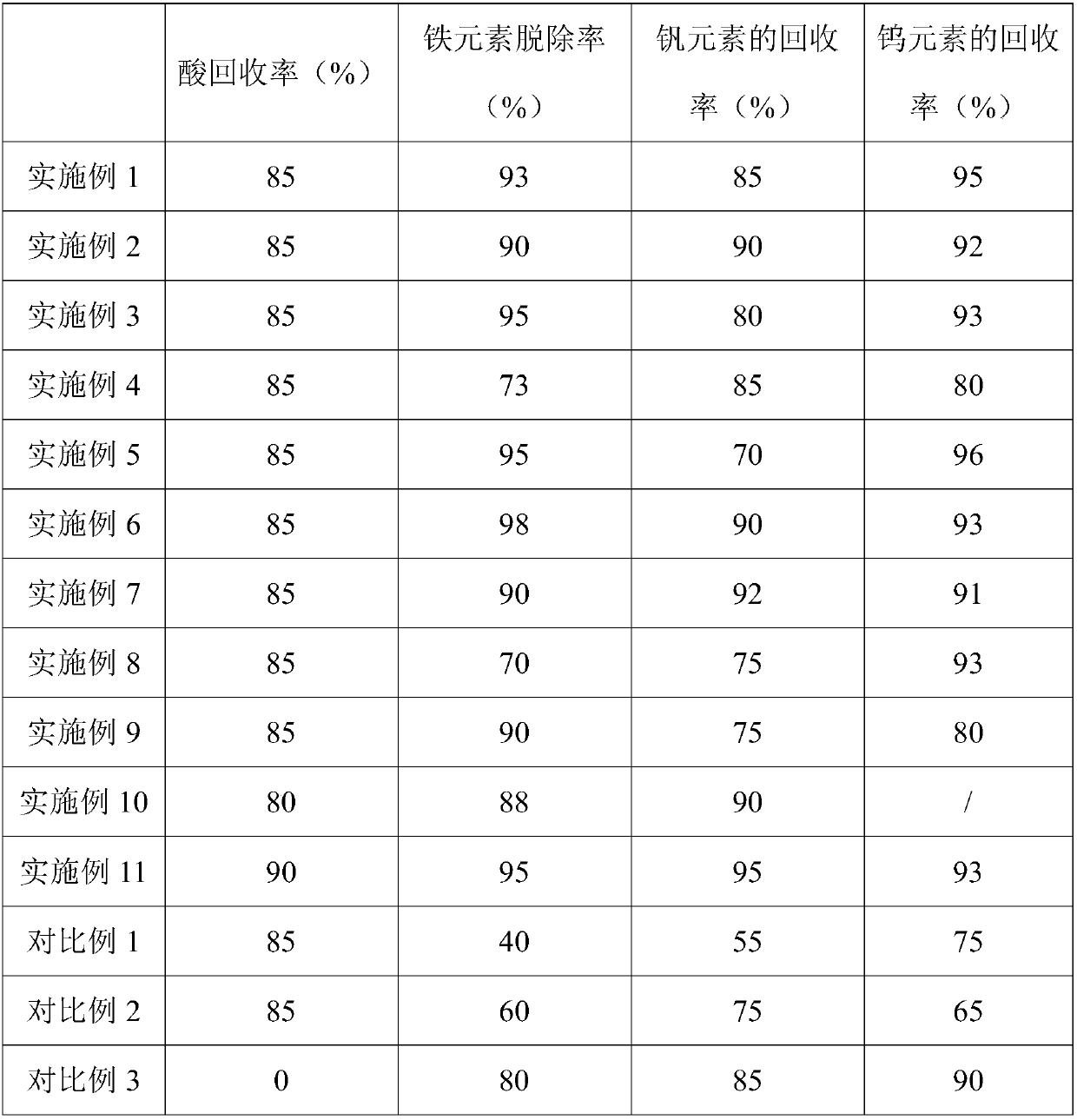

Method for recovering acid liquor and separating vanadium in process of reducing acid leaching vanadium-containing waste catalyst

ActiveCN111485105AImprove leaching rateAchieve recyclingProcess efficiency improvementVanadium CompoundsOrganic acid

The invention relates to a method for recovering acid liquor and separating vanadium in a process of reducing an acid leaching vanadium-containing waste catalyst. The method comprises the following steps: (1) carrying out acid leaching on the vanadium-containing waste catalyst by using an organic acid to obtain an organic acid leaching solution, and separating the organic acid to obtain an enrichment solution; and (2) oxidizing the enrichment solution, removing iron elements in the oxidized enrichment solution to obtain a purification solution, and then carrying out a vanadium element precipitation process on the purification solution to obtain a recovery product, wherein the recovery product is a vanadium compound. According to the method, the organic acid is recovered at first, the recovery rate reaches 80-90%, then the enrichment solution is oxidized, Fe2+ and V4+ in the enrichment solution are oxidized into Fe3+ and V5+ in the oxidation process, then the iron element is removed, the loss of the vanadium element in the iron element removal process is avoided, and the recovery rate of the vanadium compound is improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

