Coordinated control method for improving hybrid back-to-back DC system

A coordinated control, DC system technology, applied in the field of power transmission and distribution, can solve the problems of lack of flexible DC coordinated control technical solutions, flexible DC without communication exchange, etc., to improve the ability to ride through AC faults, ensure safe and stable operation, reduce The effect of the probability of commutation failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] The invention provides a coordinated control method for improving the capability of resisting commutation failure and fault ride-through capability of a hybrid back-to-back DC system. The control method is configured in an inverter station of a hybrid back-to-back DC system.

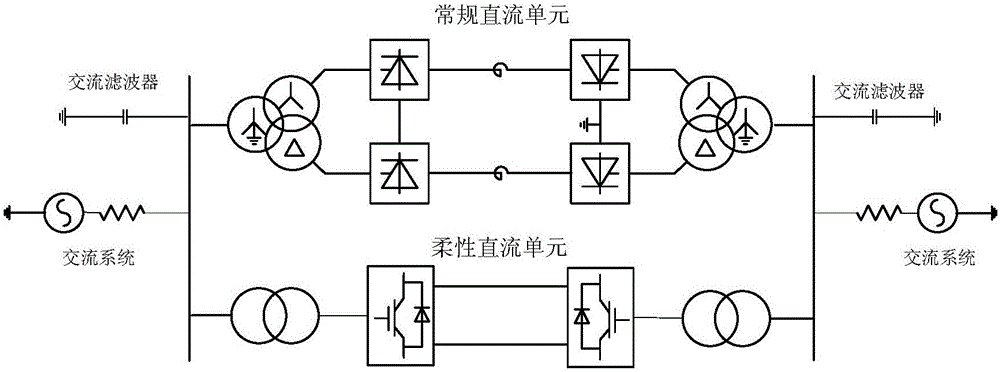

[0028] In one embodiment, a schematic structural diagram of a hybrid back-to-back DC system in which flexible DC units and conventional DC units operate in parallel is shown in figure 1 shown. The hybrid back-to-back DC system consists of a conventional DC unit and a flexible DC unit. The two DC units are in the same converter station and share the same AC bus.

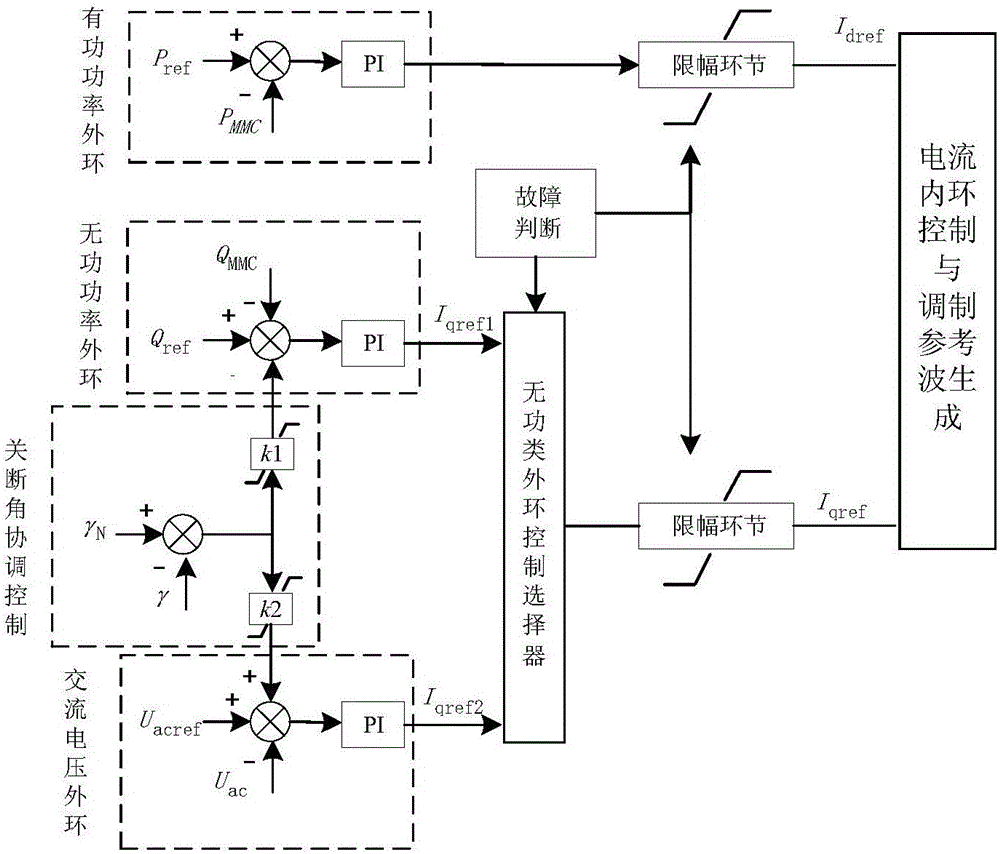

[0029] The rectifier side of the conventional DC unit adopts constant active power control or constant DC current control, and the inverter side adopts constant DC voltage or constant turn-off angle control; the flexible DC unit adopts the direct current vector control method based on dq axis decoupling, which can be It is divided into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com