Detecting equipment and detecting method for insulation and voltage resistance detection of motor coil

A technology for testing equipment and coil insulation, applied to lighting and heating equipment, dryers, drying, etc., can solve problems such as low production efficiency, misjudgment of misjudgments, product quality problems, etc., to reduce labor intensity and eliminate errors Judgment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

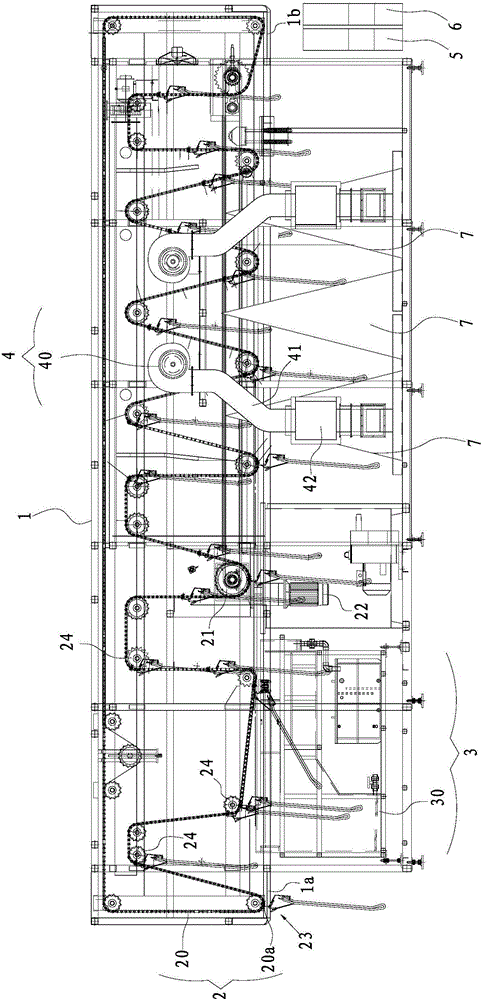

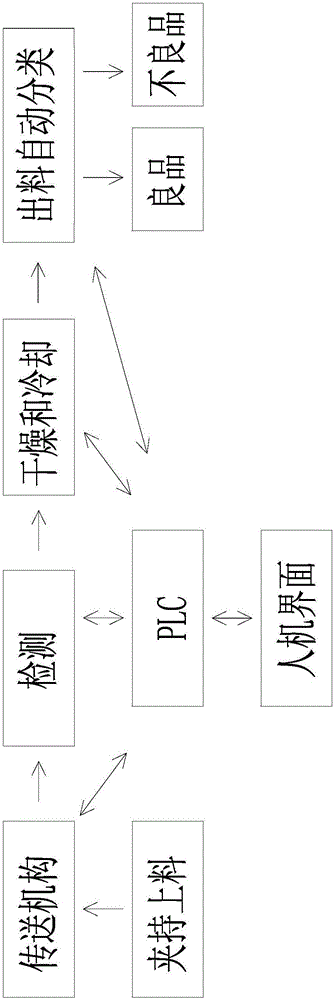

[0029] Such as figure 1 As shown, the detection equipment for the insulation withstand voltage detection of the motor coil provided by this embodiment includes a chassis body 1 with a plurality of processing stations and inlet and outlet openings 1a and 1b; being located in the chassis body 1 can make the motor coil The transmission mechanism 2 transferred between multiple processing stations; the automatic discharge insulation withstand voltage detection mechanism 3 located in the station near the feed port 1a of the cabinet body 1; the automatic discharge insulation withstand voltage detection mechanism 3 and the cabinet body 1 The air-drying mechanism 4 between the discharge port 1b is used to dry the liquid on the surface of the motor coil after detection; the retrieving mechanism is located at the discharge port 1b of the chassis body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com