Automatic production system for metal gravity casting

A gravity casting and production system technology, applied in foundry workshops, casting equipment, metal processing equipment, etc., can solve problems such as high probability of misoperation, low pass rate, and diffuse exhaust gas, so as to achieve low probability of equipment misoperation and reduce the risk of injury probability, the effect of ensuring efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical solution of the present invention clearer, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

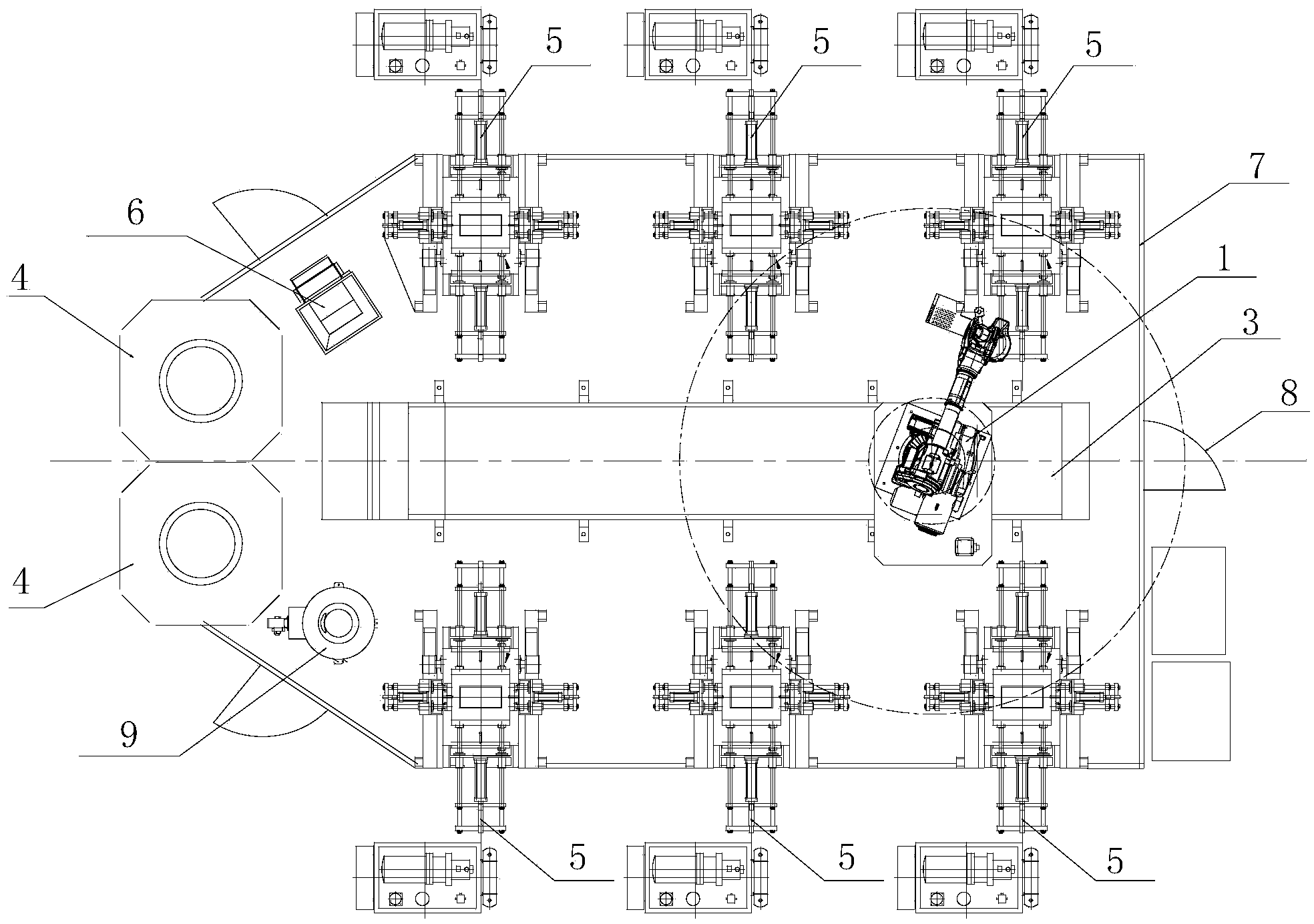

