Tunnel full-face diversion waterproof structure and construction method thereof

A waterproof structure and full-section technology, which is applied in tunnels, tunnel linings, drainage, etc., can solve the problems of increasing engineering volume and cost of grouting and water blocking, and achieves the effect of simple installation and splicing, convenience and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

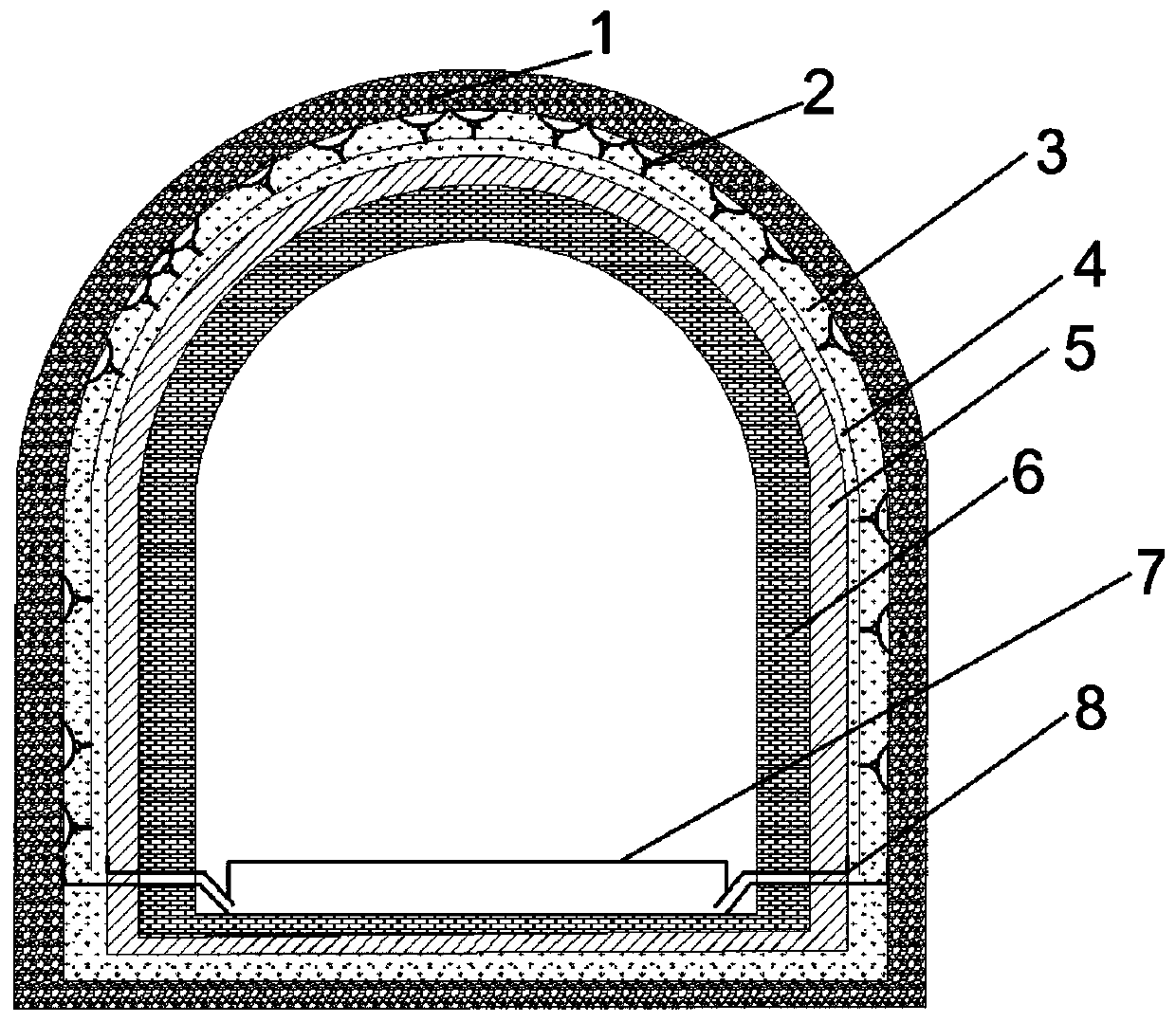

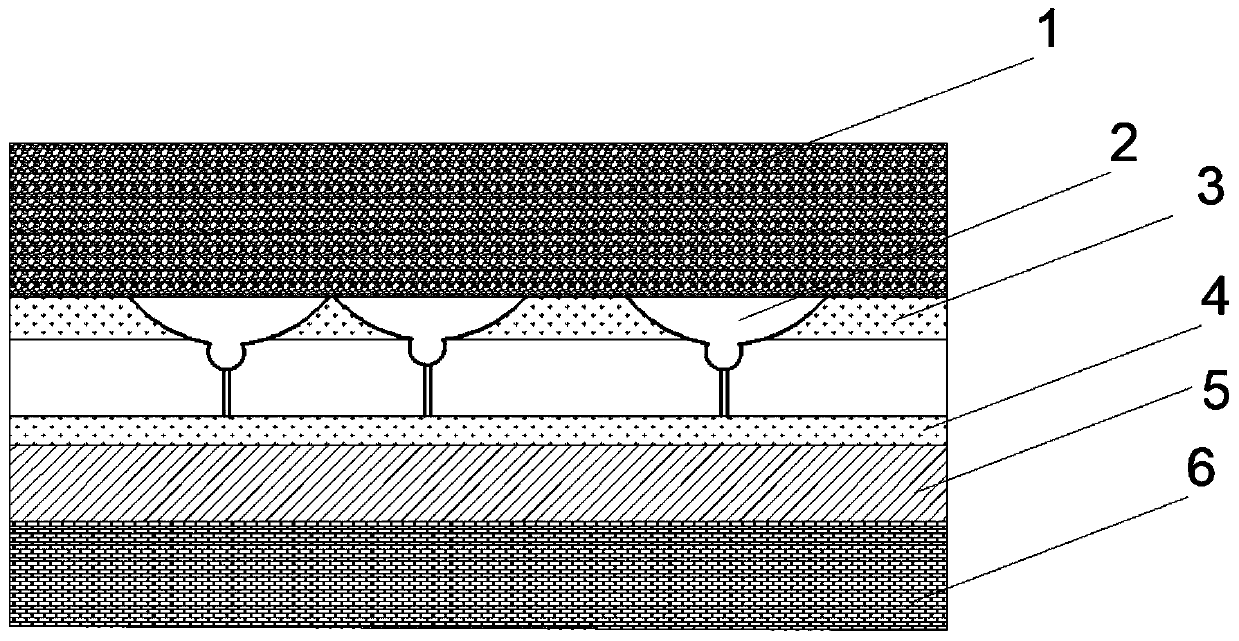

[0036] A drainage and waterproof structure for the full section of a tunnel, comprising a tunnel excavation profile layer 1, a water collection system 2, a primary support concrete layer 3, a water delivery system 4, a secondary lining waterproof layer 5, a secondary lining pouring layer 6, and a tunnel floor 7, gutter 8.

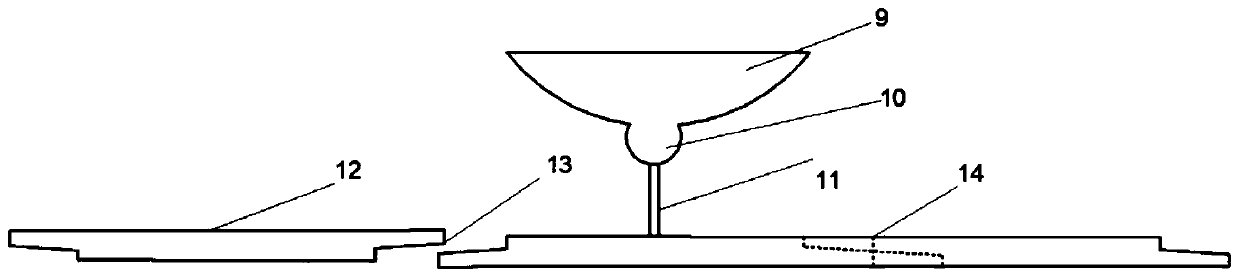

[0037] The water collecting system 2 is composed of a water collecting pan 9, a steering ball 10 and a steel pipe 11.

[0038] in:

[0039] The diameter of the outermost edge of the water collection tray 9 is 0.4m. The steering ball 10 is integrated with the water collection tray 9. The material is polyurethane rubber. The steering ball 10 has high toughness and elasticity; the upper and lower ends of the steel pipe 11 are threaded, and the diameter of the steel pipe is 5cm. The length is 0.25m, and it is used to connect the water collection system 2 and the hollow PVC board 12 for water delivery.

[0040] The position of the water collection tray 9 can b...

Embodiment 2

[0051] The construction method of the drainage and waterproof structure of the full section of the tunnel, the steps are as follows:

[0052]1) The construction drainage tank 8 is made of concrete.

[0053] 2) Record and analyze the cracks and water seepage of the tunnel excavation contour layer. Set appropriately more water collecting pans 9 at positions with dense cracks and large water seepage, and set appropriately less water collecting pans at positions with sparse cracks and small water seepage. water tray9. The diameter of the outermost edge of the water collection tray 9 is 0.4m, and the steering ball 10 is integrated with the water collection tray 9. The material is polyurethane rubber, and the steering ball 10 has high toughness and elasticity. The water collecting tray 9 is fixed through the primary support concrete layer 3 . A gap of about 7 cm is maintained between the primary concrete layer 3 and the water delivery system 4 .

[0054] 3) According to the posit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com