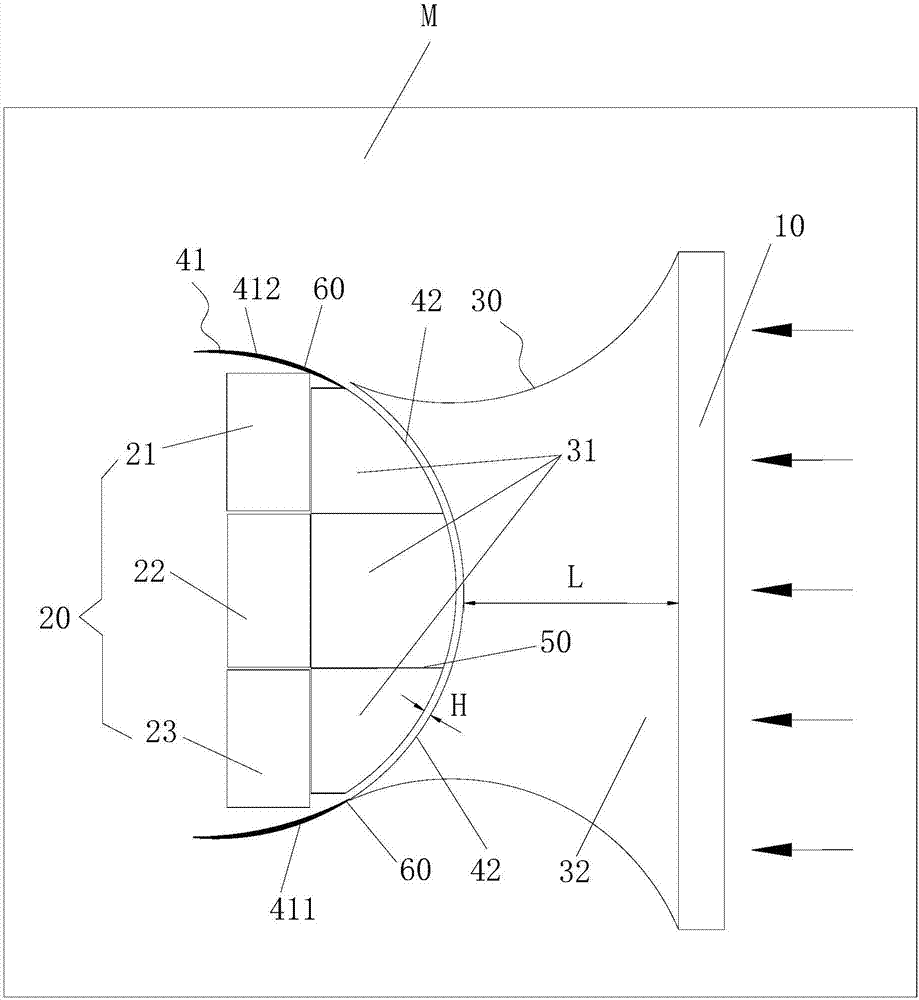

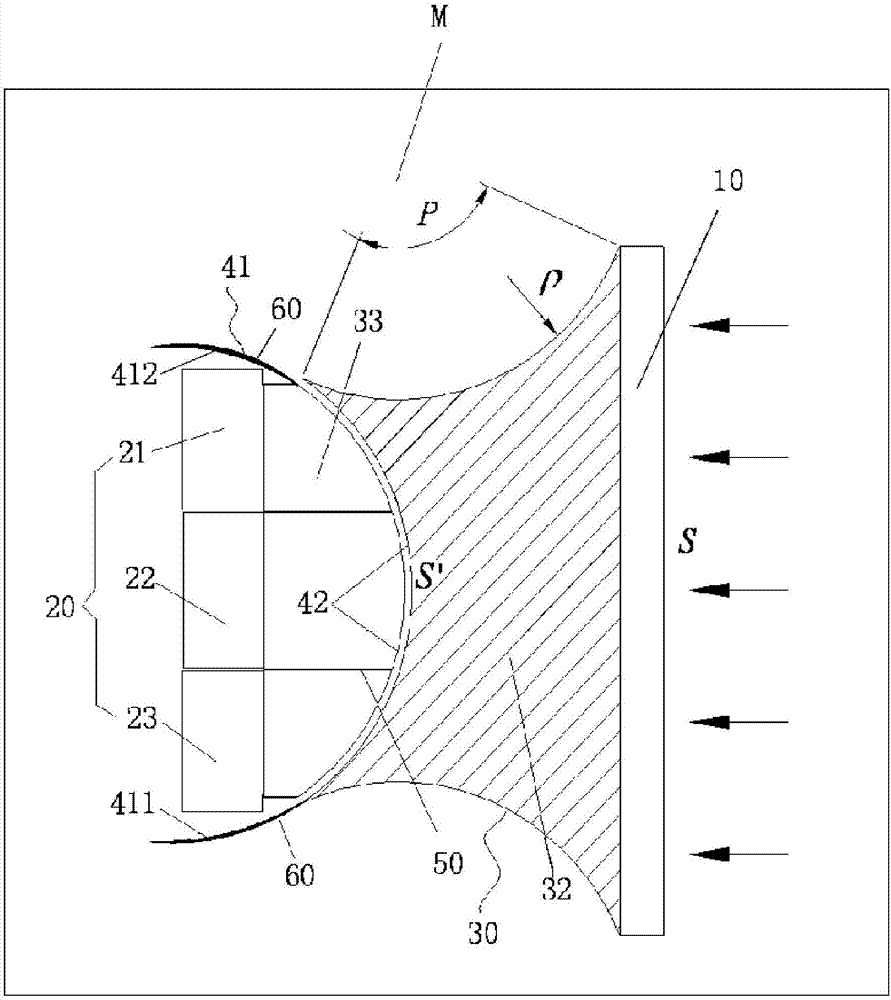

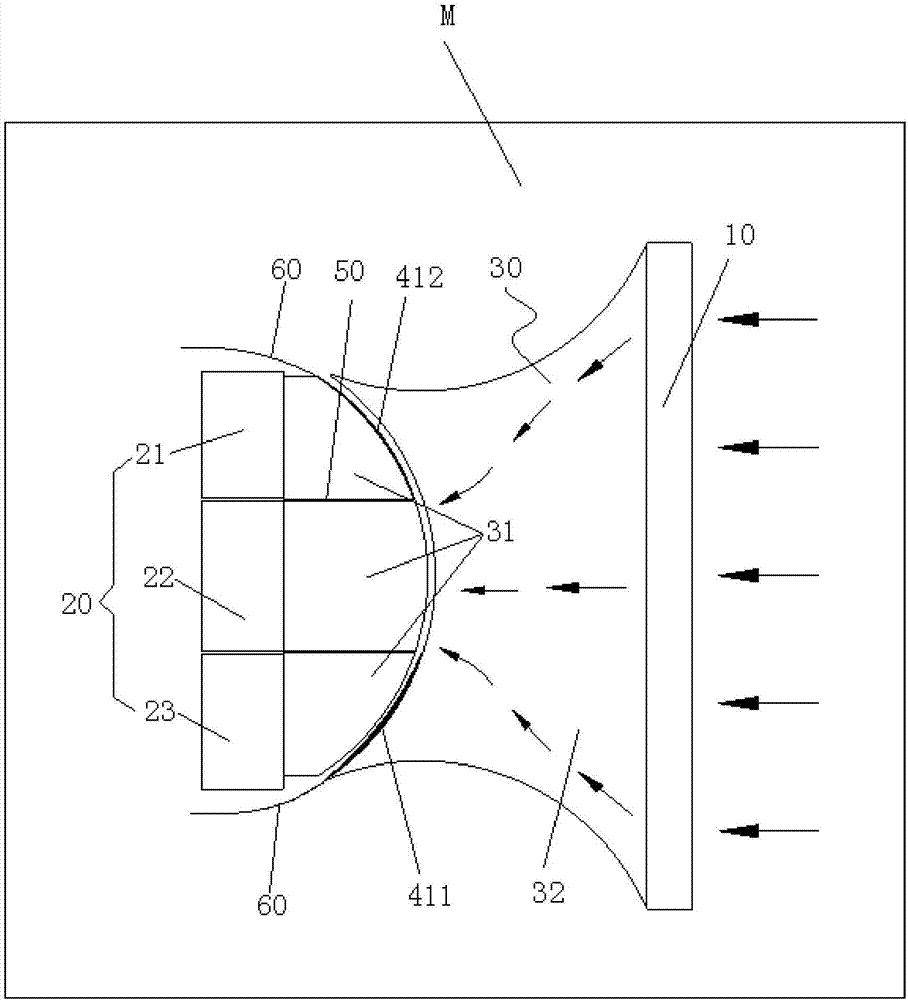

Air conditioner

PendingCN107975871ANo lossLoss will not causeLighting and heating apparatusAir conditioning systemsEngineeringHeat exchanger

The invention provides an air conditioner which comprises a heat exchanger body, a plurality of draught fans, a flow guiding structure and an air duct shielding mechanism, wherein the draught fans arearranged in sequence; the flow guiding structure is arranged between the heat exchanger body and the draught fans; air ducts which correspond to the draught fans in a one-to-one manner are arranged at the end, close to the draught fans, of the flow guiding structure; and shielding parts of the air duct shielding mechanism can enter at least on air duct so as to cut off the communication between the heat exchanger body and the corresponding draught fan. By adoption of the air conditioner provided by the invention, the problem that a conventional air conditioner is relatively low in heat exchange efficiency and heat exchange capacity can be effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC

