Aquatic product cold air drying method

A technology of aquatic products and cold air, which is applied in the direction of marine product drying, drying, drying machines, etc., to achieve the effects of short processing time, low processing efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

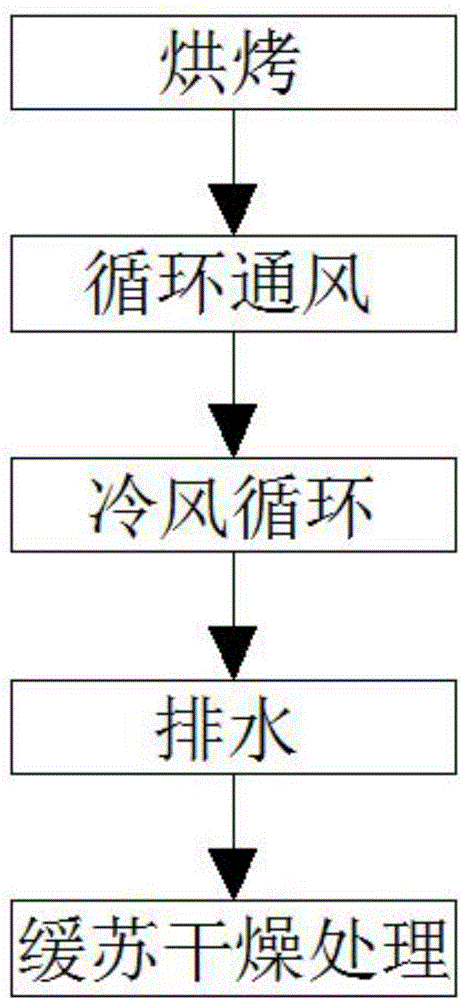

[0020] see figure 1 , a cold air drying method for aquatic products, the cold air drying method for aquatic products comprises the following steps:

[0021] S1: Baking: Drain the cleaned aquatic products after cleaning and treatment. The draining time is controlled at 4.5 minutes, and then the aquatic products are hung in a heat-insulating and airtight drying room for baking. The temperature of the drying room is controlled at 42 degrees Celsius. Set the water content detection interval of aquatic products;

[0022] S2: Circulation ventilation: adopt high-efficiency fans to force circulation ventilation, and the wind speed of the fans is controlled at 3 m / s, so that convective negative pressure is formed in the drying room;

[0023] S3: Cold air circulation: Imported air cooler is used to feed cold air into the drying room. The total power of the air cooler is 18.7kw / h, the temperature range is 10-35 degrees Celsius, the wind speed range is 0-12m / s, and the air volume is 1000...

Embodiment 2

[0027] see figure 1 , a cold air drying method for aquatic products, the cold air drying method for aquatic products comprises the following steps:

[0028] S1: Baking: Drain the cleaned aquatic products after cleaning and treatment. The draining time is controlled at 4 minutes, and then the aquatic products are hung in a heat-insulating and airtight drying room for baking. The temperature of the drying room is controlled at 35 degrees Celsius. Set the water content detection interval of aquatic products;

[0029] S2: Circulation ventilation: adopt high-efficiency fans to force circulation ventilation, and the wind speed of the fans is controlled at 2 m / s, so that convective negative pressure is formed in the drying room;

[0030] S3: Cold air circulation: Imported air cooler is used to feed cold air into the drying room. The total power of the air cooler is 18.7kw / h, the temperature range is 10-35 degrees Celsius, the wind speed range is 0-12m / s, and the air volume is 1000m ...

Embodiment 3

[0034] see figure 1 , a cold air drying method for aquatic products, the cold air drying method for aquatic products comprises the following steps:

[0035] S1: Baking: Drain the cleaned aquatic products after cleaning and treatment. The draining time is controlled at 5 minutes, and then the aquatic products are hung in an insulated and airtight drying room for baking. The temperature of the drying room is controlled at 50 degrees Celsius. Set the water content detection interval of aquatic products;

[0036] S2: Circulation ventilation: adopt high-efficiency fans to force circulation ventilation, and the wind speed of the fans is controlled at 5 m / s, so that convective negative pressure is formed in the drying room;

[0037] S3: Cold air circulation: Imported air cooler is used to feed cold air into the drying room. The total power of the air cooler is 18.7kw / h, the temperature range is 10-35 degrees Celsius, the wind speed range is 0-12m / s, and the air volume is 1000m 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com