Water jets with spouts for mixing in air

A water spray device and nozzle technology, applied in the directions of spray device, spray device, liquid spray device, etc., can solve the problems of increasing manufacturing cost, increasing the risk of failure of the water spray device, water overflow and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

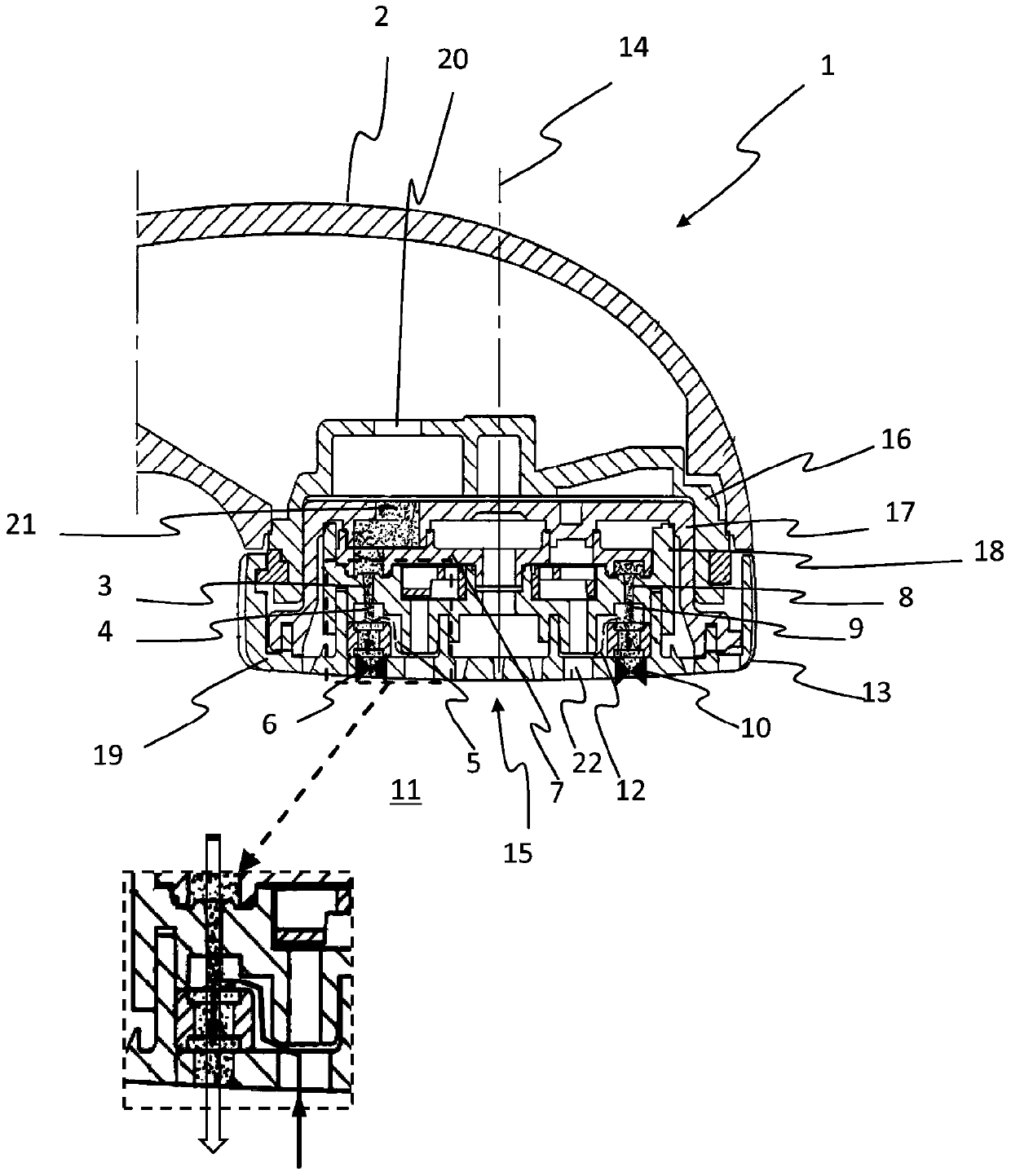

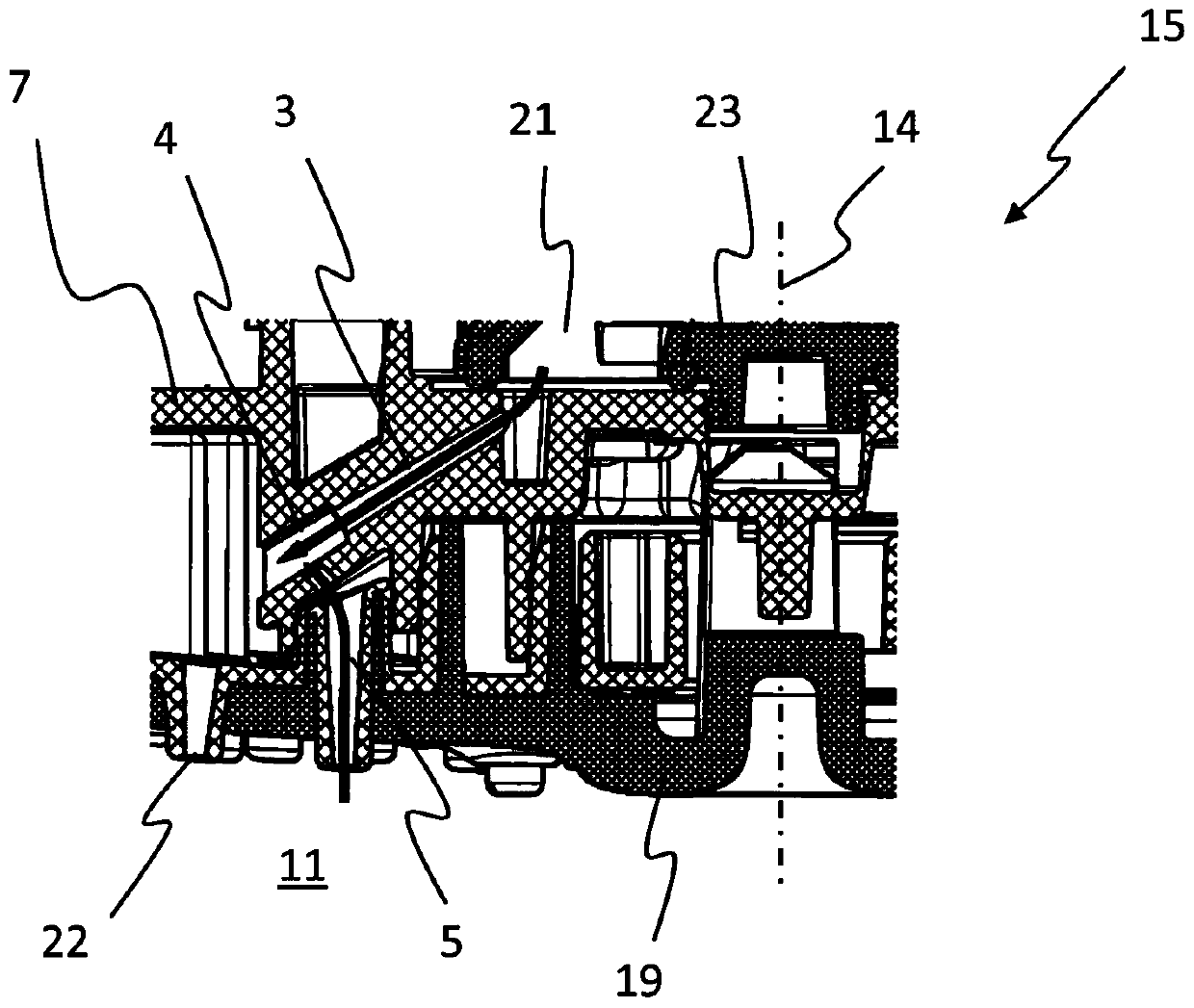

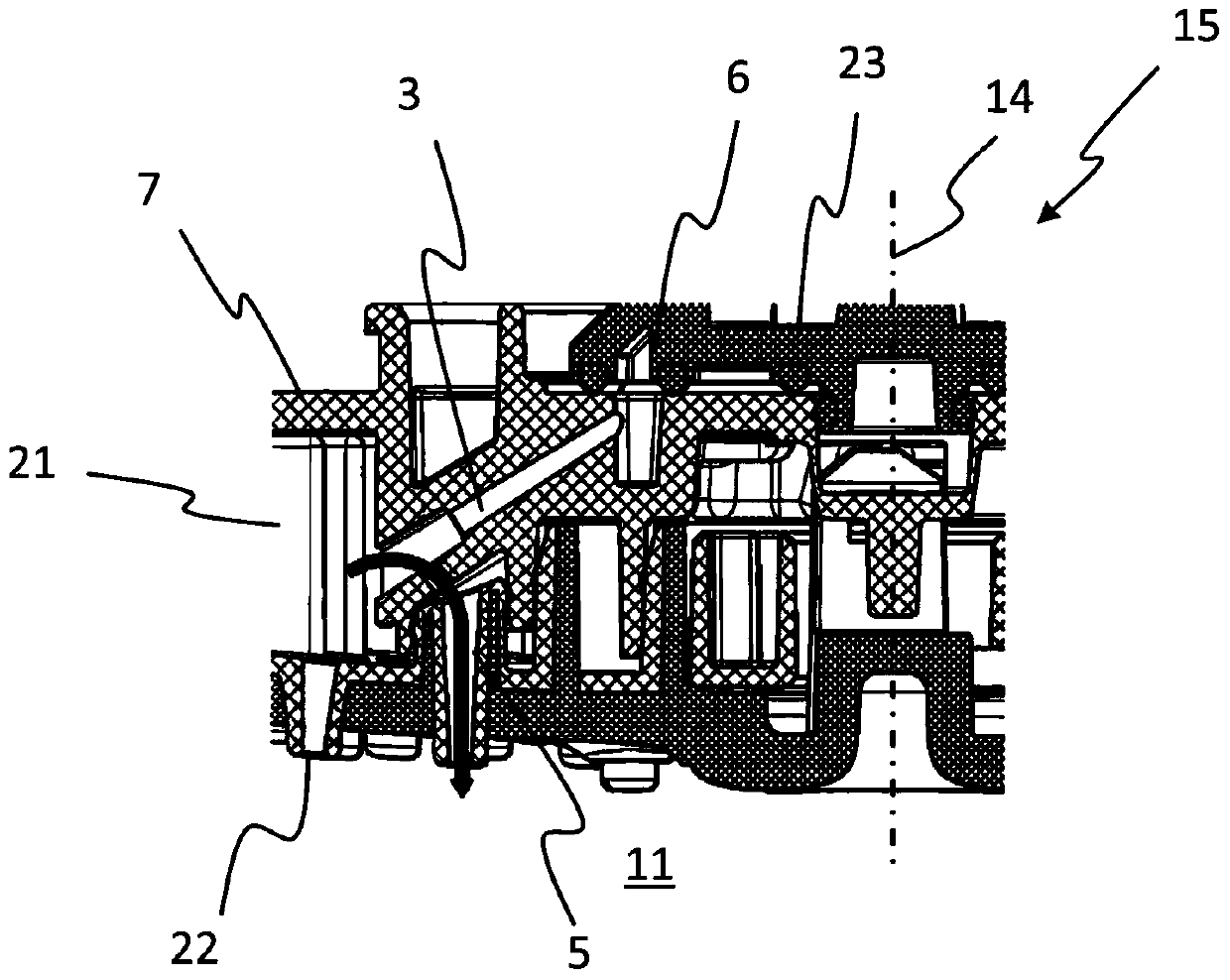

[0015] figure 1 A partial view of a sprinkler head 1 with a sprinkler housing 2 is shown in a sectional view. The basic structure of the sprinkler head 1 is described in column 2, line 61 to column 5, line 19 of DE 41 13 289 A1. The stated content of DE4113289A1 is incorporated in the present invention by reference.

[0016] The sprinkler head 1 has a jet shaper 15 with an insert body 16 , a housing bell 17 , a distributor 7 , a central body 18 and a jet discharge plate 19 . The insert body 16 is fixedly connected to the sprinkler housing 2 and basically serves the purpose of supplying the water flowing in through the opening 20 to the subsequent channel system of the sprinkler head 1 or of the jet shaper 15 . The housing bell 17 and the jet outlet plate 19 are connected to one another in a rotationally fixed manner, so that the user of the sprinkler head 1 (for example via the handle body 13 ) rotates the jet outlet plate 19 about the axis of rotation 14 and correspondingly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com