Edge penetrating device for netting machine

A net weaving machine and edge threading technology, which is applied in knotting net making, textile and paper making, knotting, etc., can solve the problems of large manpower investment, time-consuming and labor-intensive net weaving machine, and single function, so as to ensure quality and improve work Efficiency, the effect of ensuring the range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

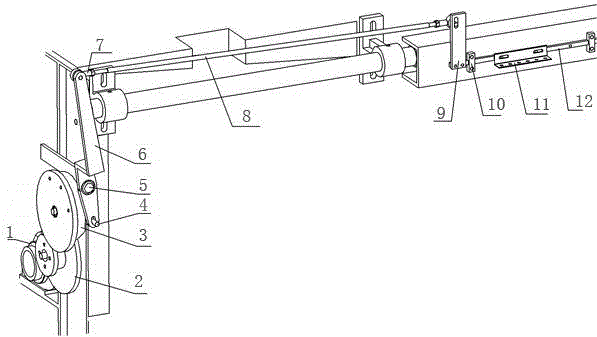

[0013] An edge piercing device for a net weaving machine, comprising a frame, a main gear 1 and a cam 3 are arranged on the frame, a gear set 2 is arranged between the main gear 1 and the cam 3, and a connecting rod 7 is arranged on the frame. A support 6 is provided under the rod 7, a rotating shaft 5 is provided on the support 6, a cam roller 4 is provided on the cam 3, a push rod 8 is provided behind the connecting rod 7, a push block 9 is connected behind the push rod 8, and a push block 9 is connected behind the push block 9. A guide rod 12 is connected, and a threading plate 11 is provided on the guide rod 12. The guide rod 12 is fixed on the frame through the connecting block 10. The support 6 is a Z-shaped structure, and the support 6 is provided with a connecting plate, which is divided into upper The connecting plate and the lower connecting plate, the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com