Open type pitot tube pump

A pitot tube pump and pump casing technology, which is applied in the field of fluid pumps, can solve problems such as liquid leakage, and achieve the effects of prolonged service life, small swing, and reduced failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

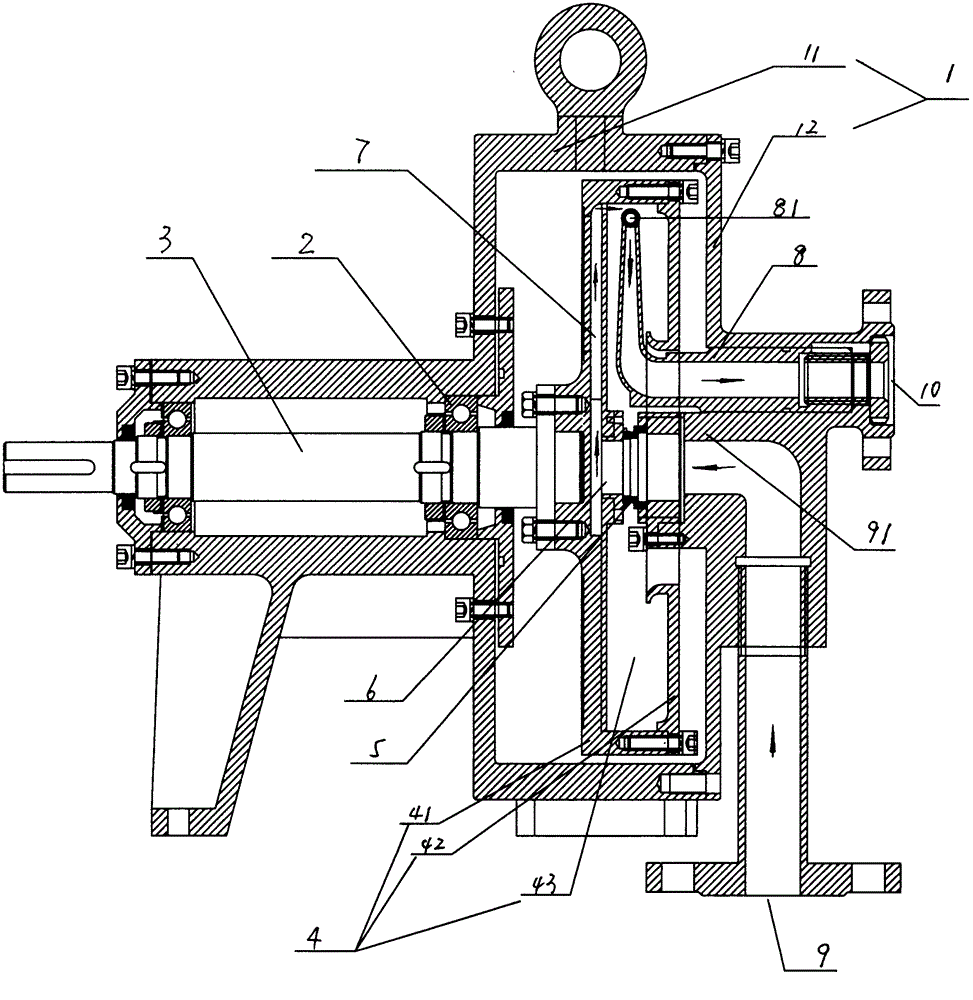

[0012] Below by embodiment, and in conjunction with accompanying drawing, the present invention will be further described:

[0013] Such as figure 1 As shown in the open Pitot tube pump, the pump shaft 3 is mounted on the bearing 2 in the pump casing 1 formed by the fixed connection of the pump body 11 and the pump cover 12, and the end of the pump shaft 3 is fixedly connected with the impeller body 41 and the impeller cover 42. The formed impeller 4 is provided with a mechanical seal 5 between the impeller suction port 6 and the pump suction port channel 91 . This impeller 4 is an open impeller, that is, its end has an opening, the impeller channel 7 is radial in the radial direction and the impeller 4 has a hollow rotor cavity 43, and the pump cover 12 is provided with a rotor cavity facing the impeller 4 The pump suction inlet flow channel 91 that stretches in 43, the pump suction inlet flow channel 91 forms a channel with the impeller suction inlet 7.

[0014] On the sid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap