Digital product 3D film sticking method

A digital product and film sticking technology, which is applied in packaging and other fields, can solve the problems of low film sticking cost, high labor cost, and long time consumption, and achieve the effects of reducing film sticking costs, improving user experience, and avoiding film sticking mistakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

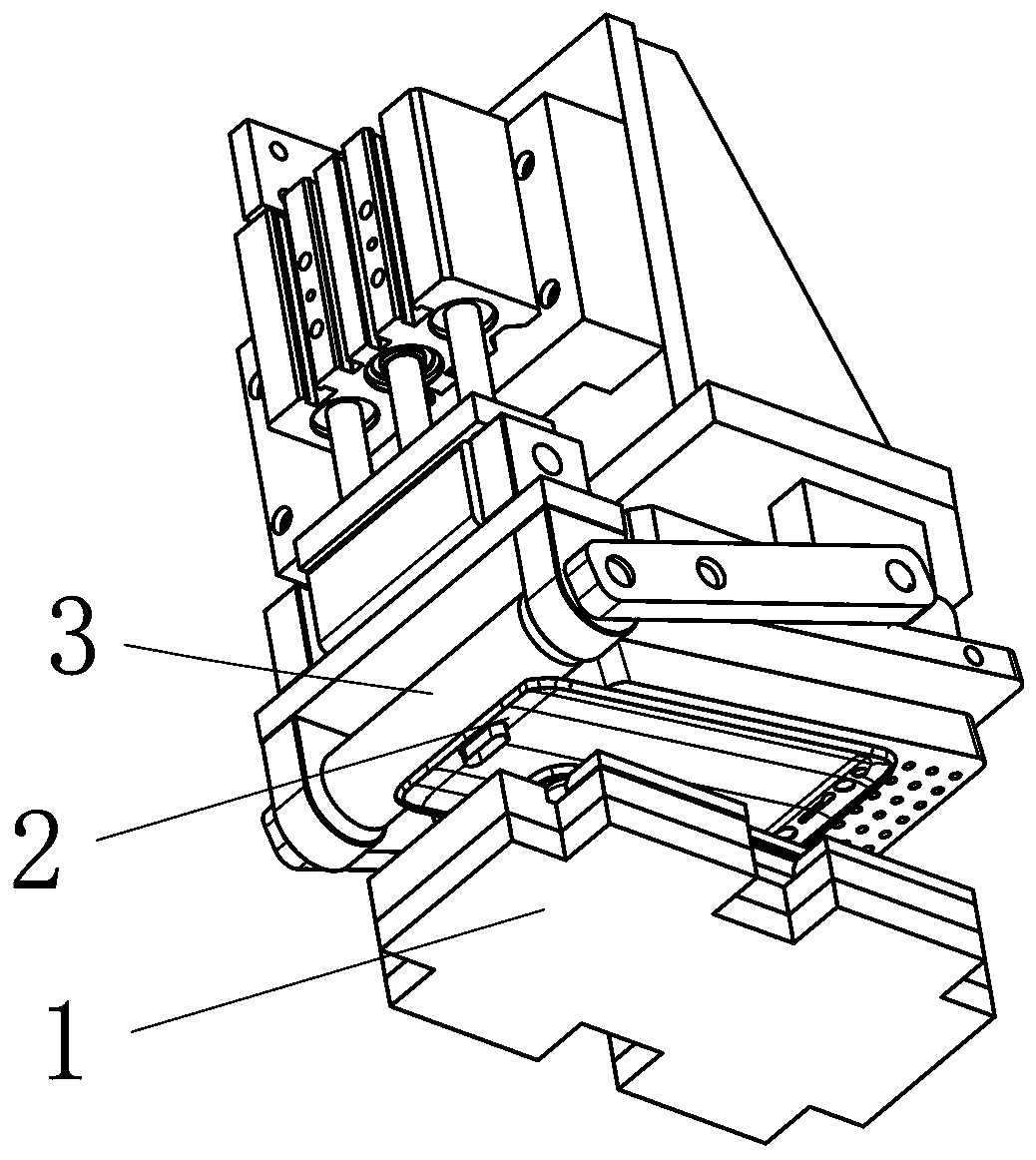

