Preparation method and product of a rare earth aluminate-based composite red luminescent material

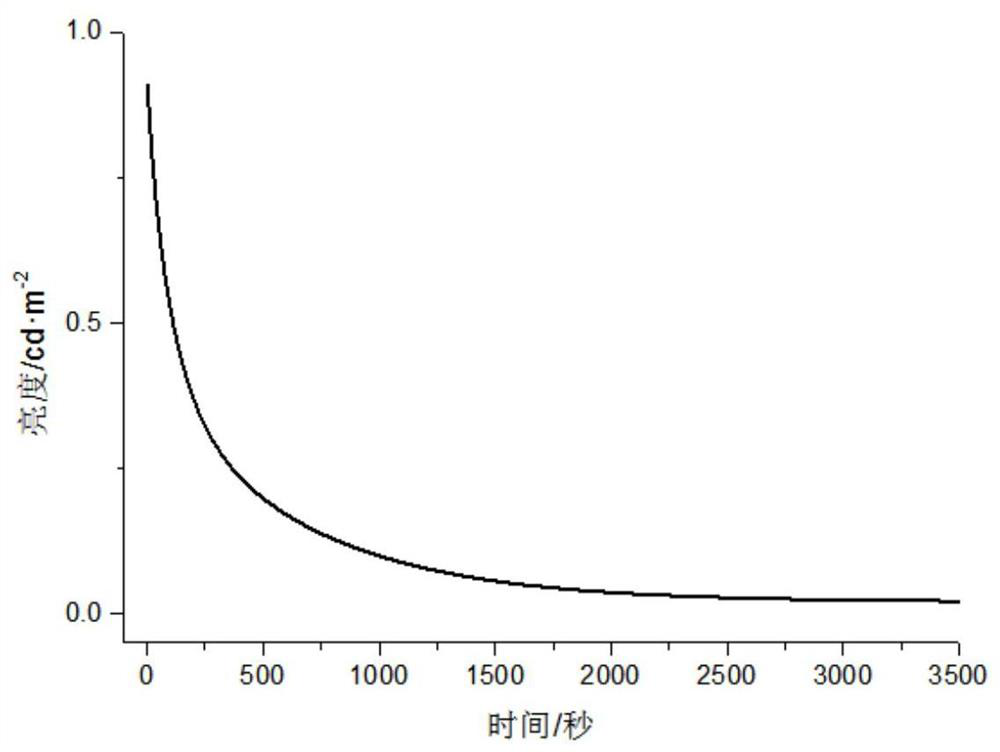

A technology of red light-emitting and light-emitting materials, applied in the directions of light-emitting materials, chemical instruments and methods, etc., can solve problems such as performance not meeting practical application requirements, low light conversion efficiency, short afterglow time, etc., and achieve good afterglow effect and light color. Good performance, the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the rare earth aluminate-based composite red luminescent material of the present invention comprises the following process steps:

[0032] (1) Preparation of luminescent matrix-polydopamine complex: scheme 1, mix polydopamine particles, absolute ethanol, and rare earth aluminate luminescent materials in proportion, and disperse them by ultrasonic, ultrasonic frequency 40KHz, temperature 25, heat to 50~ 80°C and high-speed stirring for 30-60 minutes, after the reaction, filter, wash, and dry; Scheme 2: Mix dopamine hydrochloride, rare earth aluminate luminescent material, absolute ethanol, and trishydroxymethylaminomethane in proportion, and heat to 25 ~60°C and high-speed stirring for 1-5 hours, after the reaction, filter, wash, and dry at 60-120°C to obtain a luminescent matrix-polydopamine complex.

[0033] (2) Preparation of aluminate-based composite red luminescent material: Mix luminescent matrix-polydopamine complex, absolute ethanol, eth...

Embodiment 1

[0036] (1) Preparation of luminescent substrate-polydopamine complex: polydopamine particles, SrAl 2 o 4 Eu 2+ , Dy 3+, anhydrous ethanol at a ratio of 0.002:1:10, ultrasonically dispersed for 20 minutes, heated to 50°C and stirred at high speed for 30 minutes, filtered, washed and dried after reaction to obtain a luminescent matrix-polydopamine complex.

[0037] (2) Preparation of aluminate-based composite red luminescent material: Mix the luminescent matrix-polydopamine complex, light conversion agent, absolute ethanol, and ethylene glycol at a ratio of 1:0.01:10:5, and disperse them by ultrasonic for 20 minutes. Ultrasonic frequency 40KHz, temperature 25, heating to 60°C and high-speed stirring for 30 minutes, after reaction, filtering, washing, and drying at 80°C to obtain aluminate-based composite red luminescent material.

