Special punching machine

A technology of punching and special machines, applied in metal processing, etc., can solve problems such as low efficiency and cumbersome processes, and achieve the effects of improving production efficiency, reducing process steps, and ingenious overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

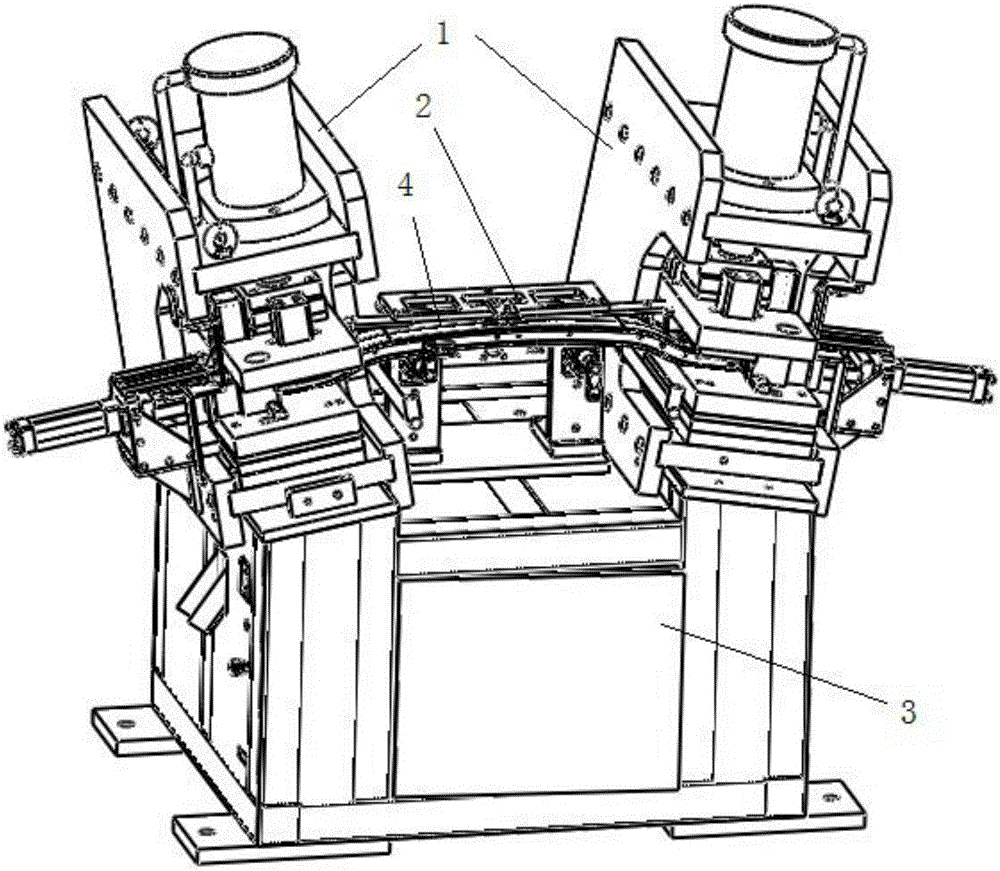

[0019] see Figure 1 to Figure 7 , a special punching machine, including a machine platform 3, a locking mechanism 2 located on the machine platform, two punching mechanisms 1, and the two punching mechanisms 1 are symmetrically arranged on both sides of the locking mechanism 2, and the product 4 The two ends are located in the two punching mechanisms 1 respectively, and the middle part of the product 4 is located in the locking mechanism 2 .

