Quick sleeve-fish drying equipment

A rapid drying technology for squid, applied in drying, drying machines, lighting and heating equipment, etc., can solve the problems of poor drying effect due to uneven heating of squid, reduce the tension on the surface of the conveyor belt, etc., and achieve enhanced The effect of the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

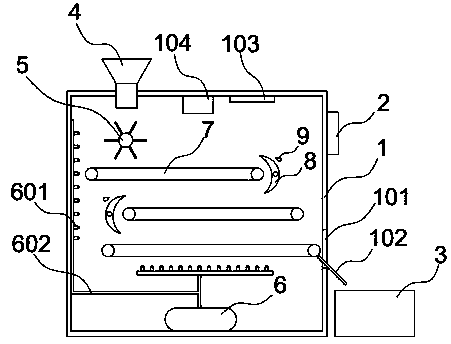

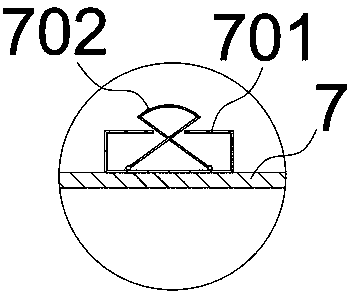

[0020] Such as figure 1 As shown, the quick squid drying equipment includes a housing 1, the top of the housing 1 is connected with a feed hopper 4, the inside of the housing 1 below the feed hopper 4 is provided with a number of conveyor belts 7 for transferring materials, and the bottom of the housing 1 A heat pump 6 for heating air is provided, a discharge port 101 is provided on the bottom side of the casing 1, a rotatable distribution cylinder 5 is provided between the feed hopper 4 and the uppermost conveyor belt 7, and the distribution cylinder 5 Distributing plates for material distribution are evenly distributed around the rotating shaft. By setting multiple conveyor belts 7 in the housing 1, the residence time of the squid in the housing 1 is prolonged, and the drying effect of the squid is enhanced. The heat pump in the housing 1 is used to 6. Heat and dry the squid, and the hot air is released through the feed hopper 4. During the feeding process of the squid from ...

Embodiment 2

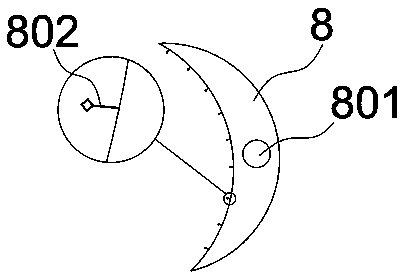

[0026] The further optimization scheme of this embodiment on the basis of embodiment 1 is as follows: figure 2 , 3 As shown, the side of the transmission end of the conveyor belt 7 is provided with a crescent-shaped baffle 8 corresponding to the end of the conveyor belt 7 and rotatable. The upper part of the baffle 8 is provided with a block 9 for limiting the baffle 8. A baffle plate 8 is set on the side of the conveying end to make the squid fall accurately on the conveyor belt 7 below. The baffle plate 8 can adjust the uniformity of the squid drop distribution according to the free rotation of the squid, and has a certain material distribution and buffer effect on the falling squid, which is beneficial It is used to improve the drying effect and drying quality of squid.

[0027]The middle part of the baffle plate 8 is provided with a rotating shaft 801, the inner surface is evenly distributed with retaining strips 802, and the ends of the retaining strips 802 are diamond-...

Embodiment 3

[0030] When the squid quick drying equipment of the present invention is actually used: the squid of drying is carried out parameter setting by control panel 2, for example the transmission speed of conveyor belt 7, the irradiation time of sterilization lamp 103, the air volume of hot fan 104, the air volume of heat pump 6 Air supply, etc. After setting the parameters of each component, pour the squid from the feed hopper 4, the squid passes through the filter plate 401 to remove part of the water and "massage" the surface of the squid, and falls to the distribution cylinder 5 to distribute the squid , so that the squid falls on the surface of the conveyor belt 7 in batches and weights, and multiple conveyor belts 7 prolong the residence time of the squid in the housing 1 to enhance the drying effect of the squid. A hot fan 104 is set to form a downward hot air blown into the housing 1 Squids everywhere, and drive the hot air generated by the heat pump 6 to move to the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com