Drainage structure of washing machine

A drainage structure and washing machine technology, applied in the field of washing machines, can solve the problems of slow start of dehydration, unable to discharge water in time, high moisture content of clothes, etc., and achieve the effect of convenient installation, good market promotion value, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

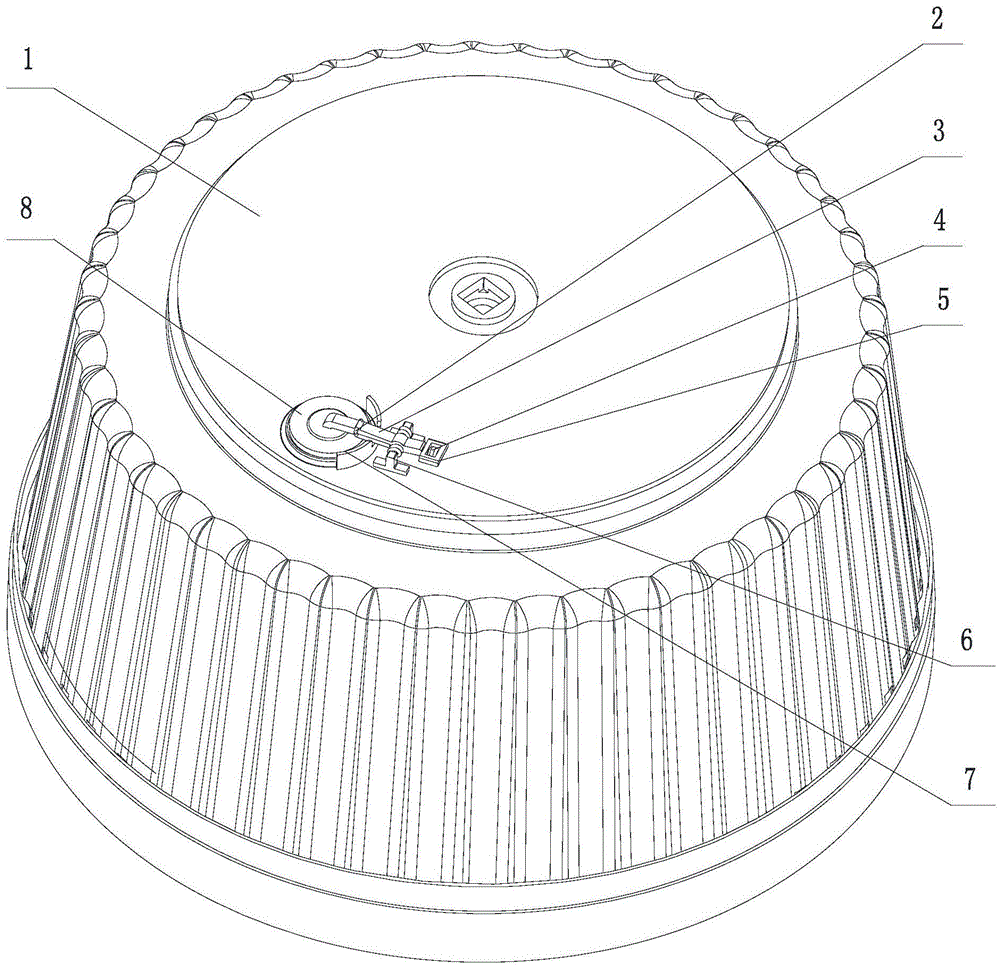

[0043] As a preferred embodiment of the present invention, the water sealing cover 8 is hingedly connected with the resistance arm end of the lever structure, the water sealing cover 8 can rotate freely around the center line of the resistance arm end of the lever structure, and the water sealing cover 8 and the inner barrel There is an included movable angle of 0-15° between the bottom walls, preferably, the included movable angle is 5°. Because the movement trajectory of the lever structure is a straight line, so when the water sealing cover 8 is covered on the drain, it is possible that a part will touch first while the other part has not been in contact, which will cause the drain cover to be lax and leak water. The drain cover 8 is used The hinged mode is connected to the lever structure, so that the sealing water cover 8 has a certain movable angle, which is more convenient for the water sealing cover 8 to cover the drain.

[0044] As a preferred embodiment of the presen...

