Stepping motor driving device and timepiece

A technology of stepping motor and driving device, applied in clocks, electromechanical clocks, electric winding, etc., can solve the problems of accelerating battery consumption and increasing power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0015] (the whole frame)

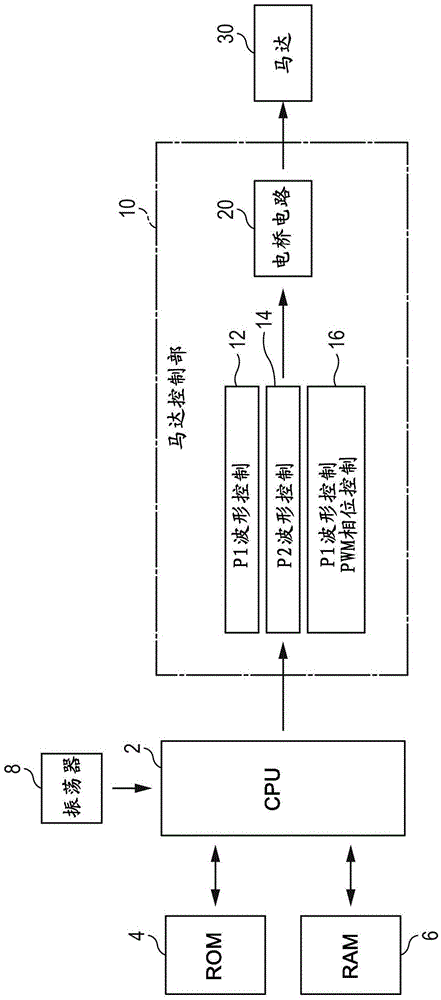

[0016] Next, refer to figure 1 The shown block diagram explains in detail the stepping motor drive device according to the first embodiment of the present invention.

[0017] exist figure 1 Among them, a CPU (Central Processing Unit) 2 outputs various commands to the motor control unit 10 based on a control program stored in a ROM (Read Only Memory) 4 . RAM (Random Access Memory) 6 is used as the working memory of CPU2. An oscillator (referred to as "OSC") 8 outputs an operating clock pulse to the CPU 2 .

