Film laminating machine and film laminating method for curved surface parts of flywheel car shell

A flywheel car and film laminating machine technology, applied in packaging and other directions, can solve problems such as low film laminating efficiency on curved surfaces, affecting assembly operations, and shell corrosion, achieving the effects of reducing film laminating costs, improving film lamination efficiency, and avoiding shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

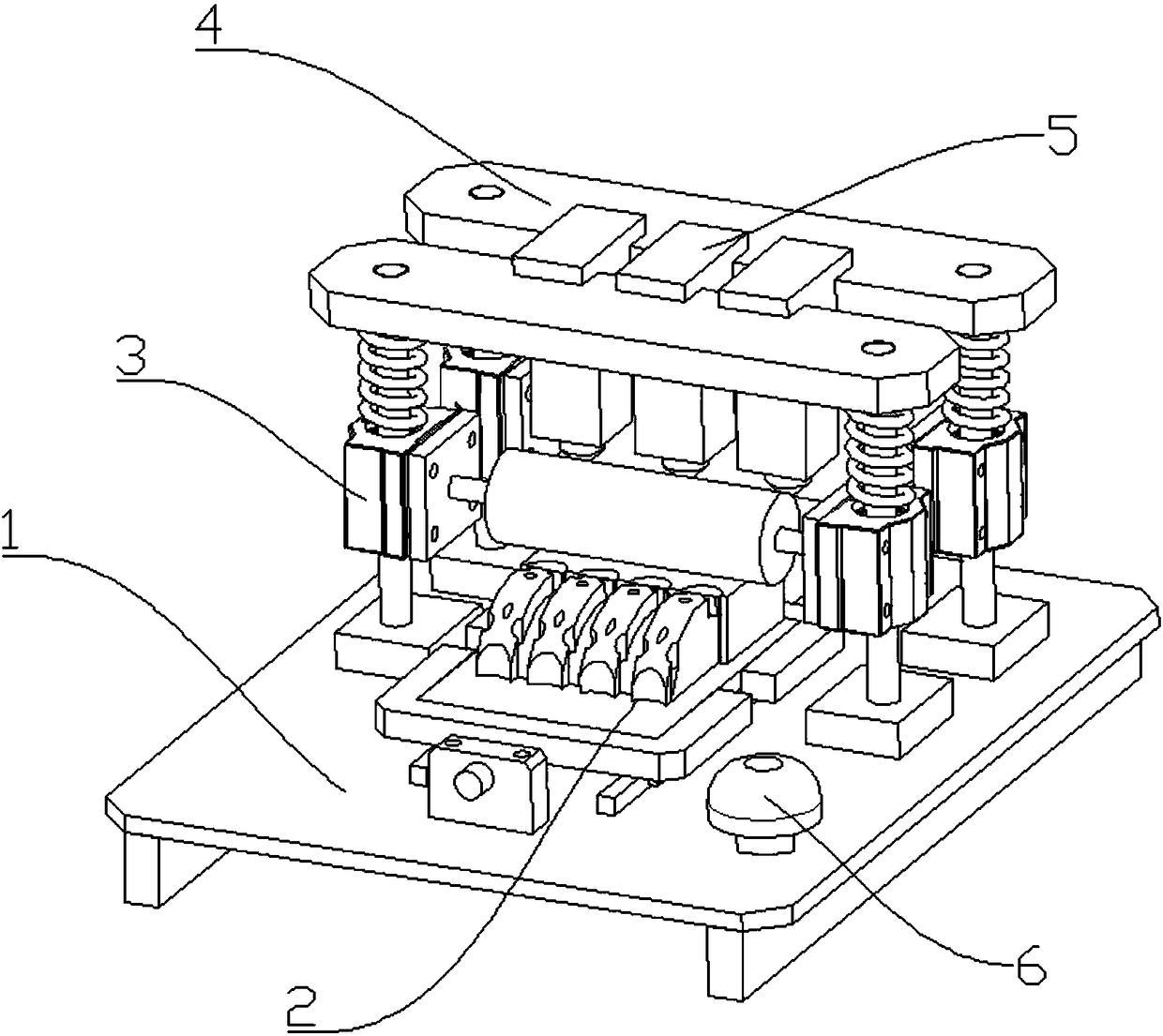

