Rectifier Transformer Cooling System and Cooling Method

A rectifier transformer and cooling system technology, applied in transformer/inductor cooling, control/regulation systems, instruments, etc., can solve problems such as the inability to adjust the temperature of the rectifier transformer in a timely, effective and rapid manner, and the inability to deal with abnormal temperature changes, and achieve efficient regulation. , the effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

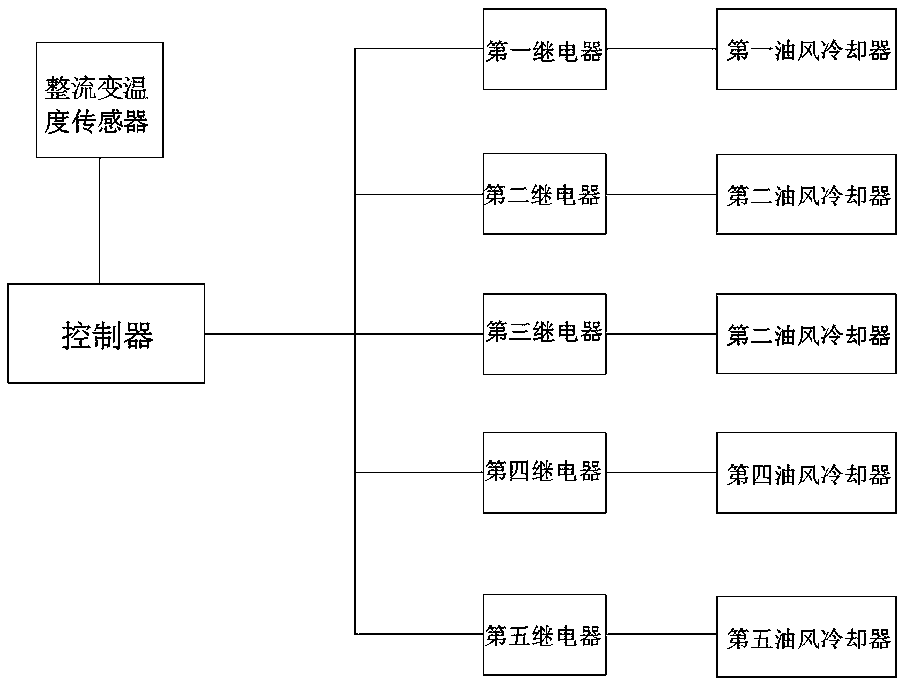

[0014] Such as figure 1 As shown, the rectifier transformer cooling system includes a rectifier transformer. Five sets of oil-air coolers are installed on the rectifier transformer. Each set of oil-air cooler control cabinets is equipped with three positions: stop, work, and backup. The rectifier temperature sensor The controller is connected, and the controller is connected with five groups of relays, each group of relays controls the stop, work and standby positions of a group of oil-air cooler control cabinets; there are four groups of rectifier temperature sensors.

[0015] Based on the cooling method of the rectifier transformer cooling system, a group of oil air coolers is selected for standby operation, and the temperature measured by the rectifier transformer temperature sensor is within the set temperature range, and the controller controls four groups of oil air coolers except for standby operation through relays. The coolers work sequentially; when the temperature m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com