Infrared heating devices and electric heating appliances

An infrared heating and infrared heating film technology, applied in the fields of electric heating appliances and infrared heating devices, can solve the problems that the heating carrier cannot meet the conditions of use and the heating is uneven, and achieve the effect of consistent resistivity and guaranteed heating power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

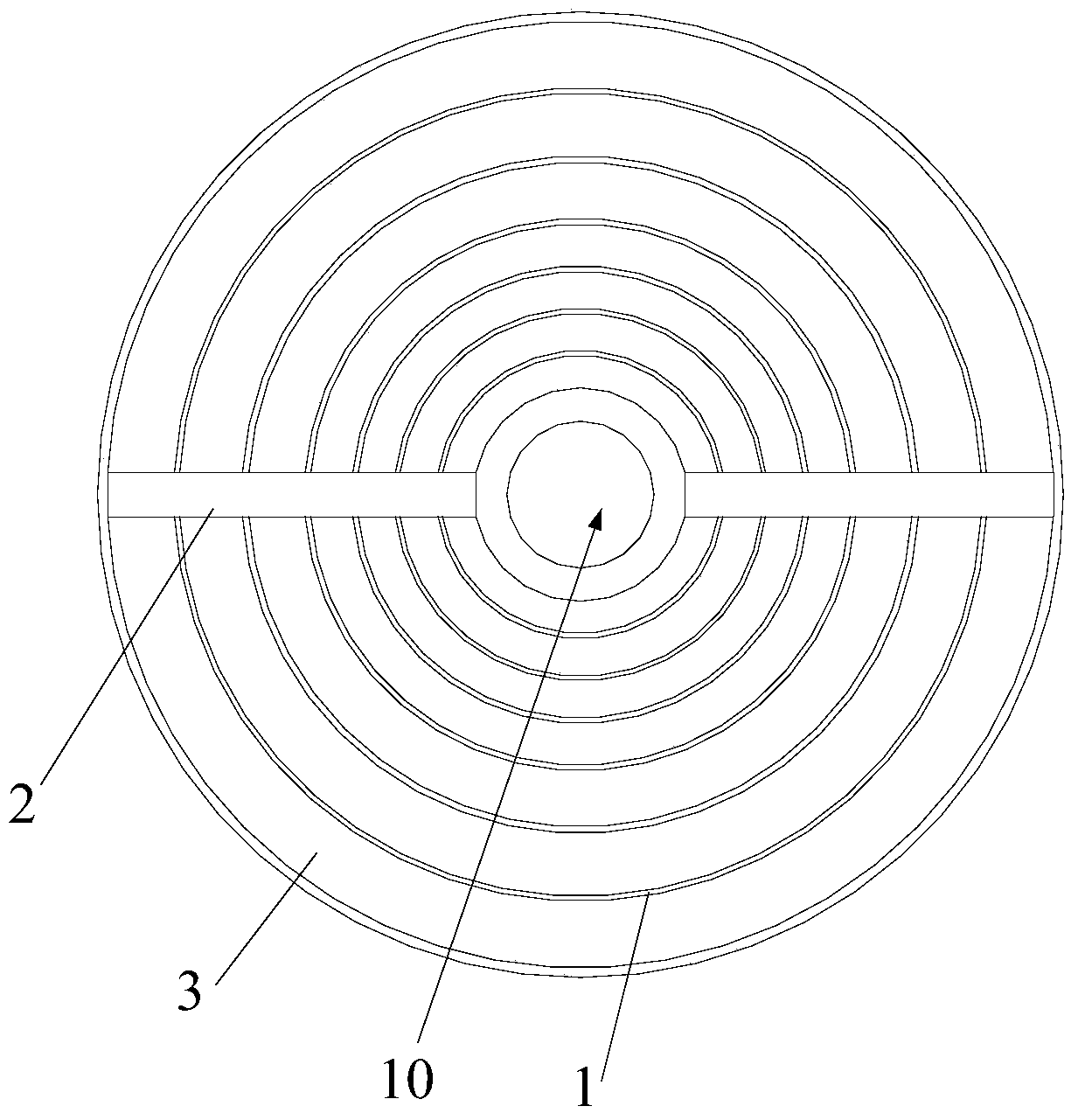

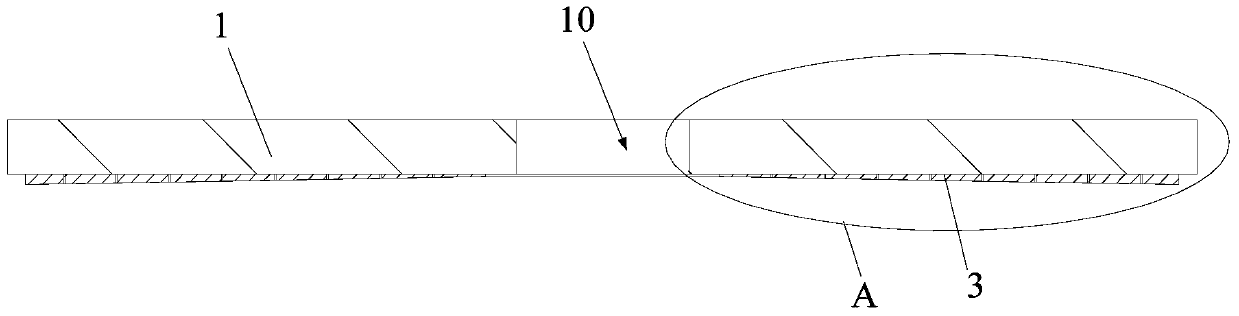

[0056] Such as Figure 2a and Figure 2b As shown, on the infrared heating film layer 3, along the radial direction of the insulating carrier 1, from the center of the insulating carrier 1 to the edge of the insulating carrier 1, the infrared heating film layer 3 The thickness gradually increases.

[0057] On the same infrared heating film layer, from the center of the insulating carrier to the edge of the insulating carrier, the thickness of the infrared heating film layer gradually increases, so that the ratio of the length and cross-sectional area of the inner and outer sides of the same infrared heating film layer is equal, so that the same infrared heating film layer The resistivity of the inside and outside of the film layer is basically unchanged, which is beneficial to ensure that the resistivity of the uniform infrared heating film layer is consistent, and then helps to ensure that the heating power of the infrared heating device is consistent.

