External resonator and semiconductor laser module using the same

An external resonator, laser module technology, applied in the structure/shape of semiconductor lasers, semiconductor laser optical devices, optical resonators, etc., can solve the problems of wide installation space, increase in the number of parts, high price, etc., and achieve the reduction of the number of parts, Reduced installation space and excellent spectral characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

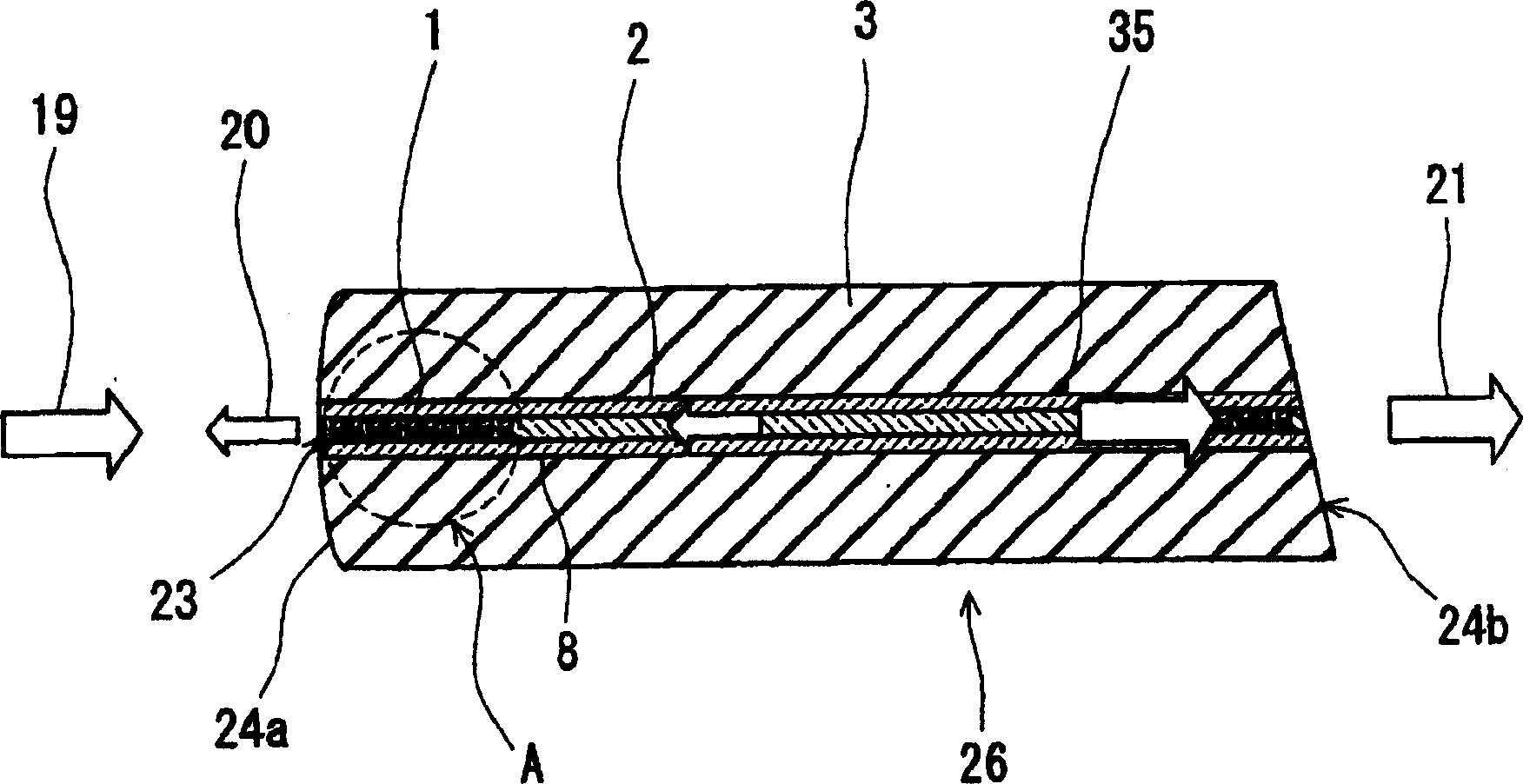

