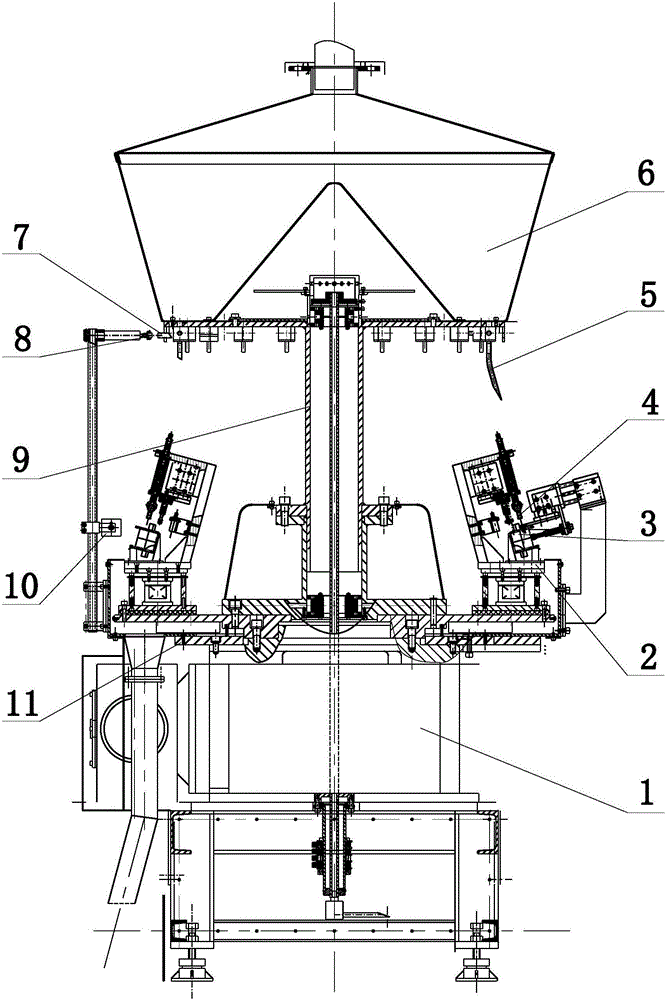

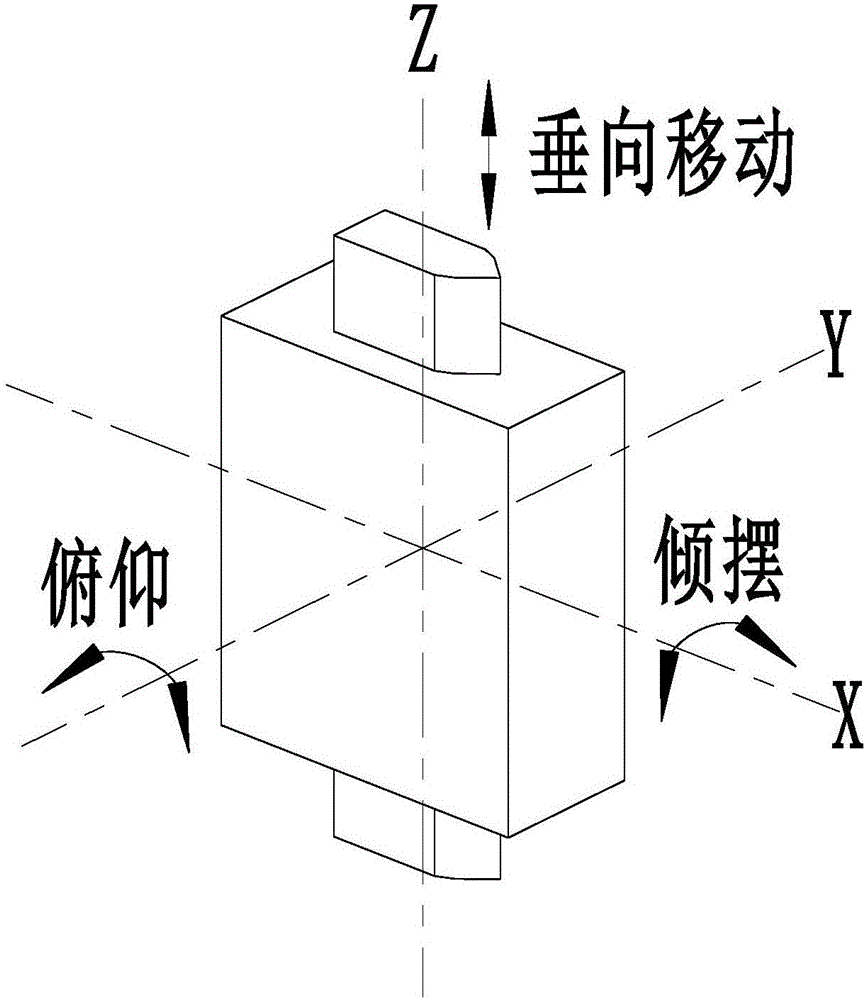

Parallel mechanism based single drive one-translation two-rotation three-dimensional sand filling vibration-compaction machine

A single-drive, parallel-connected technology, used in the manufacture of fluids and fuses using vibration, can solve the problems of single vibration mode and difficulty in improving sand filling density, and achieve a high-quality sand filling density, simple structure, and convenient manufacturing and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

