Automatic skipping device for coating machine

A coating machine and automatic technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of a large number of manual operations, worker injuries, affecting work efficiency, etc., and achieve the effect of improving coating efficiency and reducing contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

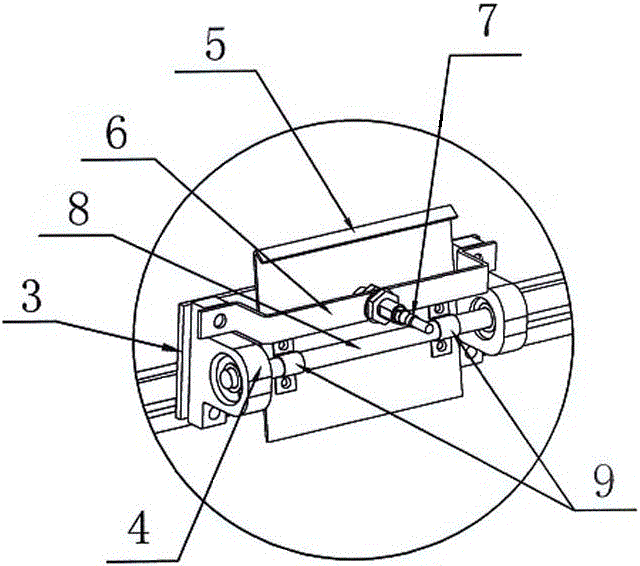

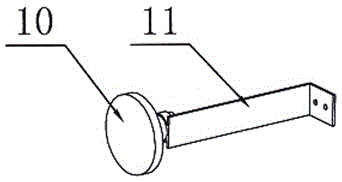

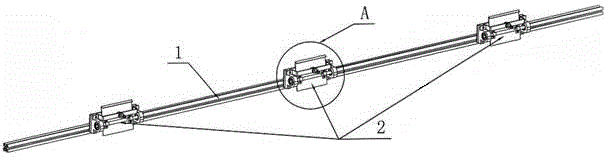

[0012] As shown in the accompanying drawings, an automatic knife jumping device for a coating machine includes a connecting rod 1, three joint identification modules 2 and a meter counter 10, and the connecting rod 1 is arranged on one side of the base fabric guide roller , the meter meter 10 is fixed to the coating platform through a connecting piece 11, the joint identification module 2 includes a base plate 3 and a scraper 5 connected to the connecting rod 1, and the base plate 3 is provided with a seated bearing 4 and a sensor mounting bracket 6. A shaft 8 is provided inside the bearing with seat, and a horseshoe clip 9 is provided on the shaft 8. The scraper 5 is fixed to the shaft 8 through the horseshoe clip 9, and a sensor 7 is provided on the sensor mounting bracket 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com