Multi-section tandem type drying device

A drying device, a series-connected technology, applied in the directions of drying, drying machine, drying gas arrangement, etc., can solve the problem of no data disclosure, and achieve the effect of prolonging drying time and long drying time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

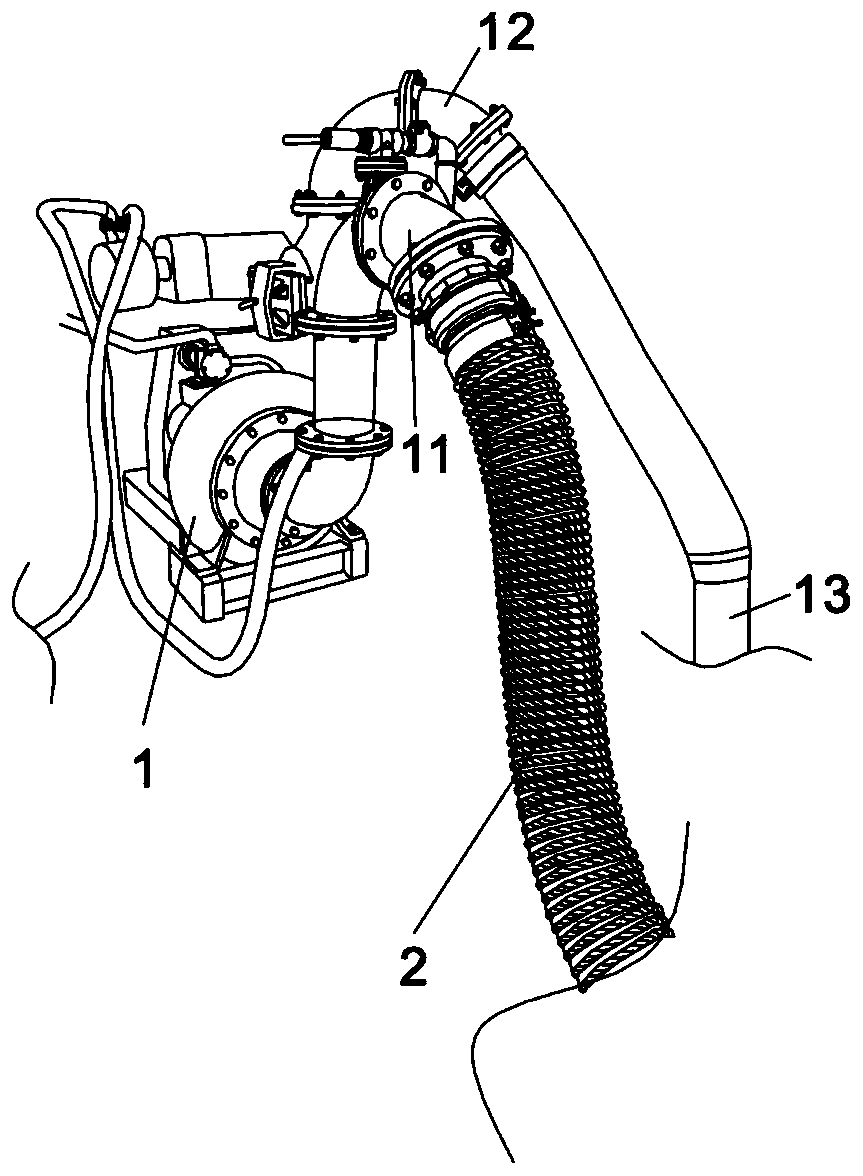

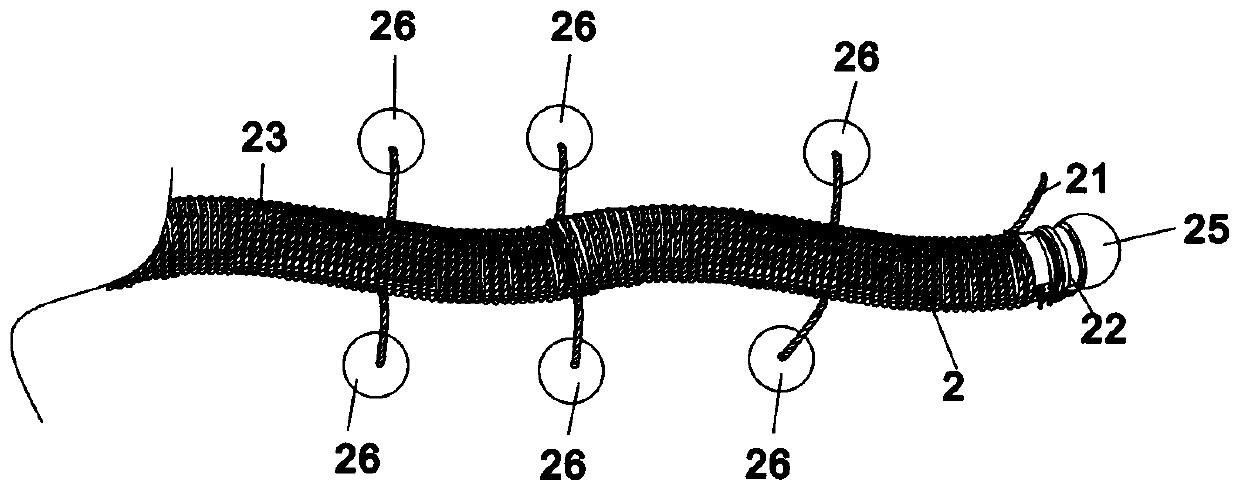

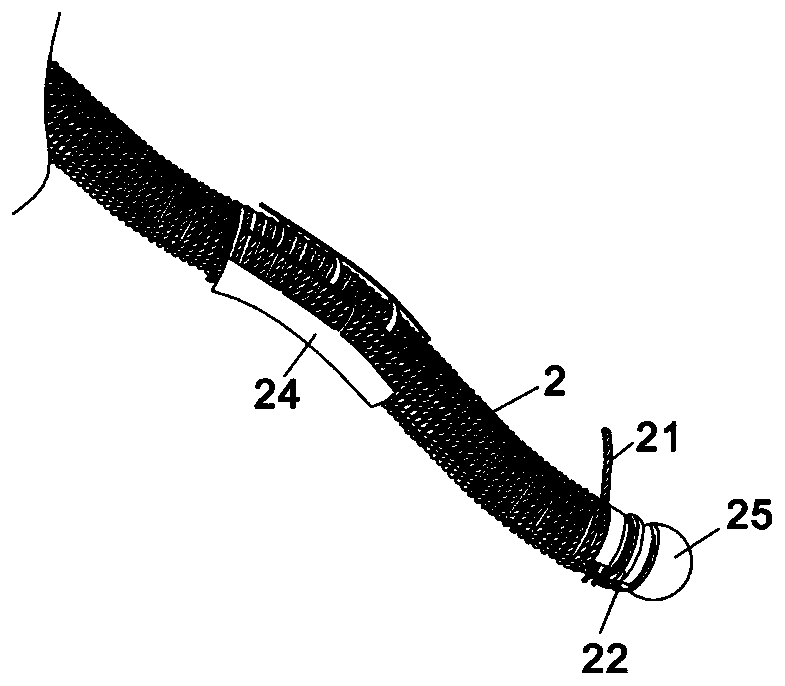

[0255]Embodiment 1 Multi-stage serial drying device, including multi-stage serial ovens, the previous oven and the rear oven are connected by conveyor belts, the ovens are divided into at least two groups, each oven group has at least one oven, and all ovens The feeding and discharging directions are the same, the entrance of the first-stage oven is used as the entrance of the current oven group, and the outlet of the last-stage oven is used as the outlet of the current oven group; a transfer conveyor belt is set between adjacent oven groups, and the transfer conveyor belt will be The output of one oven group is transported to the input of the other oven group; the previous stage oven and the subsequent stage oven are connected by the upper lifting conveyor belt, the feeding part of the upper lifting conveyor belt is lower than its discharging part, the upper lifting conveyor The feeding part of the conveyor belt undertakes the discharge of the previous stage of oven, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com