Kelp airing system

A kind of kelp and ring technology, which is used in the drying of marine products, food processing, food science, etc., can solve problems such as poor economic benefits, and achieve the effects of increasing stability, soft telescopic action and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

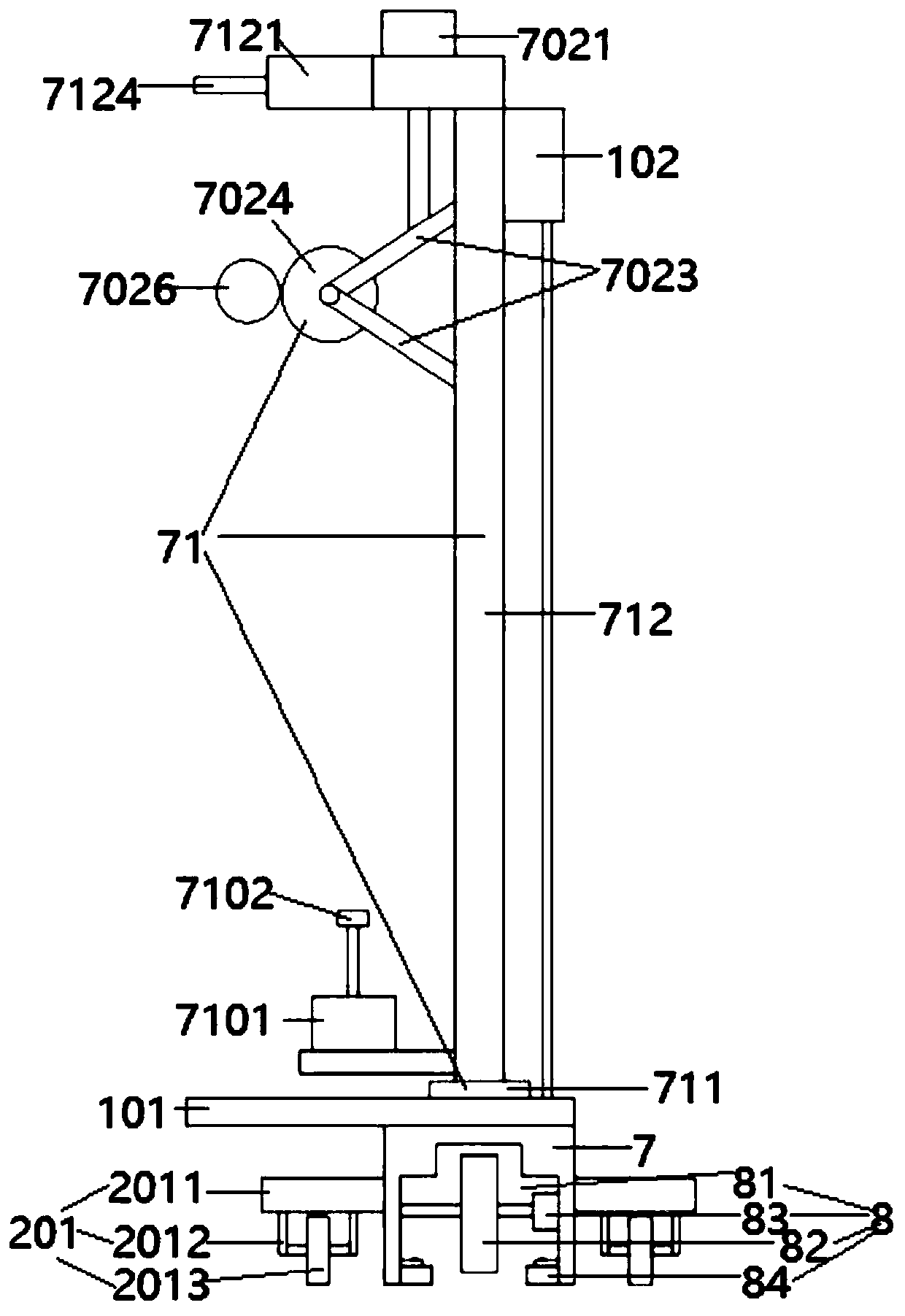

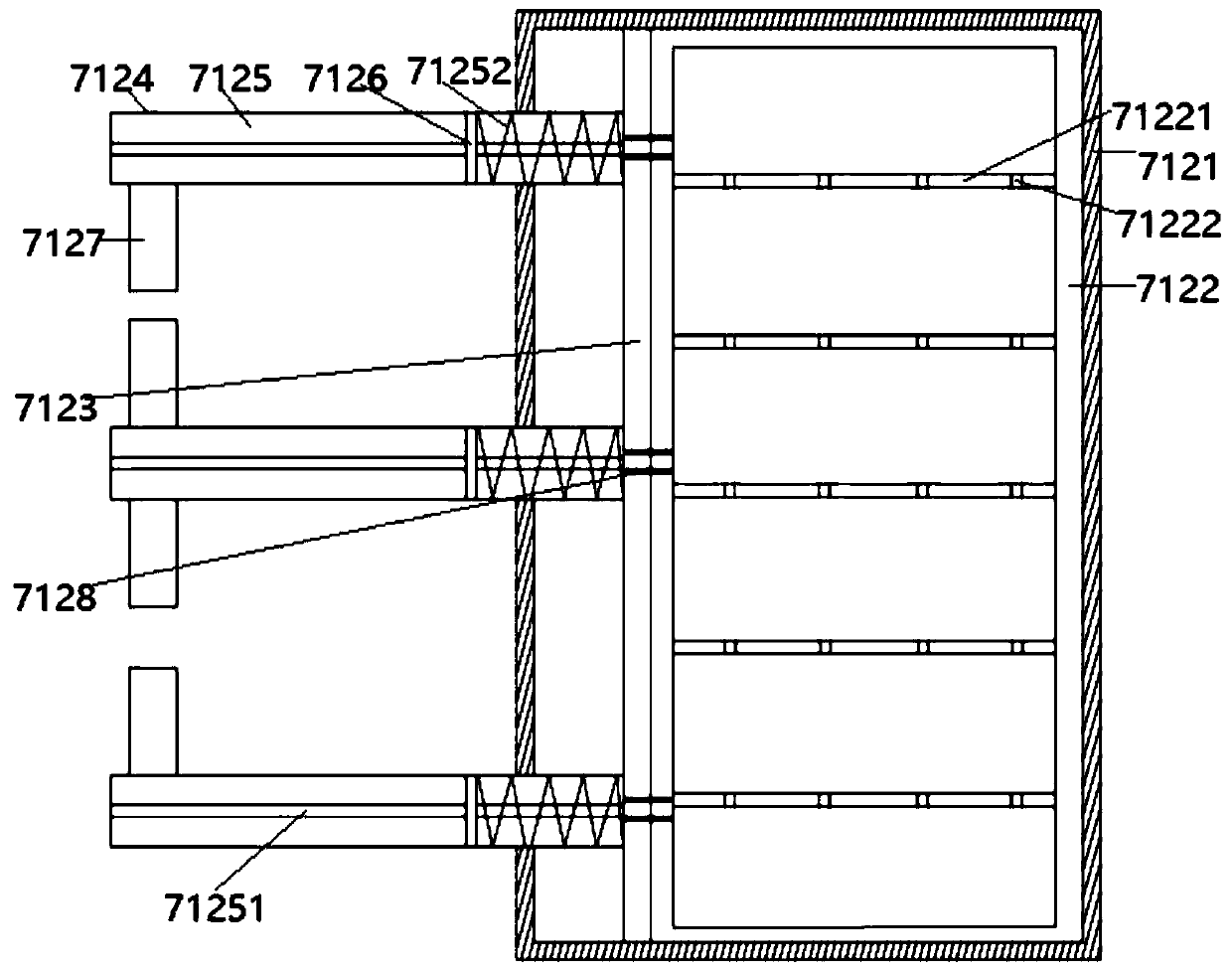

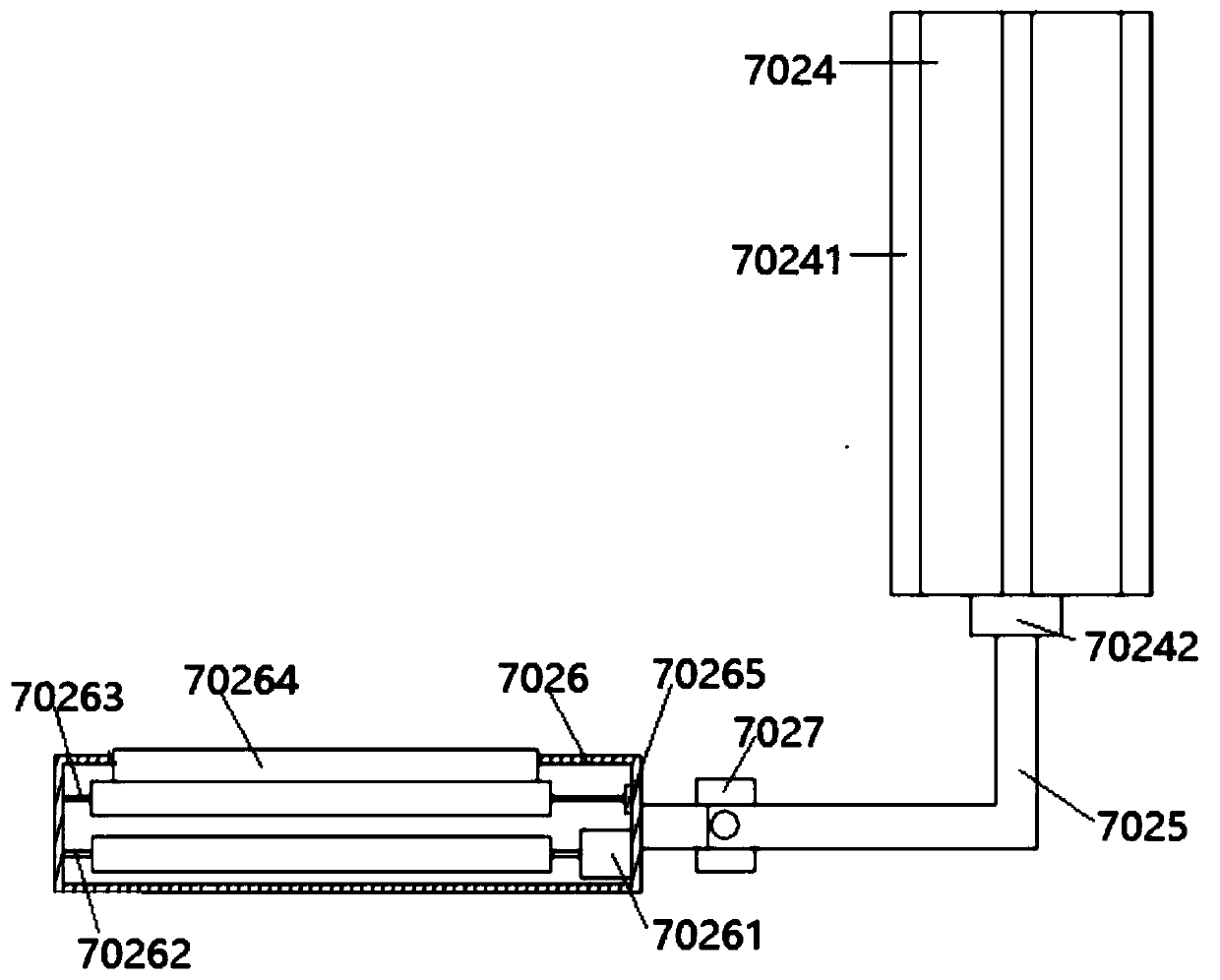

[0034] like figure 1 , figure 2 , Figure 7The illustrated embodiment is a kelp drying system, comprising a platform 1, a first ring-shaped drying rope 2 arranged on the platform, a second ring-shaped drying rope 3 positioned outside the first ring-shaped drying rope, and a second ring-shaped drying rope 3 located outside the first ring-shaped drying rope. The ring track 4 between the second annular drying rope, the first supporting column group 5 and the second supporting column group 6; the first drying rope and the second drying rope are respectively connected to the upper ends of the first supporting column group and the second supporting column group , the annular track is provided with a base 7, the base is provided with a walking mechanism 8 for driving the base to move along the annular guide rail, the base is provided with a kelp se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com