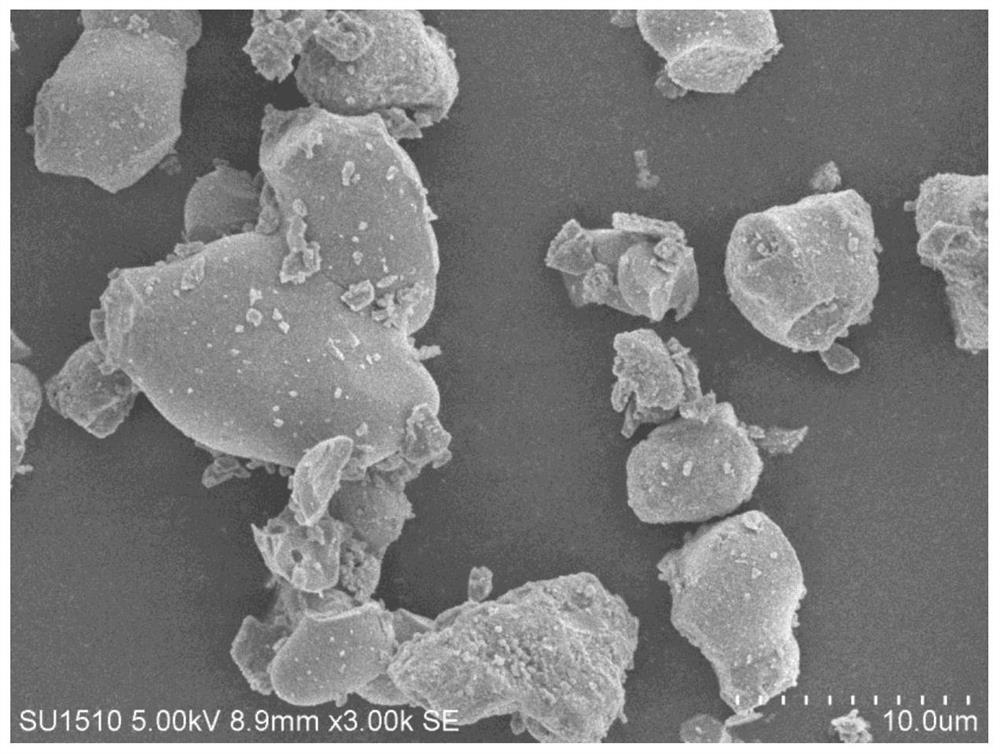

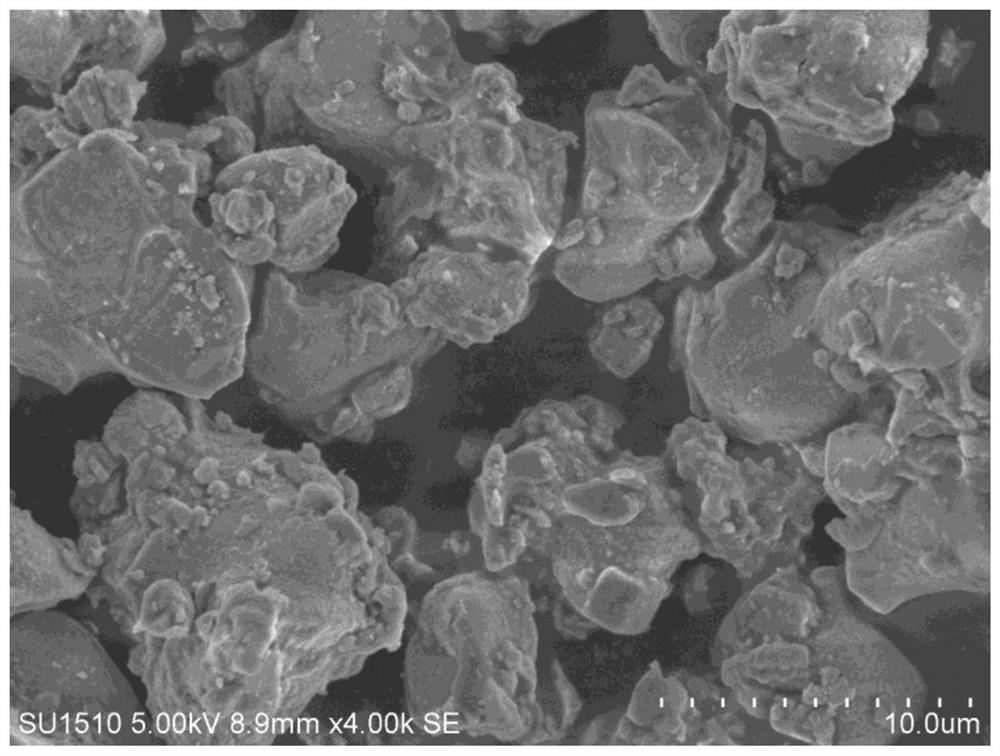

[0038] (3) Grinding of the luminescent material: pulverize the aluminate-based composite red luminescent material to obtain a powder with a partic...

Embodiment 2

[0051] (1) Preparation of luminescent substrate-polydopamine complex: dopamine hydrochloride, SrAl 2 o 4 Eu 2+ , Dy 3+ , anhydrous ethanol, and trishydroxymethylaminomethane were mixed in a ratio of 0.001:1:5:0.5, dispersed by ultrasonic for 30 minutes, heated to 30°C and stirred at high speed for 2 hours, filtered, washed, and dried after reaction to obtain a luminescent matrix - Polydopamine complex.

[0052] (2) Preparation of aluminate-based composite red luminescent material: Mix the luminescent matrix-polydopamine complex, light conversion agent, absolute ethanol, and ethylene glycol at a ratio of 1:0.03:10:8, and disperse them by ultrasonic for 30 minutes. Heating to 70°C and stirring at a high speed for 30 minutes, after the reaction, filtering, washing, and drying at 90°C to obtain an aluminate-based composite red luminescent material.

[0053] (3) Grinding of the luminescent material: pulverize the aluminate-based composite red luminescent material to obtain a po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com