Offshore machining center

A processing center and oven technology, applied in fish processing, crustacean processing, shrimp/lobster processing, etc., can solve the problem of no data disclosure, and achieve the effects of ensuring food safety, improving cleaning efficiency, and saving freshwater resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

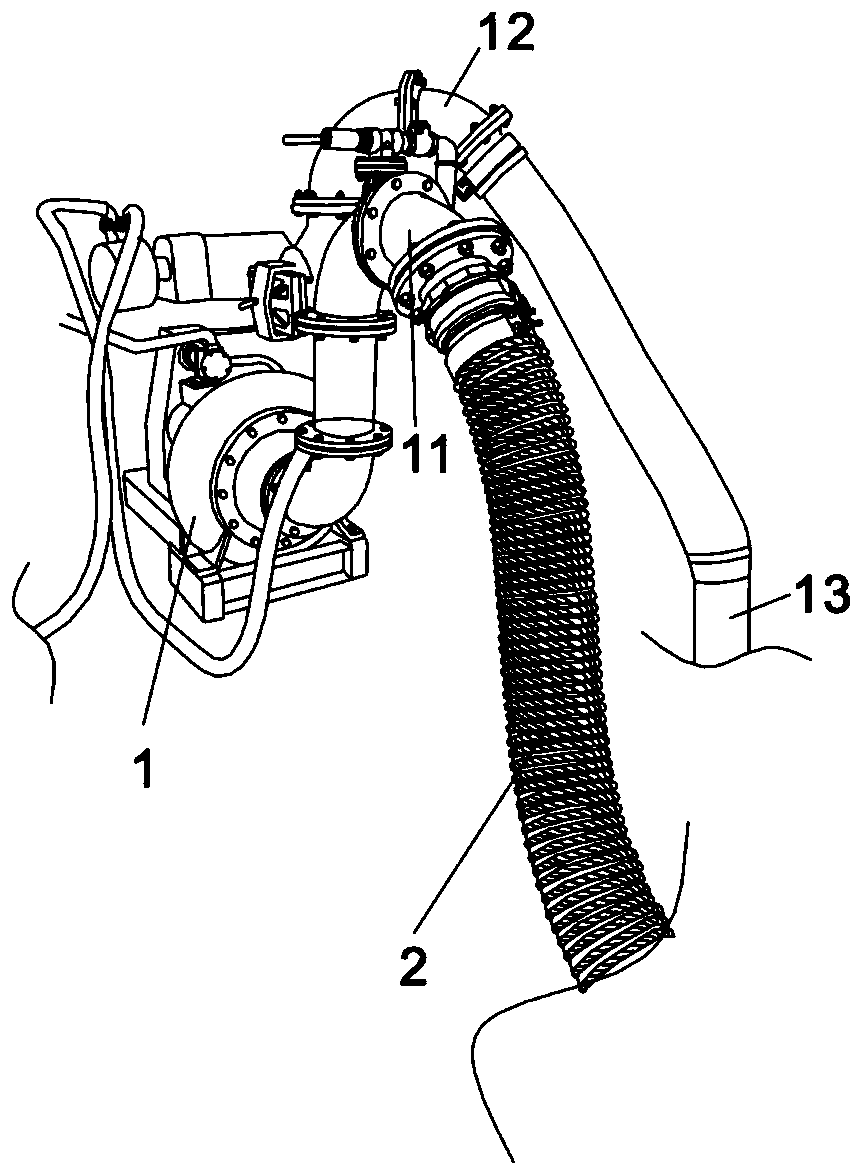

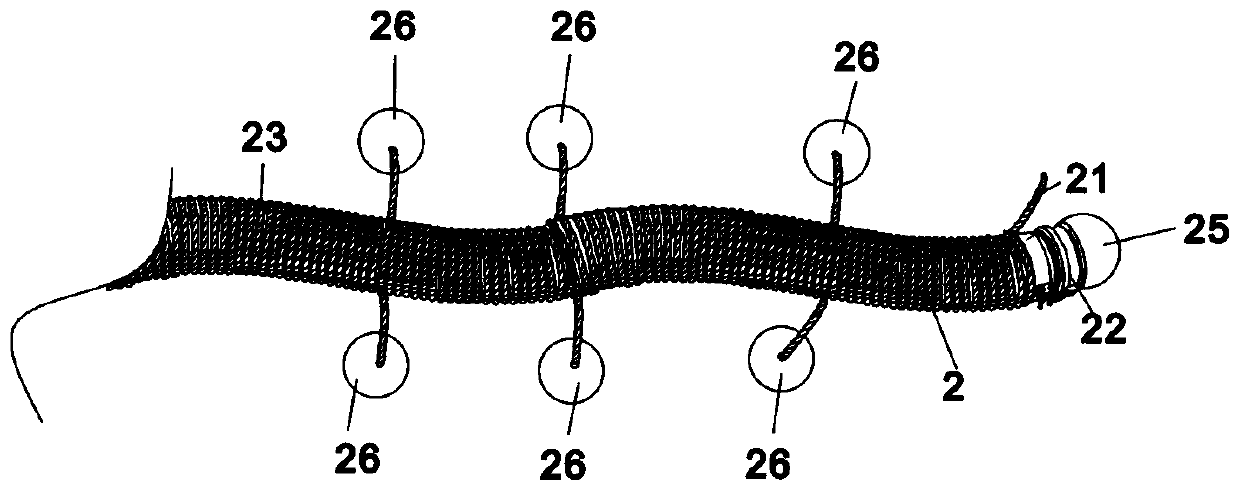

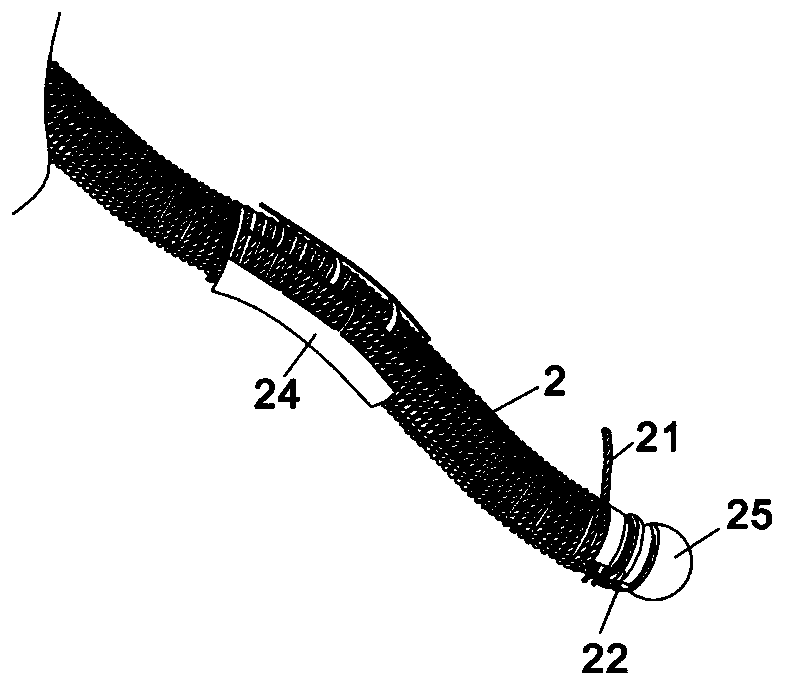

[0274] Embodiment 1 An offshore processing center, with a ship as a carrier, is characterized in that: a negative pressure pump is provided at the stern of the ship, and the negative pressure pump

[0275] A suction pipe is set at the entrance, and the suction pipe is used as a channel for the aquatic products or seafood on the transport ship to enter the offshore processing center; there are cleaning devices, cooking devices and drying devices in the cabin or ship building; the cleaning device includes an upper lifting cleaning unit and a horizontally arranged rinsing pot, the upper lifting cleaning unit includes a sloping upper lifting conveyor belt and a spray device arranged on the upper lifting conveyor belt; the upper lifting cleaning unit is located on the lower layer of the rinsing pot, and the cooking device and the rinsing pot are located on the same floor. The drying device is located on the lower layer of the cooking device; there are two sets of cleaning devices, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com