Automatic offline stacking production line

A production line and stacking technology, applied in the field of brick making machinery, can solve the problems of inability to realize brick stacking and small application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

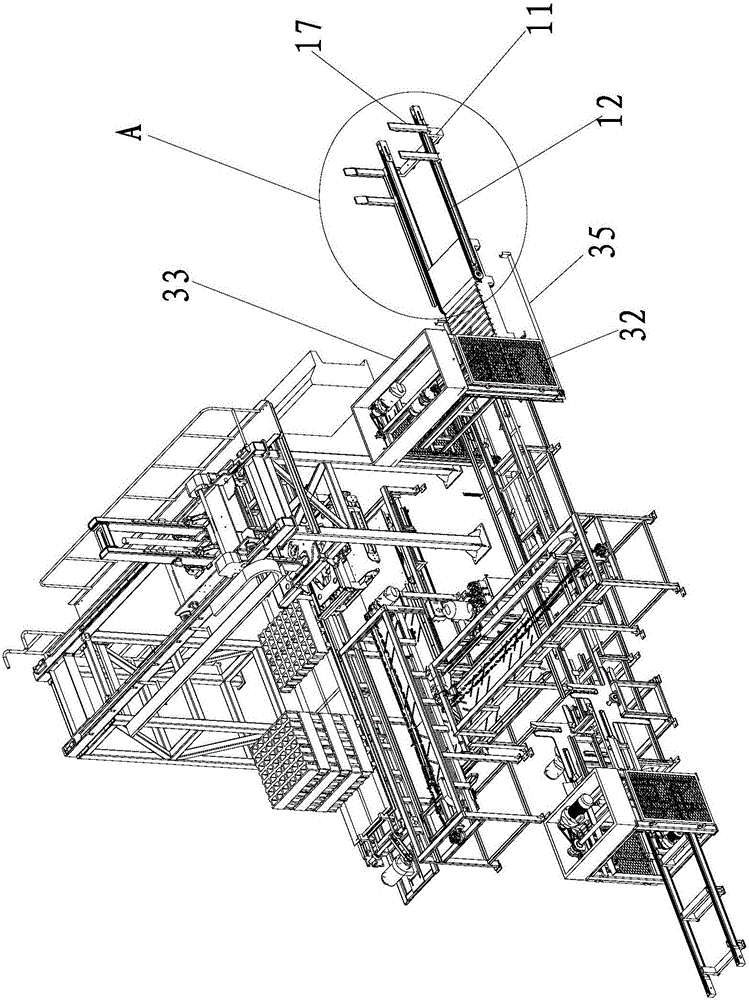

[0031] An automatic off-line palletizing production line of the present invention includes a first conveying line, a second conveying line, a third conveying line, a fourth conveying line, a first brick placing board and a second brick pushing board, the first conveying line, The conveying direction of the second conveying line and the third conveying line are the same, and they are successively connected on a straight line, taking the conveying direction of the first conveying line as the direction from front to back, wherein:

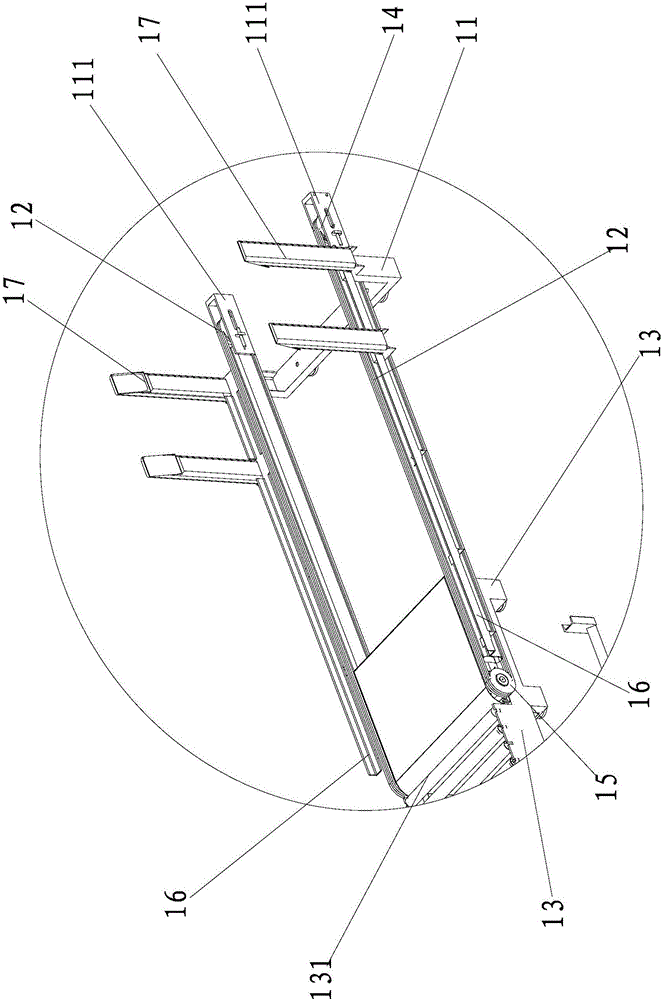

[0032] Such as figure 1 , 2 As shown, the first conveying line includes a support base 11, a transmission belt 12, a placement base 13, a front pulley 14 and a rear pulley 15, and two support bases 11 are provided, and the two support bases 11 are arranged front and back, so as to be in front of the support Seat 11 is a front support seat, and the support seat 11 behind the rear is a rear support seat. The left and right sides of the front end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com