[0058] further, s...

Embodiment 2

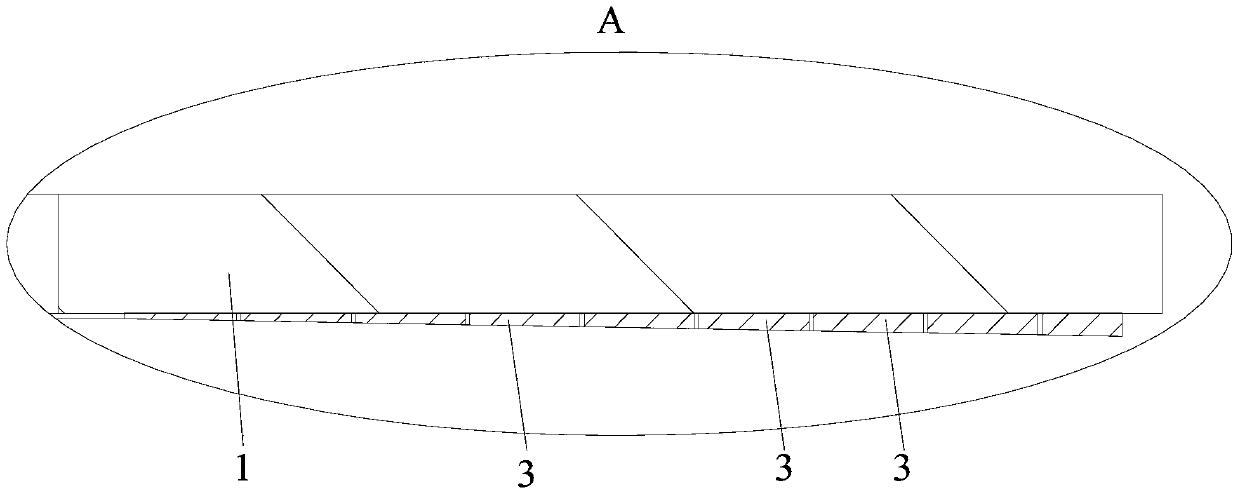

[0061] Such as Figure 3a and Figure 3b As shown, on the infrared heating film layer 3, along the radial direction of the insulating carrier 1, from the center of the insulating carrier 1 to the edge of the insulating carrier 1, the infrared heating film layer 3 The thickness remains the same.

[0062] On the same infrared heating film layer, from the center of the insulating carrier to the edge of the insulating carrier, the thickness of the infrared heating film layer remains unchanged, the cross-section of the infrared heating film layer is rectangular, and the cross-sectional area is easy to calculate. It is easier to implement the scheme of increasing the cross-sectional area of the infrared heating film layer by increasing the ratio, and the processing is convenient.

[0063] In one embodiment of the present invention, the insulating carrier 1 is circular, the cross-sections of the plurality of infrared heating film layers 3 are circular, and the connecting lines of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com