Preparation method of a nano-sized near-infrared light long afterglow material

A long afterglow material, near-infrared light technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of hindering development, excessive particle size, agglomeration, etc., and achieve the effects of good performance, simple preparation and low calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Na 2 CO 3 (analytical pure) and Ga 2 o 3 (Analytical pure) Take the material according to the molar ratio of 1:1, grind and mix it evenly, dry it, put it into a corundum crucible, and calcinate it at 850°C for 12 hours in a high-temperature furnace to obtain NaGaO 2 Powder, make it into 0.1mol L -1 of the suspension. Then measure an appropriate amount of 0.05mol·L -1 Zn(CH 3 COO) 2 and 0.02mol·L -1 Cr(CH 3 COO) 3 solution with 10mL of the above-prepared NaGaO 2 The solutions were mixed and ion-exchanged at room temperature for 3 h with a stirring speed of 500 rpm. After stirring, it was transferred to a reaction kettle, subjected to hydrothermal reaction at 200°C for 10h, centrifuged at 9000rpm, washed alternately with water and ethanol for 3 times, and then dried in a vacuum oven at 50°C for 10h to obtain the target product.

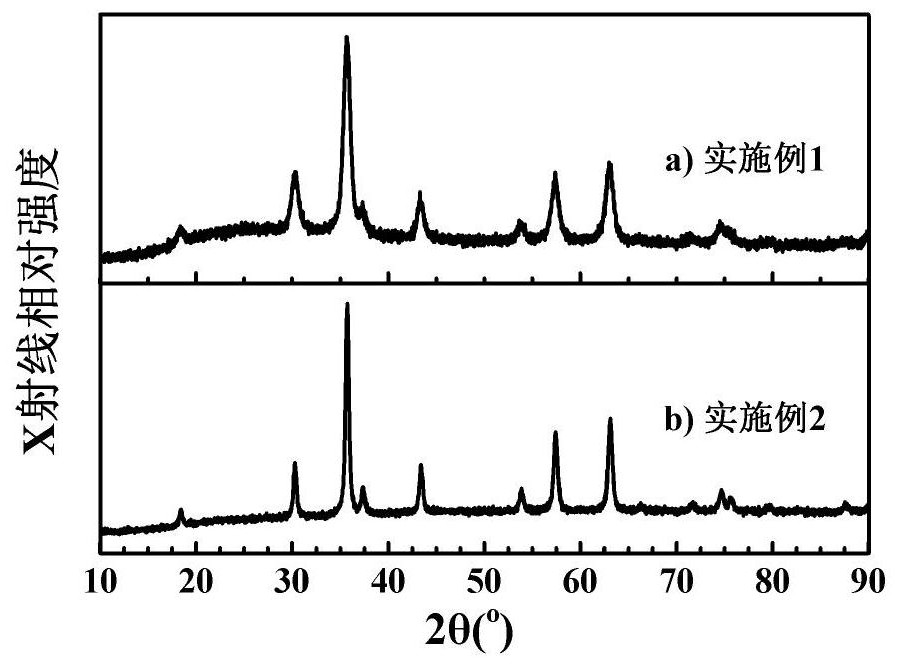

[0019] Utilize X-ray diffraction to analyze the material obtained in embodiment 1, the result is as follows figure 1 As shown in ,...

Embodiment 2

[0021] Na 2 CO 3 (analytical pure) and Ga 2 o 3 (Analytical pure) Take the material according to the molar ratio of 1:1, grind and mix it evenly, dry it, put it into a corundum crucible, and calcinate it at 850°C for 12 hours in a high-temperature furnace to obtain NaGaO 2 Powder, make it into 0.1mol L -1 of the suspension. Then measure an appropriate amount of 0.05mol·L -1 Zn(CH 3 COO) 2 and 0.02mol·L -1 Cr(CH 3 COO) 3 solution with 10mL of the above-prepared NaGaO 2 The solutions were mixed and ion-exchanged at room temperature for 3 h with a stirring speed of 500 rpm. After stirring, transfer it to a reaction kettle, conduct hydrothermal reaction at 200°C for 10h, centrifuge at 9000rpm, wash alternately with water and ethanol for 3 times, and place the precipitate in a vacuum drying oven at 50°C for 10h to obtain a powder sample. In order to improve the long-lasting luminescent properties of the obtained samples, they were placed in a muffle furnace and calcine...

Embodiment 3

[0024] Na 2 CO 3 (analytical pure) and Ga 2 o 3 (Analytical pure) Take the material according to the molar ratio of 1:1, grind and mix it evenly, dry it, put it into a corundum crucible, and calcinate it at 850°C for 12 hours in a high-temperature furnace to obtain NaGaO 2 Powder, make it into 0.1mol L -1 of the suspension. Then measure an appropriate amount of 0.05mol·L -1 Zn(CH 3 COO) 2 and 0.02mol·L -1 Cr(CH 3 COO) 3 solution with 10mL of the above-prepared NaGaO 2 The solutions were mixed and ion-exchanged at room temperature for 3 h with a stirring speed of 500 rpm. After stirring, transfer it to a reaction kettle, conduct hydrothermal reaction at 200°C for 8h, centrifuge at 9000rpm, wash alternately with water and ethanol for 3 times, and place the precipitate in a vacuum drying oven at 50°C for 10h to obtain a powder sample. In order to improve the long-lasting luminescent properties of the obtained samples, they were placed in a muffle furnace and calcined...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com