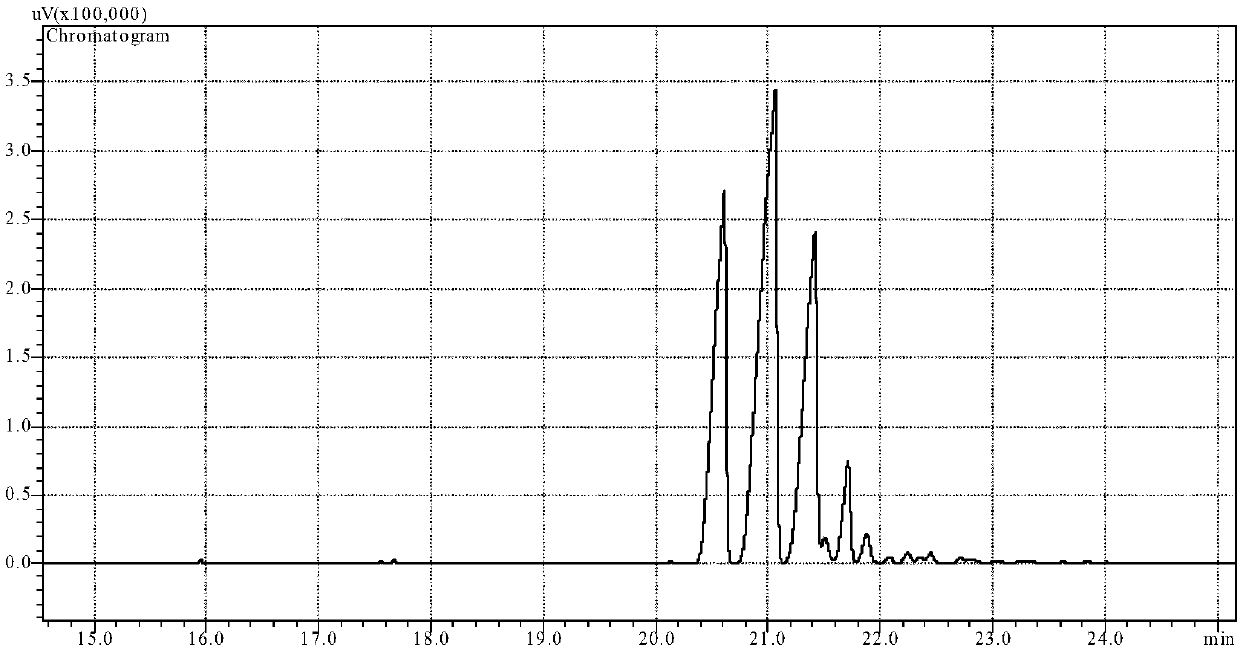

Preparation method of high-purity tricresyl phosphate

ActiveCN109593099AAchieve high purityReduce lossesGroup 5/15 element organic compoundsDistillationPlasticizer

The invention relates to a preparation method of high-purity tricresyl phosphate. The preparation method comprises the following steps: (S1) with mixed cresol and phosphorus oxychloride as the raw materials and Lewis acid as a catalyst, simultaneously adding the raw materials and the catalyst into a reactor, and reacting to obtain a crude product of tricresyl phosphate, wherein the mass percentageof o-cresol in mixed cresol is lower than 0.01%; (S2) carrying out reduced-pressure distillation on the crude product of tricresyl phosphate until the acid value of the crude product of tricresyl phosphate is less than or equal to 3mgKOH / g; and (S3) carrying out molecular distillation on the tricresyl phosphate crude product with the acid value less than or equal to 3mgKOH / g. The preparation method is simple, convenient, low in production cost, high in product purity and suitable for industrial production. High-purity tricresyl phosphate prepared by virtue of the preparation method is suitable for the fields of aviation fuel base oil, plasticizers, flame retardants, lubricating oil extreme-pressure anti-wear agents and the like.