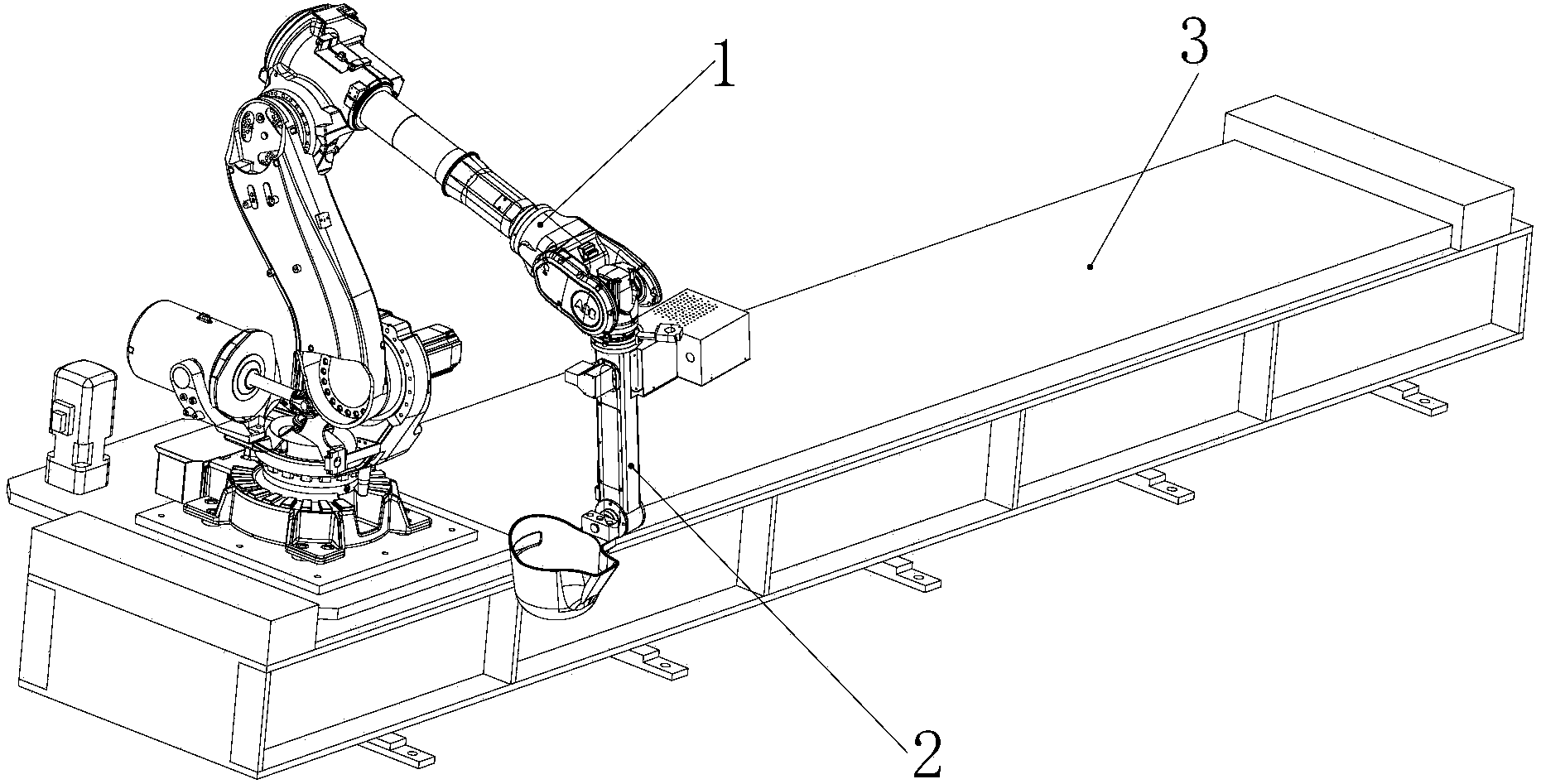

[0046] See Figure 1 ~ Figure 12 , The metal gravity casting automated production system in this embodiment includes a robot 1, a sliding table 3 on which the robot moves, a holding furnace 4 for supplying molten metal to the robot, and a gravity casting machine arranged on both sides of the sliding table 1. 5. Oxide scale removal and collection device 6. Control system (not shown in the figure). The aforementioned devices are all set in the production area enclosed by the guardrail 7, and the production area has a safety gate 8.

