Pretreatment process for recycling waste paper papermaking tail water

A waste paper papermaking and pretreatment technology, applied in the field of pulp and papermaking, can solve the problems of increasing the operating load of the reclaimed water reuse membrane treatment system and increasing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

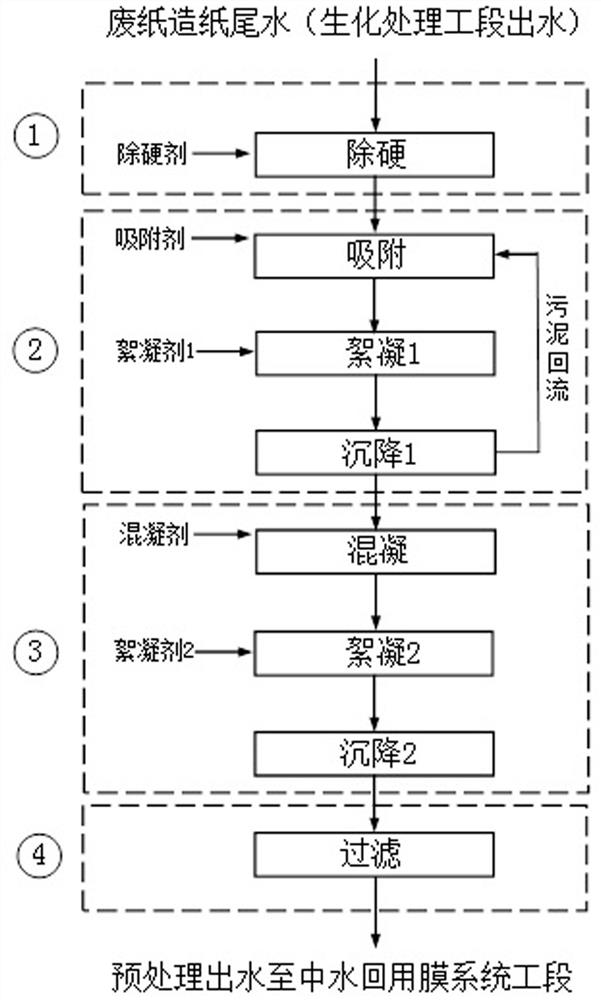

Method used

Image

Examples

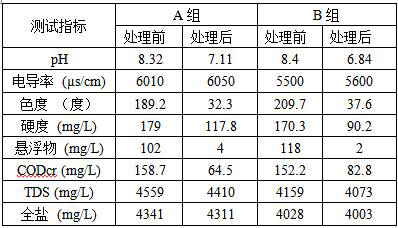

Embodiment 1

[0034] A pretreatment process for recycling tail water from waste paper and papermaking. When the hardness remover and adsorbent are added separately, and the hardness of the effluent from the biochemical pool is less than 200mg / L:

[0035] S1. Waste paper and papermaking tail water (water from the biochemical treatment section) first enters the dehardening clarification tank, adds 0.3g / L quicklime to it, stirs and reacts for 20 minutes, settles and clarifies for 1 hour, and the supernatant flows to the adsorption reaction tank by itself;

[0036] S2. First add modified attapulgite to the effluent of the hard clarification tank, the dosage is 0.2g / L, and the adsorption and stirring reaction is 30min; then add non-ionic polyacrylamide, the concentration of the solution is 2‰, the dosage 2‰, flocculation and stirring for 10 minutes; after flocculation and stirring, let it settle for 4 hours, reflux 50% of the sedimented sludge, and the supernatant flows to the coagulation reactio...

Embodiment 2

[0044] A pretreatment process for the recycling of waste paper and paper tail water. When the hardness remover and adsorbent are added separately, and the hardness of the biochemical pool effluent is greater than 200mg / L:

[0045] S1. Waste paper and papermaking tail water (water from the biochemical treatment section) first enters the hardening clarification tank, adds 0.5g / L quicklime to it, stirs and reacts for 10 minutes, settles and clarifies for 1.5 hours, and the supernatant flows to the adsorption reaction tank by itself ;

[0046] S2. Add modified attapulgite to the effluent of the hard clarification tank first, the dosage is 0.3g / L, and the adsorption and stirring reaction is 1h; then add anionic polyacrylamide, the concentration of the solution is 1.5‰, and the dosage is 1‰, flocculation and stirring for 10 minutes; after flocculation and stirring, let it settle for 5 hours, reflux 25% of the sedimented sludge, and the supernatant flows to the coagulation reaction t...

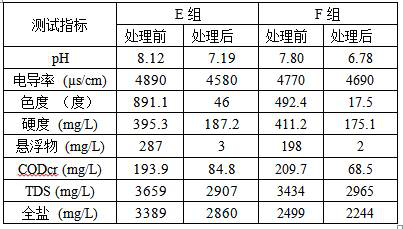

Embodiment 3

[0054] A pretreatment process for recycling tail water from waste paper and papermaking. When the hardness remover and adsorbent are added at the same time, and the hardness of the biochemical pool effluent is greater than 200mg / L:

[0055] S1. Waste paper and papermaking tail water (water effluent from the biochemical treatment section) first enters the adsorption reaction tank, and 0.5g / L quicklime and 0.2g / L modified attapulgite are added to it at the same time, and the adsorption and stirring reaction is carried out for 3 hours; then dosing Non-ionic polyacrylamide, the concentration of the configuration solution is 2‰, the dosage is 1‰, the flocculation and stirring reaction is 10min; Self-flow to the coagulation reaction tank;

[0056] S2. First add polyaluminium-iron to the effluent of the adsorption reaction tank, the dosage of coagulant is 1‰, coagulate and stir for 30 minutes; then add anionic polyacrylamide, the concentration of the solution is 2‰, and the dosage is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com