A Method for Predicting Energy Consumption of Wire Cutting Based on Geometric Features

A technology of geometric features and prediction methods, applied in special data processing applications, electric processing equipment, instruments, etc., can solve problems that are difficult to predict

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

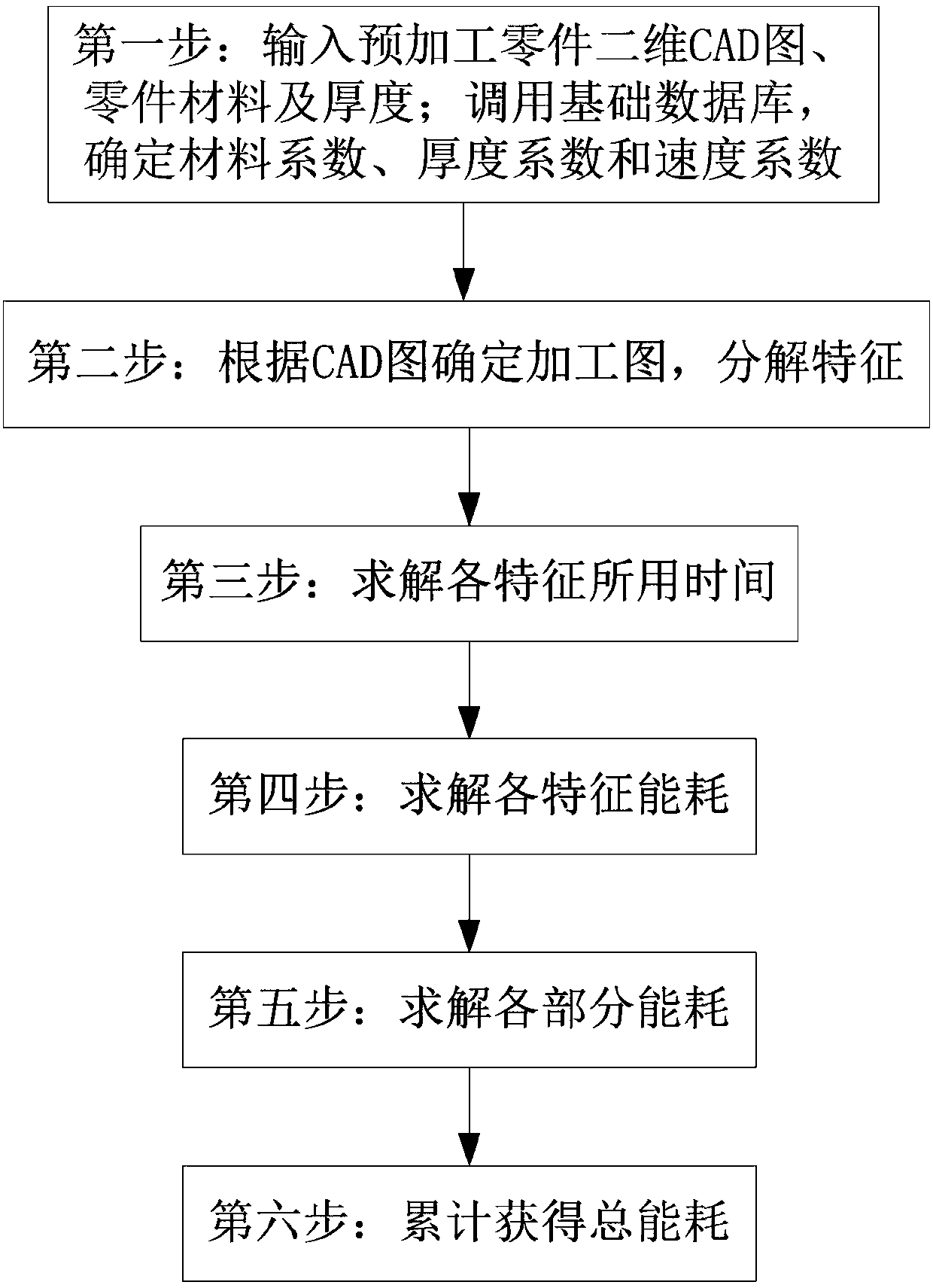

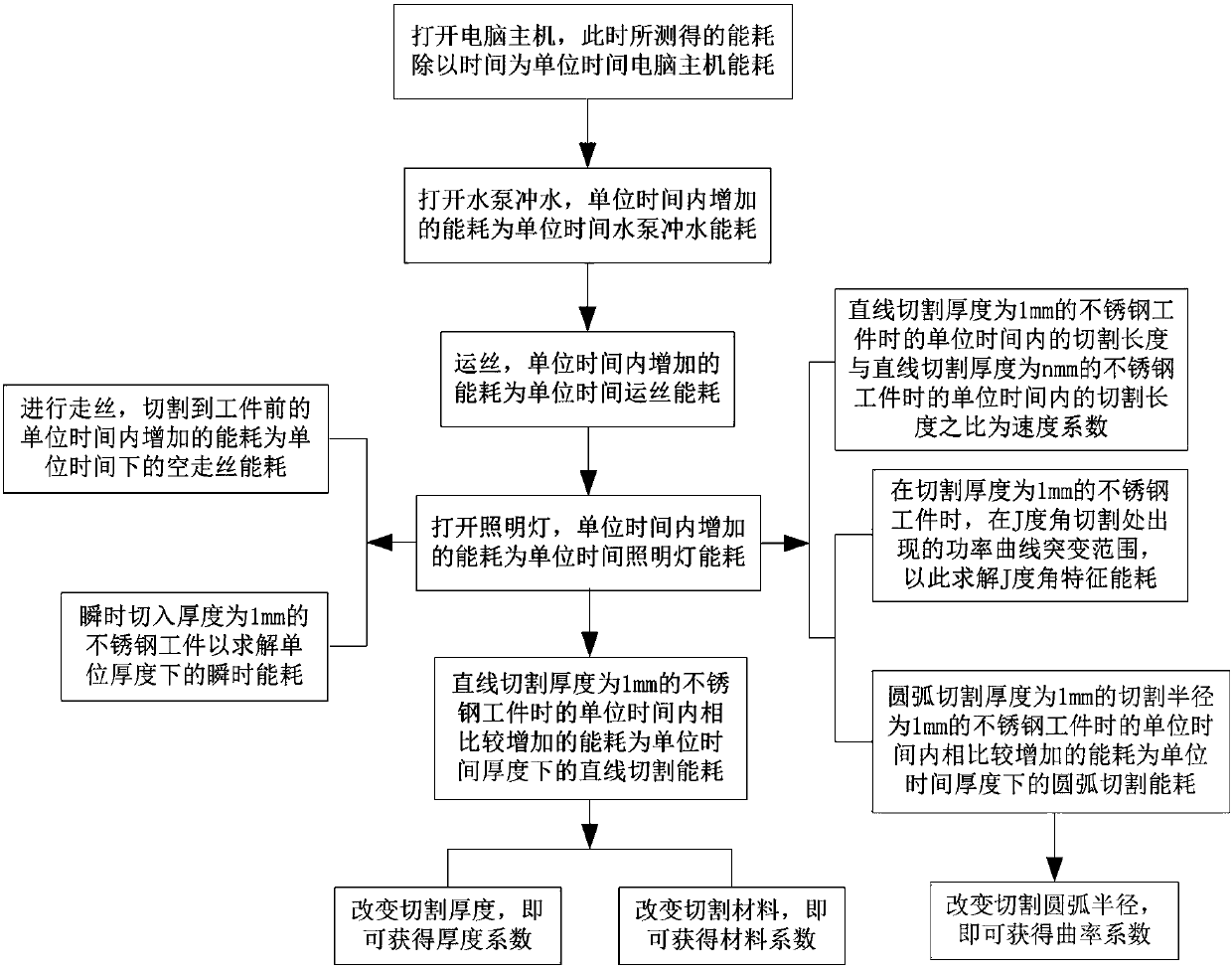

[0030] refer to figure 1 , figure 2 , image 3 and Figure 4 , the present invention comprises the following steps:

[0031] Step 1: Input the 2D CAD drawing of the pre-processed part, the material and thickness of the part; call the basic database to determine the material coefficient η C , thickness coefficient η H and speed coefficient η S ;

[0032] Step 2: Determine the processing drawing according to the CAD drawing, decompose the features, and decompose the parts according to the geometric features into idling wire features, instantaneous cutting features, straight line cutting features, arc cutting features, and angle features;

[0033] The third step: the time used to solve each feature, the empty wire time T KW pass Solving, where X KW is the length of idle wire, v w is the idle wire speed; straight line cutting time T ZCU pass Solving, where X ZCU is the straight line cutting length, v CU Cutting wire speed; arc cutting time T YCU pass Solving, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com