Owner:PETROCHINA CO LTD

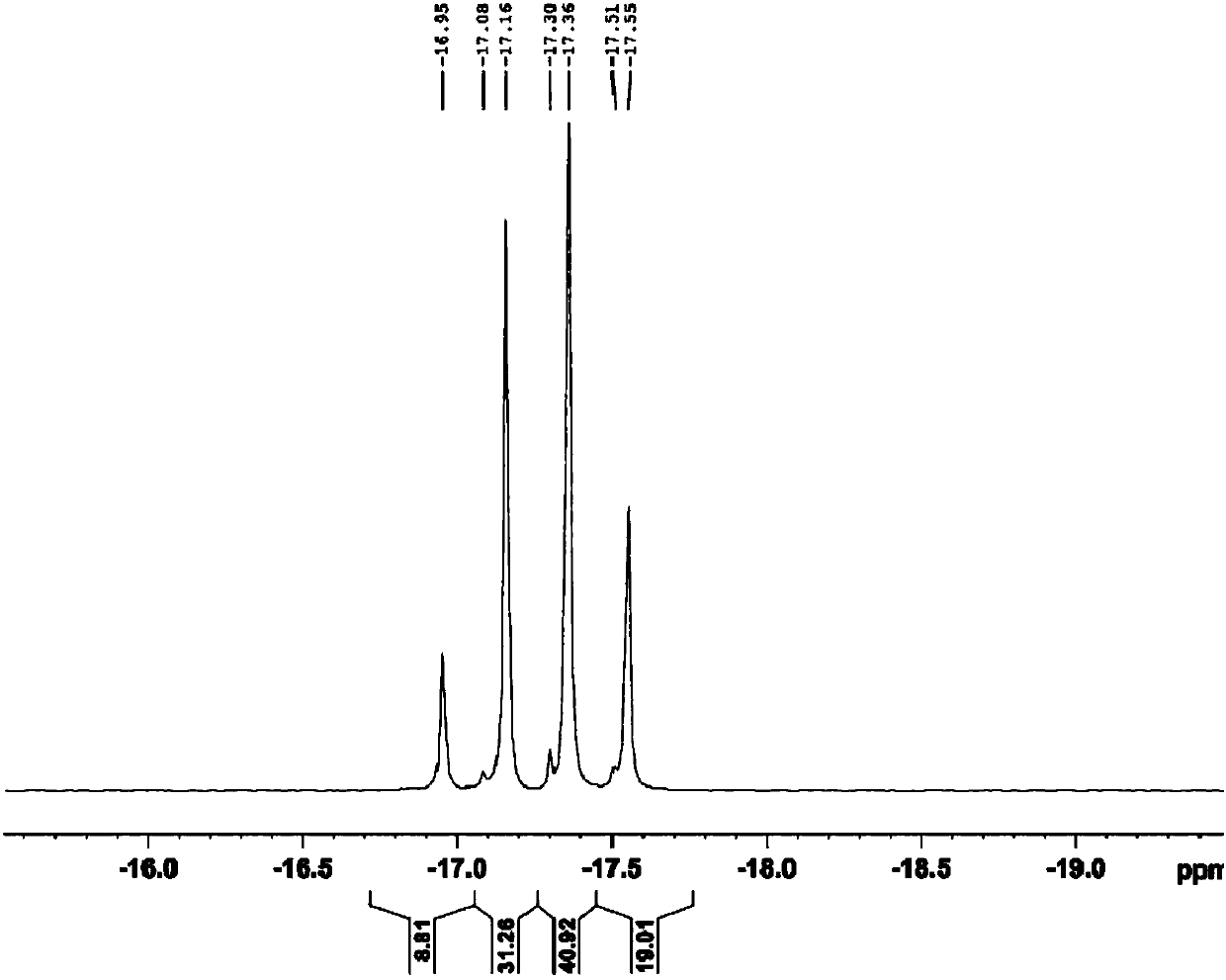

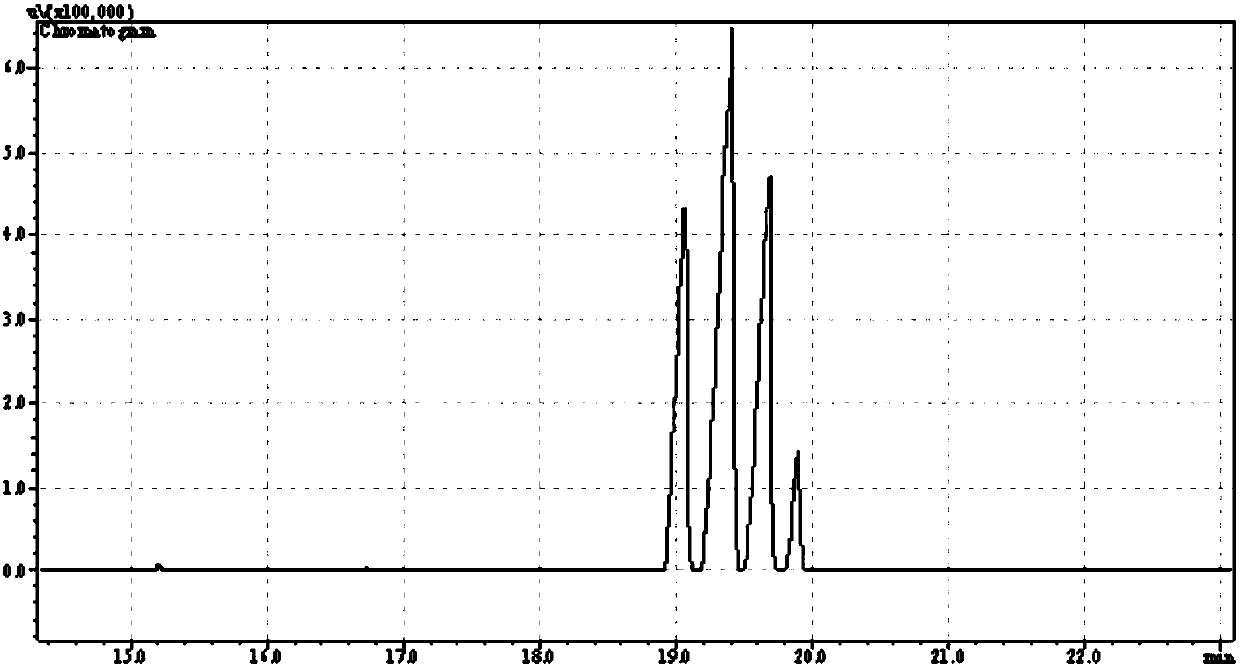

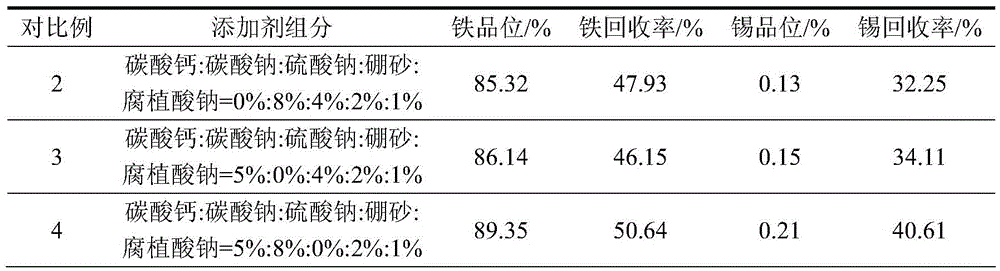

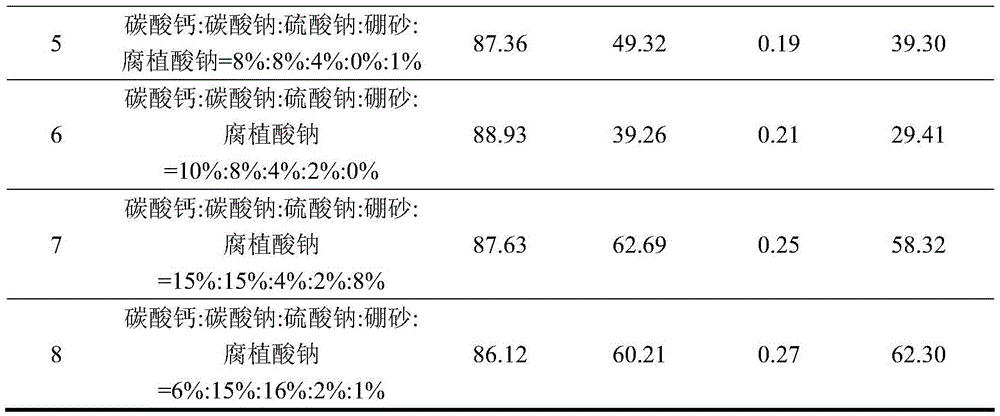

Method for preparing tin-iron coarse alloy powder from tin containing iron ore

The invention discloses a method for preparing tin-iron coarse alloy powder from tin containing iron ore. The method includes the steps that after being broken and ground, the tin containing iron ore is mixed with a composite additive formed by calcium carbonate, sodium carbonate, sodium sulfate, borax and sodium humate for agglomeration; obtained agglomerates are dried and then subjected to high-temperature reducing roasting; the products obtained after reducing roasting are sequentially cooled, broken and ground, and then are subjected to magnetic separating, and the coarse alloy powder is obtained. The method has the advantages that the requirement on the raw materials is low, the tin-iron comprehensive recovery rate is high, the flow is simple, energy consumption is low, and environment friendliness is achieved, and the prepared coarse tin-iron alloy powder can directly serve as raw materials for smelting tin containing easy-to-cut steel and tin containing alloy cast iron.

Owner:CENT SOUTH UNIV

Secret image camouflage recovery method by combining secret key and random orthogonal tensor basis

ActiveCN108717683AGuaranteed to be strictly orthogonalGuaranteed fitting accuracyGeometric image transformationRecovery methodAlgorithm

The invention discloses a secret image camouflage recovery method by combining a secret key and random orthogonal tensor basis. The method comprises the following steps: firstly dividing a secret image and a public image into equal number of small matrix blocks, and constructing random orthogonal tensor basis by using a unit orthogonal matrix generated by the secret key; secondly, performing sufficient and effective linear expression on small secret image blocks by solving the projections on the random orthogonal tensor basis on the small secret image blocks, selecting the front k projection coefficients with large amplitude and energy from the projection and recording an index location