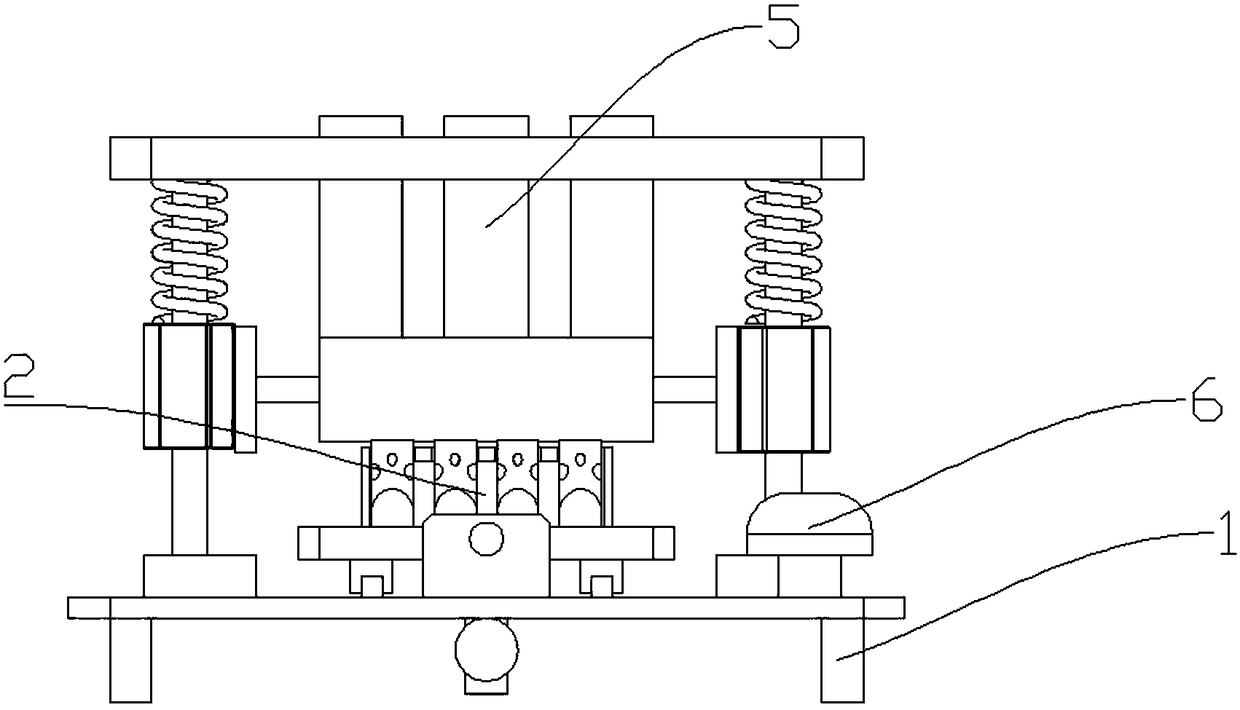

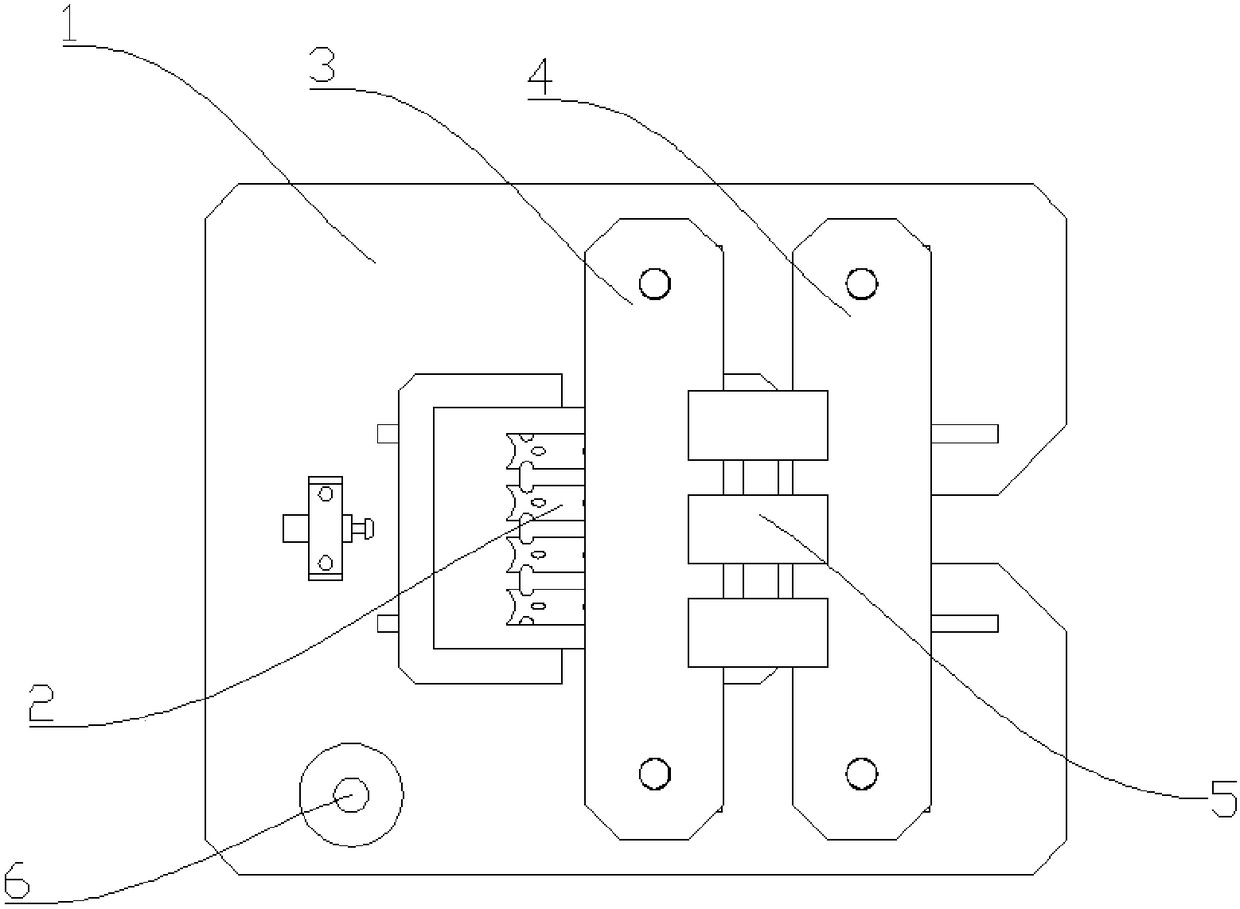

[0032] In order to achieve the purpose of the present invention, as shown in the figure, one embodiment of the present invention is: a film laminating machine for the curved surface parts of the flywheel car shell, including a base 1, a moving jig seat 2, a moving jig seat 2 and The base 1 is connected, including a moving mechanism and a jig base 16, the jig base 16 is connected to the moving mechanism, the jig base 16 is used to place curved surface components, and the moving mechanism is used to push the jig base 16 to move; dust removal device 3, dust removal device 3 It is connected with the base 1 and located above the mobile jig seat 2, and is used for dedusting the curved surface parts; the film sticking device 4, the film sticking device 4 is connected with the base 1, located above the mobile jig seat 2 and behind the dust removal device 3, It is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com