Microwave Microchip Reactor

A reaction device and microchip technology, which is applied in the field of microwave microchip reaction devices, can solve the problems of local overheating, inability to achieve, and destroy, and achieve the effects of uniform heating temperature and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

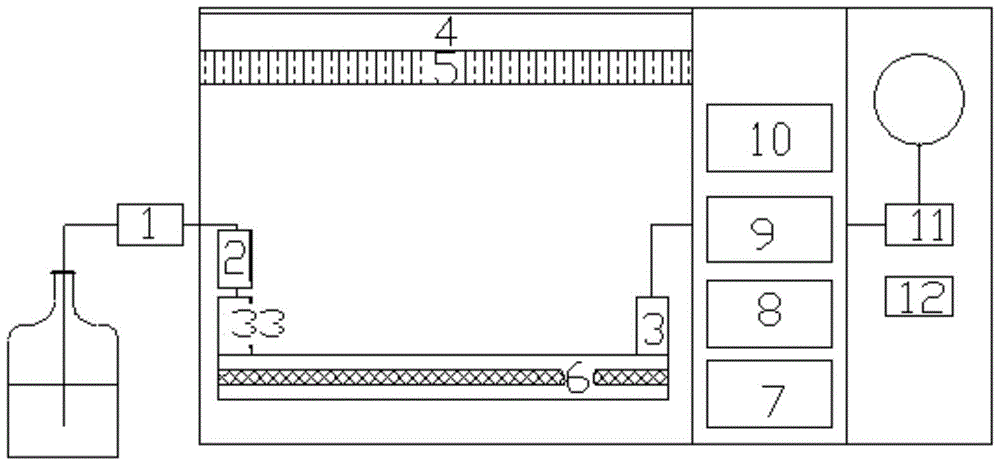

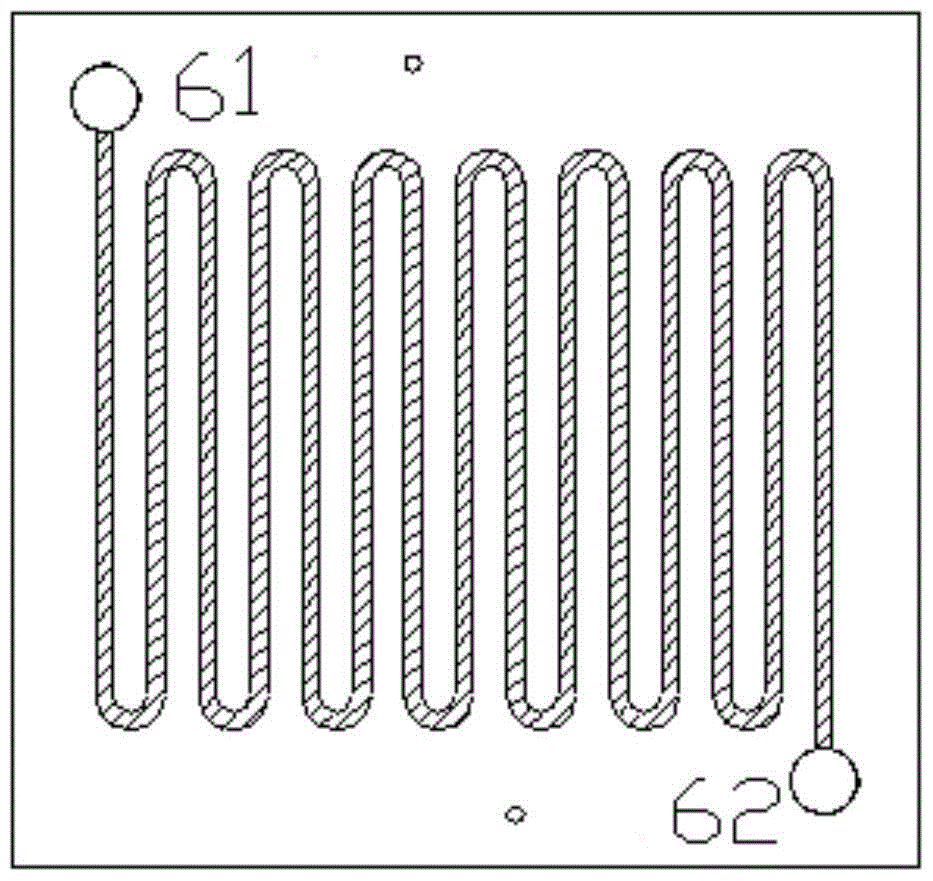

[0015] The microwave microchip reaction device of the present embodiment comprises a microwave generating module, a microchannel reactor 6, and a feeding system 11, and the feeding system 11 is communicated with the microchannel reactor 6 through a pipeline, and the microwave generating module is supplied to the microchannel reactor 6. The fluid in the channel reactor 6 provides microwave heating. The microwave generation module includes a magnetron 9, a microwave energy exporter 10, a waveguide 4, and a waveguide array 5. The waveguide array 5 is a two-dimensional plane accumulation of several waveguides on a plane perpendicular to the microwave emission direction of the waveguide array. The direction of each waveguide is the same as the emission direction of the waveguide array 5 , and the magnetron 9 generates microwaves and transmits them to the microwave energy exporter 10 through the waveguide 4 to the waveguide array 5 for emission. The microchannel reactor 6 of this em...

Embodiment 2

[0035] Other settings are the same as in Example 1, but the microchannel width of the microchannel reactor 6 is 3 millimeters.

Embodiment 3

[0037] Using the device described in Example 1, feed 1mmol of salicylaldehyde, 2mmol of malononitrile, 1mmol of p-methylthiophenol, and 0.2mmol of pyridine dissolved in 4mL of ethanol. The reaction continued for 15 minutes at a feed rate of 1 / min. After post-treatment, cooling, filtration, and washing with ethanol gave 0.306 g of a white solid, with a yield of 85%.

[0038] After conventional reaction for 3 hours, 0.266g of white solid was obtained, yield 74%;

[0039] The microwave reaction time was shortened to 8.3% of the original, and the yield increased by 11%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com