Dual-precision weighing sensor

A weighing sensor, double-precision technology, applied in the detailed information of weighing equipment, instruments, weighing, etc., can solve the problem of use, can not be used as other, can not be used as a weight scale, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

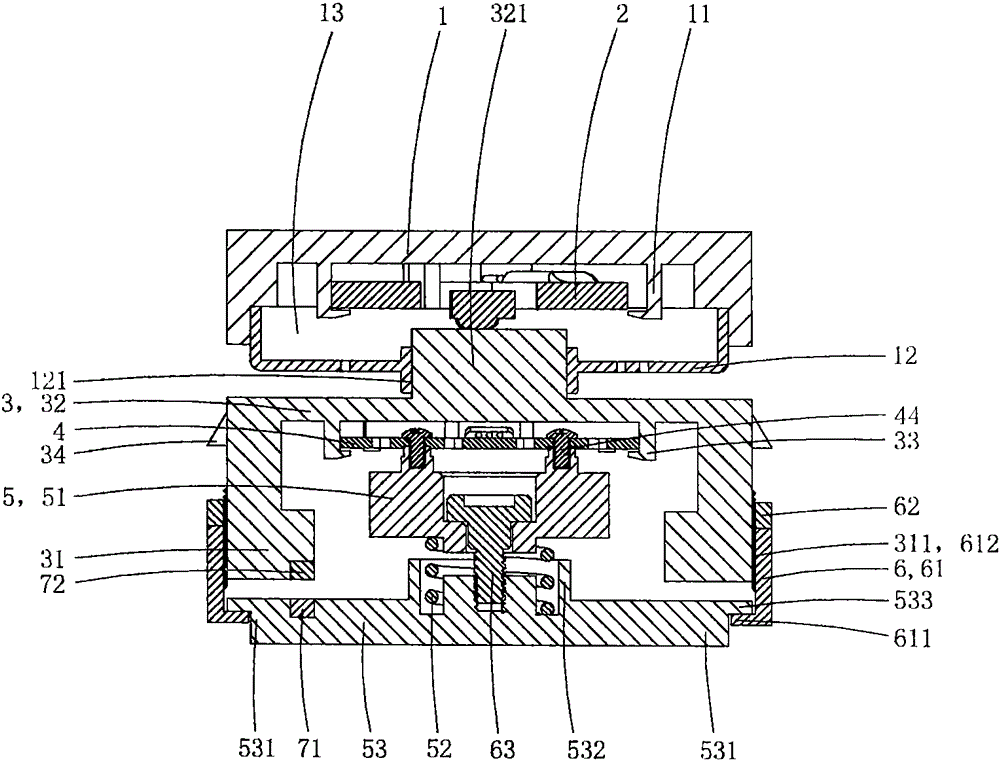

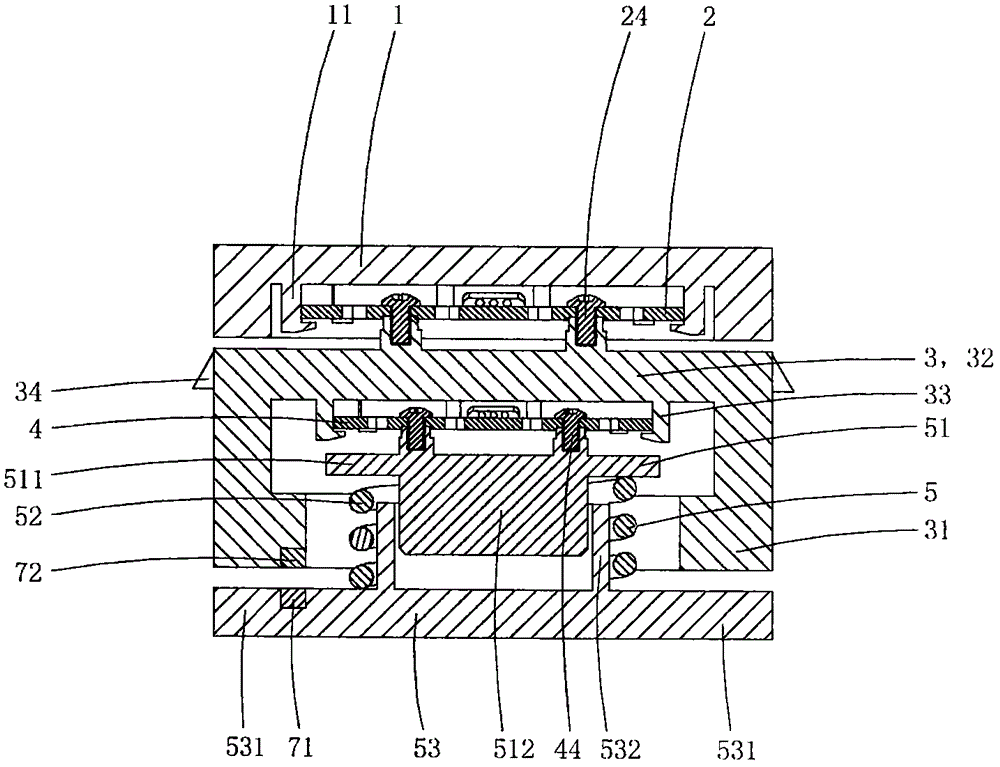

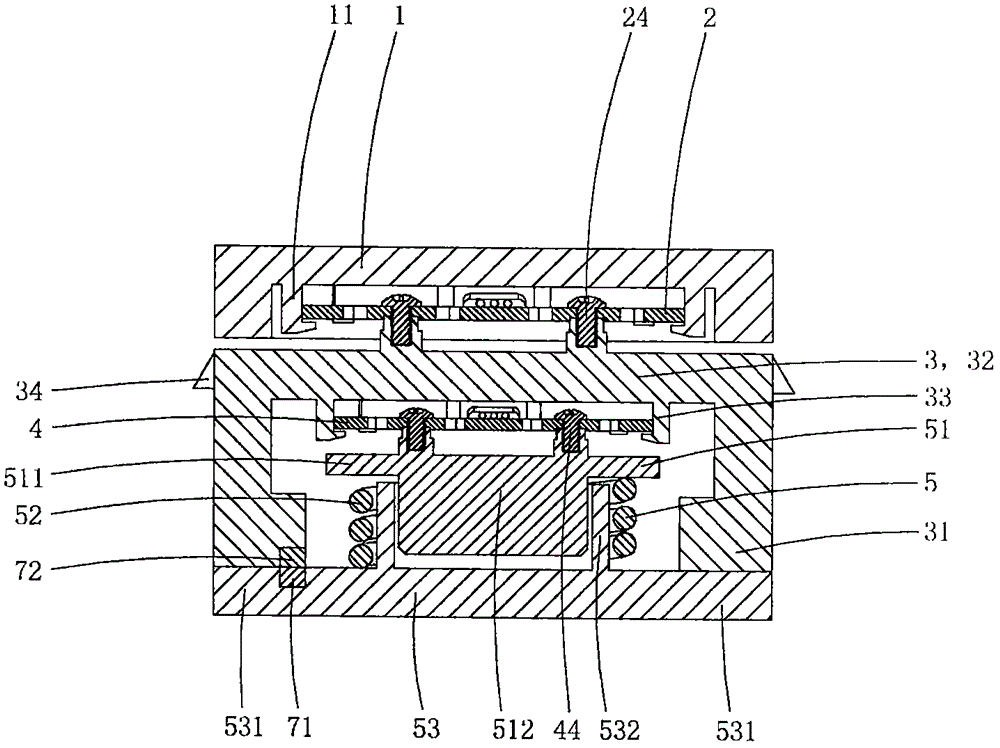

[0028] This embodiment is a double precision load cell, see Figure 1 to Figure 6 As shown, it includes the first mounting base 1, the first precision load cell 2, the second mounting base 3, the second precision load cell 4 and the elastic support 5 which are sequentially crimped; the elastic support includes an upper support 51 , Thread spring 52 and lower support 53. The top end of the spring abuts on the upper supporting member, and the bottom end of the elastic supporting member abuts on the lower supporting member; the lower supporting member is provided with a force guiding support portion 531 .

[0029] The bottom wall of the first mounting seat is provided with a first card seat 11, and the top wall of the first mounting seat has a plane for bonding and fixing on the bottom wall of the external loading plate; the first precision load cell is provided with The first fixed part 21, the first force-bearing deformation part 22 and the first resistance strain gauge 23 arr...

Embodiment 2

[0049] This embodiment is basically the same as the above-mentioned embodiment 1, the difference is: see Figure 7 to Figure 8 As shown, this embodiment also includes an adjustment mechanism 6 for adjusting the overall height of the elastic support; the outer peripheral wall of the lower support is