Automatic measurement system and measurement method based on image stitching

An automatic measurement and image stitching technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of not meeting the high-precision stitching requirements, and achieve the effects of shortening processing time, improving work efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

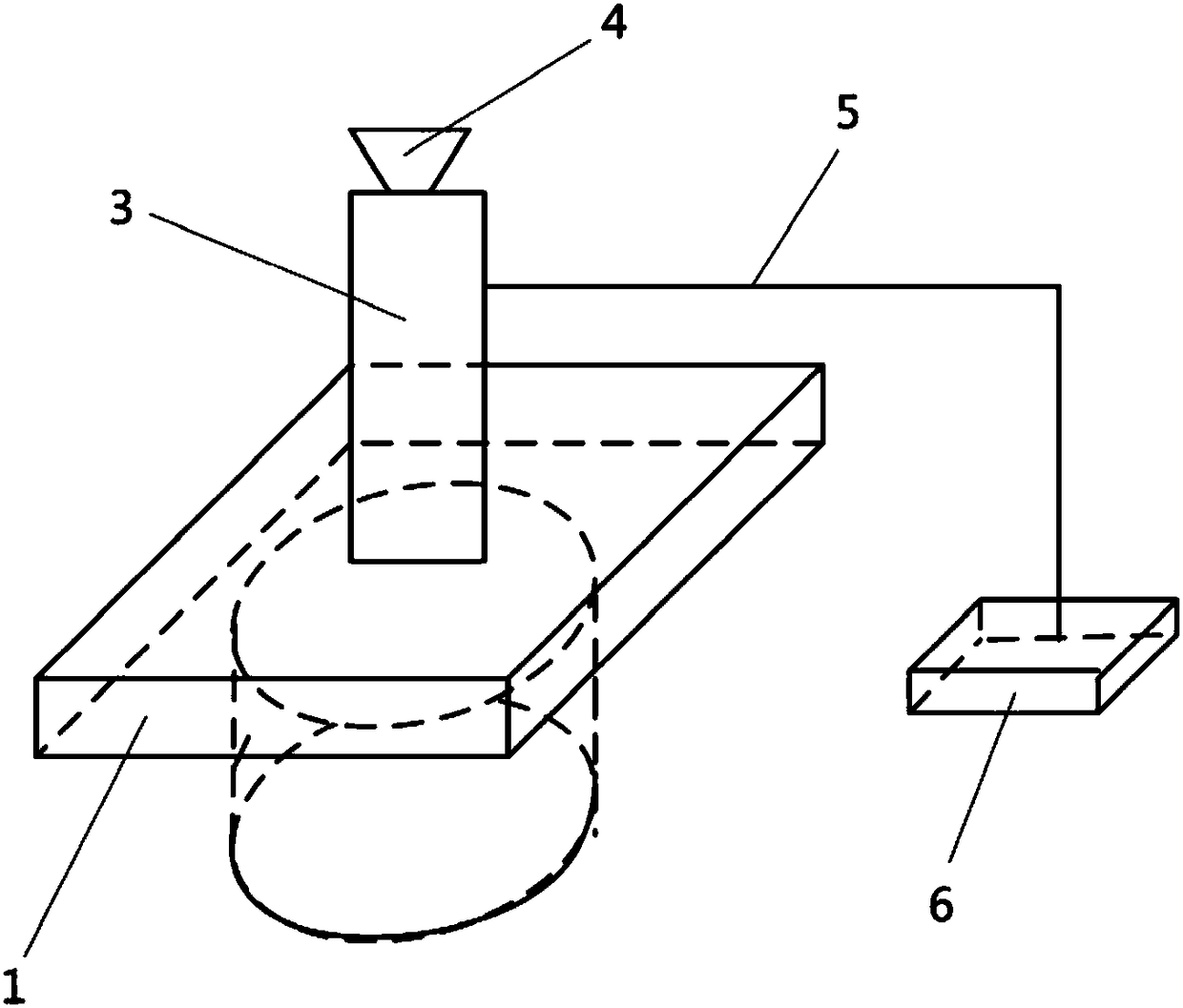

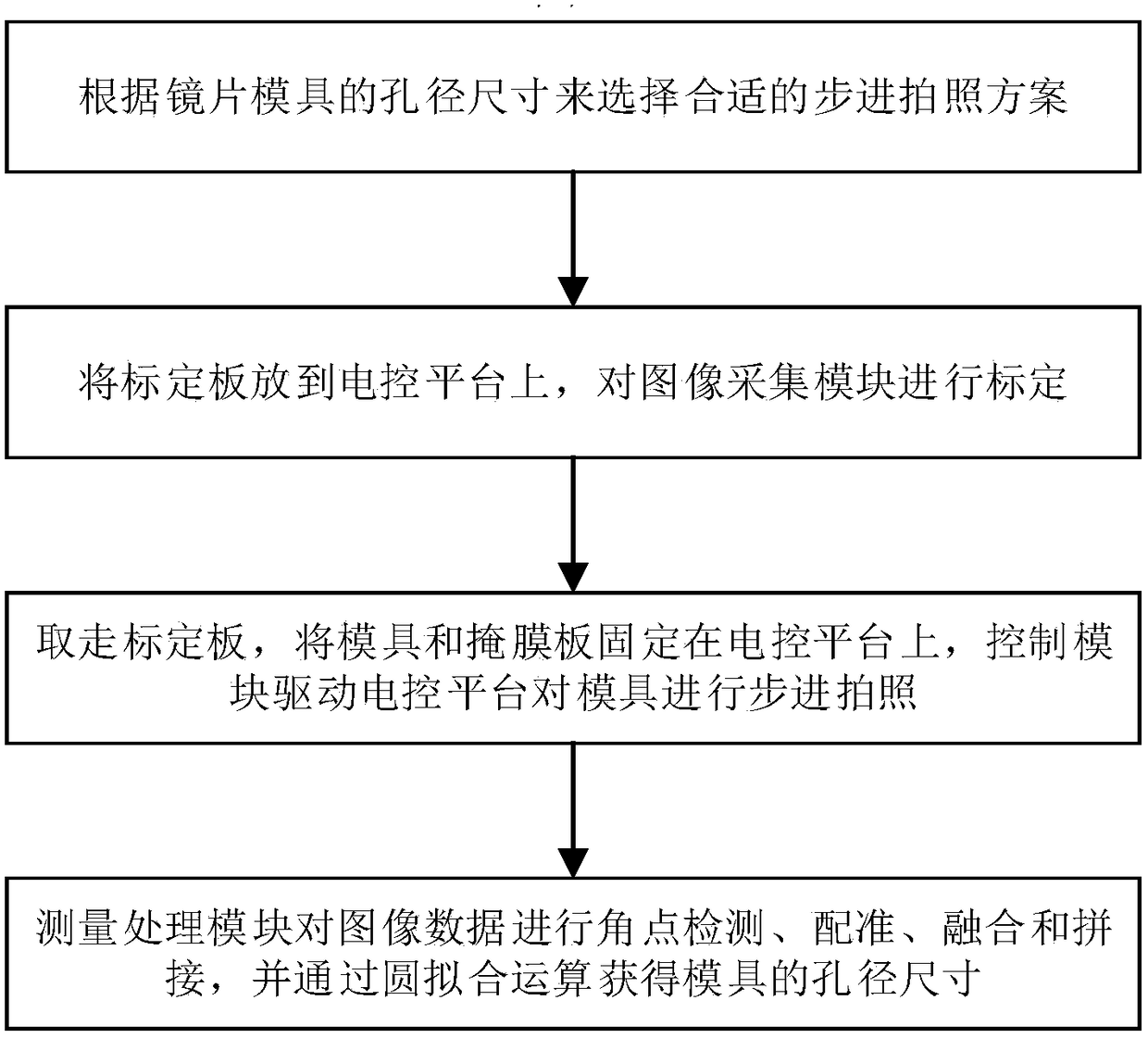

[0043] Such as figure 1As shown, the present invention discloses a micron-level automatic measurement system for wire drawing dies based on image stitching technology. The system is mainly applicable to the field of single-aperture precision mold measurement, and realizes single-aperture diameter measurement with a measurement accuracy of 1um. The measurement system mainly includes: a two-axis electronically controlled translation stage (not shown in the figure), a laser lithography mask plate 1, a calibration plate (not shown in the figure), a microscope 3, an image sensor 4, a lifting support 5, Base 6, image acquisition system (not shown in the figure), computer control and measurement processing system (not shown in the figure).

[0044] Among them, the 10um precision two-axis electronically controlled translation table is composed of a two-axis translation table and a digital control box, which is used to place the drawing die horizontally, and can realize single-step or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com