A cutting apparatus for a micro-controlled film

A cutting device and protective film technology, applied in metal processing and other directions, can solve problems such as balance, abnormal cutting, vibration, etc., and achieve the effects of saving production costs, reducing the incidence of defects, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] First, before describing the present invention in detail, if it is judged that the detailed description of known technologies or configurations related to the present invention is unnecessary and obscures the gist of the present invention, the detailed description will be omitted.

[0086] In addition, the terminology described below is a term defined in consideration of the functions of the present invention, and it is different according to the user, operator's intention or custom, etc. ” is defined based on the entire content of this specification.

[0087] Next, preferred embodiments of the "micro-control protective film cutting device" of the present invention will be specifically described.

[0088] The following examples are illustrative only for explaining the present invention, and are not intended to limit the scope of the present invention.

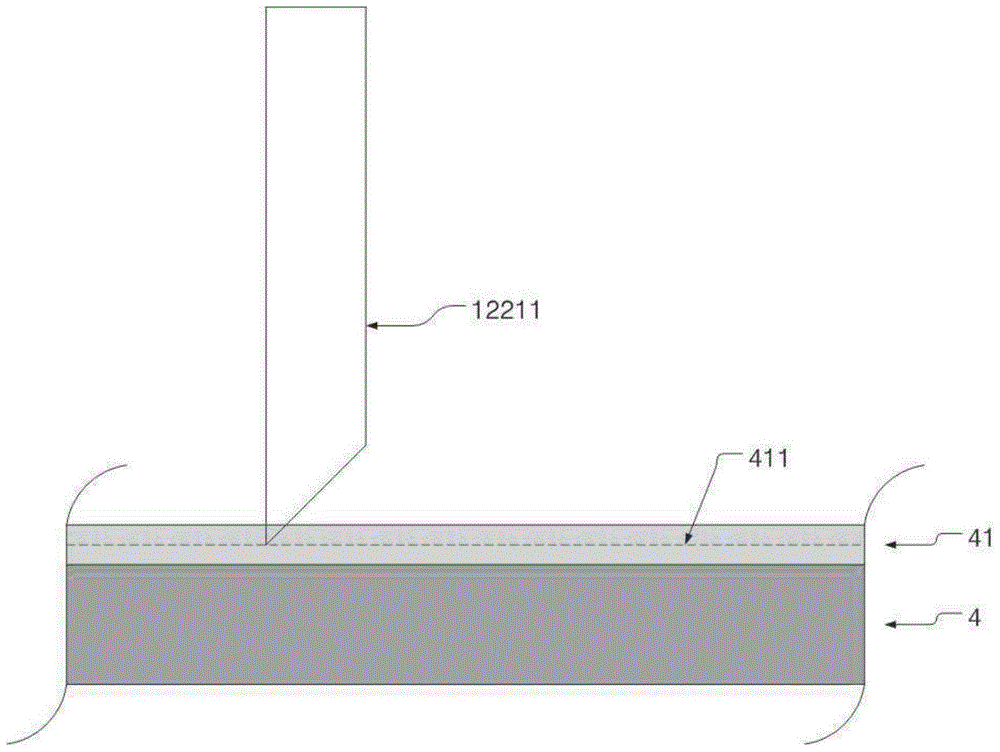

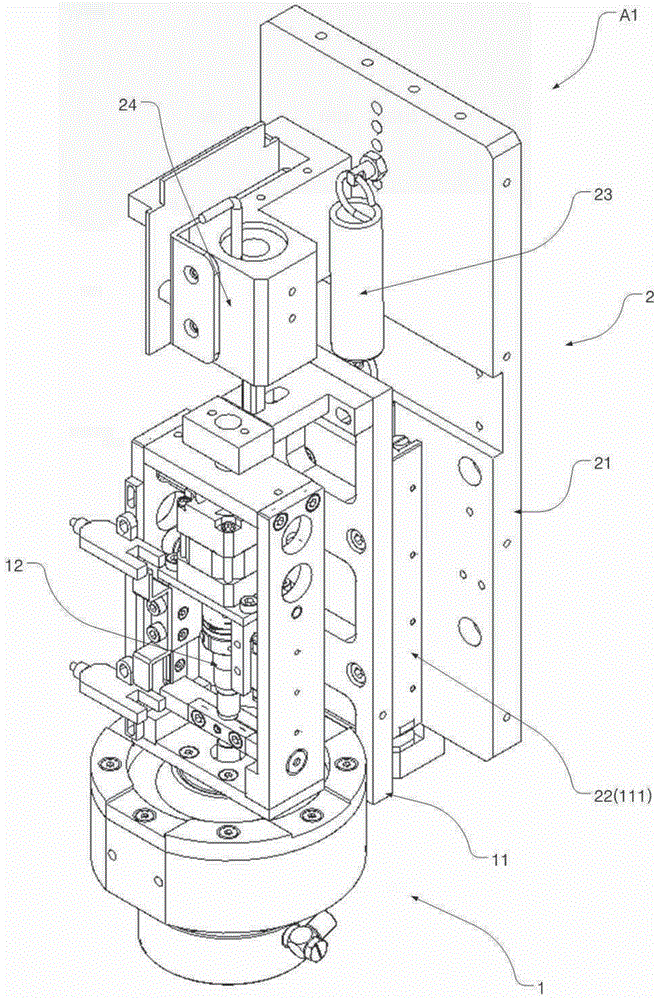

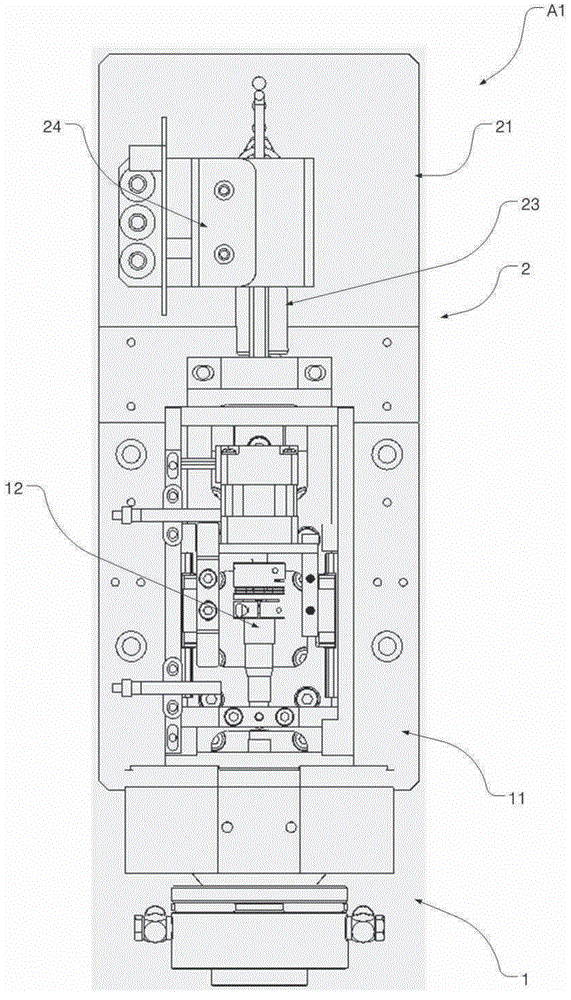

[0089] figure 1 It is a half-cut illustration of the micro-control protective film cutting device of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com