Automatic feeding device for firefighting nozzle locking fasteners

A technology of automatic feeding and locking, which is used in vibration conveyors, conveyors, transportation and packaging, etc., which can solve the problems of time-consuming and laborious, complicated work process, and inability to realize mechanization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

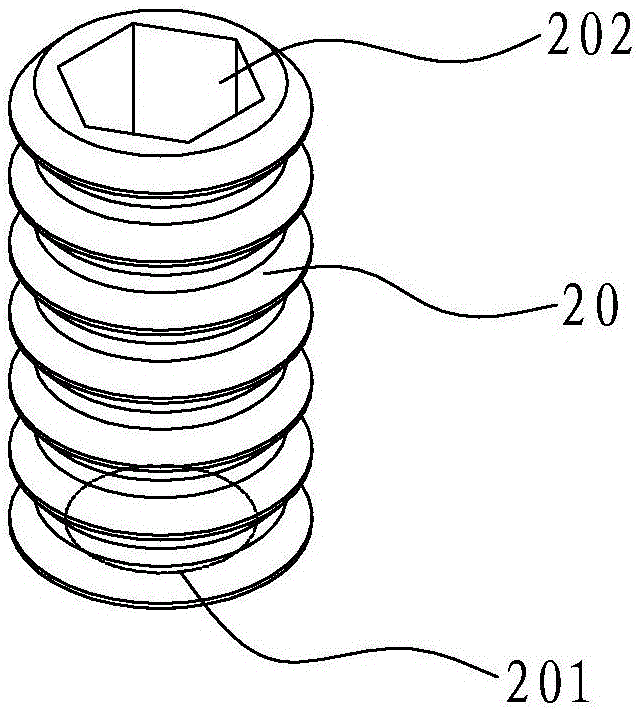

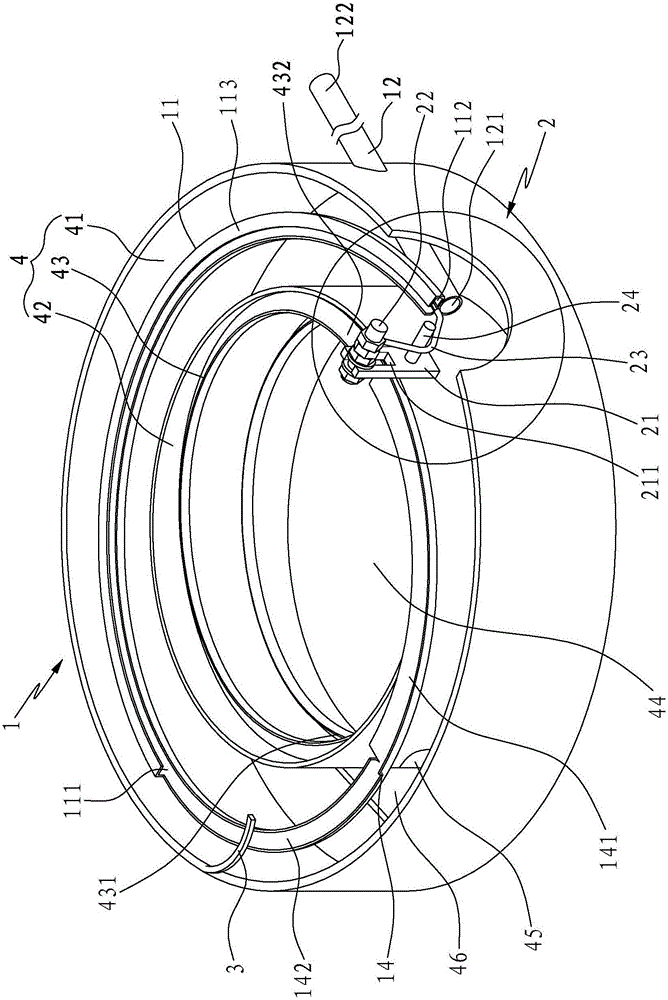

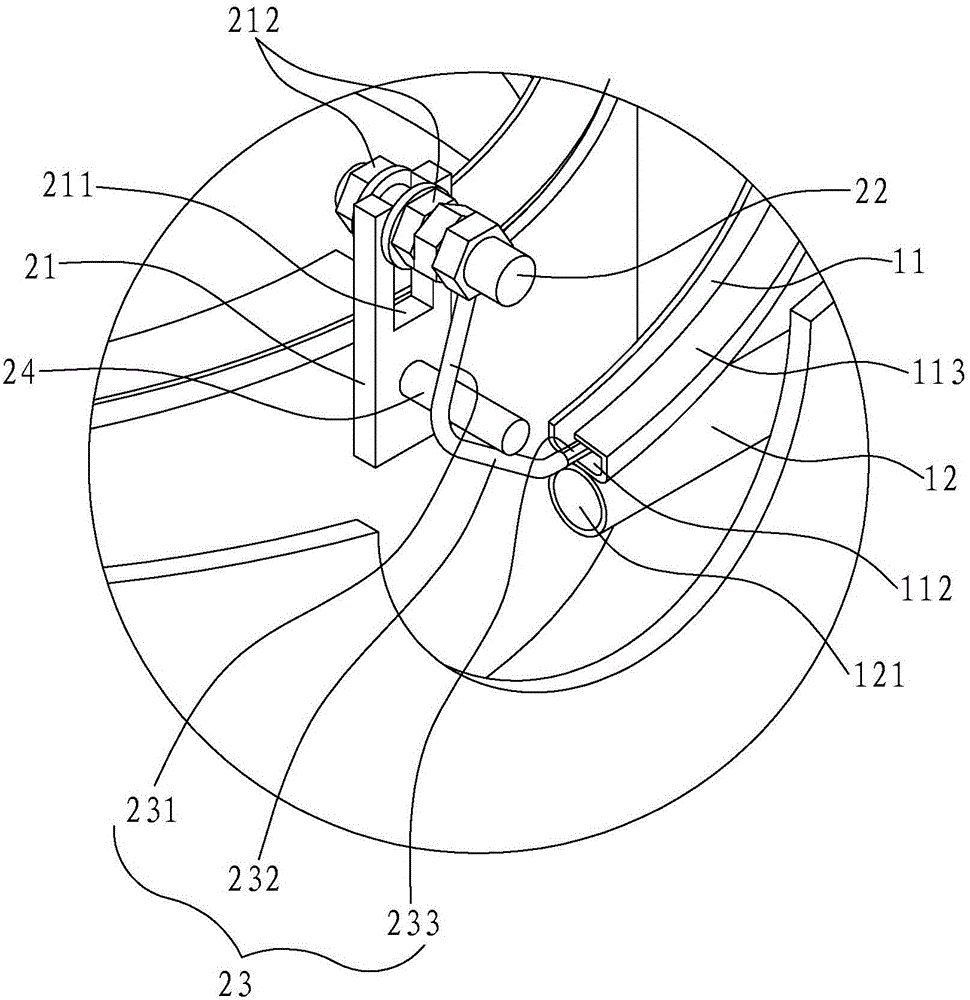

[0042] see Figure 1 to Figure 3 , the present invention discloses an automatic feeding device for a fire sprinkler locking member. The two ends of the locking member 20 are respectively formed with a concave spherical surface 201 combined with a glass tube round head and a sinking groove 202 for screwdriver insertion; the automatic feeding device It includes a vibrating discharge tray 4 for vibrating discharge, a conveying mechanism 1 for conveying the locking member 20 to the nozzle seat, and a screening mechanism 2 for screening the conveying direction of the locking member 20;

[0043] The vibrating discharge tray 4 includes an outer ring shell 41, an inner ring shell 42 and an annular conveying track 43, the outer ring shell 41 is located at the outer ring of the inner ring shell 42, the outer ring shell 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com