to construct a line sequence and a row sequence; and secondly embedding the selected projection coefficient, the line sequence and the row sequence into the corresponding public small image blocks through a secret-writing method for performing tiny adjusting and large-capacity embedding on the public image, thereby forming a channel public transmission image; and finally reconstructing the secret image through a conversion parameter extracted from the channel public transmission image and by combining the secret key.

Owner:SHAANXI NORMAL UNIV

Audio frequency camouflage and recovery method that combines secret key with random unit orthogonal basis

ActiveCN108877818AGuaranteed fitting accuracyExpress fully and effectivelyKey distribution for secure communicationGeometric image transformationRecovery methodOrthogonal basis

The invention discloses an audio frequency camouflage and recovery method that combines a secret key with random unit orthogonal basis; the method comprises the following steps: firstly dividing a secret audio frequency and a public audio frequency into small segment sequences of the same quantity, and using the secret key to build the random unit orthogonal basis; secondarily, solving the projection of the secret audio frequency small segment sequence on the random unit orthogonal basis so as to fully, effectively and linearly express the secret audio frequency small segment sequence, selecting first k projection factors with large amplitude and energy and recording index positions, and thus forming an index sequence; finely adjusting the public audio frequency and using a high capacity built-in secret writing method to embed the selected projection factors and a line sequence into the corresponding public audio frequency small segment sequence, thus forming a channel public transmission audio frequency; using transform parameters extracted from the channel public transmission audio frequency, and combining with the secret key so as to reconstruct the secret audio frequency. Compared with the prior art, the method can reconstruct the secret audio frequency with different precisions, and strictly depends on the user secret key, thus providing a higher safety.

