LED chip pad printing device capable of customizing arrangement scheme

A technology of LED chips and pad printing devices, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, and circuits. Low, ingenious effect of the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

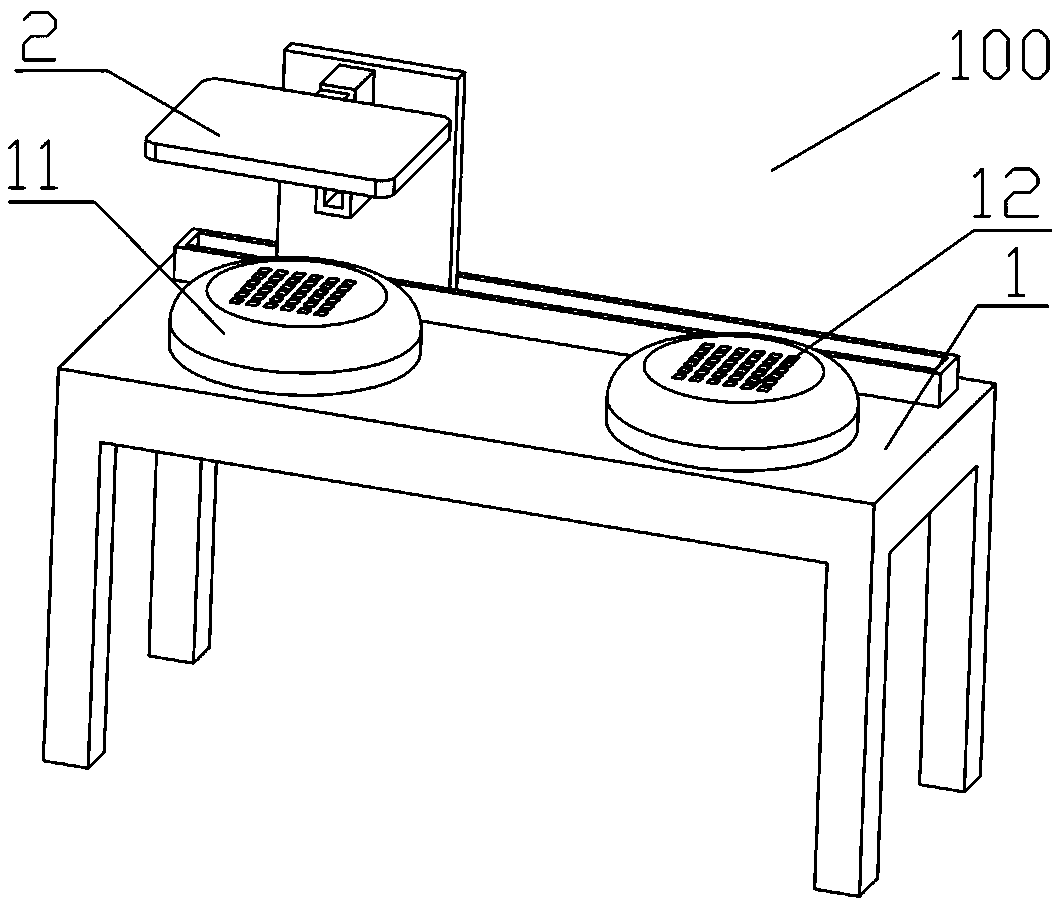

[0039] Please refer to Figure 1 to Figure 2 , an LED chip pad printing device 100 with a customizable arrangement scheme in the embodiment, including a pad printing platform 1 and an addressing adsorption control device 2; the pad printing platform 1 is provided with an initial fixed station and a target fixed station, The initial fixed station is provided with an LED chip carrier 11, and the target fixed station is provided with a target carrier 12; the addressing adsorption control device 2 includes an adsorption mechanism 21, a CCD optical positioning centering device and a wafer scanning block coordinate positioning system, the addressing adsorption control device 2 realizes transferring the LED chips on the LED chip carrier 11 to the on target vehicle 12.

[0040] The LED chip carrier 11 is customized, that is, the size and shape of the LED chip carrier 11 can be customized according to customer requirements, and can be 4 inches, 6 inches, 8 inches and other different s...