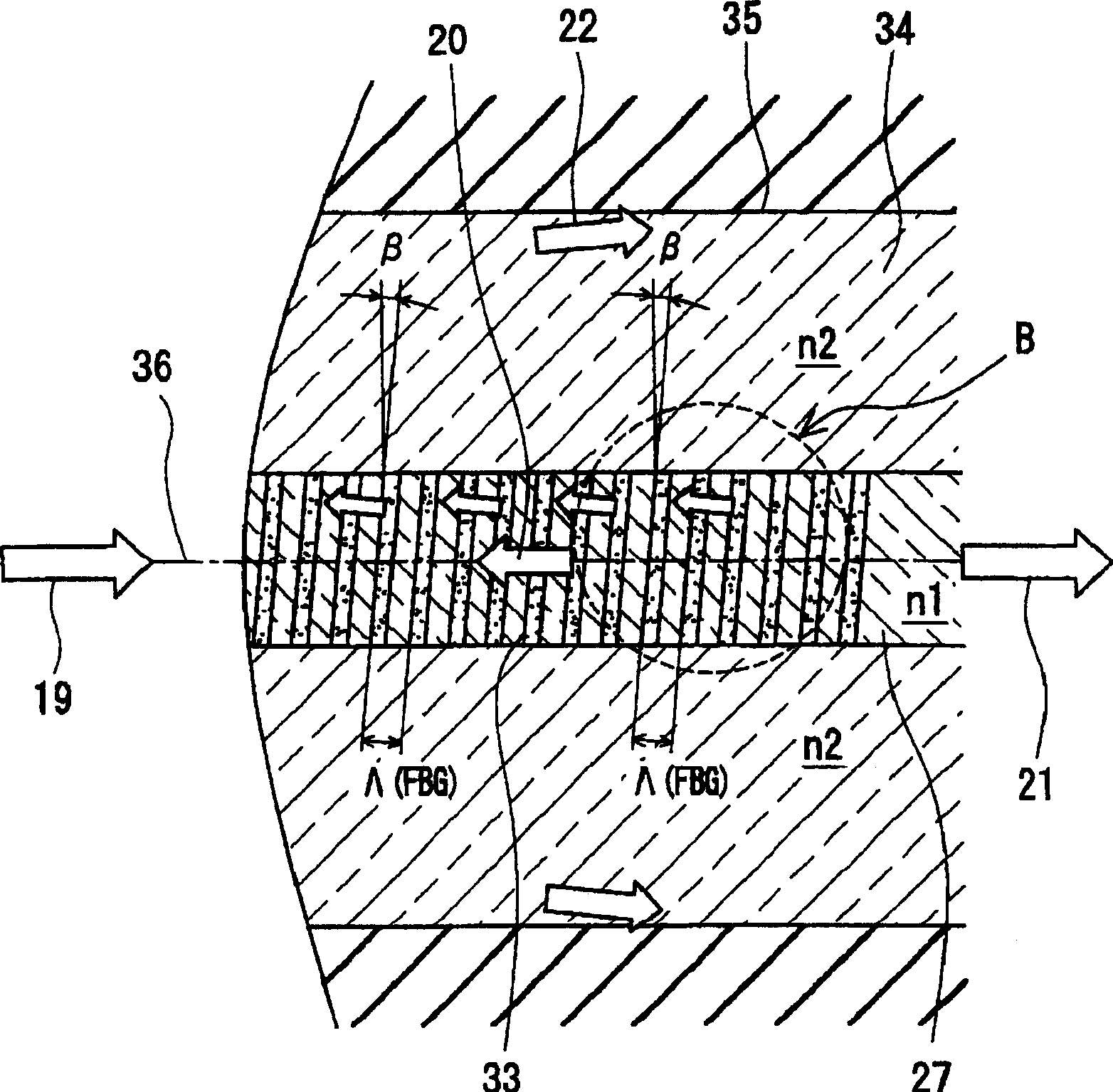

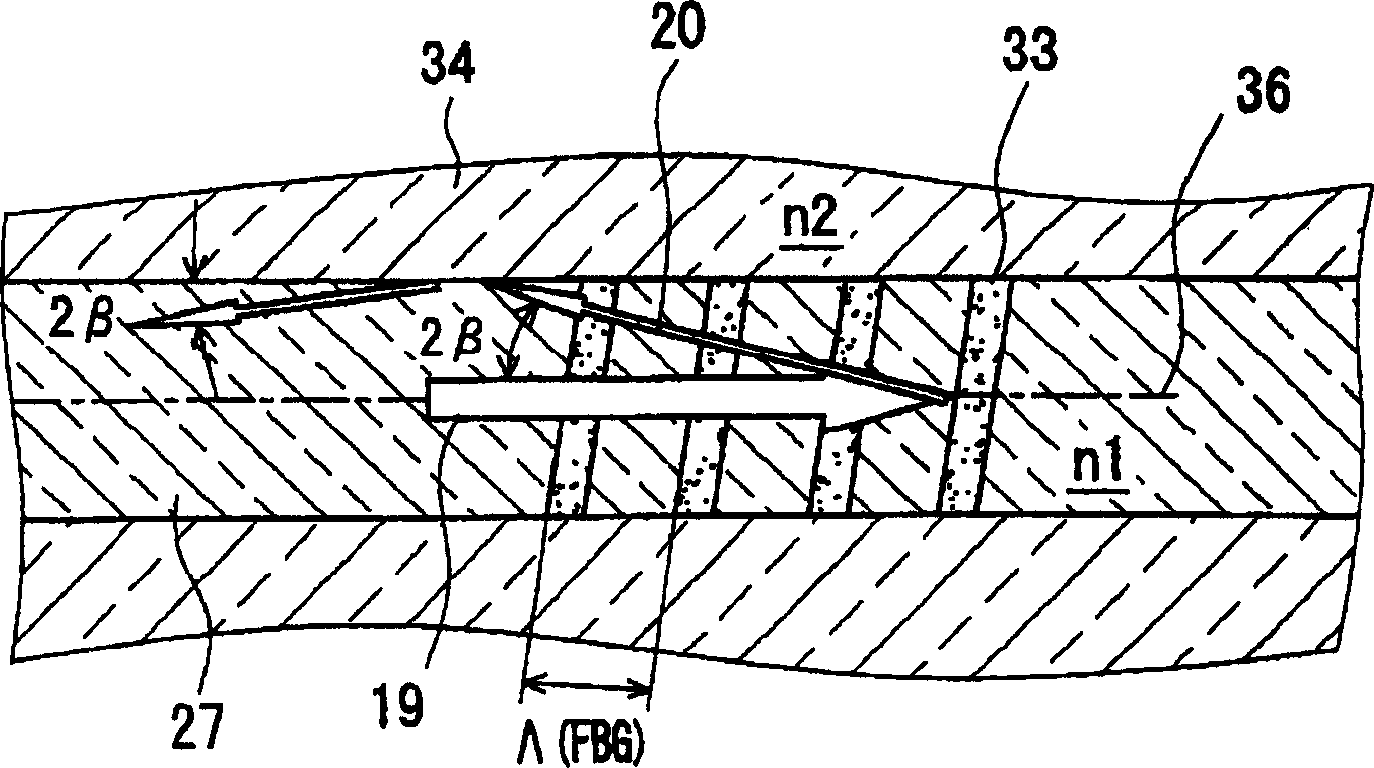

[0090] actually fabricate the external resonator according to the invention and install it in Figure 7 shown in the semiconductor laser module. Using the mode effective refractive index n 1 =1.525, n 2 =1.51, Δ=0.00979, the phase mask 17 of the optical fiber 2 of θc=8° and Λ (MASK)=951 (nm), make reflected light central wavelength λ B FBG1 at 1450nm. Here, Δ and θ c It can be calculated by the following formula.

[0091] Δ=(1.525 2 -1.51 2 ) / (2×1.525 2 ) = 0.00979

[0092] θ c = sin -1 (2×0.00979) 1 / 2 =8.04°

[0093] The intensity of the UV light irradiated to the phase mask 17 is about 500 mW. In addition, the intensity distribution of UV light has a Gaussian shape, and the magnitude of the amount of change in the refractive index of FBG1 has a Gaussian shape distribution in the central axis direction of FBG1. And, at the time of recording, the optical fiber is tilted by the inclination angle β from the horizontal. Here, the inclination angle β=3° (0°c / 2).

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com