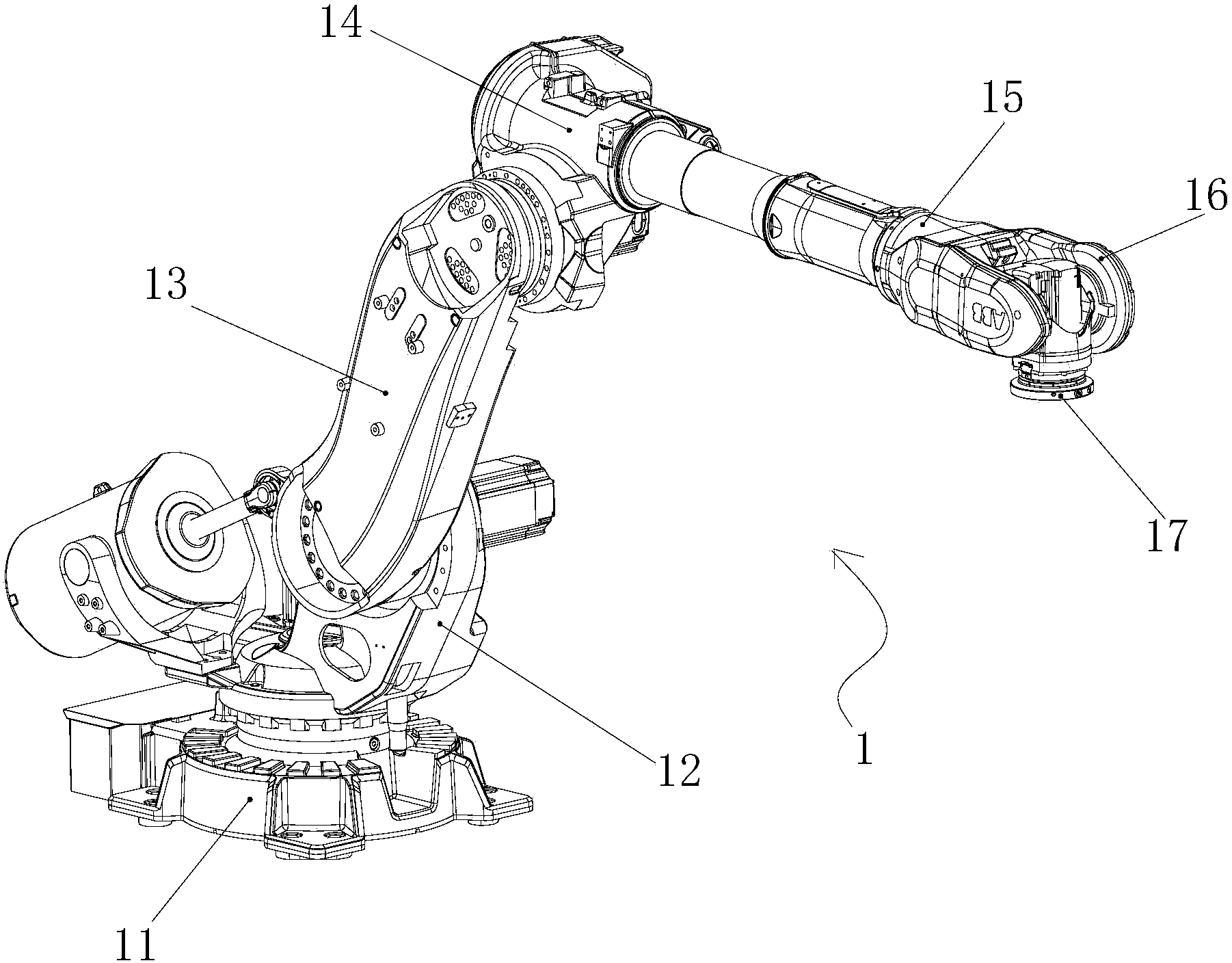

[0047] Wherein, the robot 1 adopts a six-axis robot in the prior art, which includes a body 11, a first axis 12, a second axis 13, a third axis 14, a fourth axis 15, a fifth axis 16, and a sixth axis 17; A liquid extraction arm 2 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com