Intelligent lubricating grease supply device for coal mine

A technology of lubricating grease and supply device, applied in lubricating oil containers, lubricating pumps, lubricating parts and other directions, can solve the problems of increasing the maintenance cost of mechanical equipment, easily polluted lubricating grease, consuming a lot of manpower and material resources, and saving manpower and material resources. , the overall structure is ingenious, the effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

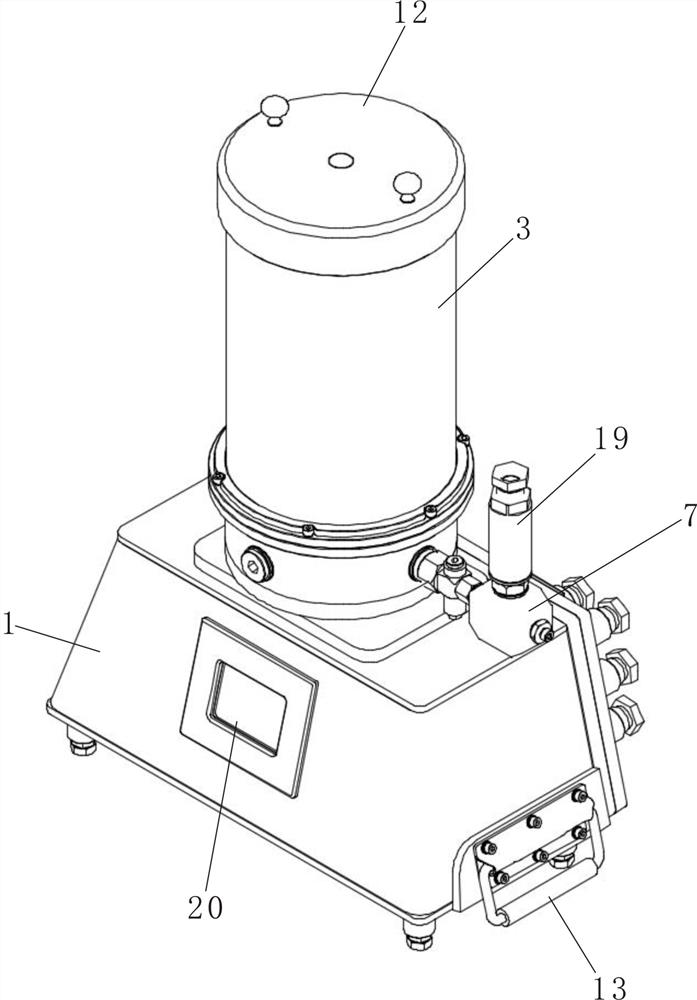

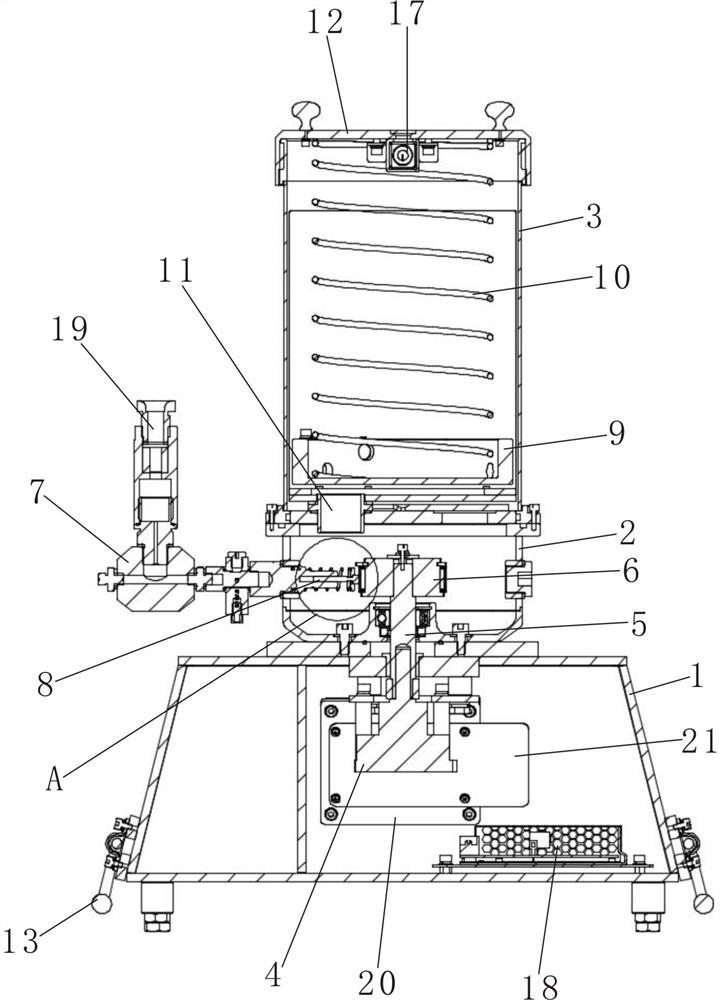

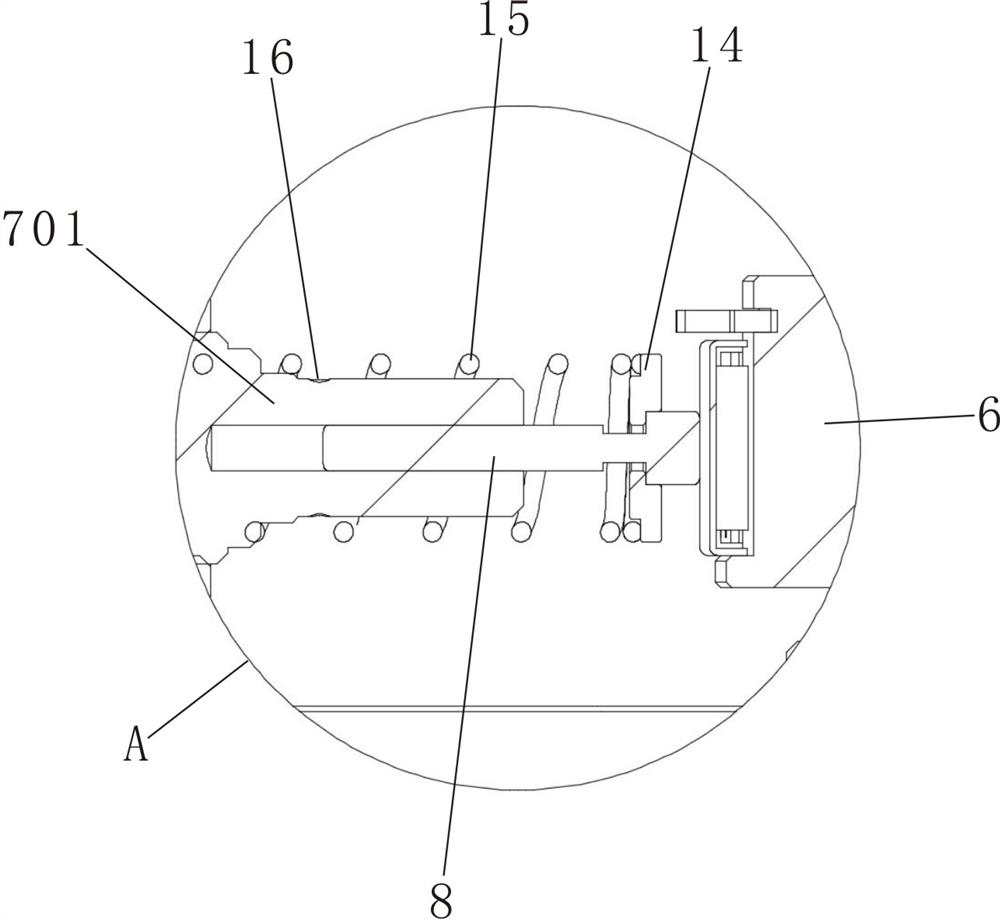

[0011] Now referring to the accompanying drawings of the description, combined with specific embodiments, the description is as follows: An intelligent lubricating grease supply device for coal mines according to the present invention includes an organic casing 1, an oil storage cylinder 3, a motor 4, a rotating shaft 5, and an eccentric 6 and the priming pump 7. The top of the casing 1 is provided with a buffer oil tank 2 , the top of the buffer oil tank 2 is provided with an oil storage cylinder 3 , and the top of the oil storage cylinder 3 is provided with a laser type liquid level gauge 17 . The inside of the casing 1 is provided with a motor 4, the motor 4 is connected with a rotating shaft 5, one end of the rotating shaft 5 is connected with the output shaft of the motor 4, and the other end of the rotating shaft 5 penetrates into the buffer oil tank 2, and is connected with an eccentric wheel. 6. A host 21 is also disposed inside the casing 1 , and a display unit 20 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com