A kind of preparation method of yellow luminous fiber

A luminous fiber, yellow technology, applied in the direction of fiber chemical characteristics, rayon manufacturing, single-component polyamide rayon, etc., can solve the problems of single color and low afterglow brightness of yellow luminous fiber, to expand the scope of application, enrich The effect of color variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: A kind of preparation method of yellow luminous fiber, comprises the following process steps:

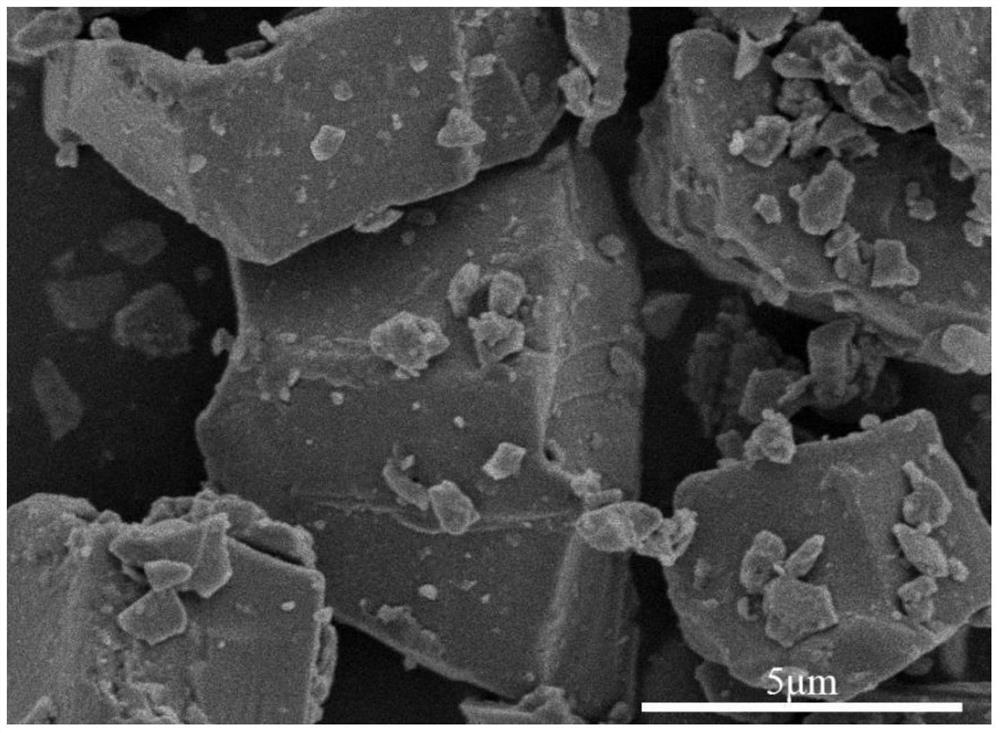

[0027] (1) Preparation of yellow fluorescent material: Mix silane KH550, absolute ethanol, yellow light conversion agent and fluorescent material at a mass ratio of 0.05:50:0.2:10, and treat it with an ultrasonic cleaner at a temperature of 50°C for 40 minutes, and then Heat to 55°C in a closed reaction system, stir rapidly for 90 minutes to make it react, then open the stirring to volatilize the ethanol to obtain a viscous reactant, then dry it at a temperature of 65°C, and obtain a yellow fluorescent material after grinding. The particle size is 5 μm;

[0028] (2) Dry the PA6 slices in a vacuum drum dryer for 4 hours at a drying temperature of 120°C. After drying, pre-mix with the yellow luminescent material. The mass ratio of PA6 powder and yellow luminescent material is 2:1, and the obtained Luminous masterbatch;

[0029] (3) Evenly mix the PA6 slices with...

Embodiment 2

[0033] Embodiment 2: a preparation method of yellow luminous fiber, comprising the following process steps:

[0034] (1) Preparation of yellow fluorescent material: Mix silane KH560, absolute ethanol, yellow light conversion agent and fluorescent material at a mass ratio of 0.1:60:0.4:10, and process it at 60°C for 30 minutes with an ultrasonic disperser, and then Heat to 65°C in a closed reaction system, stir rapidly for 70 minutes to make it react, and then open the stirring to volatilize ethanol to obtain a viscous reactant, then dry it at 75°C, and prepare a yellow fluorescent material after grinding. The particle size is 15μm;

[0035] (2) Dry the PA6 slices in a vacuum drum dryer for 4 hours at a drying temperature of 125°C. After drying, pre-mix with the yellow luminescent material. The mass ratio of PA6 powder and yellow luminescent material is 3:1, and the obtained Luminous masterbatch;

[0036] (3) Evenly mix the PA6 slices with the luminous masterbatch obtained in...

Embodiment 3

[0037] Embodiment 3: A kind of preparation method of yellow luminous fiber, comprises the following process steps:

[0038] (1) Preparation of yellow fluorescent material: Mix silane KH570, absolute ethanol, yellow light conversion agent and fluorescent material at a mass ratio of 0.15:70:0.6:10, and process it at 70°C for 20 minutes with an ultrasonic disperser, and then Heat to 75°C in a closed reaction system, stir rapidly for 50 minutes to make it react, and then open the stirring to volatilize the ethanol to obtain a viscous reactant, then dry it at 85°C, and obtain a yellow fluorescent material after grinding. The diameter is 10μm;

[0039] (2) Dry PA6 slices in a vacuum drum dryer for 3 hours at a drying temperature of 130°C. After drying, pre-mix them with yellow luminescent materials. The mass ratio of PA6 slices to yellow luminescent materials is 4:1 to obtain luminous Masterbatch material;

[0040] (3) Evenly mix the PA6 slices with the luminous masterbatch obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com