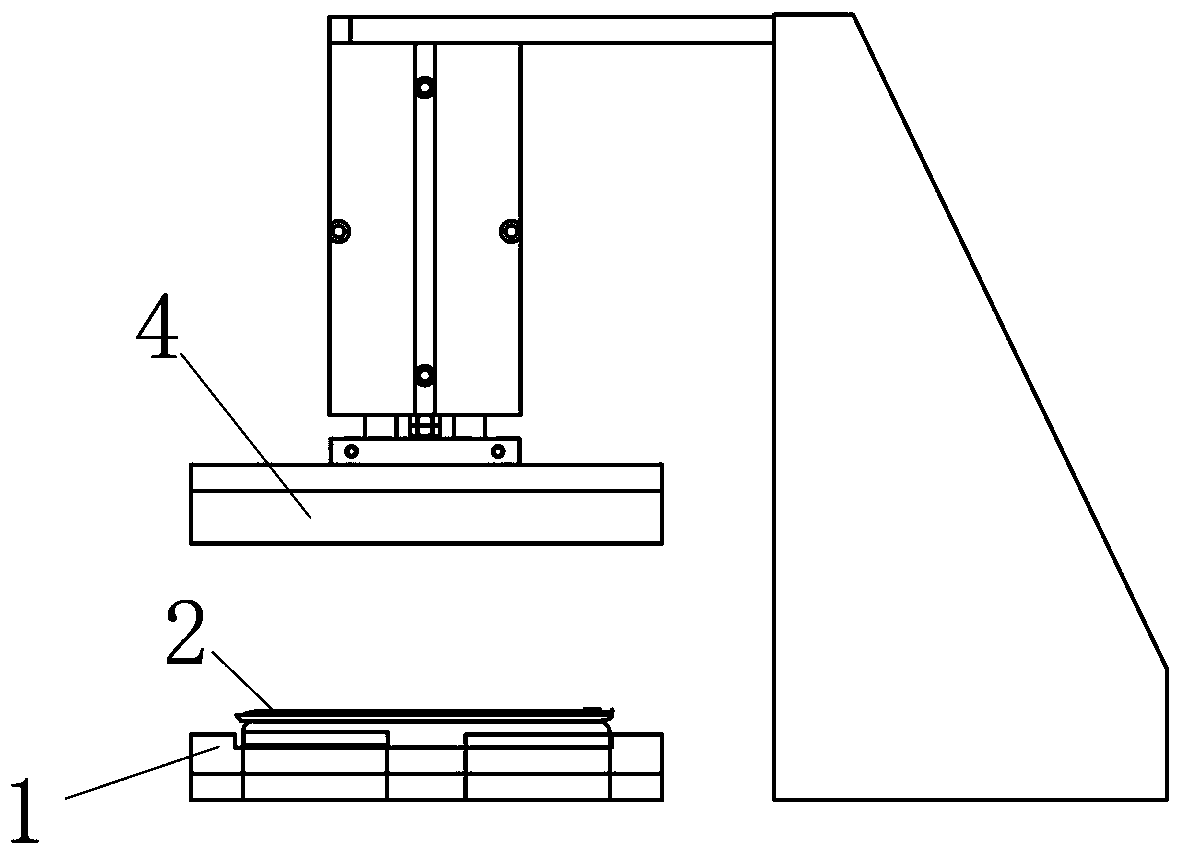

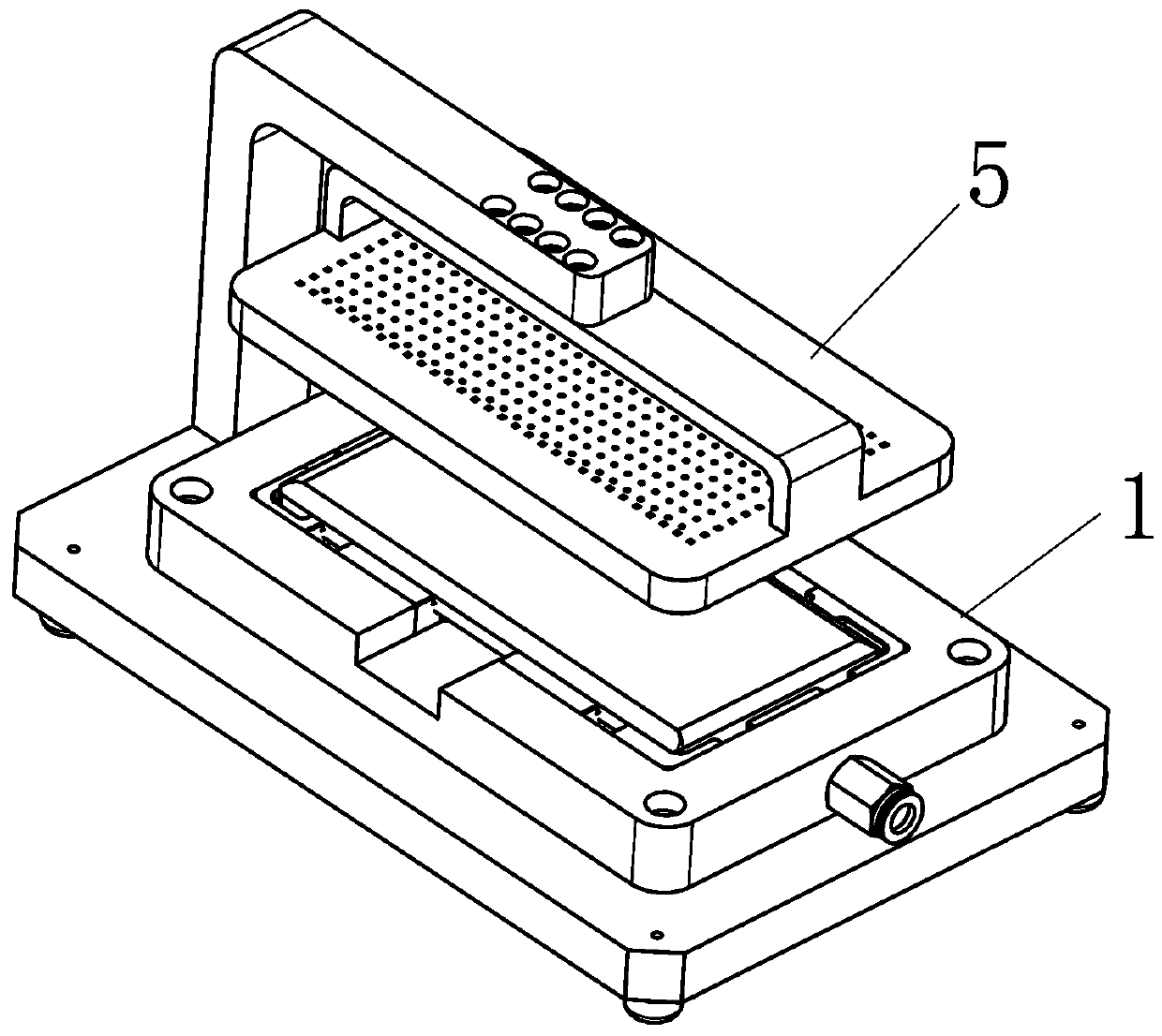

[0022] refer to figure 1 , 2 , 3, and 4 are schematic diagrams of a preferred embodiment of the present invention. The present invention relates to a 3D film-attaching method for digital products, which is suitable for digital products such as mobile phones and tablet computers. The method includes the following steps:

[0023] S01. Provide a film sticking workbench 1 for positioning and placement of digital products. In order to increase the effect and quality of film sticking, the film sticking workbench 1 is equipped with corresponding fixture positioning, photoelectric positioning or a combination thereof; positioning is accurate and convenient.

[0024] S02. Provide a protective film 2, and remove the protective layer on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com