Method for flotation of carbonate mineral from mud-stone type uranium ore

A technology of carbonate minerals and carbonates, applied in the field of uranium mining and metallurgy, can solve problems such as metal loss and achieve the effect of reducing sulfuric acid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

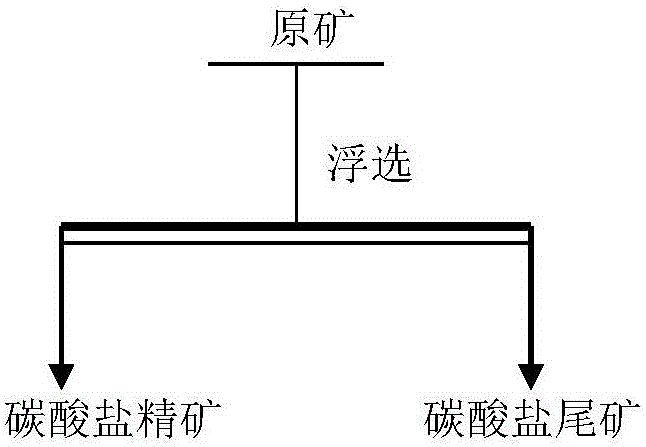

[0022] Such as figure 1 Shown, a kind of method for flotation carbonate mineral from mudstone type uranium ore of the present invention, it floats carbonate mineral from mudstone type uranium ore, specifically comprises the following steps:

[0023] (1) Carry out classification or ore grinding to carbonate raw ore, obtain the ore pulp that fineness-0.074mm accounts for 85wt% of raw ore total amount;

[0024] (2) putting the ore pulp gained in step (1) into a flotation machine, adjusting the concentration of the ore pulp to 20wt%, and the temperature of the ore pulp at 45°C;

[0025] (3) add dispersant water glass in the described ore slurry of step (2), water glass is used as the inhibitor of other minerals simultaneously; Water glass consumption is that every ton of raw ore adds 5000g, stirs 5min; So that water glass fully acts on detoxification The surface of other types of minerals except carbonate minerals enhances the hydrophilicity, so that the mineral fine mud is fully...

Embodiment 2

[0029] Such as figure 1 Shown, a kind of method for flotation carbonate mineral from mudstone type uranium ore of the present invention, it floats carbonate mineral from mudstone type uranium ore, specifically comprises the following steps:

[0030] (1) Carry out classification or ore grinding to carbonate raw ore, obtain the ore pulp that fineness-0.074mm accounts for 80wt% of raw ore total amount;

[0031] (2) putting the ore pulp obtained in step (1) into a flotation machine, adjusting the concentration of the ore pulp to 10wt%, and the temperature of the ore pulp at 15°C;

[0032] (3) add dispersant water glass in the described ore slurry of step (2), water glass is used as the inhibitor of other minerals simultaneously; Water glass consumption is that every ton of raw ore adds 2000g, stirs 1min; So that water glass fully acts on removing The surface of other minerals other than carbonate minerals enhances its hydrophilicity, so that the mineral fine mud is fully disperse...

Embodiment 3

[0036] Such as figure 1 Shown, a kind of method for flotation carbonate mineral from mudstone type uranium ore of the present invention, it floats carbonate mineral from mudstone type uranium ore, specifically comprises the following steps:

[0037] (1) Grading or grinding the raw ore of mudstone type uranium ore to obtain ore pulp with a fineness of -0.074mm accounting for 90wt% of the total raw ore;

[0038] (2) putting the ore pulp obtained in step (1) into a flotation machine, adjusting the concentration of the ore pulp to 35wt%, and the temperature of the ore pulp at 60°C;

[0039](3) add dispersant water glass in the described ore slurry of step (2), water glass is used as the inhibitor of other minerals simultaneously; Water glass consumption is that every ton of raw ore adds 8000g, stirs 10min; The surface of other minerals other than carbonate minerals enhances its hydrophilicity, so that the mineral fine mud is fully dispersed and is conducive to flotation.

[0040...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com