Owner:SHAANXI NORMAL UNIV

Use method of lignin in phenolic resin molding compound

InactiveCN112143246AImprove plasticityImprove heat resistanceCompression moldingPlastic injection molding

The invention discloses a use method of lignin in a phenolic resin molding compound. The use method specifically comprises the following operation steps: S1, preparing a proportioning base solution; S2, preparing mixed raw materials; S3, mixing liquefied lignin; S4, mixing talcum powder; S5, mixing heavy calcium carbonate Sanfei powder; S6, mixing liquefied stearic acid; S7, curing a mixed solution; S8, carrying out compression molding; S9, carrying out solid-phase molding; S10, detecting quality. Lignin is added in the high-strength plastic injection molding process, the problem of consumables at present is solved, and the heat resistance of the plastic mold is improved by adding the stearic acid solution; the talcum powder is added into the mold, so that the strength of the mold is improved, and the impact resistance of the mold is improved; by adding the heavy calcium carbonate Sanfei powder into the mold in a mixed manner, the stability of the whole mold can be improved; by designing and adding waste plastic bags and rubber into the plastic mold, the plasticity and high elasticity of the plastic mold are improved, and cyclic utilization of resources is achieved.

Owner:周静

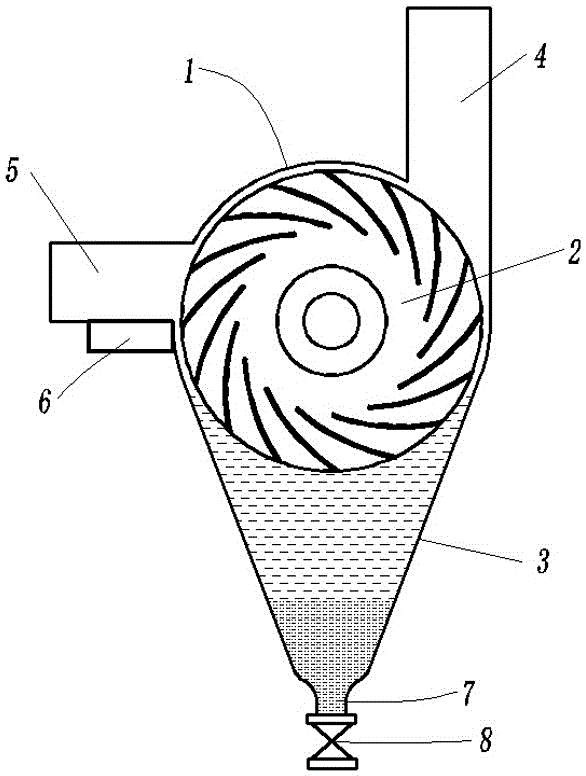

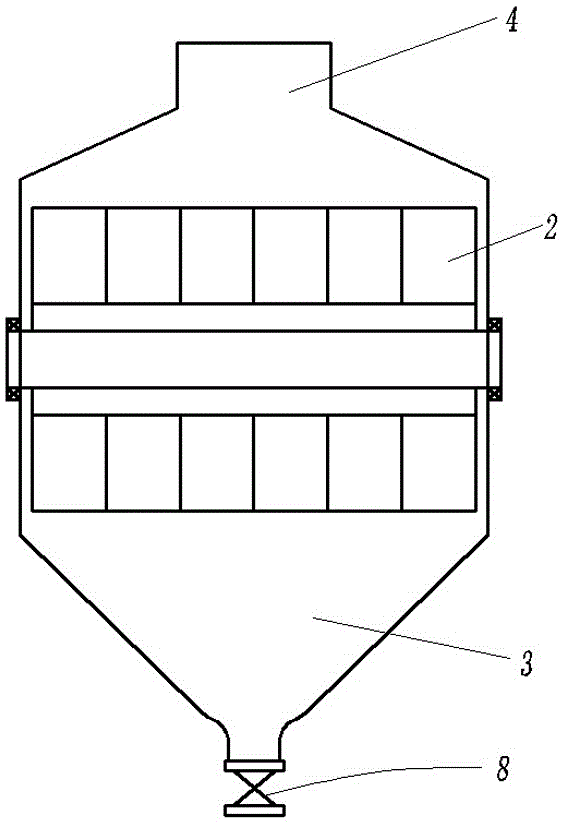

Wet impeller dust collector

InactiveCN107433099AMake up for pressure lossMake up for the lossCombination devicesImpellerSemi open

The invention relates to the technical field of dust collectors, in particular to a wet impeller dust collector which comprises a cylindrical shell and a plurality of semi-open impellers. The semi-open impellers are arranged in the shell and coaxial with the shell, a vertical air outlet is formed in one side of the upper end of the shell, a horizontal air inlet is formed in the other side of the upper end of the shell, a detachable sand settling box is arranged at the lower end of the air inlet, a linear funnel is arranged at the lower end of the shell, a drain outlet is formed in the lower end of the funnel and provided with a valve, the shell is filled with liquid medicines, and the liquid level of the liquid medicines is lower than the air inlet. The wet impeller dust collector has efficient dust collection effects, and pressure loss of a system is avoided.