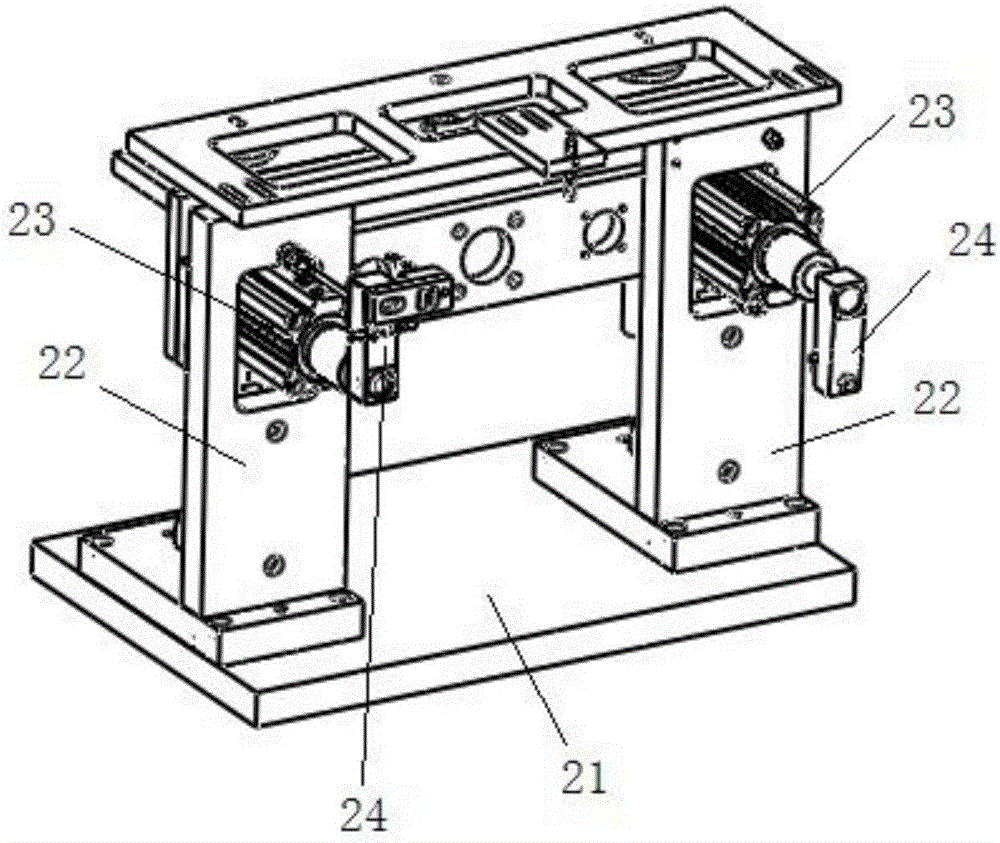

[0020] The locking mechanism 2 includes a base plate 21 installed on the machine platform, and two parallel vertical plates 22 located on the base plate 21. A rotary cylinder 23 is arranged on the two vertical plates, and a locking block is provided at the end of the rotary cylinder 23. 24. The rotating cylinder 23 drives the locking block 24 to rotate to complete the locking of the product.

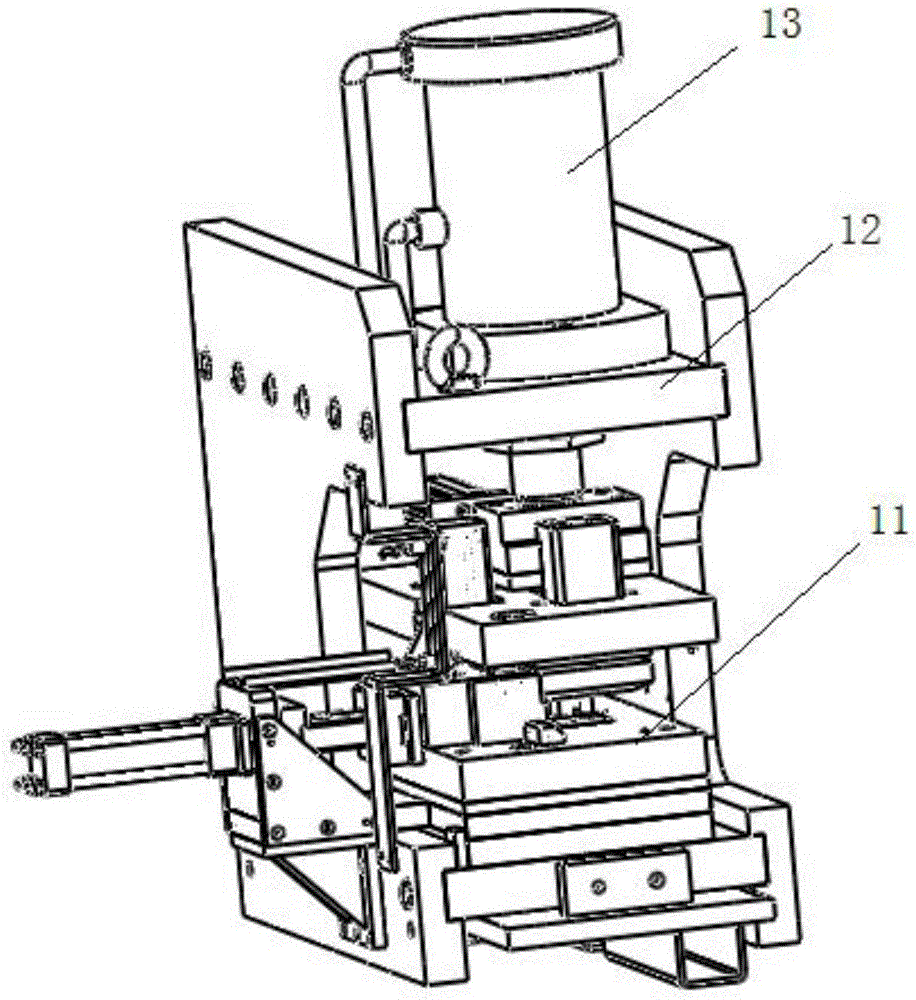

[0021] The punching mechanism 1 includes a mounting frame 12, a driver 13 positioned on the mounting frame 12, and a punching die 11. The driver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com