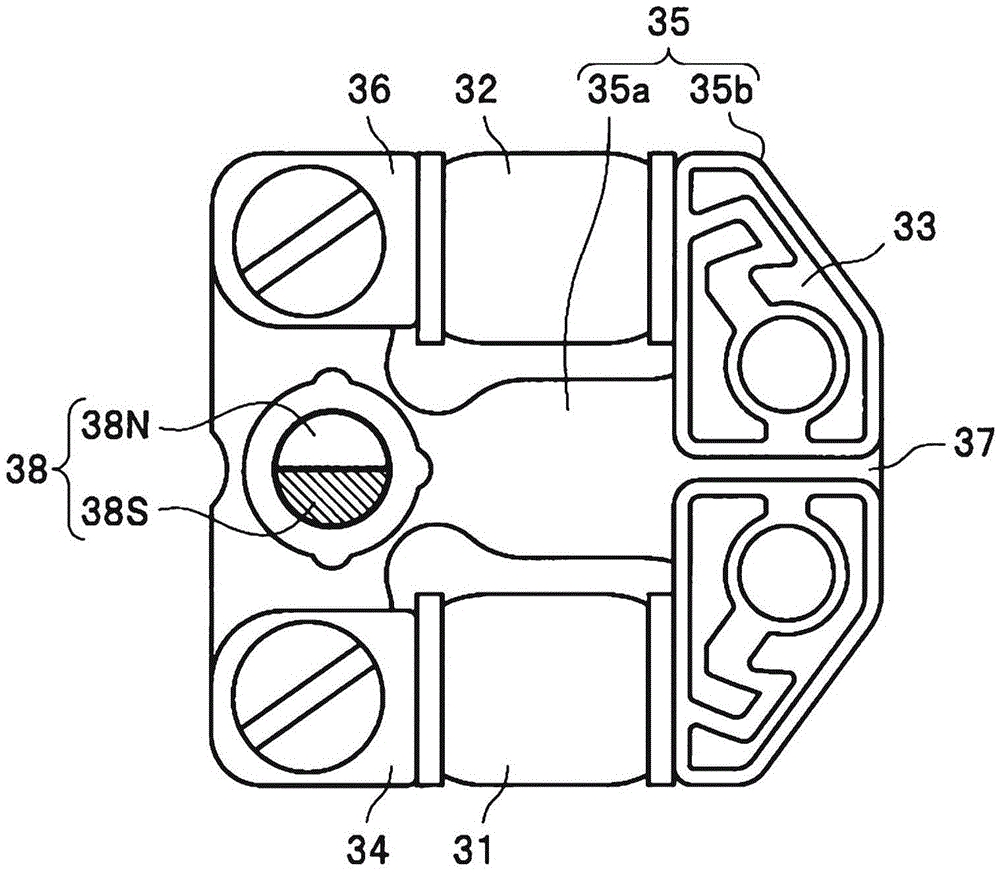

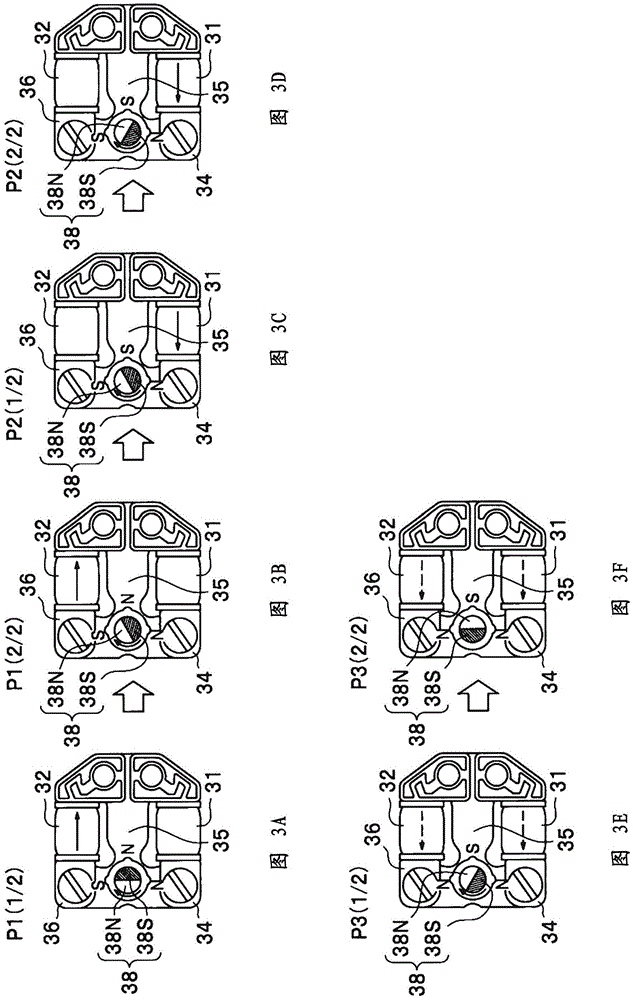

[0018] The stepping motor 30 has a rotor with permanent magnets and a stator with two coils. The bridge circuit 20 in the motor control unit 10 drives the stepping motor 30 by applying a square wave or PWM (pulse width modulation) modulated voltage to these two coils. In the driving state of the stepping motor 30 , there are three phases of phases P1 , P2 , and P3 , which will be described later. The P1 waveform control unit 12 , the P2 wave...

no. 2 Embodiment approach

[0047] Next, refer to Figure 8 The plan view shown is an explanation of an analog timepiece according to a second embodiment of the present invention.

[0048] exist Figure 8 Among them, the analog timepiece 500 has: a dial 501 , and two hands (hour hand and minute hand) 502 that rotate on the dial 501 around a pointer axis 504 . In addition, two stepping motors 30 are installed on the back side of the dial 501 corresponding to the two pointers 502 , and the corresponding pointers 502 are rotationally driven via respective needle movement mechanisms 503 .

[0049] These stepping motors 30 are the same as the stepping motors 30 described in the first embodiment, and are composed of figure 1 Driven by the stepper motor driver shown. It also goes without saying that more hands can be provided on the analog timepiece 500. According to this embodiment, using the stepping motor drive device of the first embodiment ( figure 1 ) rotates the pointer 502, so that the peak value o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap