A cleaning device for automatically cleaning vertical cylindrical components

A cleaning device and automatic cleaning technology, applied in the direction of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of difficult cleaning, unsafe cleaning manual climbing, etc. The effect of convenient disassembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

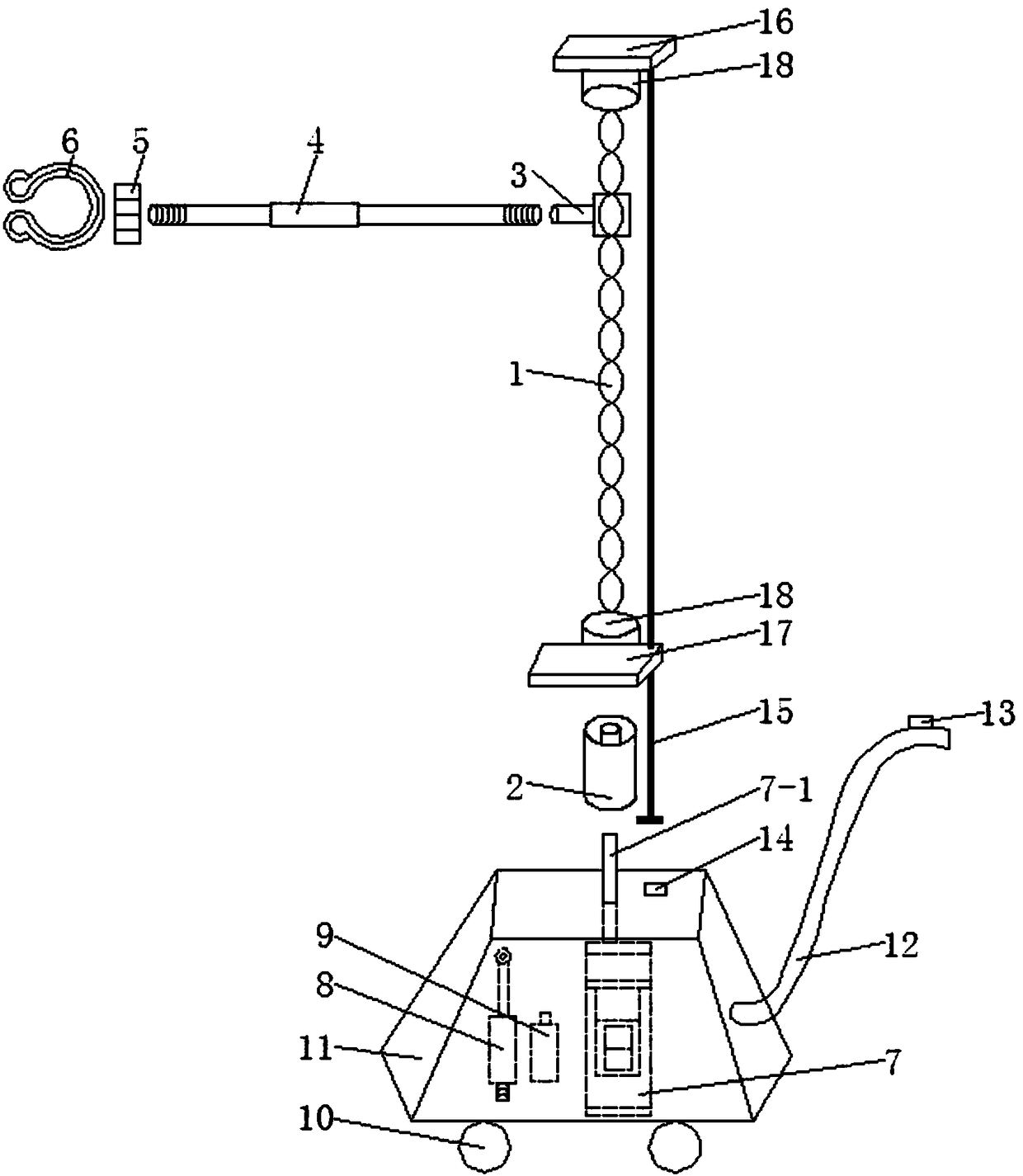

[0014] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0015] See figure 1 , a cleaning device for automatically cleaning vertical cylindrical members of the present invention, has a screw screw 1, a coupler 2, a T-shaped slider 3, a telescopic rod 4, a fastening nut 5, an Ω-shaped cleaning sleeve 6, a rotating The motor 7 and the packaging base 11; the Ω-type cleaning cover 6 is an elastic steel sheet with a cleaning sponge fixed on the inside; one end of the telescopic rod 4 is connected with the Ω-type cleaning cover 6 through a fastening nut 5, and the other end of the telescopic rod 4 The T-shaped slide block 3 is connected with the screw screw 1; the package base 11 is fixed with a rotary motor 7, a travel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com