Flying saucer

A flying saucer and saucer body technology, applied in the field of aircraft, to achieve the effect of small air resistance and good stealth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

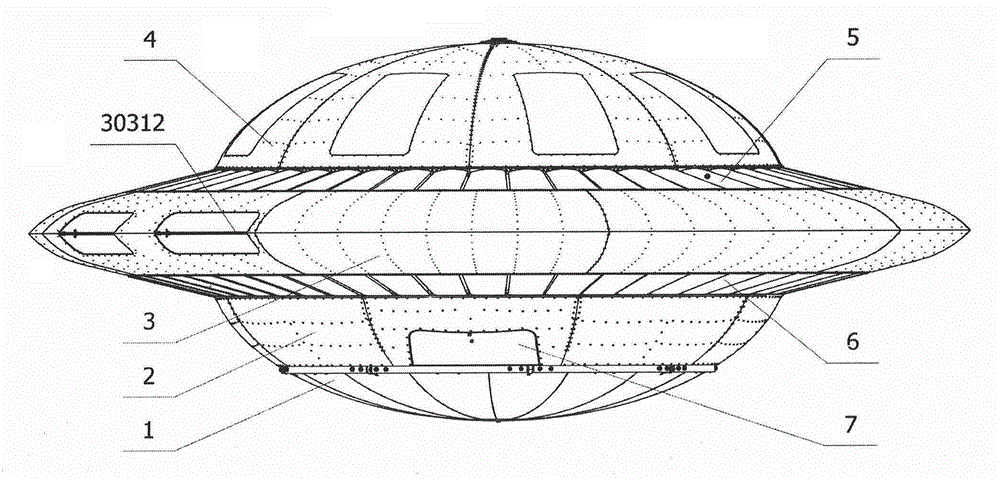

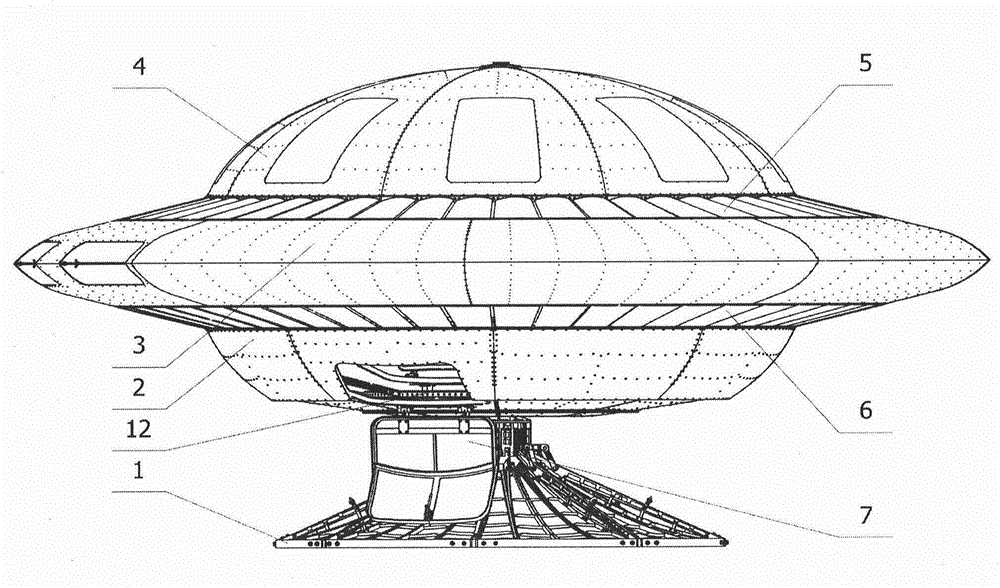

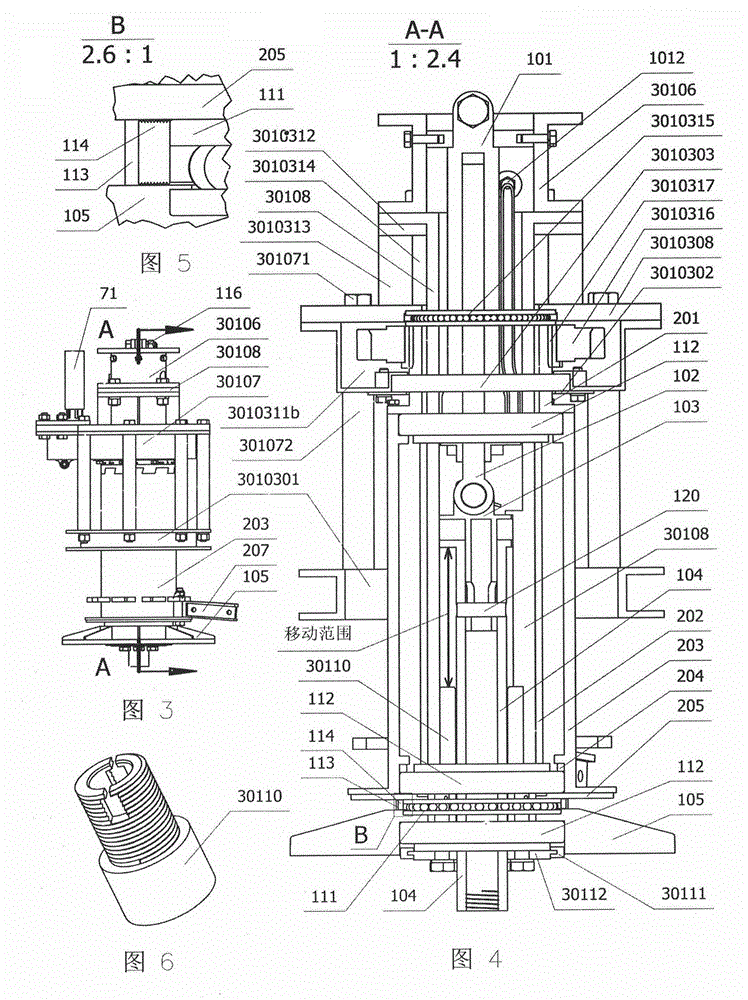

[0054] refer to Figure 1 to Figure 44 , the present invention comprises: landing gear 1, lower spin body 2, dish body 3, upper spin body 4, upper blade 5, lower blade 6, outer door 7, flight control system, described landing gear 1 closes against The bottom of the bottom spin body 2 is shaped like a spherical crown body, and its combined body and top spin body 4 are symmetrically distributed on the upper and lower sides of the side body. When landing, the undercarriage is shaped like a cone to support the flying saucer to land safely. Bottom spin body 2 is rotationally connected; the circular body in the middle of disc body 3 is the disc cabin, and the outer ring is the side body. The area between is the air flow channel that the rotating body drives the blades to rotate; the notch at the right fine-tuning plate 30803 of the side body is the air inlet, and the notch at the left fine-tuning plate 30312 is the air outlet; the lower rotating body 2 is installed Between the unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com