Beam-pumping unit based on direct drive motor

A technology of beam pumping units and direct drive motors, which is applied in the direction of machines/engines, engines, mechanical equipment, etc., can solve the problems of small changes in motor output power, increase production costs, and increase failure rates, so as to reduce failures probability, efficiency improvement, and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

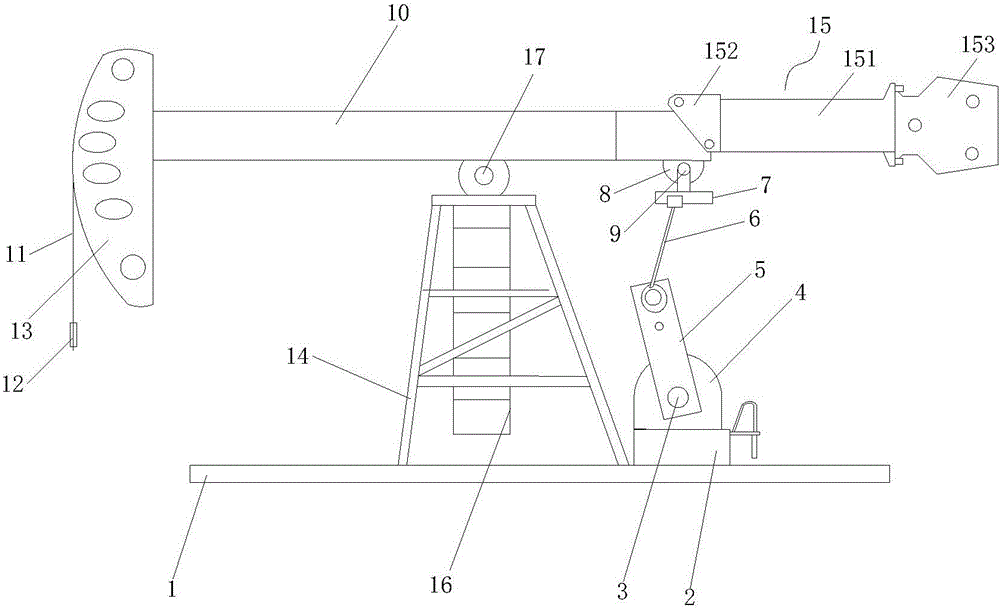

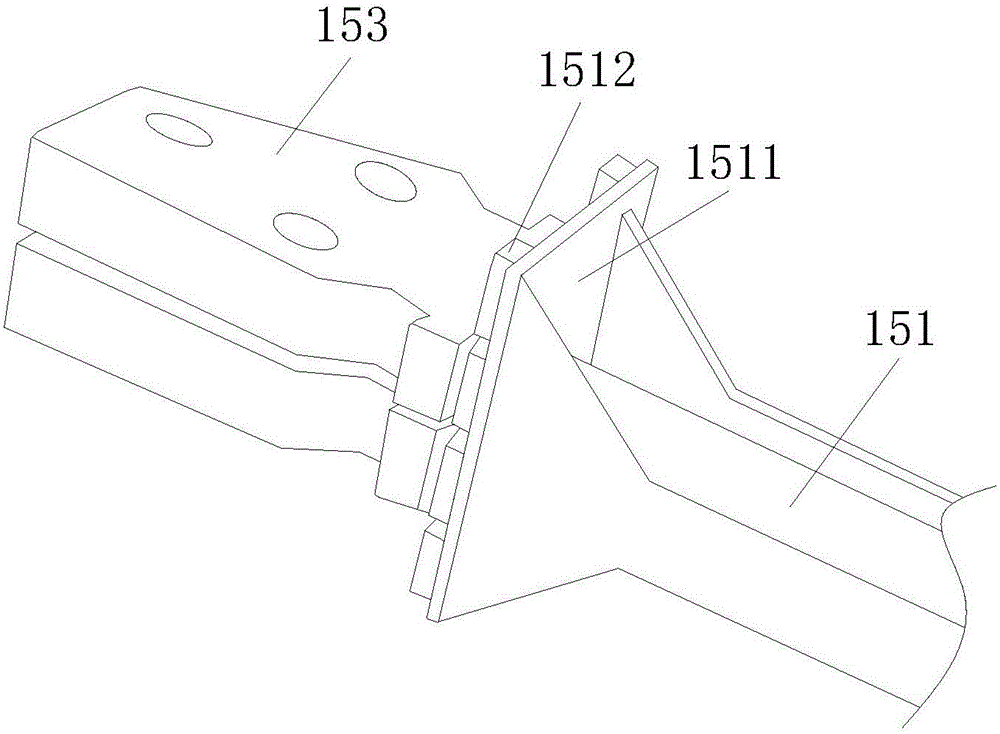

[0015] refer to figure 1 and figure 2 , a beam pumping unit based on a direct drive motor, comprising a base 1, the upper end of the base 1 is provided with a bracket 14, the bracket 14 is fixed on the base 1 by locking screws, increasing the stability of the pumping unit, the bracket The upper end of 14 is provided with beam 10, and support 14 is connected with beam 10 rotation by support shaft 17, can facilitate beam 10 to rotate and work. One end of the beam 10 is provided with a donkey head 13, and the donkey head 13 is provided with a suspension rope 11, and the suspension rope 11 is provided with a rope hanger 12. One end of the beam 10 away from the donkey ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com