Owner:申青林

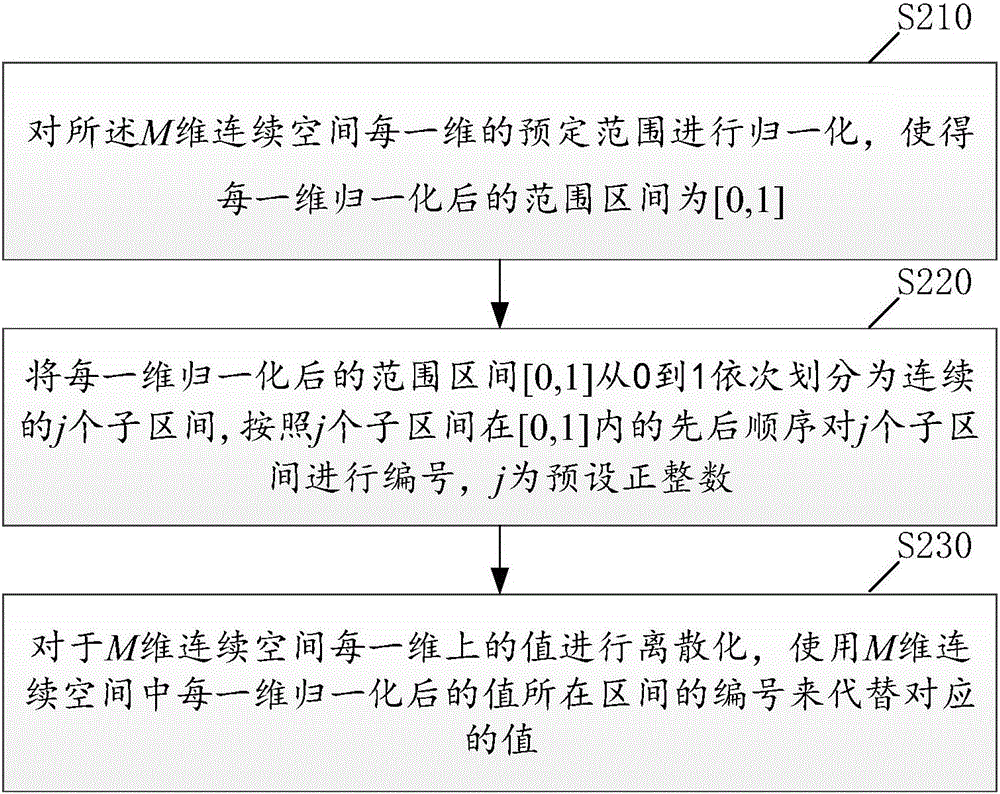

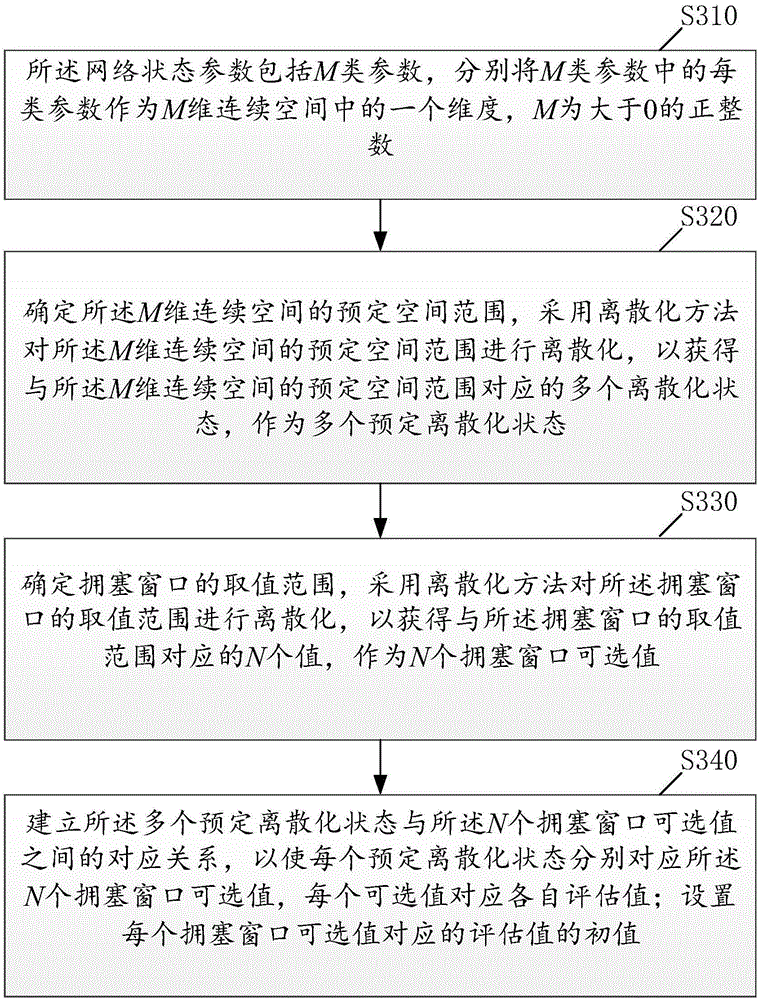

Network congestion control method based on discrete model

ActiveCN106130927AControl congestionLoss will not causeData switching networksCongestion windowState parameter

The present invention provides a network congestion control method based on a discrete model. The method comprises the following steps: establishing a discrete congestion control model in advance; obtaining the discrete network state of the current transmitting end through discretization of current network state parameters of the transmitting end; corresponding the network state to the preset discrete network state, where all the parameters are the same, of the discrete congestion control model; selecting a proper congestion window optional value as the determined value of the current congestion window size of the transmitting end; and applying a discrete model learning method to update the assessed value corresponding to the determined value of the last congestion window size, through calculation of the corresponding reward value of the current network state. The network congestion control method is able to effectively control network congestion problems from transmitting ends.

Owner:HARBIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com