Secondarily-excited type silicon-aluminate long-afterglow fluorescent powder and preparation method thereof

A type of aluminosilicate, secondary excitation technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of poor chemical stability, short afterglow time, low luminous brightness, etc., and achieve low cost, easy operation, high brightness high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

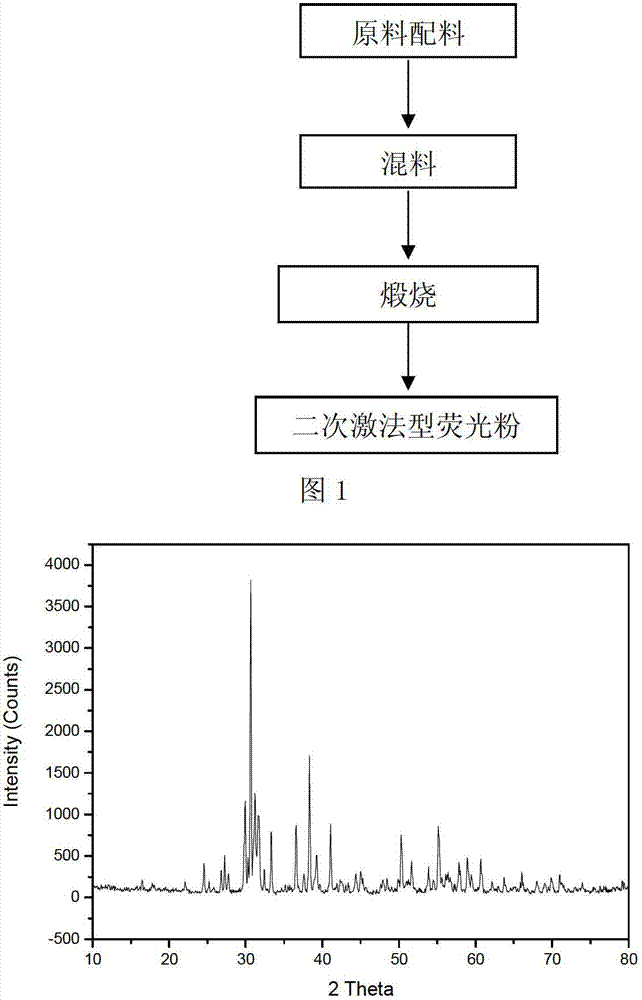

Method used

Image

Examples

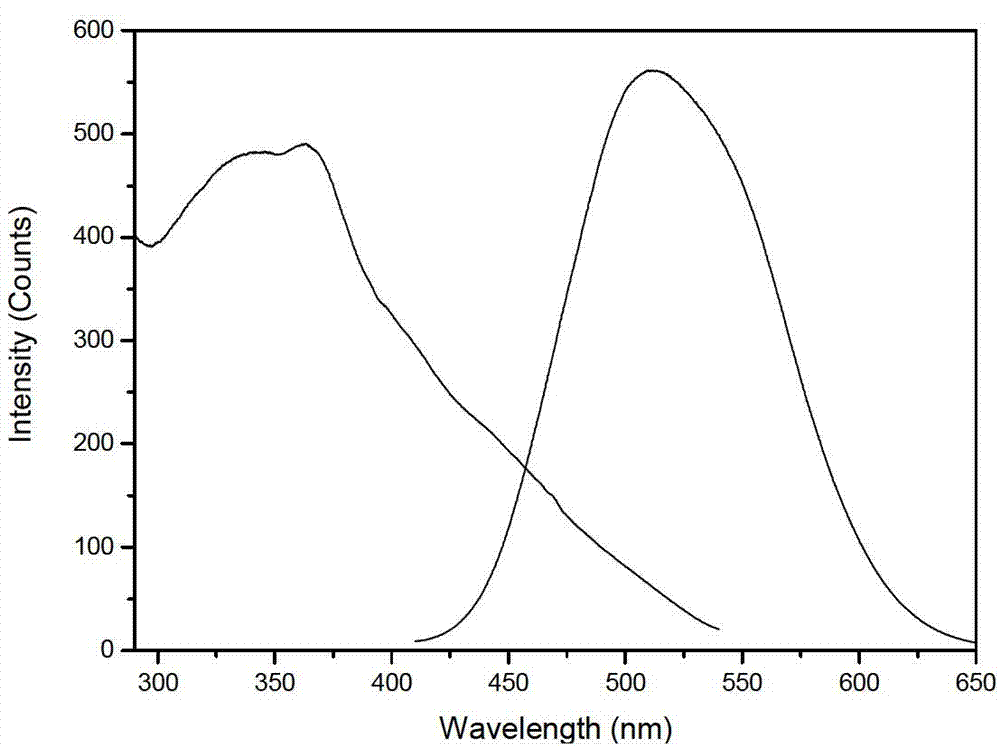

Embodiment 1

[0018] According to the structural formula Sr 3.94 Al 1.994 SiO 9 :0.06Eu 2+ ,0.006Dy 3+ Weigh out SrCO 3 (A.R.)3.94mol, Al 2 o 3 (A.R.)0.997mol, SiO 2 (A.R.) 1mol, Eu 2 o 3 (A.R.)0.03mol and Dy 2 o 3 (A.R.) 0.003mol, then weigh the flux H of 5wt% of the total mass of the above drugs 3 BO 3 Mix the above weighed raw materials evenly, and then calcinate under the reducing atmosphere provided by the combustion of activated carbon powder, the calcining temperature is 1400°C, and the calcining time is 8h, to obtain the target product.

Embodiment 2

[0020] According to the structural formula Sr 2.94 CaAl 1.994 SiO 9 :0.06Eu 2+ ,0.006Nb 3+ Weigh out SrCO 3 (A.R.) 2.94mol, CaCO 3 1mol, Al 2 o 3 (A.R.)0.997mol, SiO 2 (A.R.) 1mol, Eu 2 o 3 (A.R.) 0.03mol and Nb 2 o 3 (A.R.) 0.003mol, and then respectively weigh the flux BaF of the total mass of the above drugs 3wt% 2 ; Mix the above-mentioned raw materials weighed uniformly, then in H 2 -N 2 (Volume ratio 5:95) calcined under reducing atmosphere, the calcined temperature is 1420°C, and the calcined time is 8h to obtain the target product.

Embodiment 3

[0022] According to the structural formula Sr 2.94 CaAl 1.994 SiO 9 :0.06Eu 2+ ,0.005Dy 3+ Weigh out SrCO 3 (A.R.) 2.94mol, CaCO 3 1mol, Al2 o 3 (A.R.)0.997mol, SiO 2 (A.R.) 1mol, Eu 2 o 3 (A.R.)0.03mol and Dy 2 o 3 (A.R.) 0.003mol, and then weigh the flux CaF of 0.5wt% of the total mass of the above drugs 2 ; Mix the above-mentioned raw materials weighed uniformly, then in H 2 -N 2 (Volume ratio 10:90) calcined under reducing atmosphere, the calcined temperature is 1420°C, and the calcined time is 8h to obtain the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com