Heatable hollow body

A technology of hollow body and heating layer, which is applied in pipeline heating/cooling, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve problems such as difficult heat transfer, and achieve the effect of simplifying production and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

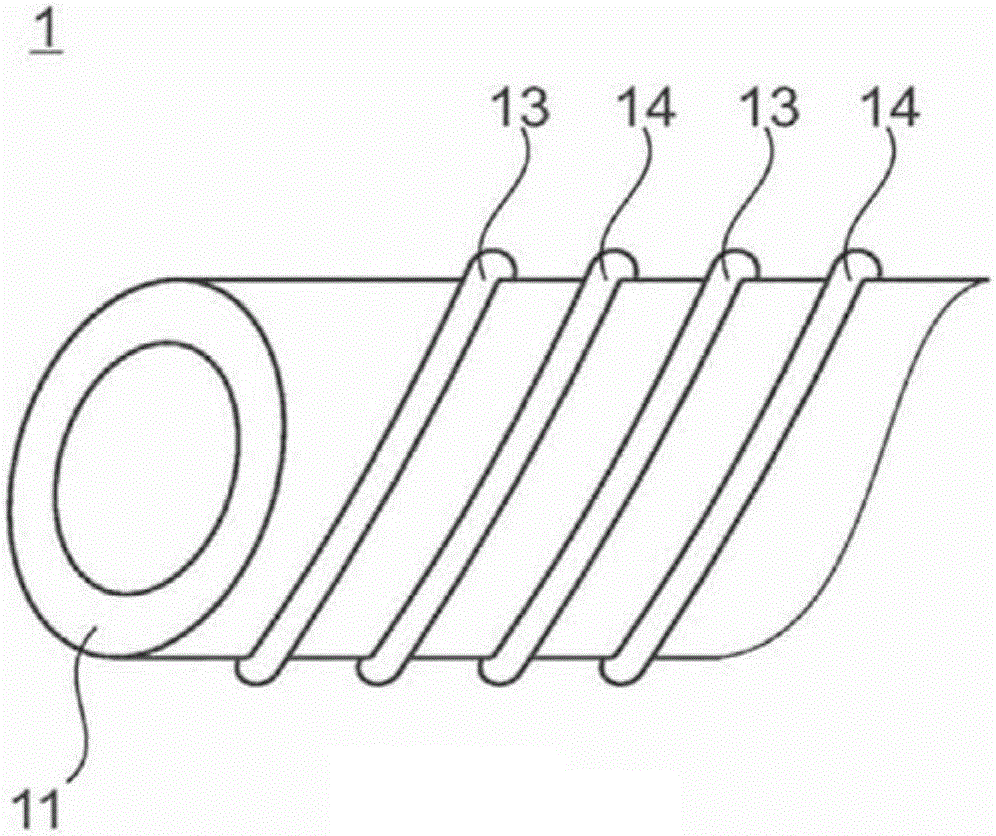

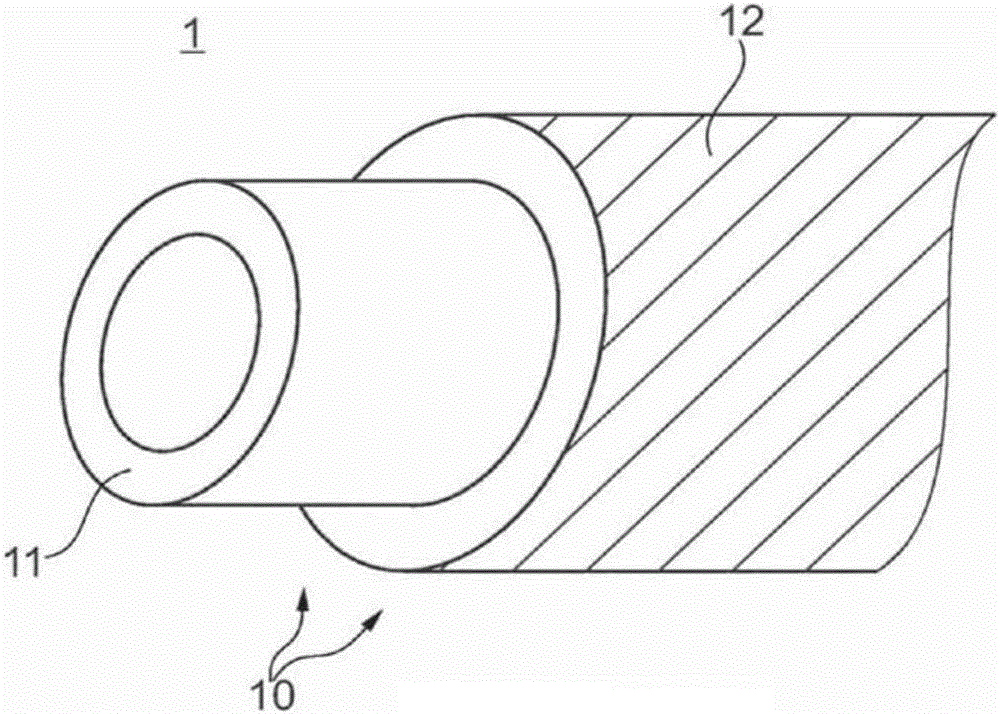

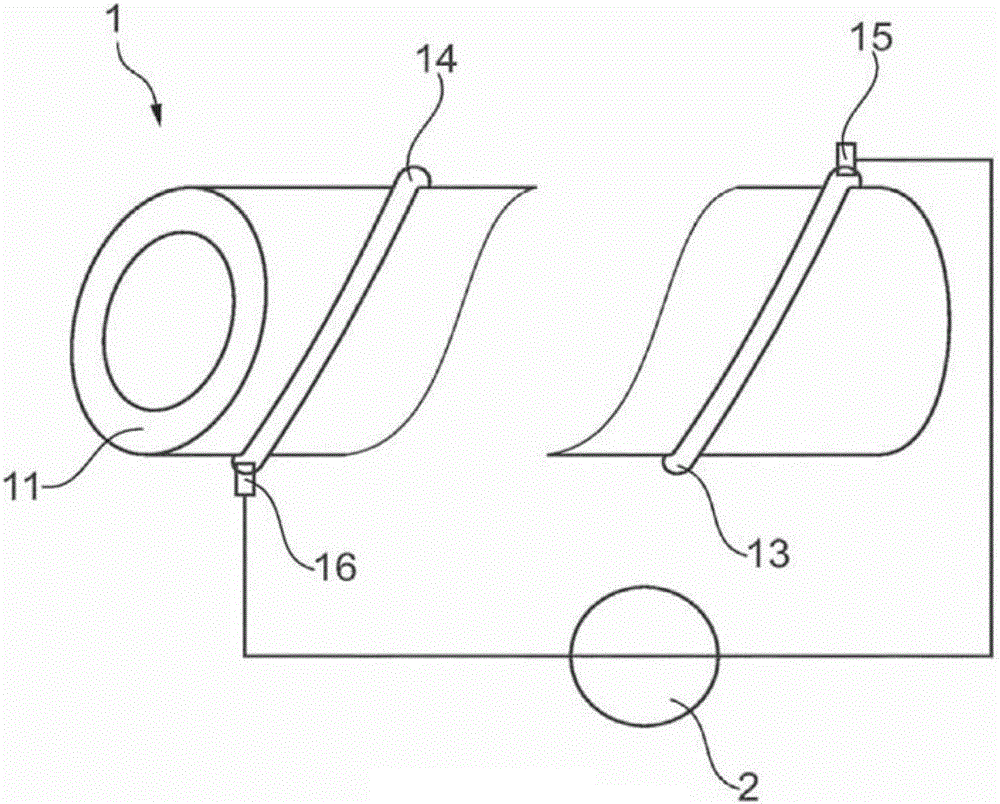

[0032] figure 1 A schematic perspective view of a heatable hollow body 1 in the form of a heatable hose 1 according to a first exemplary embodiment is shown. The heatable hose 1 has a heatable layer 11 which is the innermost layer 11 of its wall structure and as a result is completely in direct contact with the medium to be heated inside the heatable hose 1 . Around this heatable innermost layer 11 further layers (not shown) may be provided. A pair of electrodes 13, 14 in the form of a first electrical conductor 13 and a second electrical conductor 14 are arranged on the heatable layer 11 such that said electrodes pass through an electrically conductive material, such as conductive carbon black, metal powder, in an electrically conductive manner. Or carbon nanotubes are extensively linked together. If a voltage is now applied to the electrodes 13 , 14 , the galvanic heat loss of the electrically conductive material through the thus heated innermost layer 11 of the hose 1 lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com