Embodiment 2

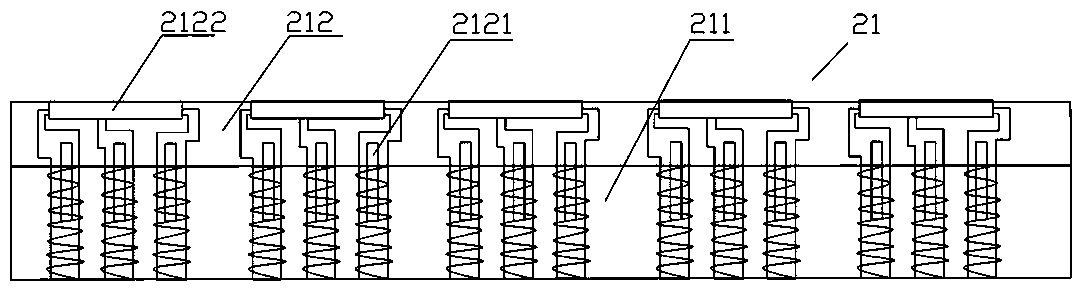

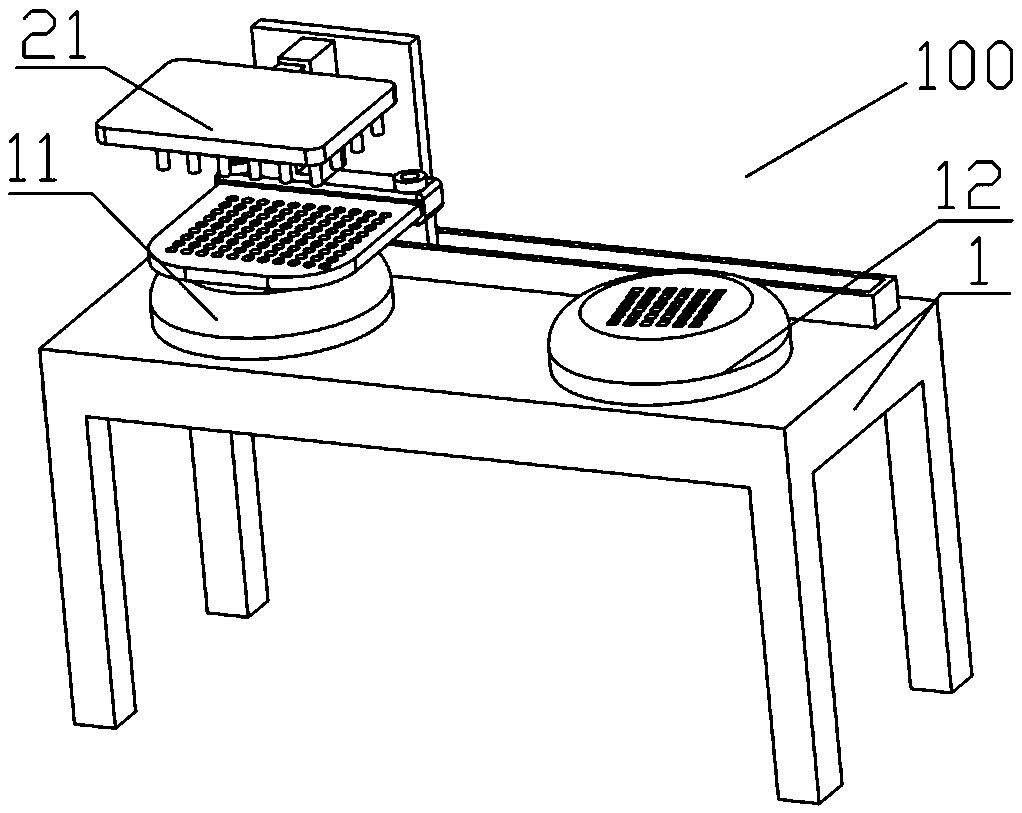

[0049] Please refer to image 3 , Figure 4 with Figure 5 The difference between embodiment 2 and embodiment 1 is that the adsorption mechanism 21 includes a magnet array template 221 and a conductive coil plate 222, and the conductive coil plate 222 is uniformly arranged with adsorption holes according to the chip unit pitch, and the adsorption Conductive coils are arranged in the holes, and the conductive coils in the adsorption holes are connected in series. The magnetic conductor array template 221 is arranged with several magnetic conductors 2121 according to the required array, and the conductive coil plate 222 can be lifted and arranged on the Above the LED chip carrier 11 and the adsorption holes correspond to the LED chips one by one, the magnetic conductor array template 221 can be lifted and arranged above the conductive coil plate 222 and the magnetic conductor 2121 and the adsorption holes corresponding settings.

[0050] Specifically, a threaded groove is pro...

Embodiment 3

[0054] Please refer to Image 6 The difference between embodiment 3 and embodiment 2 is that the adsorption mechanism 21 includes a magnet array template 221 and a conductive coil plate 222, and the conductive coil plate 222 is evenly arranged with a number of adsorption holes according to the chip unit pitch, so Conductive coils are provided on the outer wall of the conductive coil plate 222, and the magnetic conductor array template 221 is provided with a number of magnetic conductors 2121 arranged in an array as required. In addition, the suction holes correspond to the LED chips one by one, the magnetic conductor array template 221 can be lifted and lowered above the conductive coil plate 222 and the magnetic conductors 2121 are correspondingly provided to the suction holes.

[0055] Specifically, the outer side of the conductive coil plate 222 is provided with a threaded groove, and the threaded groove is used to fix and wind the conductive coil. One end of the conductive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com