Automatic chain annular connecting and head riveting machine

A riveting head machine and chain ring technology, which is applied in the field of automatic chain linking equipment, can solve the problems of man-hour occupation and low efficiency of manual work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

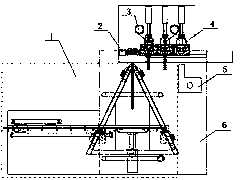

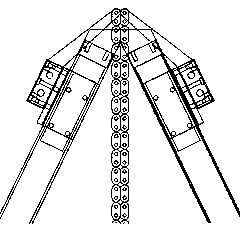

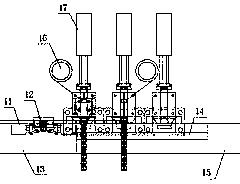

[0020] refer to Figure 1-Figure 4 , the chain automatic loop riveting head machine of the present embodiment, it comprises positioning device 1, transmission device 2, feeding device 3, riveting head device 4, grasping device 5, described positioning device 1 is located at the front of transmission device 2, transmission The device 2 is connected with the feeding device 3 and the riveting head device 4 , and the grasping device 5 is arranged in front of the riveting head device 4 . The positioning device 1 includes a guide rail, a bracket 7, a sliding rodless cylinder 9 and a positioning seat 12. A pair of fixed rodless cylinders are installed at the front end of the guide rail, and the fixed rodless cylinder is connected with a shift fork, which can push the chain forward along the guide rail; A positioning cylinder A8 for positioning the two ends of the chain is installed, and a pair of rodless cylinders that can slide along the bracket are installed. The front end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com