provided with an outwardly convex stopper 533, and the outer peripheral wall of the force-guiding crimping part is provided with an outer Threaded area 311; the adjustment mechanism includes an adjustment screw cap 61 and a top screw cap 62, the inner wall of the lower part of the adjustment screw cap is provided with an inwardly convex annular anti-off crimping part 611, and the inner wall of the upper part is provided with a guide force crimping part. The internal thread area 612 adapted to the external thread area; the anti-off crimping portion is sleeved on the outer peripheral wall of the lower support member below the stopper portion, and the top screw cap is also screwed on th...

Embodiment 3

[0052] This embodiment is basically the same as the above-mentioned embodiment 2, the difference is: see Figure 9 to Figure 12As shown, the first precision load cell in this embodiment is still provided with a first fixing part, a first force-bearing deformation part, and a sensor set on the first force-bearing deformation part for detecting the deformation amount of the first force-bearing deformation part. The first resistance strain gauge; but the shape of the first precision load cell in this embodiment is similar to the reverse "G" shape, its first fixed part is similar to "C" shape, and the shape of the first force-bearing deformation part is similar to A smaller "C" shape is connected with the first fixed part to form a reverse "G" shape. The measuring range and accuracy of this first precision load cell are the same as those in Embodiment 1, and this structure can also be made by stamping, and its manufacturing process is simpler. The bottom of the first mounting sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com