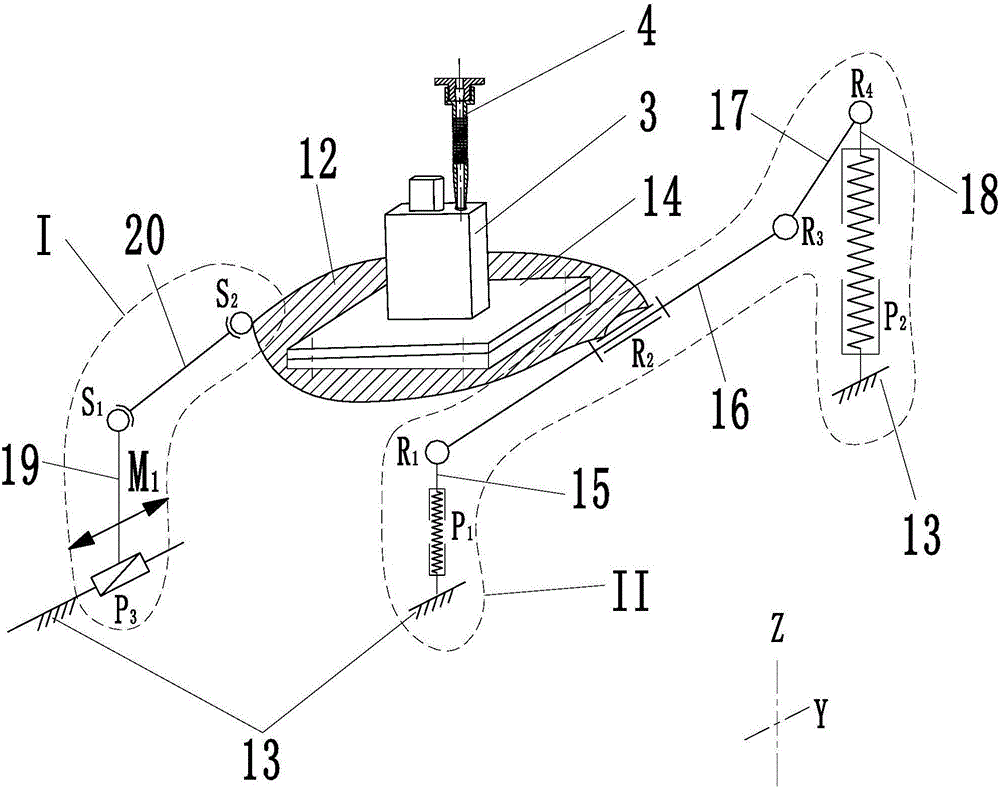

[0046] The active branch chain I includes the third moving pair P3, the first connecting rod 19 and the second connecting rod 20:

[0047] The lower end of the first connecting rod 19 is connected to the fixed base 13 through the third moving pair P3, and the first connecting rod 19 can translate along the Y direction on the fixed base 13;

[0048] The front end of the second connecting rod 20 is spherically hinged on the upper end of the first connecting rod 19, and the rear end is spherically hinged on the left side of the moving platform 12;

[0049] The passive branch chain II includes the first spring damper P1, the first driven rod 15, the second driven rod 16, the third driven rod 17, the fourth driven rod 18 and the second spring damper P2:

[0050] One end of the first spring damper P1 is installed on the fixed base 13, and the other end is connected with the first driven rod 15, the first spring damper P1 can elastically expand and contract along the Z direction, the...

Embodiment 2

[0061] The active branch chain I includes the third mobile pair P3, the first connecting rod 19 and the second connecting rod 20:

[0062] The lower end of the first connecting rod 19 is connected to the fixed base 13 through the third moving pair P3, and the first connecting rod 19 can translate along the Y direction on the fixed base 13;

[0063] The front end of the second connecting rod 20 is spherically hinged on the upper end of the first connecting rod 19, and the rear end is spherically hinged on the left side of the moving platform 12;

[0064] The passive branch chain II includes the first spring damper P1, the first driven rod 15, the second driven rod 16 and the fourth spring damper P4:

[0065] The lower end of the first driven rod 15 is installed on the fixed base 13 through the first spring damper P1, and the first spring damper P1 can elastically expand and contract along the Z direction, thereby driving the first driven rod 15 to translate along the Z directio...

Embodiment 3

[0077] Active branch chain 1 comprises first connecting rod 19 and second connecting rod 20:

[0078] The lower end of the first connecting rod 19 is rotatably connected to the fixed base 13, where the rotation axis of the revolving pair R7 is along the X direction;

[0079] The front end of the second connecting rod 20 is spherically hinged on the upper end of the first connecting rod 19, and the rear end is spherically hinged on the left side of the moving platform 12;

[0080] The passive branch chain II includes the first driven rod 15, the second driven rod 16, the fourth spring damper P4, the fifth rotating pair R5 containing the torsion spring 25 and the sixth rotating pair R6 containing the torsion spring 25:

[0081] The lower end of the first driven rod 15 is rotatably mounted on the fixed base 13, and constrained by the torsion spring 25, the first driven rod 15 can rotate around the lower end;

[0082] The front end of the second driven rod 16 is rotatably mounted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com