Embodiment 1

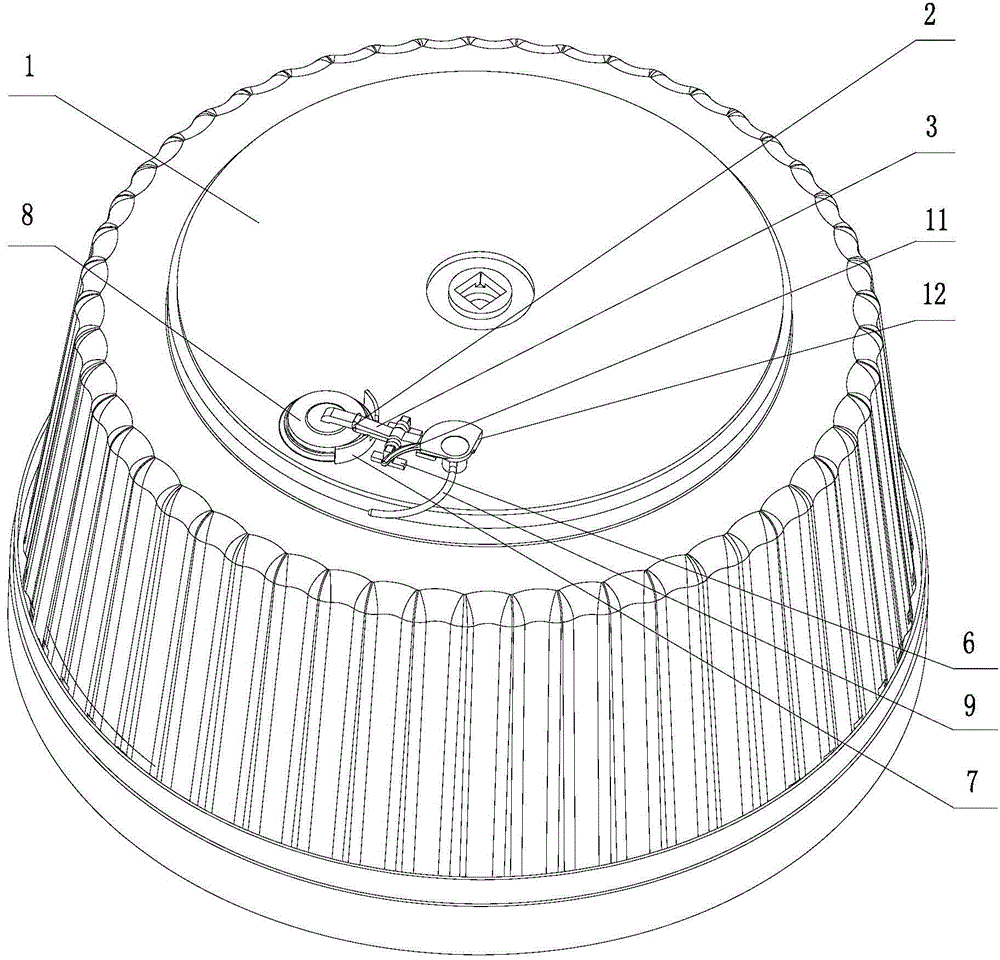

[0069] Such as figure 2 and image 3 As shown, the difference between this embodiment and the above-mentioned embodiment is that a kind of cam structure 12 suitable for the drainage structure of the washing machine of the present invention is provided. Since the cam 12 of the present invention is installed on the bottom wall of the inner tub 1 of the washing machine, as far as the installed position of the cam 12 is concerned, the contour curved surface is arranged on the upper surface of the cam 12 .

[0070] The cam 12 described in this embodiment is provided with a first lever 9 and a second lever 12, and the first lever 9 and the second lever 12 have a certain arc setting, and the center of the arc is located at the first stop lever assembly 16 and the second lever assembly. Second gear lever assembly 17 side. In this way, when the first lever assembly 16 and the second lever assembly 17 block the first lever 9 and the second lever 12, the first lever assembly 16 and th...

Embodiment 2

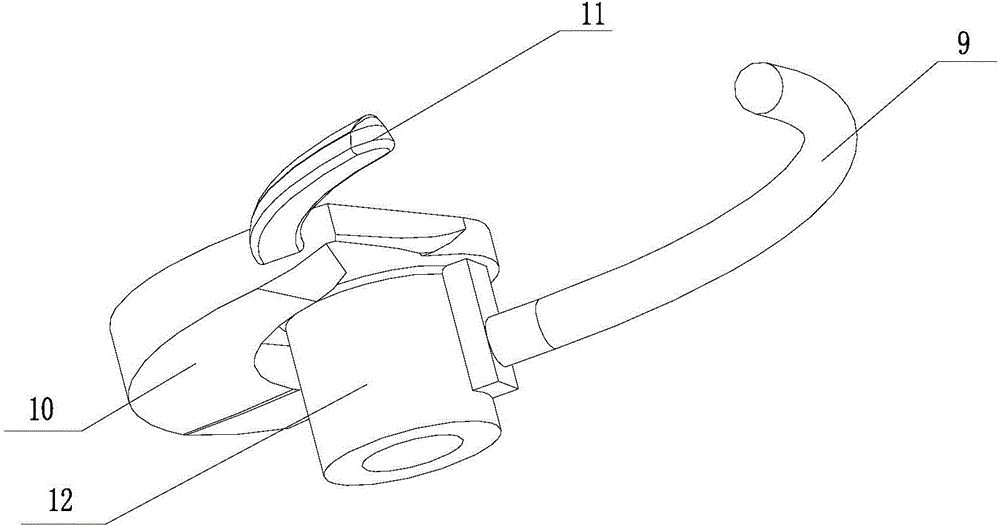

[0072] Such as Figure 12 and Figure 13 As shown, the difference between this embodiment and the above-mentioned embodiment is that a kind of cam structure 12 suitable for the drainage structure of the washing machine of the present invention is provided. Since the cam 12 of the present invention is installed on the bottom wall of the inner tub 1 of the washing machine, in terms of the installed position of the cam 12 , the curved surface 10 is arranged on the upper surface of the cam 12 .

[0073] The first driving rod 9 and the second driving rod 12 are arranged on the cam 12 described in this embodiment.

[0074] The cam 12 described in this embodiment is also provided with a first limiting portion 34 and a second limiting portion 35, the first limiting portion 34 is used to limit the rotation of the cam 12 to the position where the water sealing cover 8 opens the drain stop, the second limiting portion 35 is used to limit the rotation of the cam 12 to the position where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com