High-pressure gas cylinder structure for inflation

A high-pressure gas cylinder and gas cylinder technology are applied in pressure vessels, fixed-capacity gas storage tanks, and container discharge methods, etc., and can solve the problems of waste and environmental protection, easy to cause safety problems, and uneconomical practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

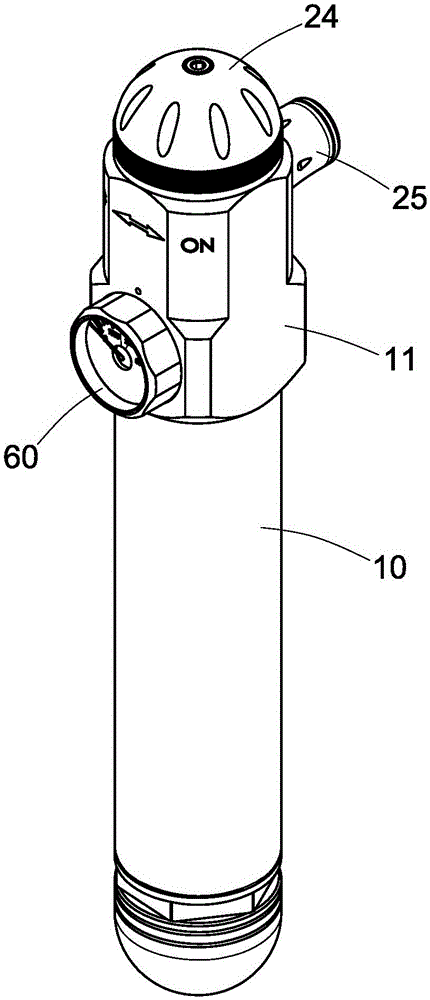

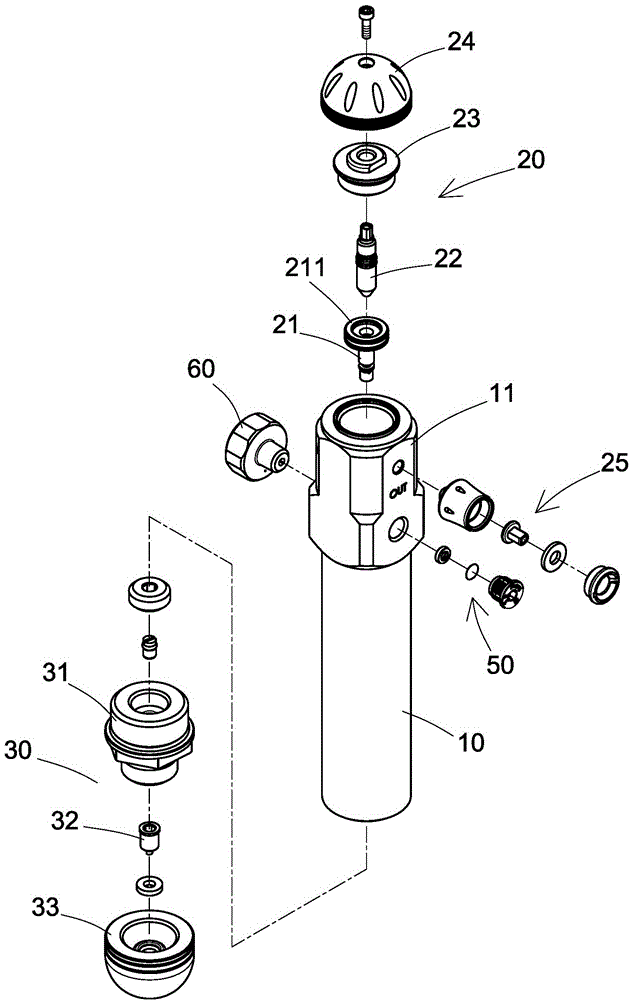

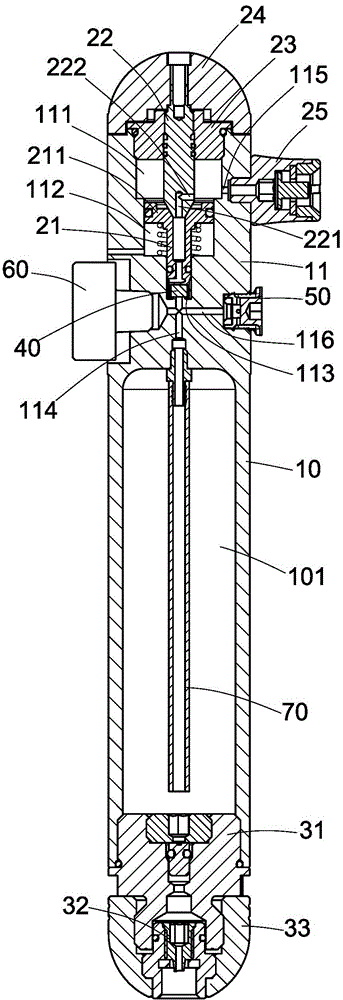

[0052] The drawings of the preferred embodiments of the present invention are further described below in order to enable those familiar with the relevant technologies of the present invention to implement according to the statements in this specification.

[0053] First, please refer to Figure 1 to Figure 7 As shown, it is a high-pressure gas cylinder structure suitable for inflating gas, which includes:

[0054] A gas cylinder body 10, the gas cylinder body 10 has a gas storage space 101 that can be filled with high-pressure gas, the top of the gas cylinder body 10 has a connecting portion 11 integrally formed with the gas cylinder body 10, the connecting portion 11 The interior has a first chamber 111, a second chamber 112, a third chamber 113 and an air guide channel 114 in axial communication, and the air guide channel 114 communicates with the gas storage space 101;

[0055] A decompression assembly 20, the decompression assembly 20 is mounted on the connecting portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com