Dry burning preventing glass kettle

A dry-boiling and glass-proof technology, which is applied to boiling water utensils, cooking utensils, household utensils, etc., can solve the problems of short pot life, casualties, product damage, etc., achieve simple structure, reduce damage, and improve use safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

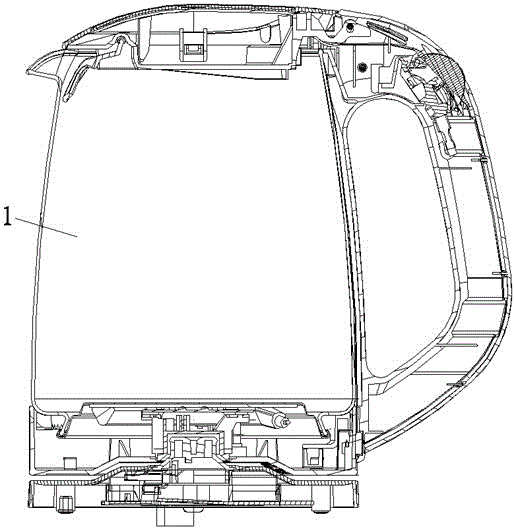

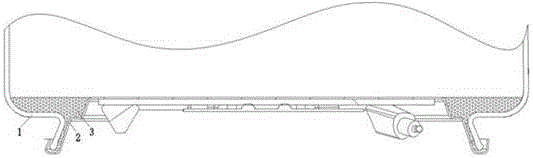

[0018] refer to Figure 1-2 , this embodiment proposes an anti-dry boiling glass kettle, comprising a kettle body 1, the bottom of the kettle body 1 is provided with an annular connecting wall, and the annular connecting wall is a trumpet-shaped structure, and the periphery of the kettle body 1 is provided with a sealing recess. groove, and the sealing groove is located at the end of the ring-shaped connecting wall, the bottom of the pot body 1 is provided with a heating plate 2, the periphery of the heating plate 2 is provided with a side wall, and the edge of the side wall is provided with an annular groove. The wall is located in the annular groove, and the side wall is fixed in the sealing groove, the annular connecting wall and the side wall form a sealing structure, and the top of the heating plate 2 and the sealing structure form a water storage tank, the water storage tank is connected with the sealing structure, and the storage The sink is filled with water 3;

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com