A transfer transport vehicle for automatic garbage sorting boxes

A technology of garbage sorting and sorting boxes, which is applied in the field of sanitation tool carts, and can solve the problems of poor working environment and insufficient automation of sanitation workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

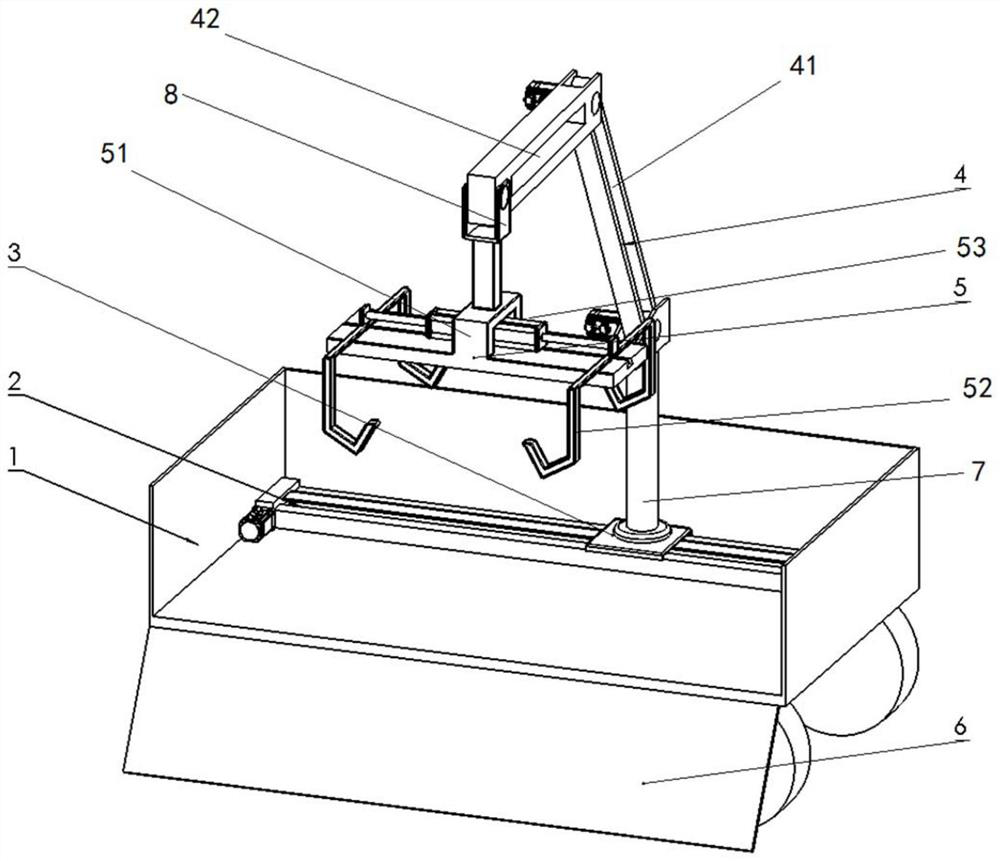

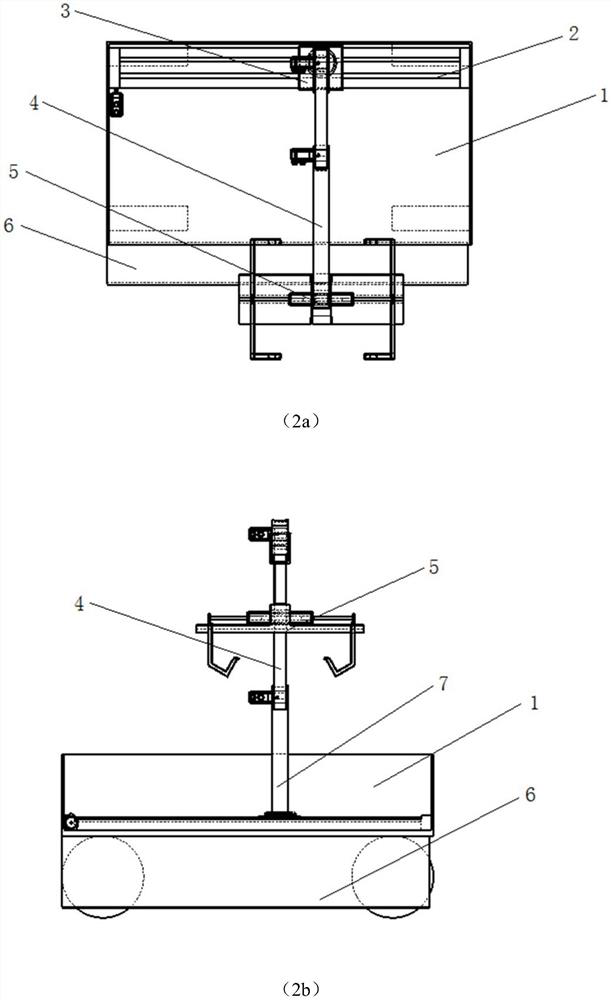

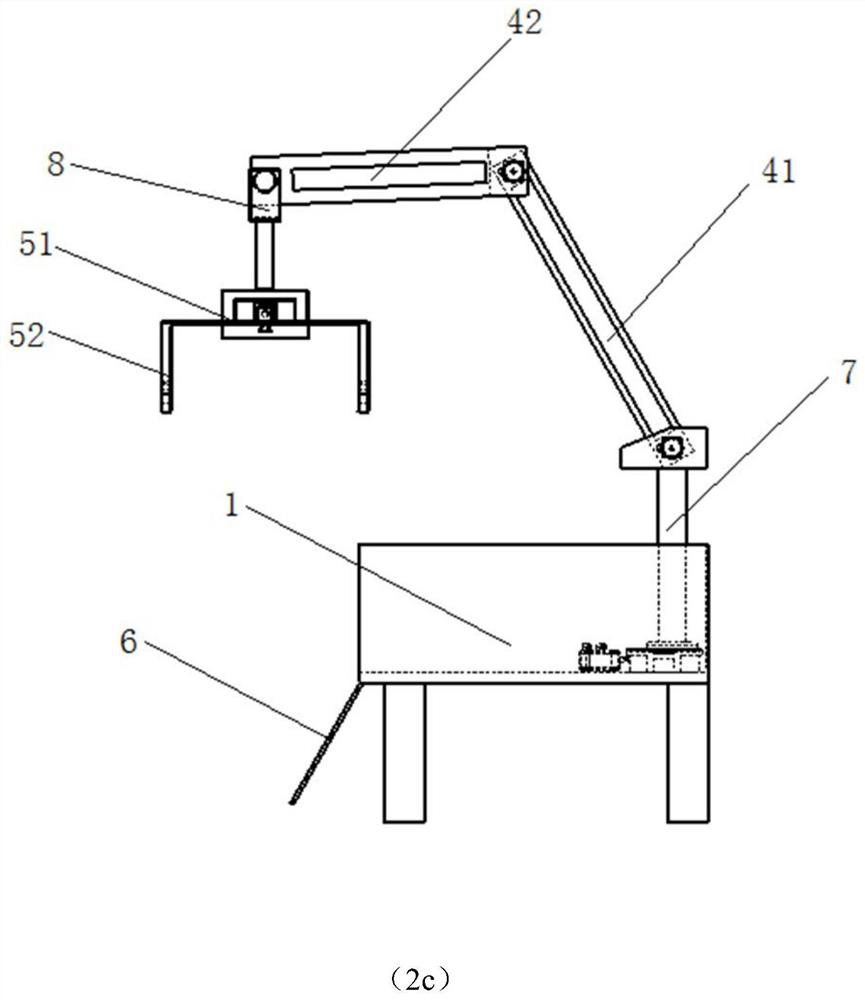

[0035] Such as figure 1 and figure 2 As shown, the present invention provides an automatic garbage sorting box transfer vehicle, including a carriage 1, a longitudinal linear guide rail 2, a mobile base 3, a mechanical arm 4, a clamp 5, and a side door panel 6.

[0036]The side door panel 6 of the compartment is an automatic overturning side door panel, which can be automatically opened and automatically retracted outwards and downwards by an electric push-pull rod. The longitudinal linear guide rail 2 is arranged on the carriage chassis, which is a sliding table type linear guide rail of aluminum alloy profiles, driven by a servo motor and driven by a synchronous belt. The mobile base 3 is installed on the longitudinal linear guide rail 2 through a slide table, and the mechanical arm 4 is connected to the mobile base 3, which is a light electric rigid arm balance crane, and its end effector is a clamp 5, which is a pneumatic box The body fixture is designed for the barrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com